This functionality, also referred to as HAS AREA/HAS LENGTH, allows part stock to be managed based on lengths and dimensions and to ensure costings are correctly calculated if purchased by the tonne. In these cases, each GRN is recorded as a number of units with the associated length/dimensions. All inventory transactions are also based on a number of units instead of being based on the unit of measure (UOM) assigned. This functionality is not available by default due to the additional work required to set it up and has to be switched on by Progress.

NOTE: Due to the additional information recorded for the HAS LENGTH/HAS AREA parts, a number of the grids in Progress will need to be reset to ensure the additional information and other relevant columns are displayed. Typically, these will be BOM, inventory transaction and purchasing related grids (i.e. BOM screens, WO issue, etc.).

Creating HAS LENGTH/HAS AREA parts

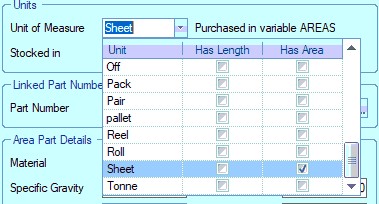

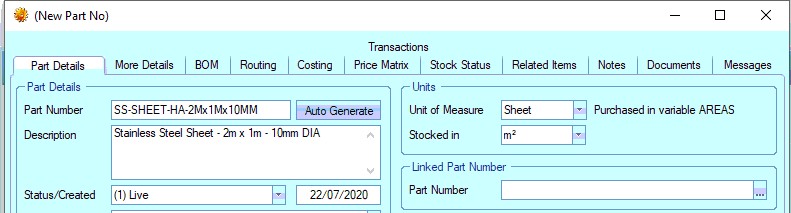

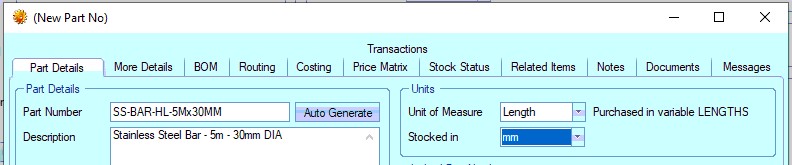

To create parts as HAS LENGTH/HAS AREA, the part is created as normal, but the unit of measure is assigned to to a value that has been set up as a HAS LENGTH or HAS AREA unit of measure in the List Maintenance section of Progress.

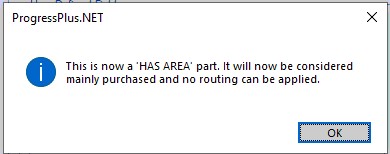

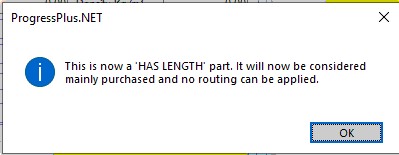

When selected, the system confirms some restrictions that will be put in place for this part. These ensure the part is a mainly purchased items and cannot be assigned a routing, which would make it possible to raise a WO for the part.

(HAS AREA part)

(HAS LENGTH part)

Once a part has been set as HAS LENGTH/HAS AREA, the user will have to specify how the item is stocked. The user will be able to select another unit of measure for this purpose via the STOCKED IN field.

(HAS AREA part)

(HAS LENGTH part)

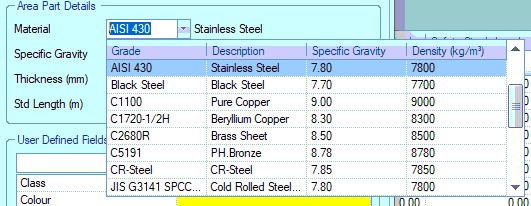

In addition to these settings, the user also has to specify the type of material for these parts. These details allow the system to correctly calculate costs for the material if purchased by the tonne. The list of material types is set up in the List Maintenance section of Progress and is the same list used by both HAS LENGTH and HAS AREA parts.

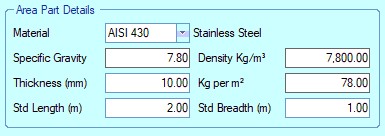

Once the material grade is selected, the user must complete the thickness, length and breadth values. These values are used when calculating the costings of the material when purchased by the tonne, with the standard dimensions used were purchasing. If the part number has no standard length or area (i.e. it is purchased in different sizes each time) then these can be left at 0. Purchasing will then see the exact sizes required when reviewing purchasing requirements.

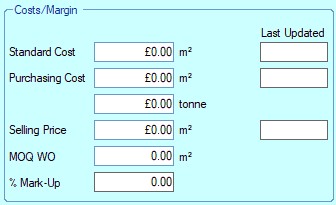

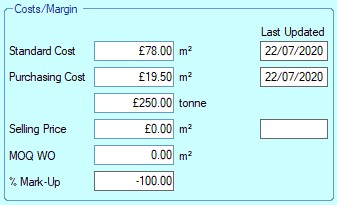

The user also had an additional field available in the Costings section of the part for recording the price per tonne if this is known. The system now has all the information it needs to ensure costings are calculated correctly based on the price they pay for the material, be it based on the unit of purchase or price per tonne.

Entering either a purchasing cost will calculate the equivalent cost per tonne and vice versa based on the material grade details entered,

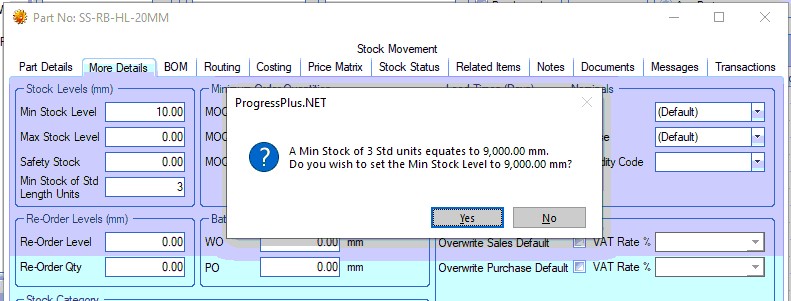

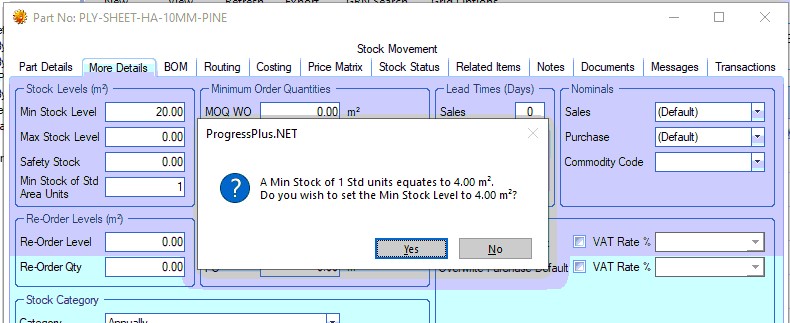

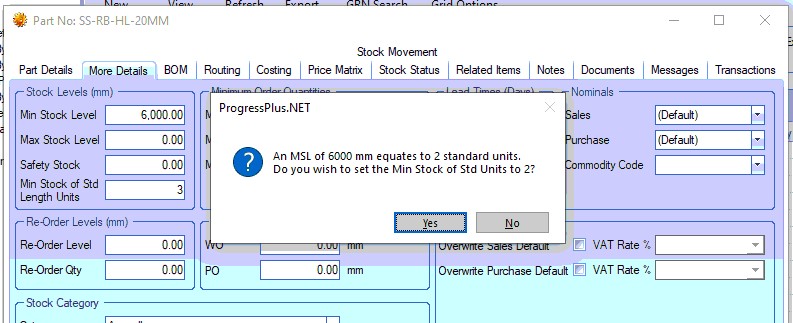

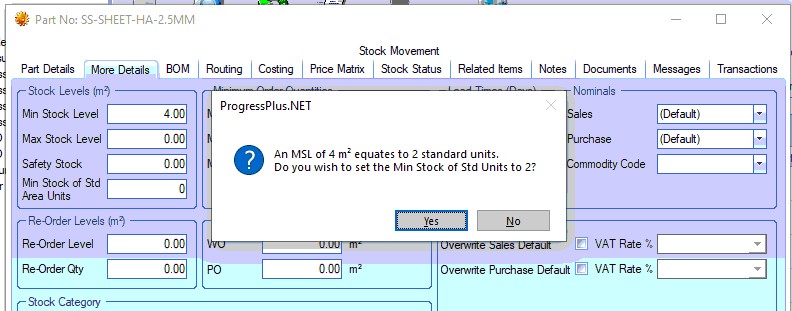

Minimum stock levels (MSL) can also be set for HAS LENGTH and HAS AREA parts. This information is added via the More Details tab of the part record. There are two fields for this;

MIN STOCK LEVEL This is the minimum quantity of the parts UOM that the user wishes to maintain in stock

MIN STOCK OF STD AREA/LENGTH UNITS This is the minimum quantity of standard area/legth that the user wishes to maintain in stock

Setting either of these values will calculate the equivalent value for the other. This allows the user to work in both standard lengths/areas, as well as stocked UOM values. Below shows the prompts the user will received when entering values for MIN STOCK LEVEL and MIN STOCK OF STD AREA/LENGTH UNITS respectively.

(Setting HAS LENGTH minimum standard units and updating MSL)

(Setting HAS AREA minimum standard units and updating MSL)

(Setting HAS LENGTH MSL and updating minimum standard units)

(Setting HAS AREA MSL and updating minimum standard units)

The user can complete the rest of the part's information just like any other part in the system. As per the system warning displayed at the start of setting up these parts, the part is restricted to being mainly purchased, so no routings can be added nor can the MAINLY PURCHASED flag be changed.

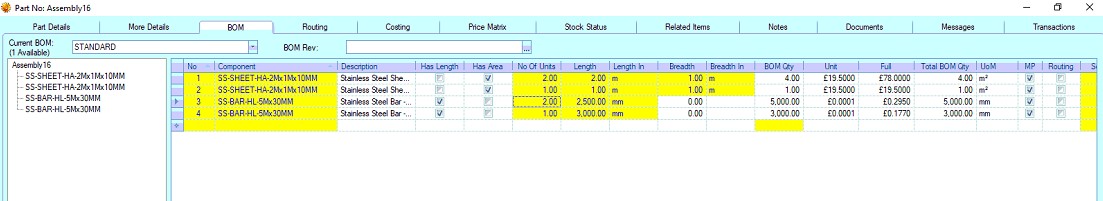

Adding HAS LENGTH/HAS AREA parts to BOMs

Adding HAS LENGTH/HAS AREA parts to a BOM is no different to adding standard parts in the system. The user can search for and select the parts to be added to the BOM from their inventory list. Once added to the BOM, the user will then see the additional information that's required for these parts.

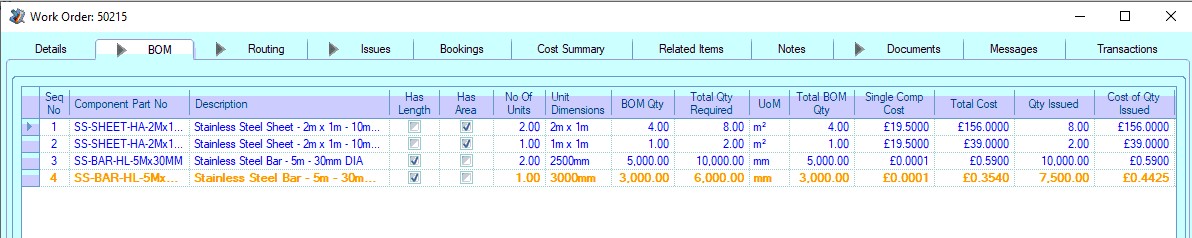

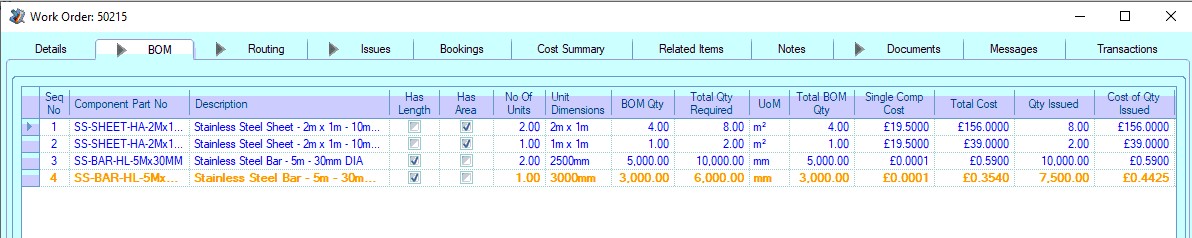

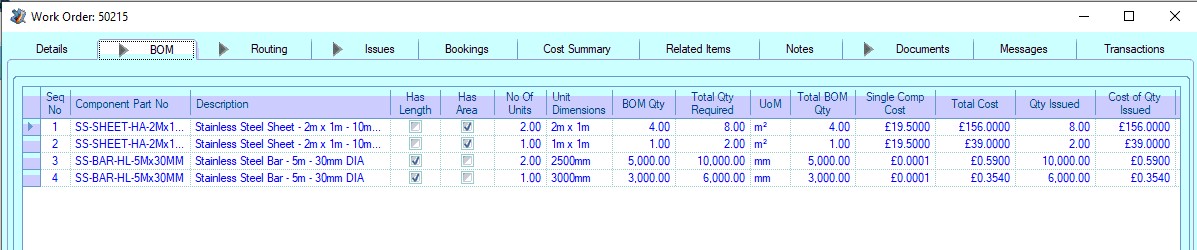

As can be seen above, and as previously mentioned, adding HAS LENGTH/HAS AREA parts to a BOM requires the user to specify the number of units of this part along with the dimensions and units of that requirement. All costings will be calculated based on the information already entered against the parts to ensure the correct material costs are calculated as can be seen in the example shown above.

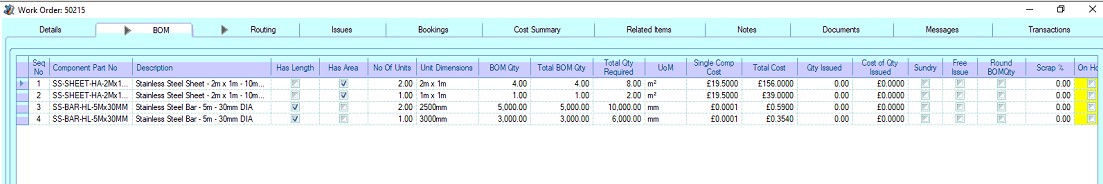

Generation of Work Orders

The generation of WOs in the system, be it standalone or via the SO Line Requirements/WO Demand screens, is no different to the standard process. Creation of a WO which contains a HAS LENGTH/HAS AREA part will create the necessary demand for the part to allow the purchasing team to raise the required POs if required. The WO itself will show all the relevant material details based on the number of manufactured parts being made on the WO along with all the relevant planned costing information for the job.

As can be seen in the example above, the parts are listed with all their lengths/dimensions and costing information.

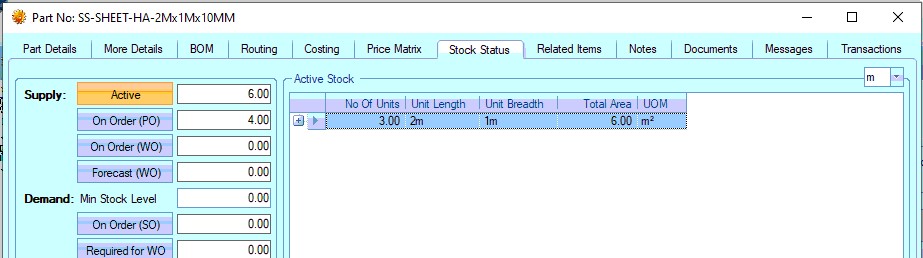

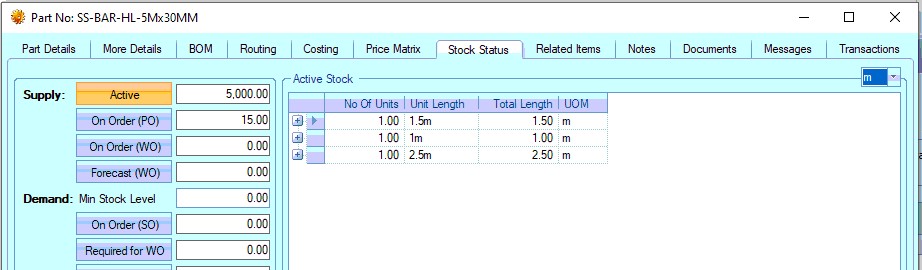

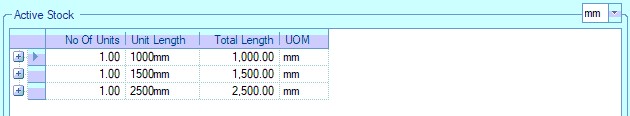

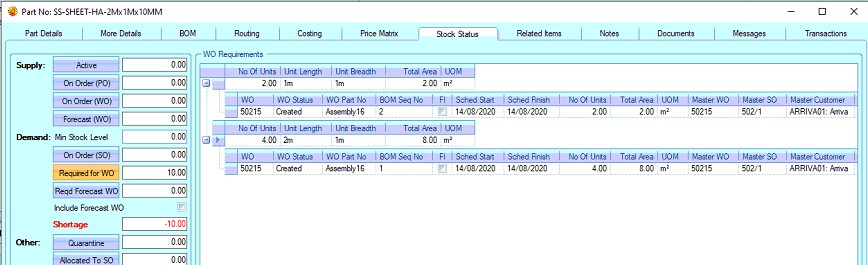

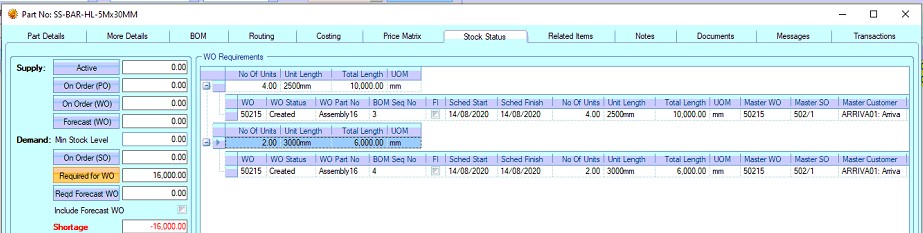

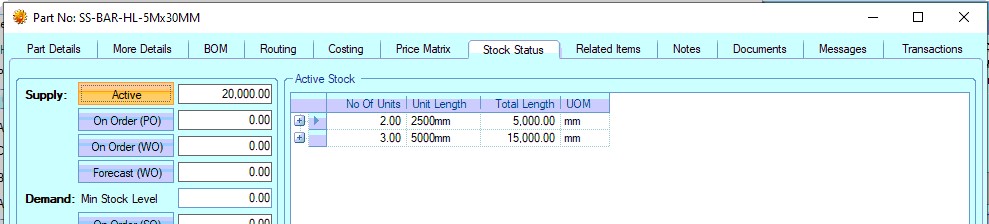

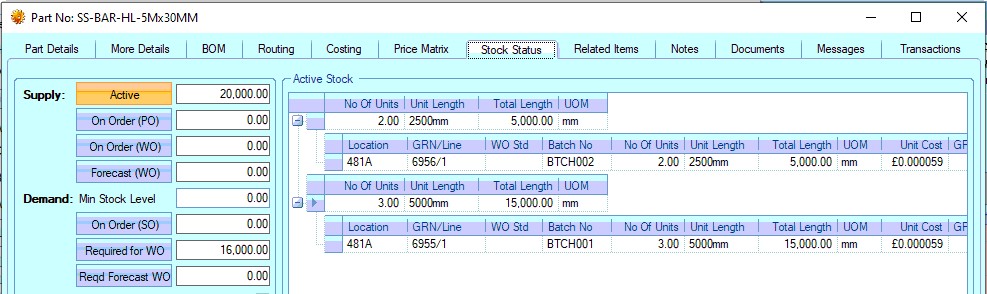

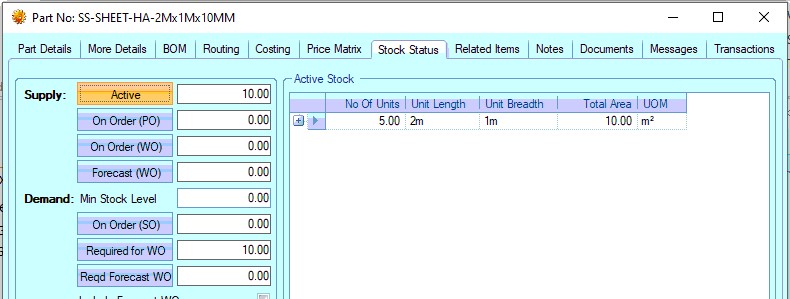

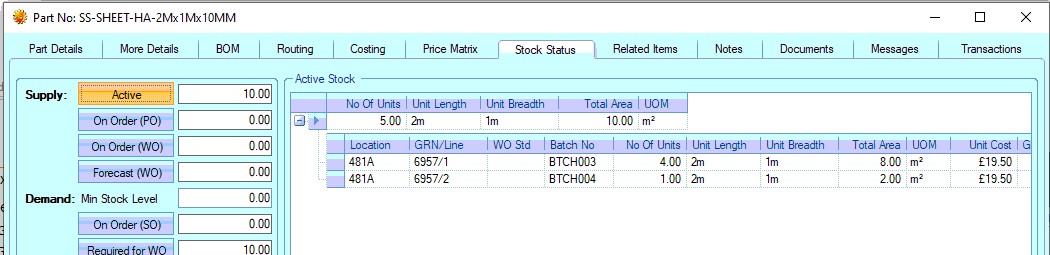

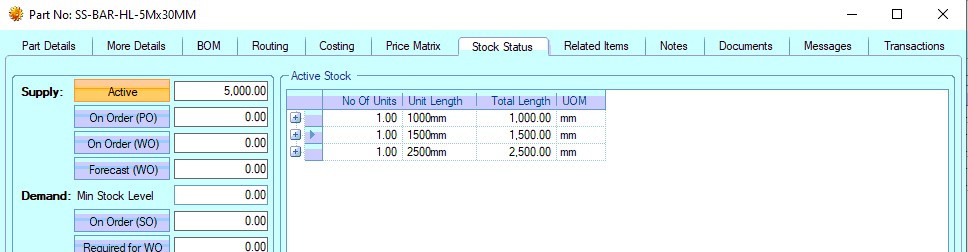

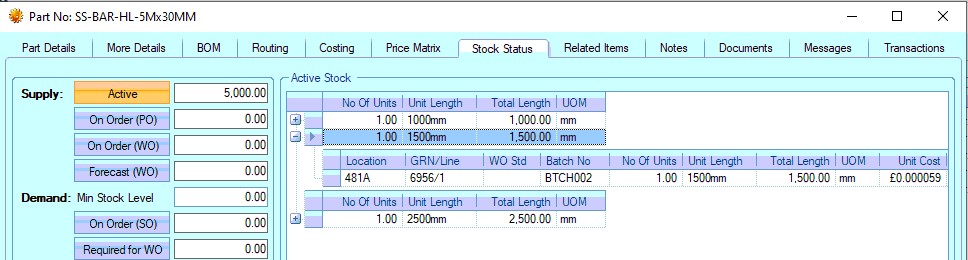

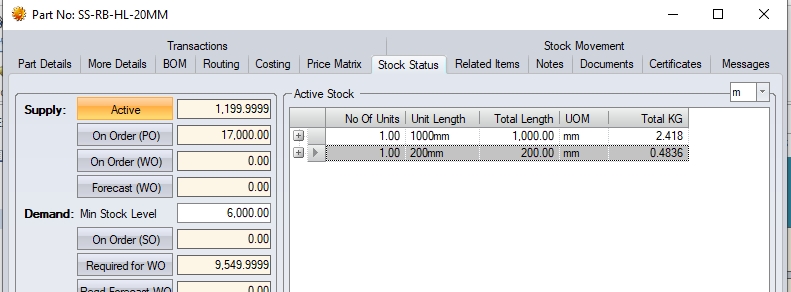

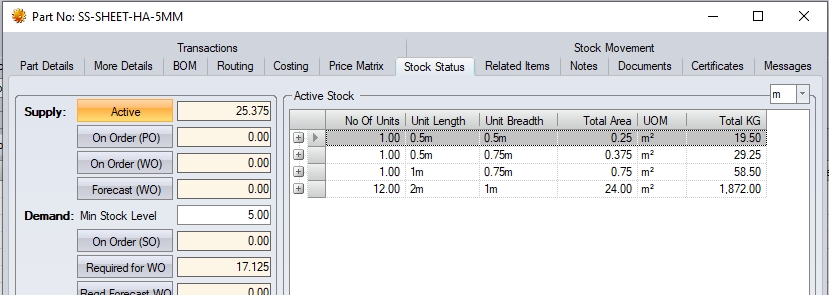

Inventory Stock Status

All stock of HAS LENGTH/HAS AREA parts is shown in the standard Stock Status screen but, unlike standard parts, the requirements are shown broken down into the number of units along with the units' dimension/length requirements of those units as shown below.

(HAS AREA part)

(HAS LENGTH part)

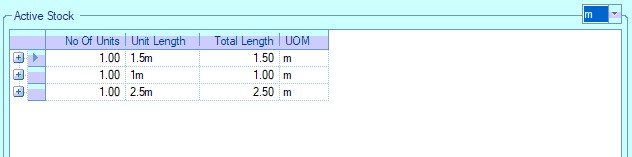

The user can also change the units of measure/area using the option at the top right corner. This retains the part's UOM but allows the user to view their stock/requirement in different dimensions as demonstrated below.

![]()

(shown in meters)

(shown in millimetres)

Expanding the individual dimension/length units shows all the associated GRN information.

(HAS AREA example)

(HAS LENGTH example)

This formatting is used on all applicable options on the Stock Status screen (i.e. ACTIVE, ON ORDER (PO), REQUIRED FOR WO and QUARANTINE).

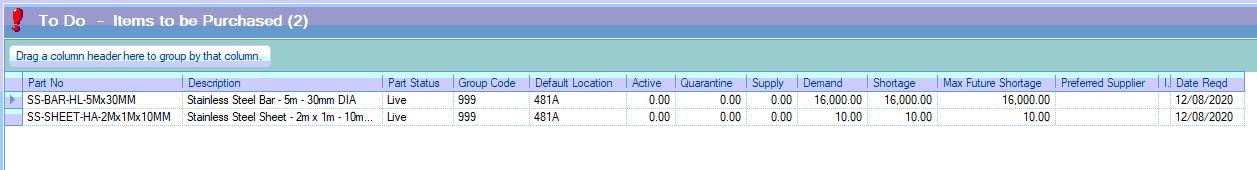

Raising Purchase Orders for HAS LENGTH/HAS AREA Parts

As per normal, the system will highlight any purchased material demand on the Today > To Do > Items To Be Purchased screen and on the PO Shortage screen if accessed directly via the Purchasing section of Progress.

(Items To Be Purchased screen)

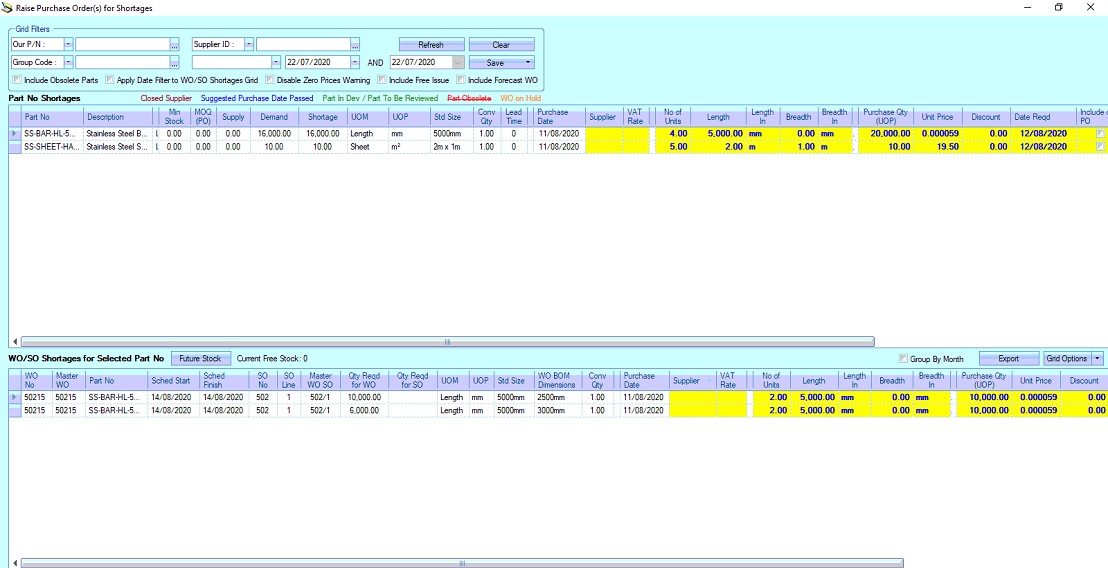

(PO Shortage screen)

Again, all length and dimension information is displayed to inform the user raising the PO of what's required, both overall and also on a WO-by-WO basis. The system will default most of the information on this screen based on how the HAS LENGTH/HAS AREA parts have been set up, although the user does have the ability to amend the information highlighted in yellow if the default information needs to be changed (i.e. different lengths/areas are available from the supplier).

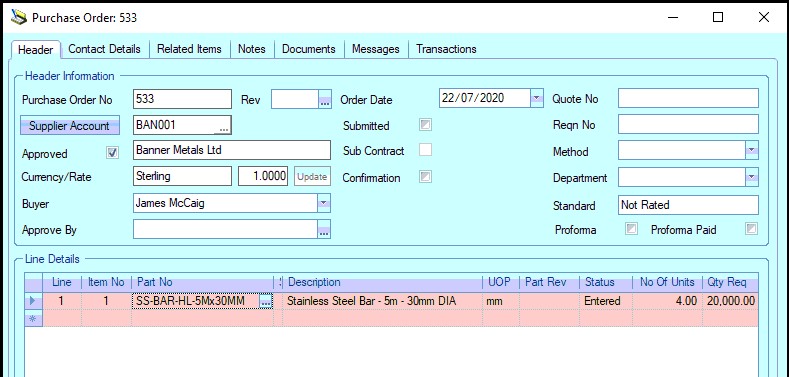

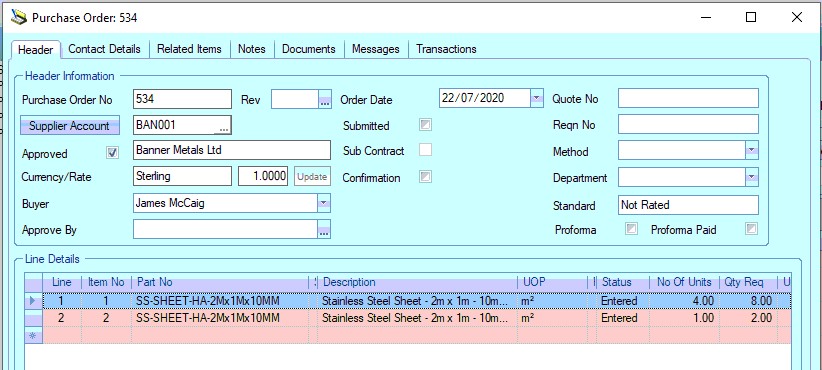

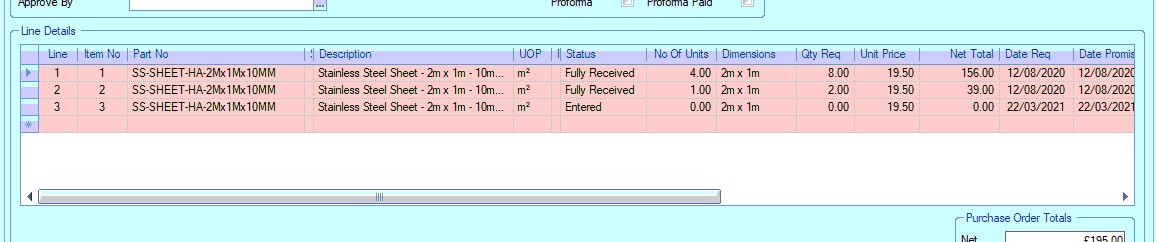

The process of raising POs from the PO Shortage screen is no different to that of standard parts, with the user selecting the items listed in the top half of the screen for a general PO covering all requirements or via the bottom half of the screen for WO specific requirements. POs created will record all the relevant dimension/length information so the supplier is given the exact details of what's required. Examples below show a general PO and a job specific PO. As previously mentioned, the requirements are shown as a number of units, however, the QTY REQ figure shown on the PO is based on the part's STOCKED IN unit of measure.

(HAS LENGTH example)

(HAS AREA example)

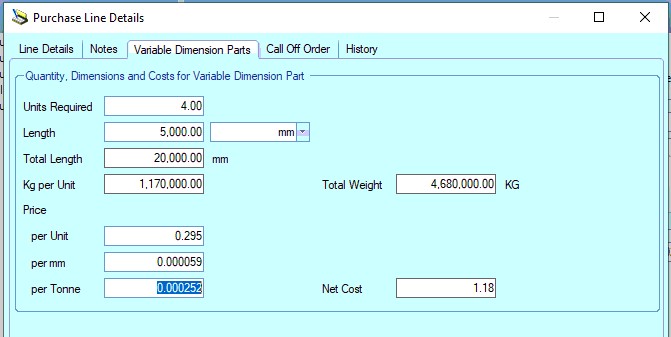

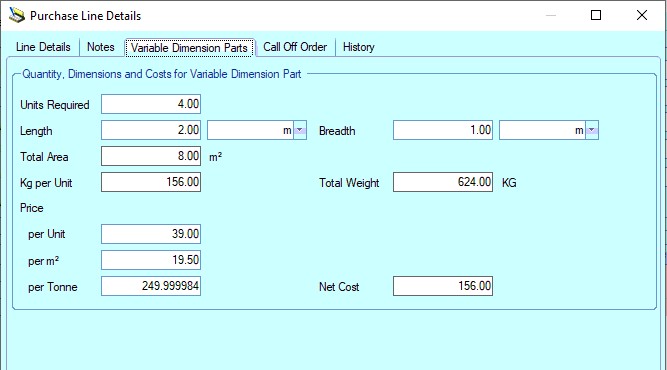

The PO line details also has an additional tab for HAS LENGTH/HAS AREA parts that shows the length/dimension/price details. This information will be populated based on the part details when the PO is created but allows the user to amend if necessary if the material is different to what is typically ordered (i.e. different lengths/dimensions, pricing, etc.).

(HAS LENGTH example)

(HAS AREA example)

The dimension details and UOMs are also visible on the PO line details as shown below.

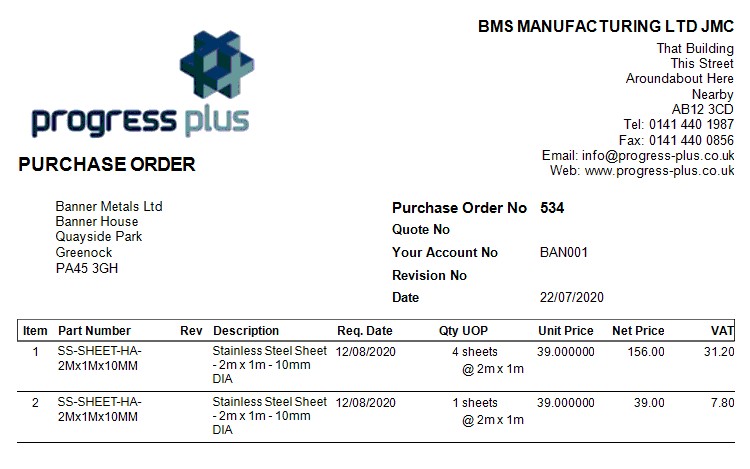

Once the POs have been created, they can be sent off to the suppliers. An example of one showing the length/dimension details is shown below.

NOTE: The PO layout, as with all layouts in Progress Plus, can be designed to show the relevant dimension/length information in a way that suits our customers, so this can be tailored to your own requirements. Please contact Progress Plus to discuss your requirements further.

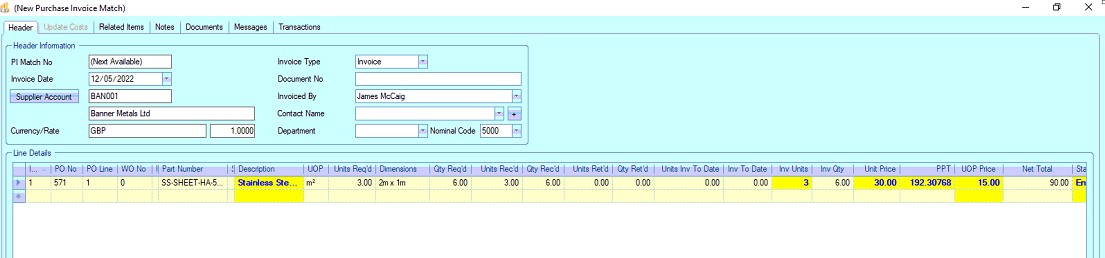

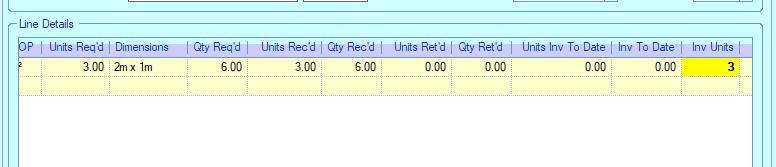

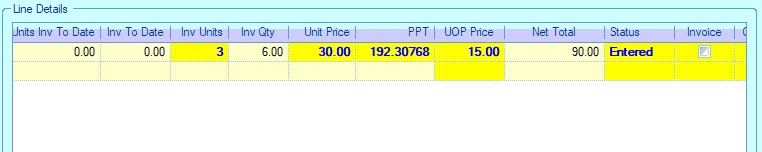

PI Matching HAS LENGTH/HAS AREA Parts

As per most of the areas of the system, the purchase invoice (PI) process is the same for standard parts and HAS AREA/HAS LENGTH parts, with the only different being the use of the number of units instead of the unit of purchase.

When a PI is created for HAS AREA/HAS LENGTH parts, the relevant dimensions are shown on the line details, along with both the number of units ordered, received, returned and invoiced to date and their equivalent quantities

Just like standard PI matching, the user simply has to match the correct number of units (INV UNITS) being billed by the supplier. From a pricing perspective, the user has the ability to enter the price based on the unit price, the unit of purchase (UOP) price or the price per tonne (PPT). The PI match will default these based on the purchase order itself, but amending any of these will update the others.

Once the details have been checked/amended and as per standard PI process, the user will tick the INVOICE option to include the item in the PI being created. The user would then repeat the process for any additional lines included on the PI before clicking ACCEPT to complete the PI. Again, just like the standard PI process, all associated GRNs will be updated to reflect the PI price, with the Purchasing Cost and Price Per Tonne of the part itself also being updated.

Receipting HAS LENGTH/HAS AREA Parts into Stock

There are a number of ways of adding HAS LENGTH/HAS AREA stock to the system, the most common being PO Receipt and Adjustment Receipt, both of which require the user to enter the details based on the number of units of each length/dimension. This ensures the system is able to calculate the available stock (and any surplus/shortage figures) correctly.

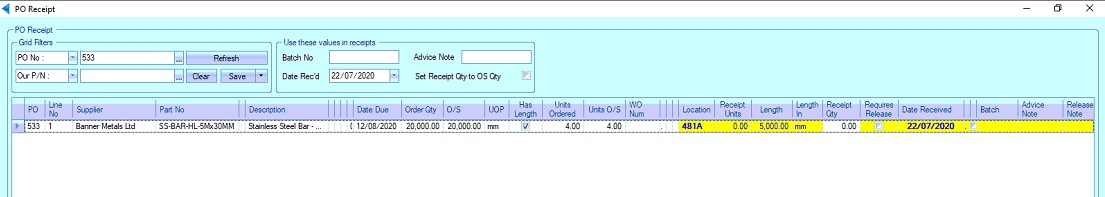

PO Receipts (HAS LENGTH example)

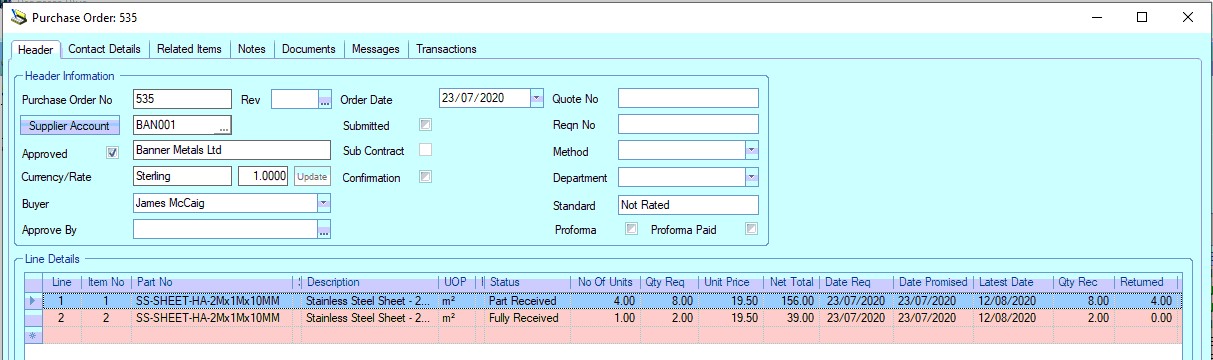

When stock is receipt from a supplier, the user will receipt the PO via the PO Receipt option in the Inventory > Receipts section or via the RECEIPT option in the PO via the MENU option. These screens will know whether the parts being received are HAS LENGTH/HAS AREA parts and will display the relevant information accordingly. Most of the information will be pulled from the PO itself, but the user does have the ability to amend some details based on what they have received. An example PO is shown below.

The example HAS LENGTH PO above was raised for 4 lengths of material, each 5000mm in length, as this is the standard size when purchasing. If the user received 4 lengths exactly this size, then they can simply enter the RECEIPT UNITS value as 4. This will book 4 units of 5000mm into stock. If they received 3 units at 5000mm and 2 at 2500mm then these can also be booked in from this screen. Both would ensure the correct stock is created in the system but would need to be done as separate receipts to ensure the correct dimensions are captured for each of the different lengths. These different lengths of material would then be listed separately in the part's STOCK STATUS screen, grouped by the lengths/dimensions received, as is shown below.

The system is able to calculate the amount of material received based on how the part is set up to ensure the PO is updated correctly to reflect what's been received into stock and also any outstanding quantities/units still to arrive from the supplier.

HAS AREA parts work in exactly the same way, except for them having length and breadth details recorded at the point of receipt. Again, these are grouped by dimensions against the part's stock figures with the individual GRN details shown when expanded as shown in the example below. This HAS AREA example was for 5 sheets of material, each 2mx1m. Since all were received with the same dimensions, all are listed under the one group.

As for all receipts, if the system is set up to produce a GRN label for PO receipts, then one will be printed with all the relevant HAS LENGTH/HAS AREA information on it.

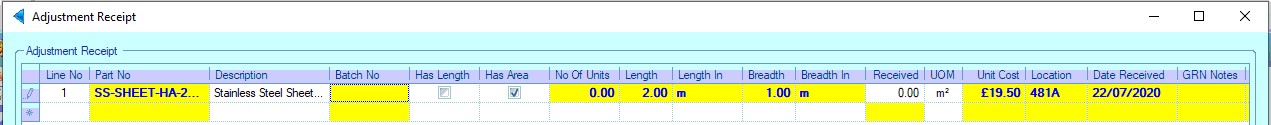

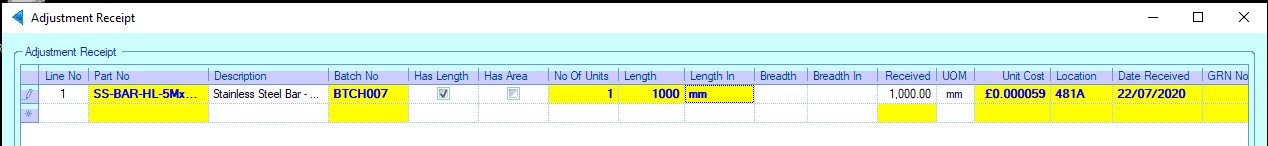

Adjustment Receipts

The Adjustment Receipt option, which allows stock to be created without a PO, will also prompt the user for the specific number of units as well as the lengths/dimensions for the part being received. Once the user enters the part number, the screen refreshes to show the fields required for the receipt of the part.

(HAS AREA example)

(HAS LENGTH example)

Again, the part's STOCK STATUS will show the stock as the number of units of each length/dimension along with the details of each GRN in that group. As for all receipts, if the system is set up to produce a GRN label for adjustment receipts, then a one will be printed with all the relevant HAS LENGTH/HAS AREA information on it.

All other receipt transactions (i.e. PO Receipt (Ind Batch), Free Issue Receipt, Free Issue Receipt (Ind Batch), etc. ) work in a similar manner and will be based on units and dimensions.

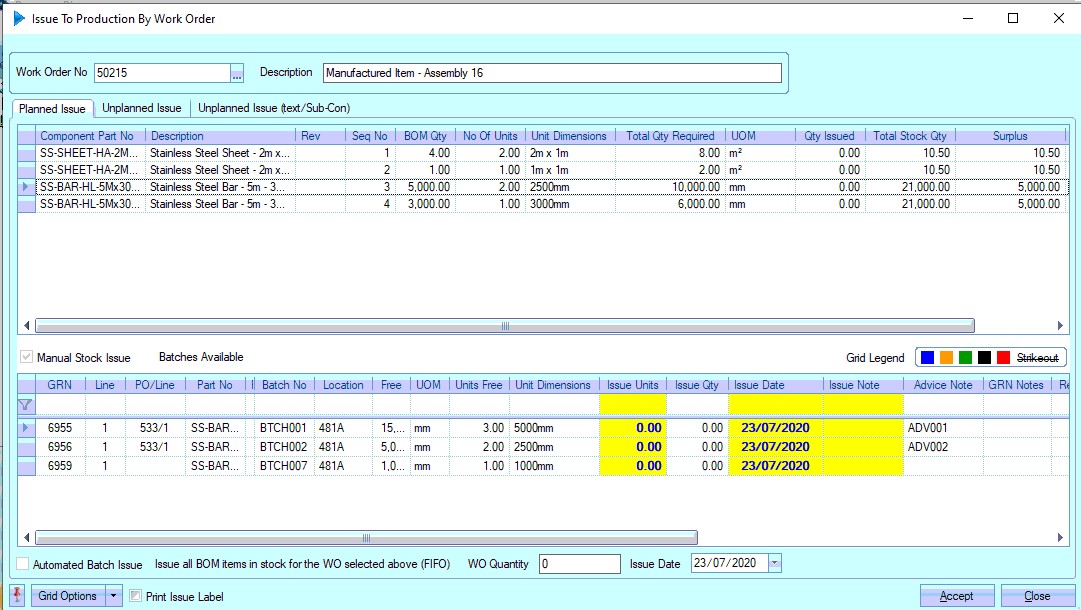

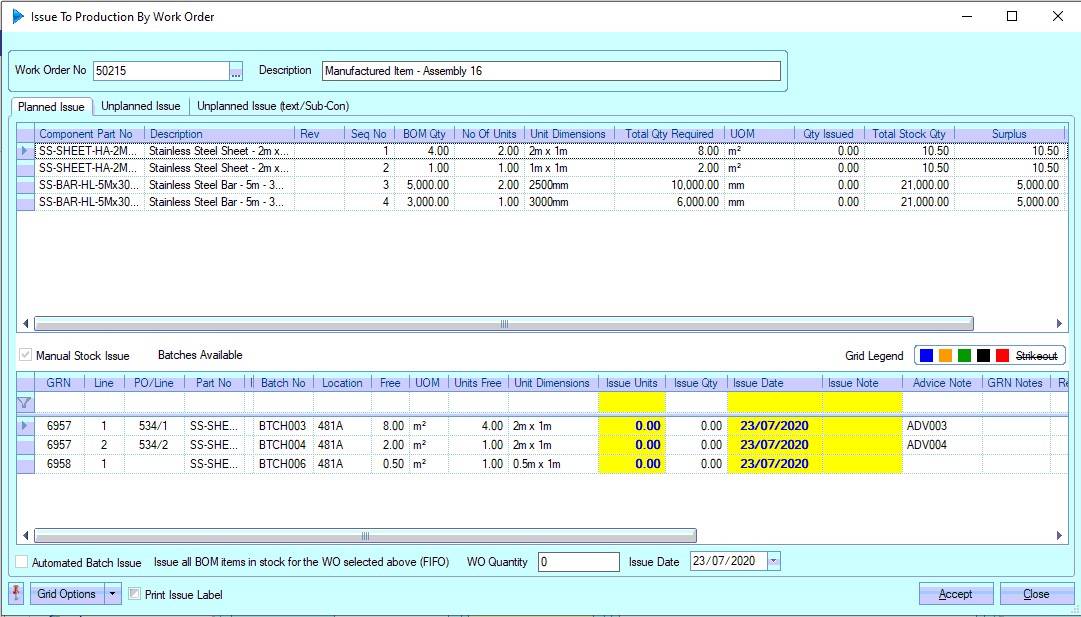

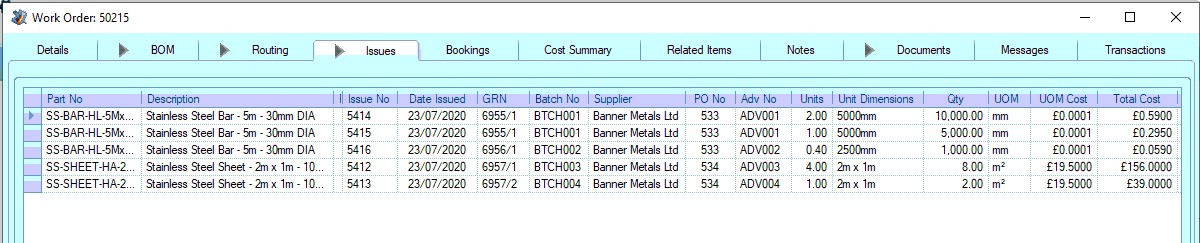

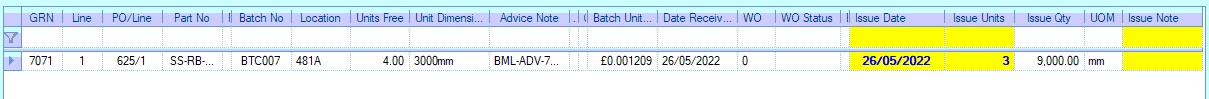

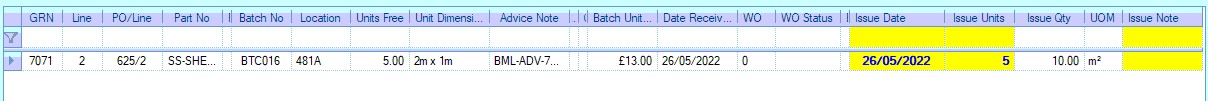

Issuing HAS LENGTH/HAS AREA Material

Issuing HAS LENGTH/HAS AREA parts to WOs uses the same option used for standard parts, with the exception of all transactions being based on a number of units. The standard WO Issue screen shows all the available stock, along with the lengths/dimensions of all available units.

(HAS LENGTH example)

(HAS AREA example)

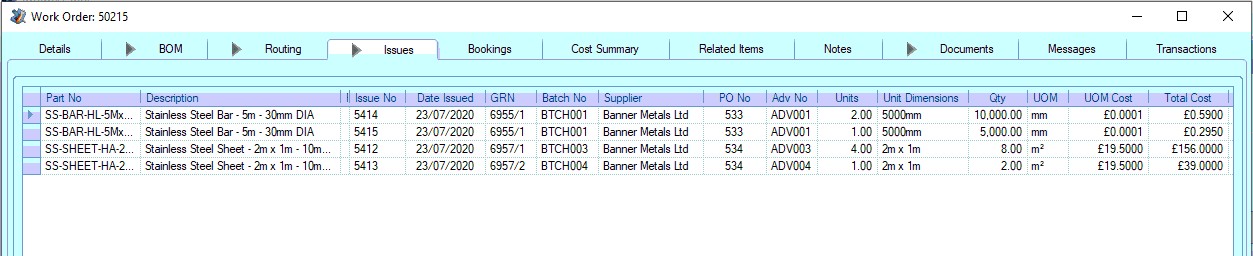

Once complete, all material issues are listed on the WO's ISSUE tab, along with the relevant length/dimensions. The WO BOM tab will also be updated to reflect the status of the material requirements and also with the associated material costs based on the batches of material that have been issued.

If the system is set up to produce an issue to production label, then one will be printed with all the relevant HAS LENGTH/HAS AREA information on it.

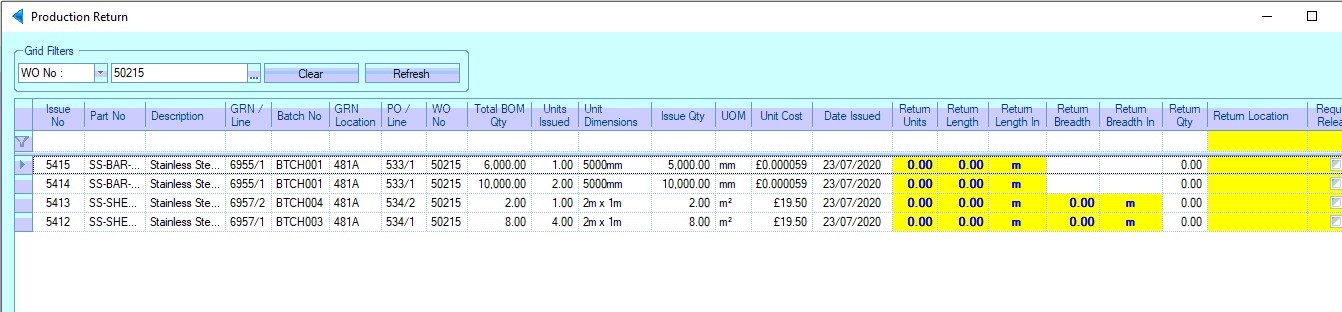

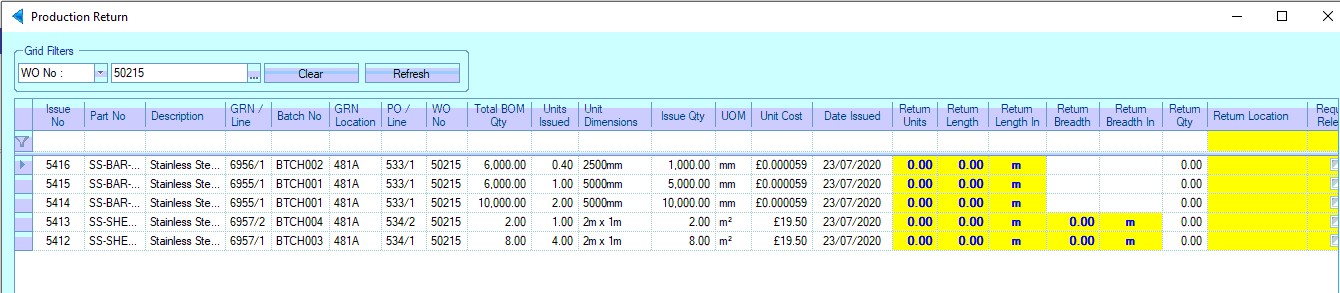

Returning Extra Material to Stock (Production Returns)

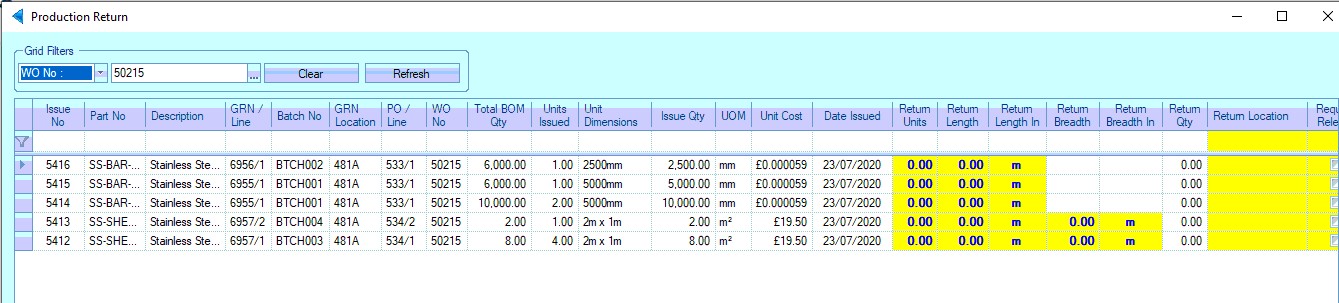

Where material has been issued to a WO that is in excess of what is required (i.e. a full sheet when only a partial size is required or a longer length of material where only a short length is required), the user can return the excess material back to stock using the Production Return process. This can be done via the WO MENU option (Menu > Production Return) or via the Inventory > Receipts > Production Return option. When either these options are used, the user will be presented with a list of material that's been issued to the selected WO. Any HAS LENGTH/HAS AREA parts will be highlighted with the length/dimension information shown.

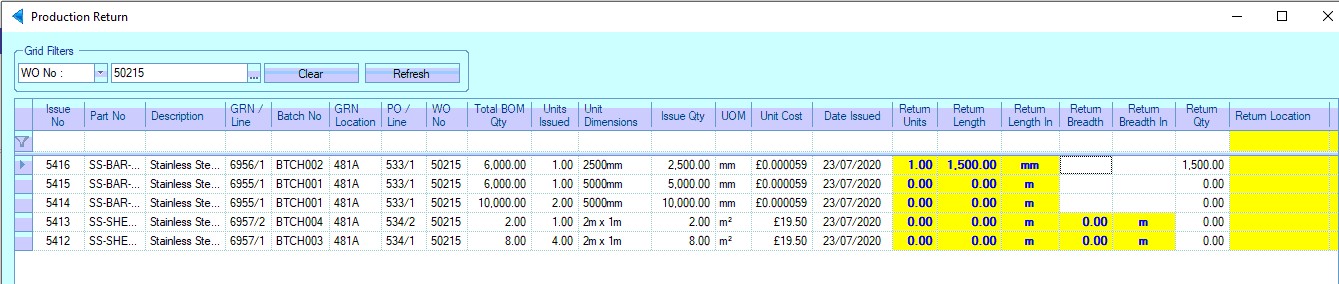

From here, the user can specify the number of units being returned along with the units' associated lengths/dimensions. These units will then be returned to stock against the part number with the new length/dimensions.

Example:

The part number highlighted in orange on the WO BOM above has been over issued. The WO requirement was for 6000mm and lengths of 7500mm were issued. Since the excess material could be used for another job, this can be returned to stock using the Production Return process. Using the Production Return option for this WO presents the user with the following.

From the above, we can see issue number 5416 is where the excess material was issued, an excess of 1500mm. To return this to stock, the user would specify the number of units being returned, in this case 1, along with the length of the returned unit, in this case 1500mm.

Once the details have been entered, the user can complete the return to stock by clicking ACCEPT. The system will then confirm the return as normal.

Once the return is complete, the Production Return screen is refreshed to show the updated ISSUE QTY on the WO. As for all receipts, If the system is set up to produce a GRN label for production returns, then one will be printed with all the relevant HAS LENGTH/HAS AREA information on it.

The WO too is updated to reflect the return. The BOM tab no longer shows the part as being over issued.

The WO ISSUES tab shows a reduced issue figure against the batch that was originally issued and subsequently returned.

The inventory STOCK STATUS screen also shows the new returned unit with its new length/dimensions too.

This new "offcut" can then be used for another job when required.

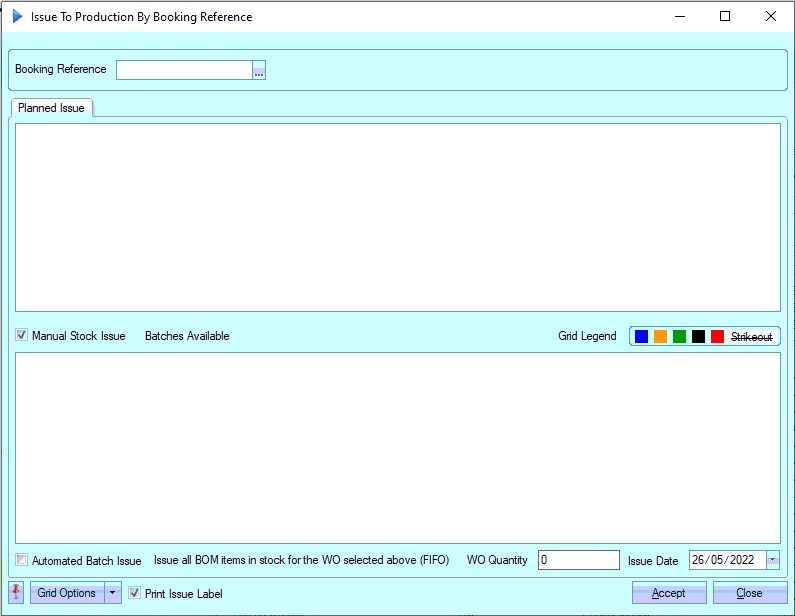

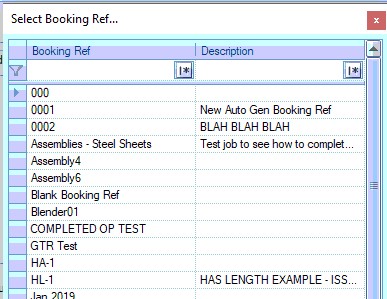

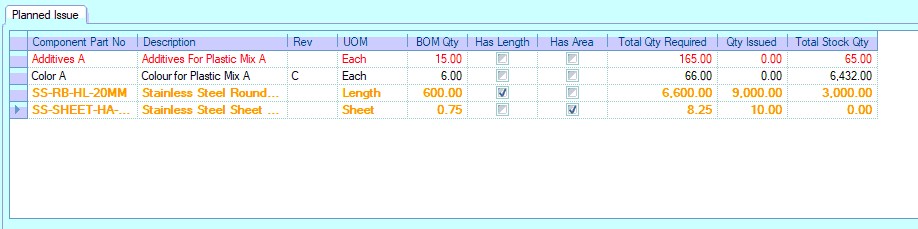

Issuing HAS LENGTH/HAS AREA Material (Booking Ref)

The user also has the ability to issue quantities of HAS LENGTH/HAS AREA parts to a range of work orders using the Issue To Production By Booking Ref option (Inventory > Issues). As with standard parts issued by this method, the system pro-ratas the issued material to all the WOs set up as part of the booking reference based on their BOM requirements. This option is often used where larger sheets or lengths are issued to fulfill multiple WOs. For more information on setting up booking references, please refer to the Booking Reference section of this manual.

Issuing material to a booking reference will present the user with the screen below. This is a standard screen for all material issues, including HAS LENGTH/HAS AREA parts.

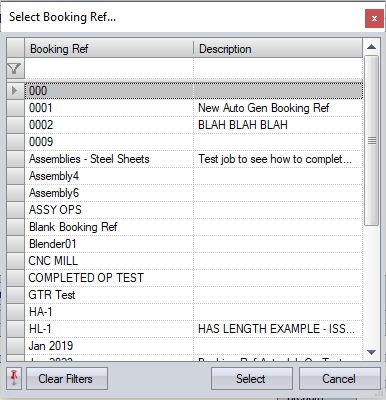

The first step of this process is for the user to select the booking reference required. The user will see a list of all available booking references in the system.

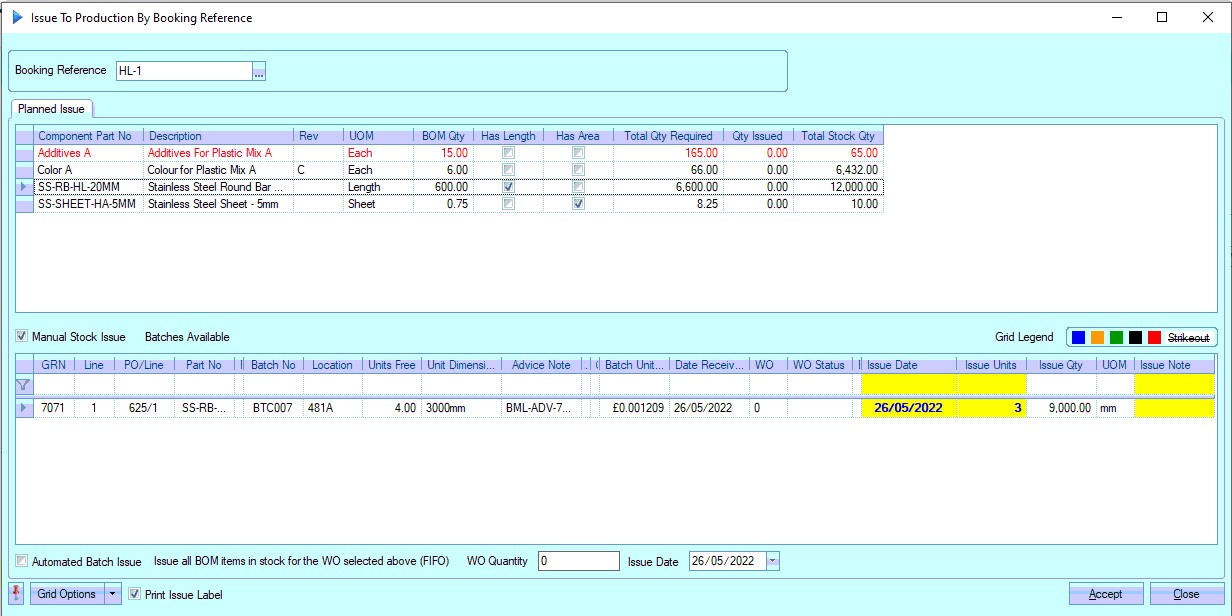

Once selected, the user will then be presented with a complete list of material part numbers required across all the work orders assigned to the booking reference, the top-half of the screen showing the total requirements across all work orders for each part number and the bottom-half of the screen showing the individual batches of each part (when selected).

As is the case with all other inventory transactions relating to HAS LENGTH/HAS AREA parts, all transactions are based on a number of units. From here, the user can specify the number of units to be issued to the booking reference against the relevant dimensions available in stock.

(HAS LENGTH example)

(HAS AREA example)

Once the user has selected the batch and quantity required, clicking ACCEPT will issue the material to the associated WOs on a pro-rata basis based on the WO BOM quantities.

Once the material has been issued to the booking reference, the top-half of the screen will be updated to reflect the issues. Where more material has been issued than is required, common where larger sheets/lengths are issued to multiple WOs, the items will show as being "over issued" and will be highlighted in orange.

Excess material issued can be returned to stock from the booking reference once the remaining material is know.

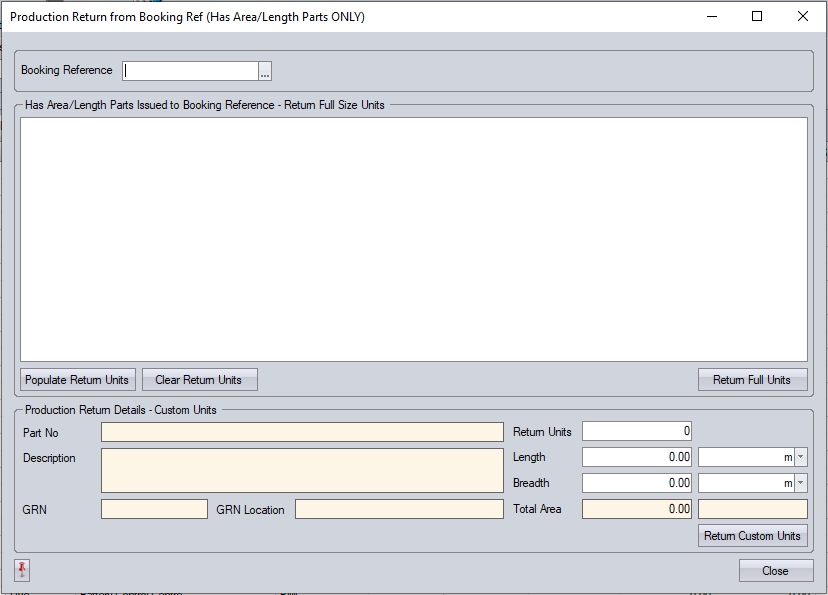

Returning HAS LENGTH/HAS AREA Material (Booking Ref)

Where HAS LENGTH/HAS AREA material has been over issued to a booking reference, the user has the ability to return the excess material to stock for use elsewhere. This process allows the user to specify the number of units being returned as well as their lengths/area, providing accurate stock control of all lengths and areas remaining. The option to return HAS LENGTH/HAS AREA material to stock from production is the Production Return By Booking Ref option, which can be found in the Inventory > Receipts section of Progress.

NOTE: THIS OPTION IS FOR HAS LENGTH/HAS AREA PARTS ONLY. ALL OTHER PRODUCTION RETURNS SHOULD BE DONE USING THE STANDARD PRODUCTION RETURN OPTION.

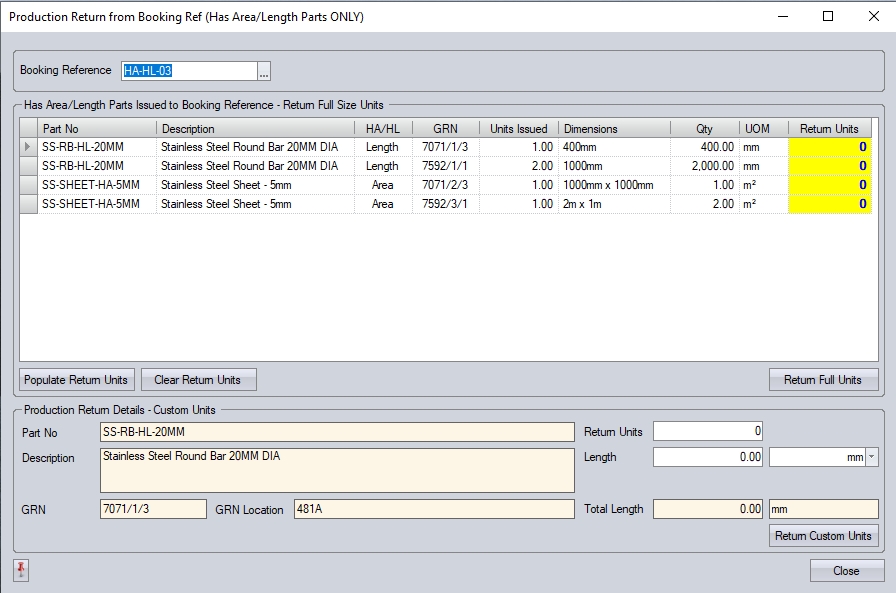

When selected, the user will be presented with the screen below.

The user, once again, selects the booking reference from the option at the top of the screen.

Once selected, this will display a list of all HAS LENGTH/HAS AREA parts issued to the booking reference, with the same part listed for each length/area that was issued to the booking reference.

Returning Full Units

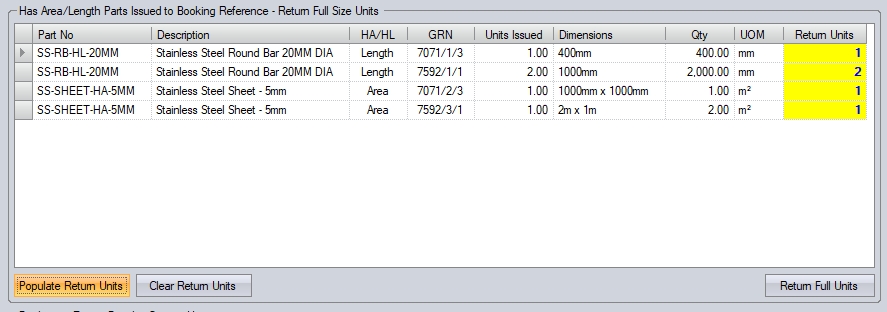

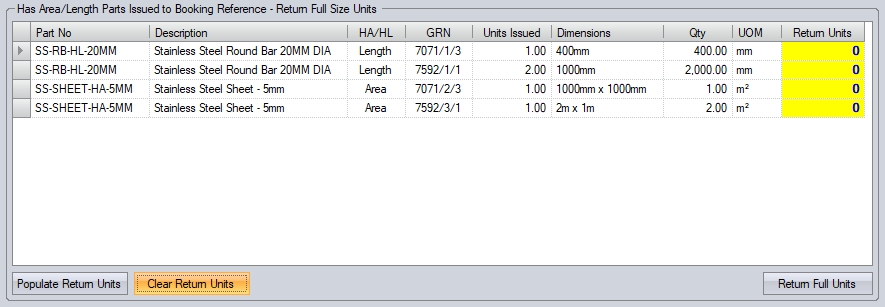

The user can use the POPULATE RETURN UNITS/CLEAR RETURN UNITS to quickly populate/clear the quantities to be returned against all the items issued, however, they can also enter the preferred quantities by typing the number of units into the RETURN UNITS box manually.

(Using POPULATE RETURN UNITS to fill in the values of the RETURN UNITS field)

(Using CLEAR RETURN UNITS to remove the values from the RETURN UNITS field)

The RETURN FULL UNITS option will complete the return of the full units set in the RETURN UNITS field in the grid and add them back into stock.

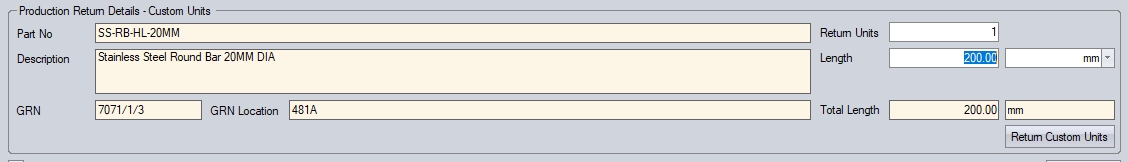

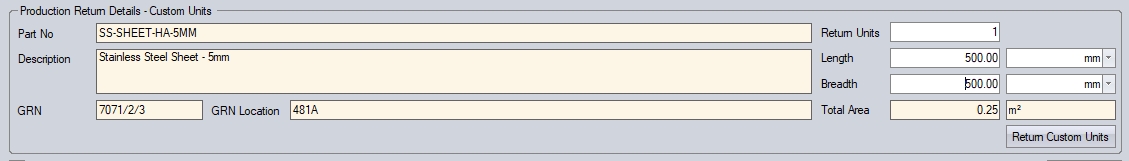

Returning Custom Dimensions

If the user is returning parts and dimensions that are different to what has been issued to the booking ref, they can use the bottom half of the screen to set the quantities and dimensions of the items being returned. The user will still select the relevant issued item to return, but will then enter the details of the returning item.

(Returning a custom HAS LENGTH part/length quantity)

(Returning a custom HAS AREA part/length quantity)

Once the details have been added, clicking RETURN CUSTOM UNITS will return the specified number of units, and their dimensions, to stock.

(HAS LENGTH example)

(HAS AREA example)

The issue transactions against the work orders associated with the booking reference will also be updated to reflect the final issue quantities (i.e. total issued - production returned) to ensure the job costings are correct.

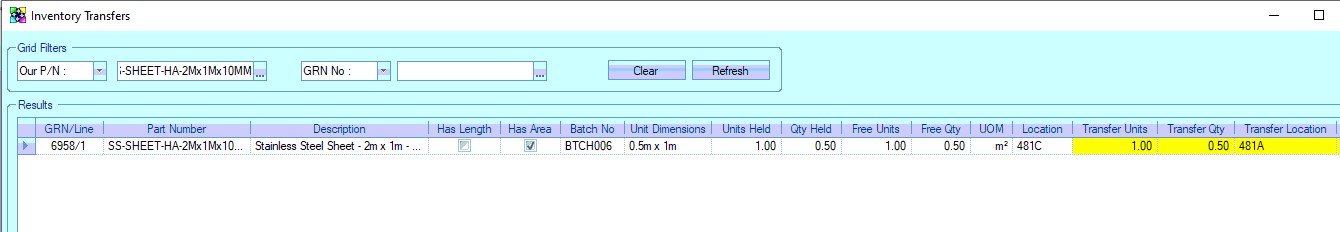

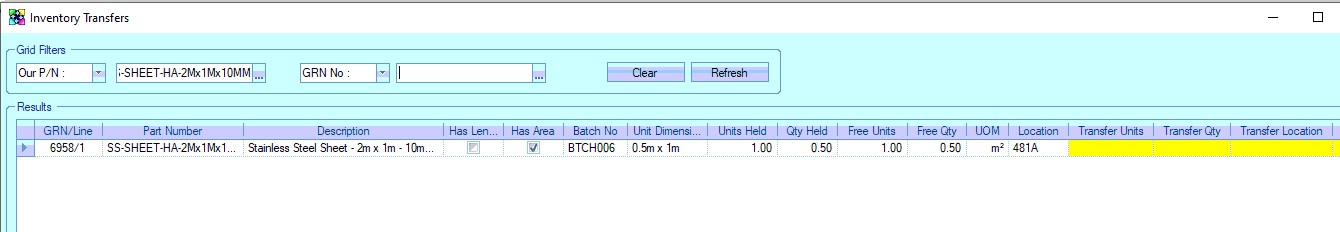

Transferring HAS LENGTH/HAS AREA Stock

The process of transferring HAS LENGTH/HAS AREA stock between stock locations is the same process as with standard parts, using the Inventory > Transfers option, with the only difference being that all transfers are based on the number of units. Below is an example with a HAS AREA part. Once the transfer is complete, the Transfer screen is refreshed to reflect the changes.

(Before transfer)

(After Transfer)

If the system is set up to produce a transfer label, then one will be printed with all the relevant HAS LENGTH/HAS AREA information on it.

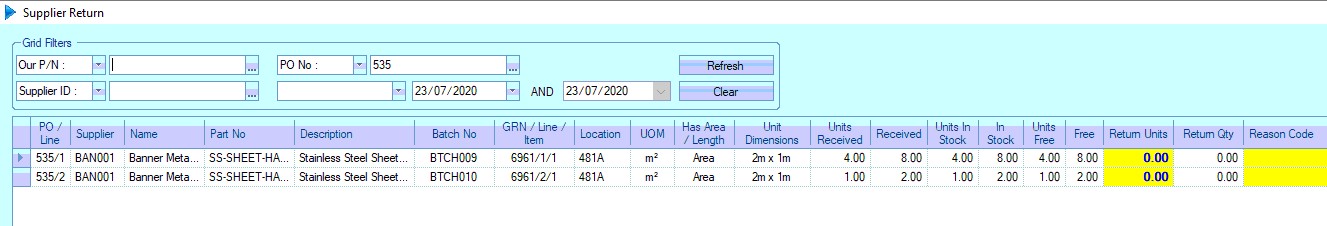

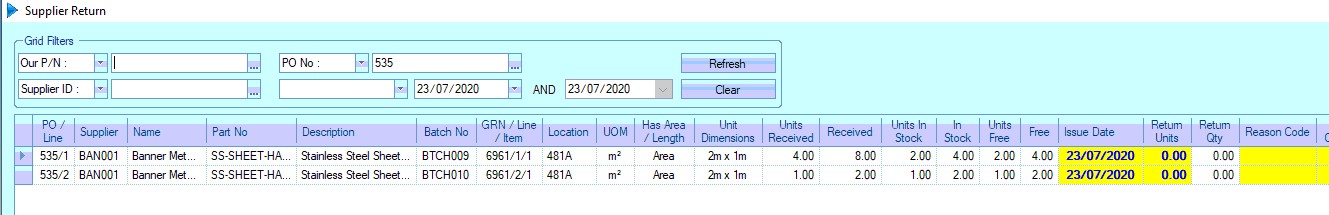

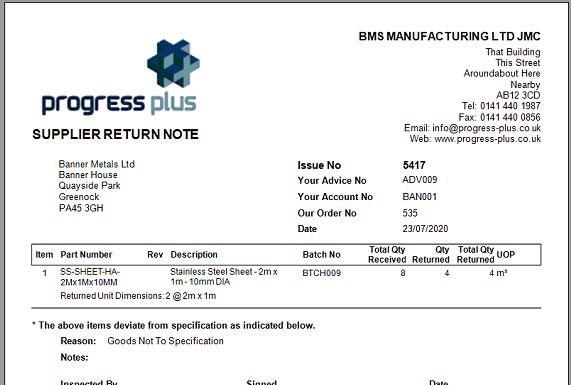

Supplier Returns

In the event HAS LENGTH/HAS AREA parts need to be returned to the supplier, the user can do this via the standard Supplier Return screen. This is accessed either directly from the PO (Menu > Supplier Return) or via the Inventory section of Progress (Inventory > Issues > Supplier Return).

(HAS AREA example - Before)

For HAS LENGTH/HAS AREA parts, the Supplier Return screen lists all available individual lengths/dimensions for returning to the supplier. As with all other transactions involving HAS LENGTH/HAS AREA parts, all returns are done based on unit quantities. Options relating to raising credits and non conformances are also available for use.

Once the return has been complete, the Supplier Return screen is refreshed to reflect the current available stock as shown below.

(HAS AREA example - After)

The associated PO(s) will also reflect the return of units with the system calculating the outstanding quantities correctly based on the number of units returned and the PO line status updating accordingly.

In addition to the supplier return transactions above, the user can also print the Supplier Return document to send with the goods. This document is generated via the Inventory > Issues > Print Supplier Return option just like standard returns. This document will reflect the details of the part being returned along with the length/dimension details. An example is shown below.

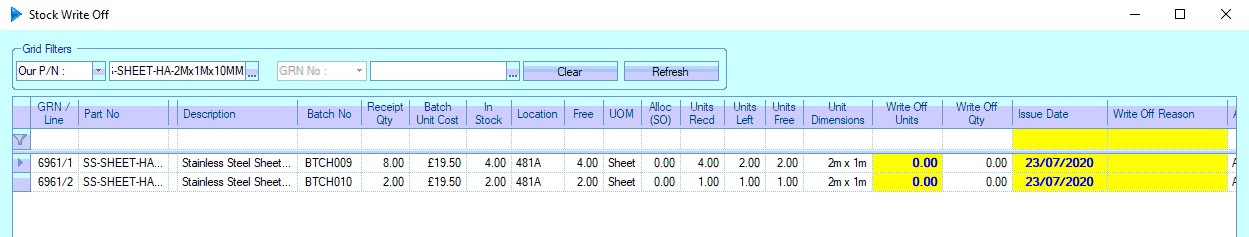

Write Offs

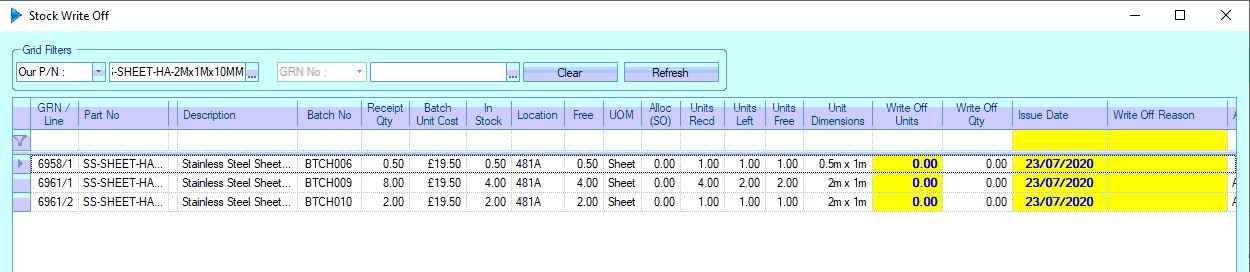

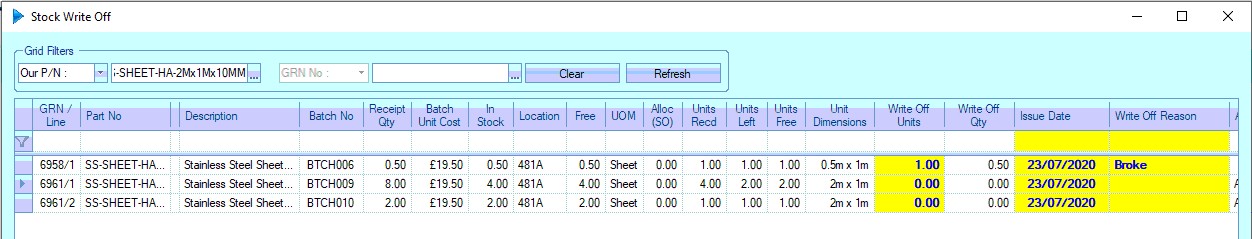

In the event that HAS LENGTH/HAS AREA stock need to be removed from the system, the standard Write Off (Inventory > Issues > Write Off) option is used. This can be used where a batch of stock has been damaged/scrapped or the stock figures need to be adjusted down after a stock take.

All the length/dimension information is displayed against each unit in stock. As already mentioned, all HAS LENGTH/HAS AREA transactions are based on units.

To write off the stock, the user simply has to enter the number of units against each listed batch of material. Options to amend the write off date and a suitable reason are also available.

(HAS AREA example - Before)

(HAS AREA example - After)

All other receipt and issue screens will also include the relevant dimension information when dealing with any HAS AREA or HAS LENGTH part number. As per above examples all transactional quantities will be for a number of "units" and will reflect this when the user has the information displayed.