Phantom Parts – Setup and Functionality

The basic concept of Phantom Parts in Progress Plus is to allow the user to plan a structured BOM as normal, however for certain groups of parts the system will not create a Works Order at the manufacture stage, instead it will roll them up to the next level, therefore flattening the BOM.

This facilitates the use of a “kit of parts” which can then be used on multiple products but then flattened into the next level, hence reducing the number of Works Orders Required.

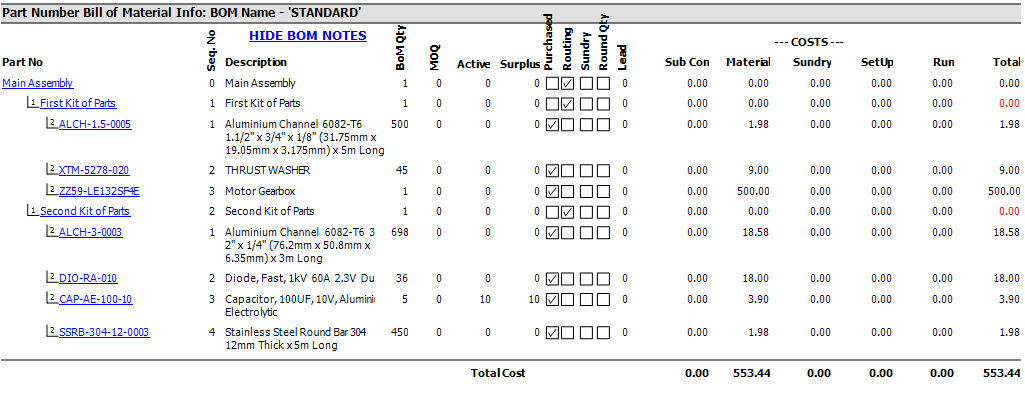

From a planning cost perspective the cost of the parts will be rolled up as normal and for actual cost everything will be attributed to the higher level Works Order.

To use Phantom Parts the user should contact Berkeley Myles support line 0141 440 1987 to request it be activated.

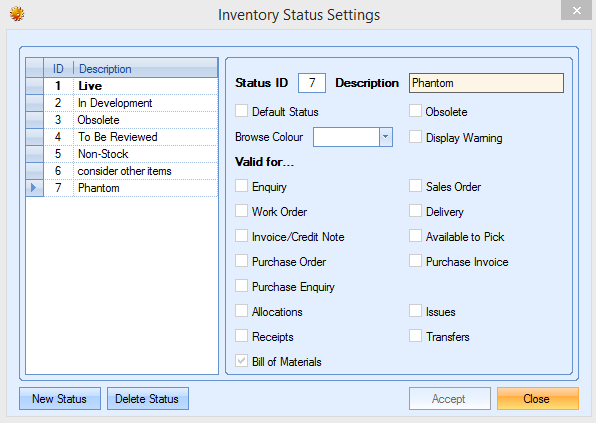

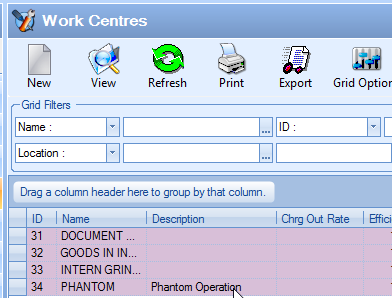

Phantom Specific Status and Work Centre

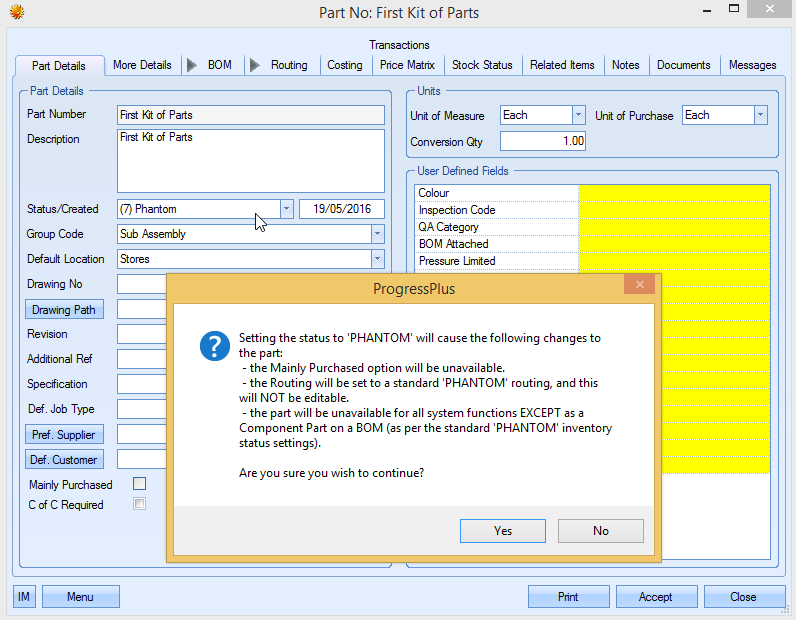

When the function is activated the system will automatically create an inventory status “Phantom” with predefined options selected that cannot be changed. Only the Browse colour can be changed.

The first time a part status is changed to PHANTOM, a specific Work Centre “PHANTOM” will be created that is fixed and not amendable.

Phantom Functionality

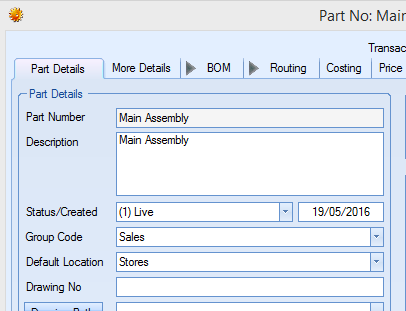

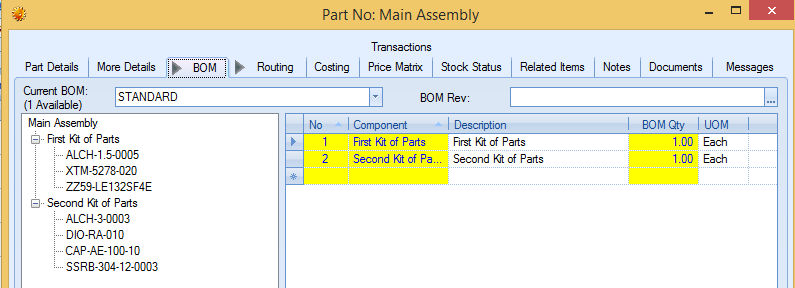

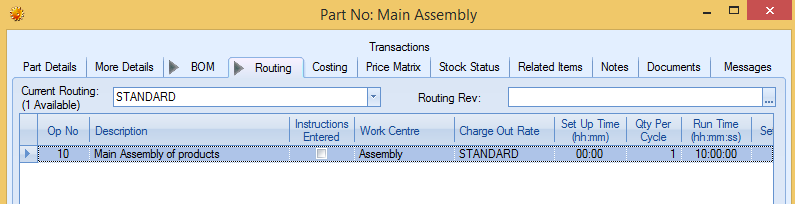

The following part, “Main Assembly” is setup as normal with a BOM and Routing

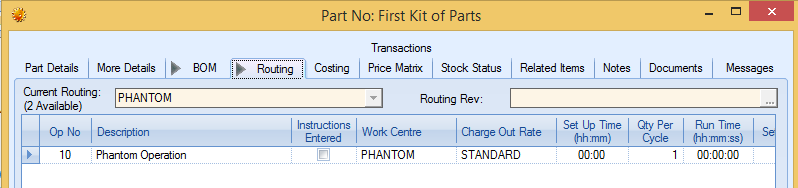

However “First Kit of Parts” and “Second Kit of Parts” have been categorised as “Phantom” parts by changing the Part Status, which will generate a message and create a routing as shown below.

Creating Works Order(s)

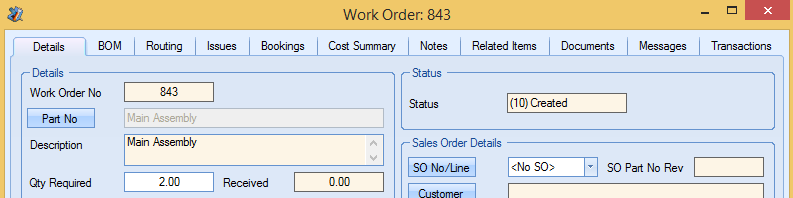

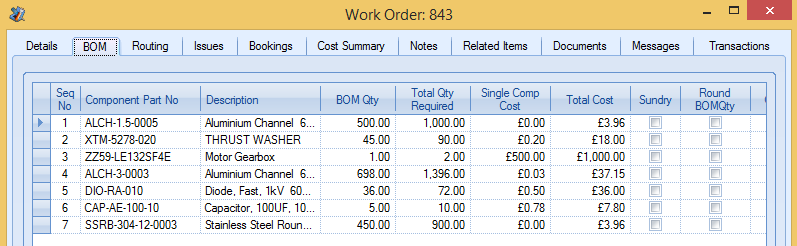

In this simple example, a Works Order is created from the “Main Assembly” part number and with the 2 Kit Of Parts being marked as Phantom parts, there is no prompt to create lower level WOs, instead the system amalgamates all of the BOM items from both into the same BOM. The user would continue to buy materials and issue to this works order as normal.

This principle applies when a WO is created for the “Main Assembly from the Sales Order Line Requirement screen or by creating a New WO from the Works Order browse screen.

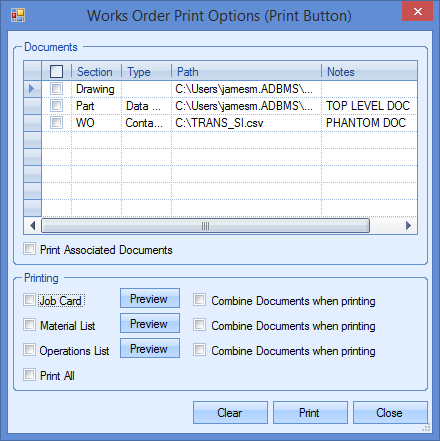

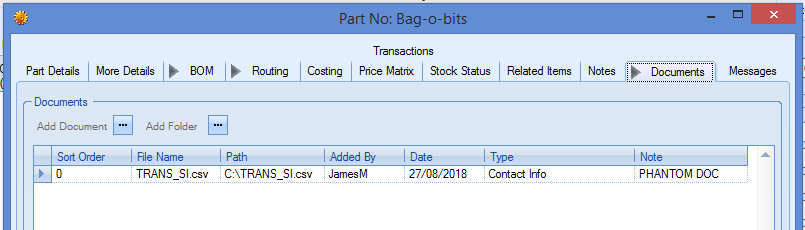

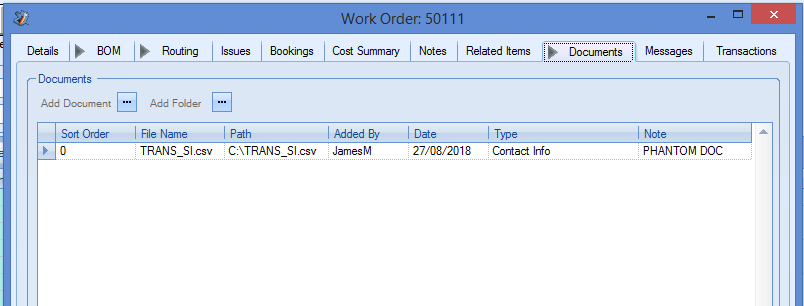

In addition to the rolling up of the component items to the parent work order, any associated documents attached to the phantom part are also pushed up to the work order. This allows the documents to be viewed and printed from the work order, as shown in the example below.

Phantom part showing attached document

New WO showing phantom part document

The document is also available in the PRINT option under the associated documents section as shown below.