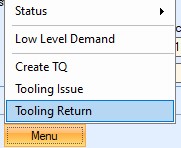

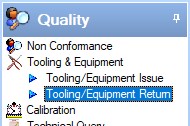

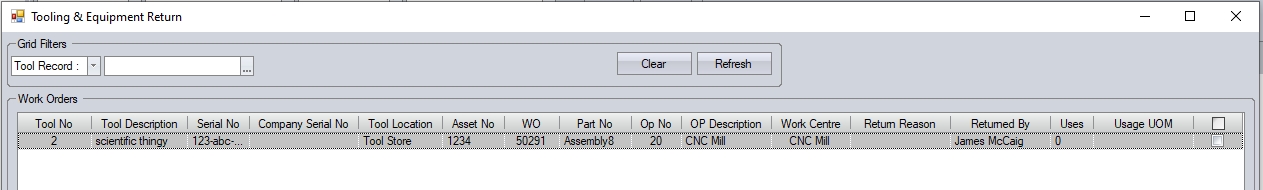

Once Production have finished using tools issued for manufacture, the tools are returned so they are available for use against other work orders. This process can be carried out from the Tooling & Equipment > Tooling/Equipment Return option or from within the work order itself via the Menu > Tooling Return option.

(from within the work order itself)

(from the Tooling & Equipment section)

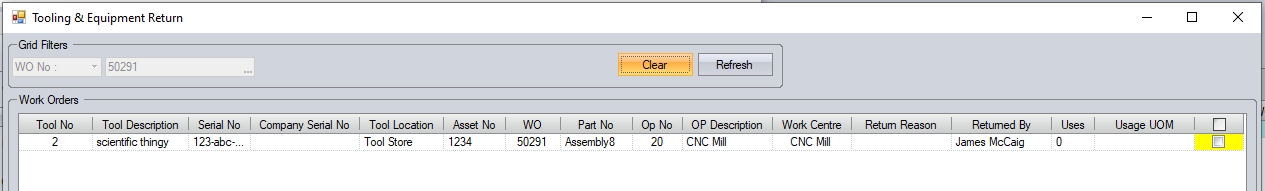

Just like the tooling issue process, both options will present the same screen, with the work order option filtering specifically for the specific work order.

(from within the work order itself)

(from the Tooling & Equipment section)

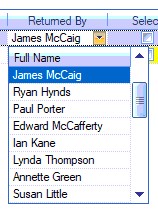

Once the user has filtered the screen as required, they can tick the tools to be returned. If required, they can also select a Return Reason from the drop-down list as well as specify who is returning the tool(s).

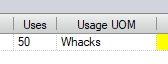

The user can also record the usage quantity at this stage too. This allows them to specify how many times the tool was used during its issue period. This information can be recorded towards the right-hand side of the return screen.

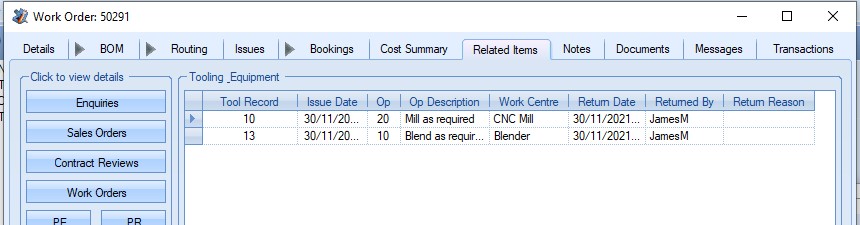

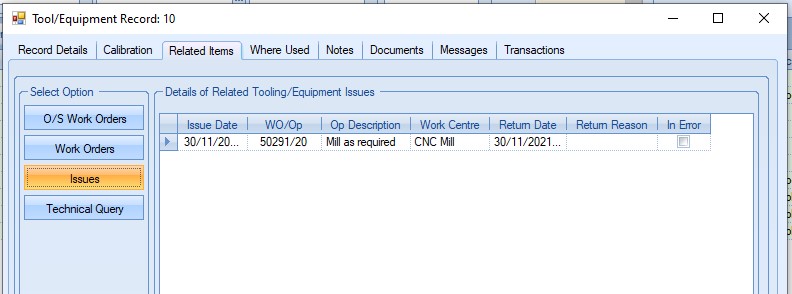

Once selected, clicking ACCEPT will complete the return process and update the tool record so its available for use elsewhere. All issue transactions are updated with a Return Date, Returned By and Return Reason (if recorded). This can be seen in the work order's Related Items > TE and also in the tool record itself in the Related Items > Issues.

(from within the work order)

(from within the Tool record)

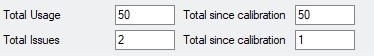

Once the tool has been returned, the system also updates the tool record so the Total Issues and Total Usage figures are updated accordingly.