As well as acting as a tooling and equipment register, the user is able to issue specific tooling and equipment to production for work order operations that require them from the Tooling & Equipment section.

The issuing of tooling to work orders is based on the list of associated tools set up against the WO routing operation(s). The tooling can be set up against the master part's routing operations, which will then be inherited by any work orders created for the part number, however, it is possible to amend the tooling on the individual work order operation if required. The user is also able to do "unplanned" issues of tooling to WO operations too. This is where a tool is issued to a WO that was not planned against the WO operation(s).

For more information on setting up the tooling against part and work order operations, please refer to the Inventory > Parts List and Work Orders sections of the manual respectively.

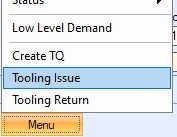

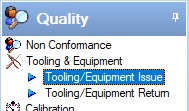

The user can issuing tooling to work orders from within the individual work orders itself using the Menu > Tooling Issue option, or via the Tooling & Equipment > Tooling/Equipment Issue option, both of which are shown below.

(from within the work order itself)

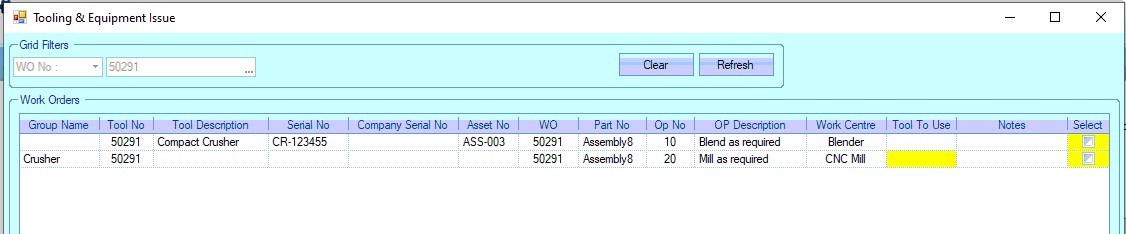

(from Tooling & Equipment section)

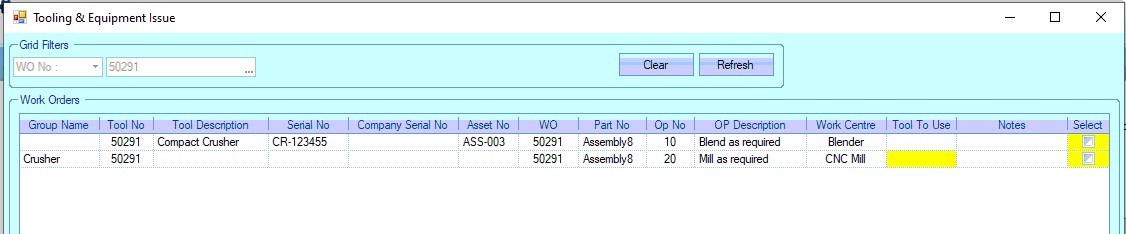

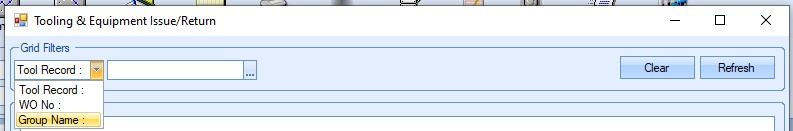

Both options will open the same screen, with the user able to filter by work order, tool number or tool group, however, the work order option will open for the current work order number.

(from within the work order itself)

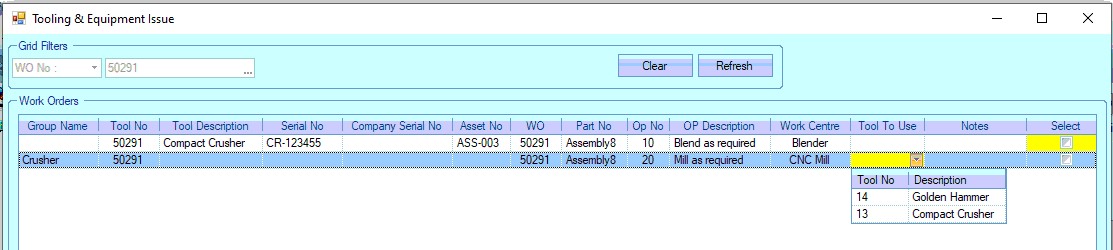

(from Tooling & Equipment section)

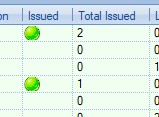

Once the relevant work order, tooling number or group has been selected and the grid refreshed, the user should see a list of tooling to be issued based on the selected criteria.

Where a group of tools has been assigned to the work order operation, the user can select the specific tool being issued from the Tool To Use column. The drop-down list allows the user to select any tool assigned to the group that's currently within calibration.

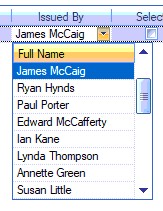

The user can also specify who is issuing the tool by selecting the appropriate employee name from the drop-down list.

This will default to the current user's name, but can be amended if required.

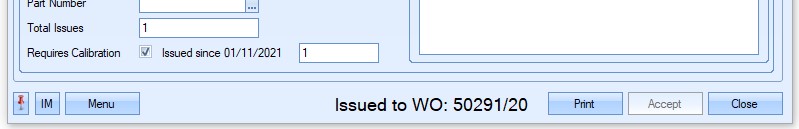

Once the tool(s) has been selected for issue, the user can complete the issue process by clicking ACCEPT. The system will then update the tool record(s) to indicate that these tools are now issued/unavailable. The main Tooling & Equipment screen will highlight this in the grid as well as the individual tool record.

(main Tooling & Equipment grid)

(within the tool record itself)

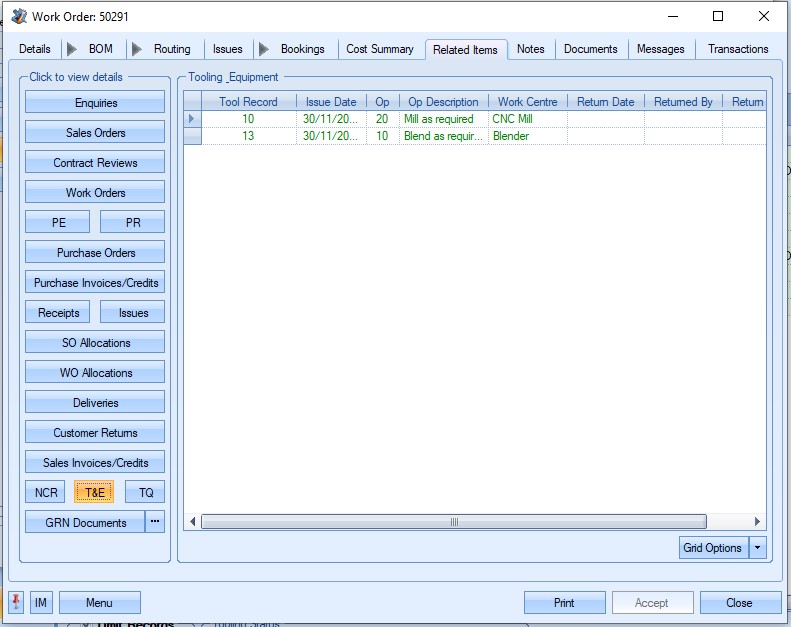

The work order(s) the tools have been issued to will show any issued tools in their Related Items > T&E screen.

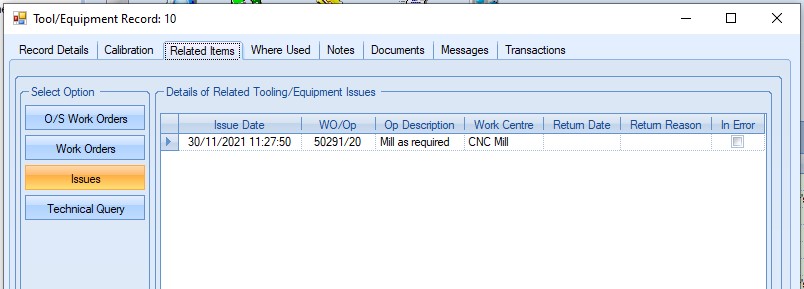

Similarly, details of all issues of the tool can be seen in the tool's Related Items > Issues screen.

Unplanned Issues of Tooling

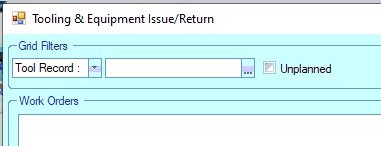

Unplanned issues of tooling can be done using the UNPLANNED option when selecting a specific Tool ID. This option is only available when selecting an individual tool.

Ticking the UNPLANNED option and then REFRESH will allow the user to issue the selected tool to any available WO, or select a specific WO if known.

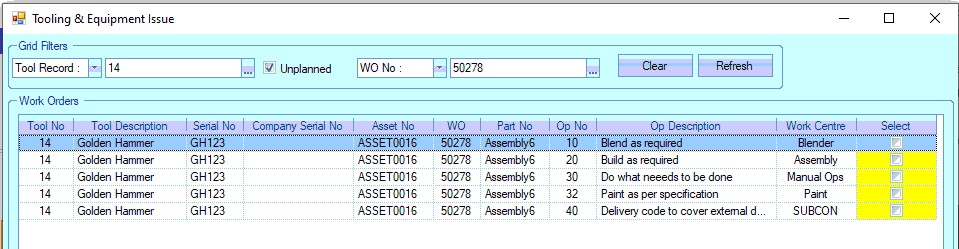

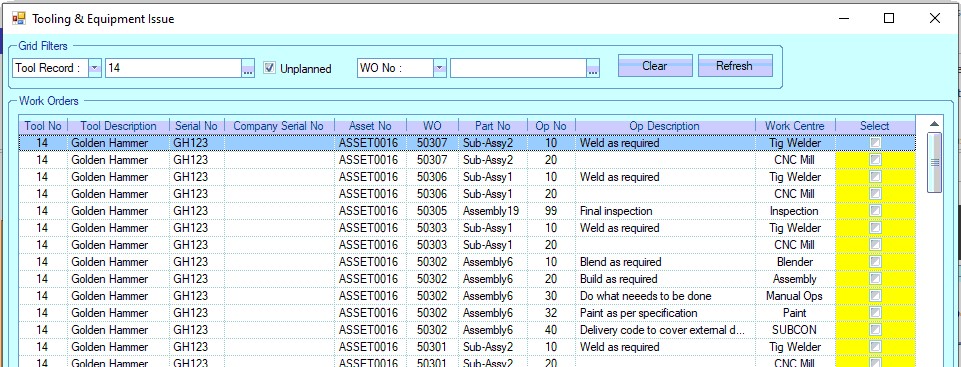

Once a specific WO has been selected, or the user has simply clicked REFRESH, the relevant WO operations will be displayed in the grid below.

(specific WO selected for unplanned issue)

(no specific WO selected for unplanned issue)

As per planned issue process, the user selects the WO operation the tool is to be issued to and clicks ACCEPT to complete the issue.