This section allows the creation and maintenance of the inventory parts in Progress Plus.

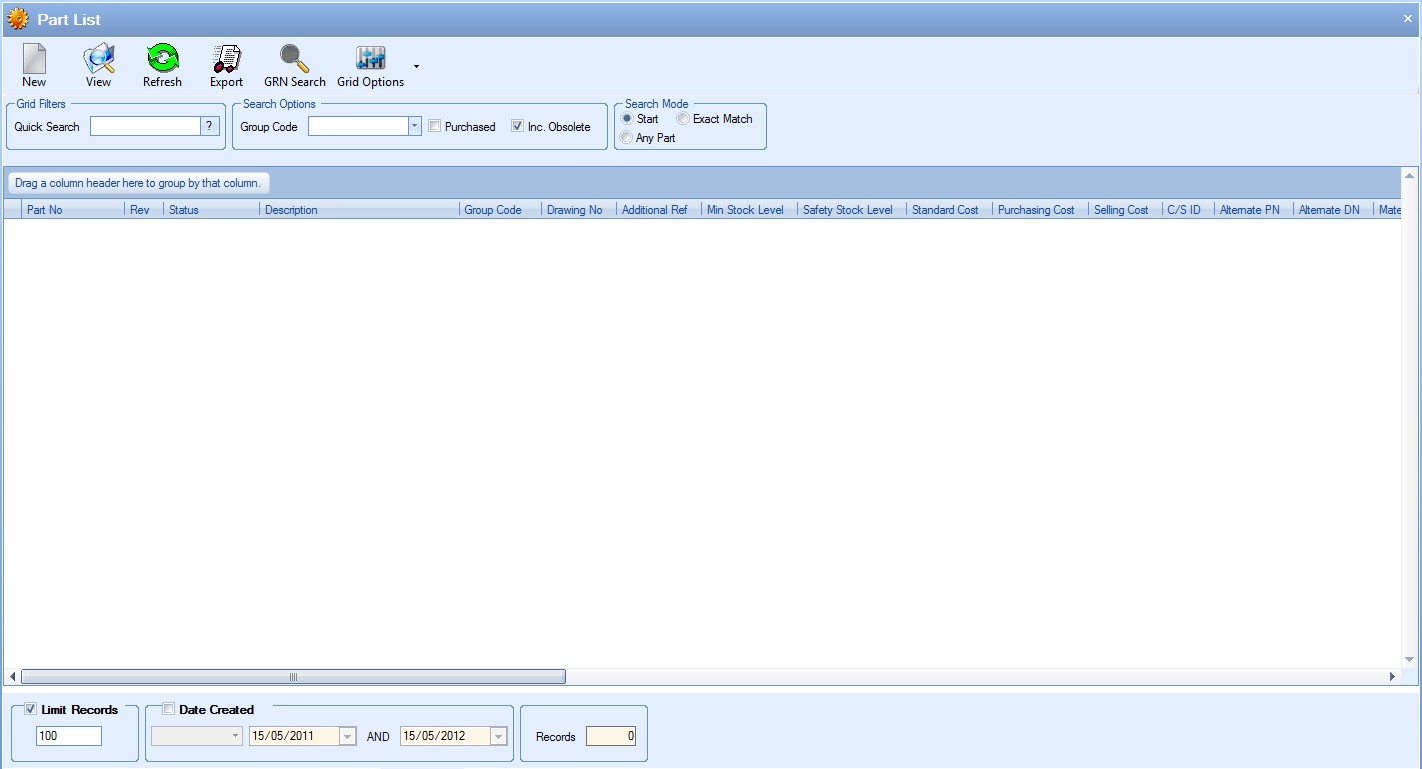

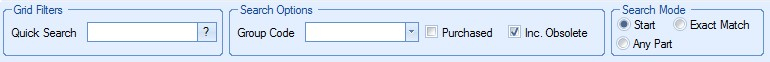

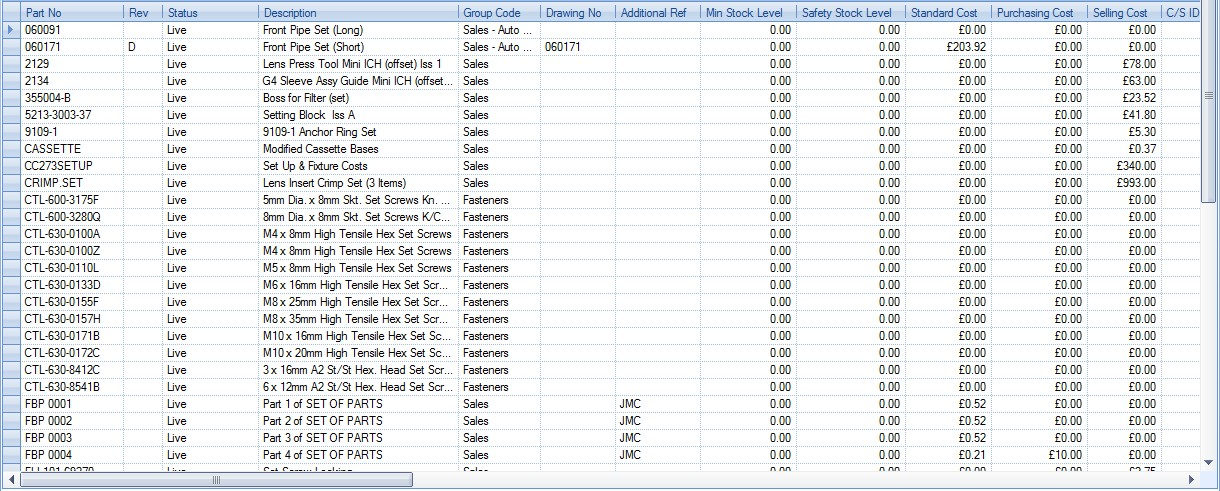

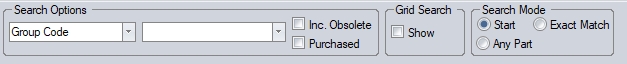

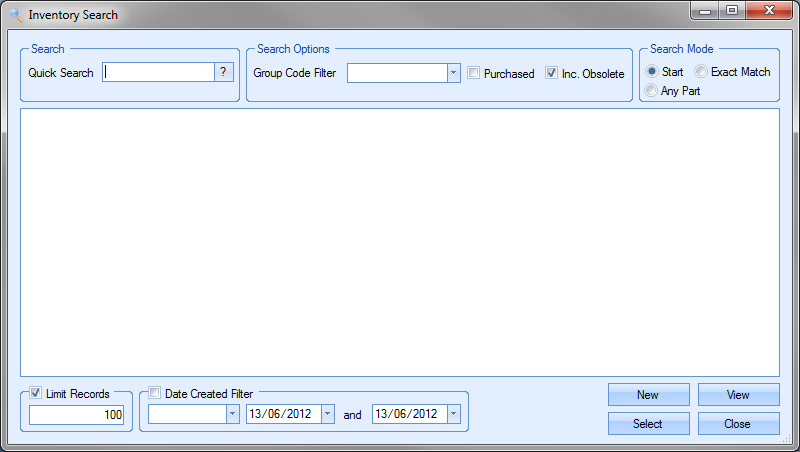

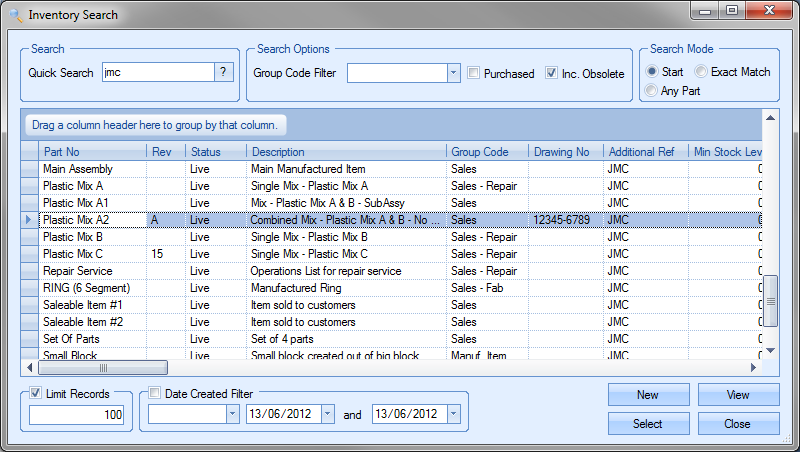

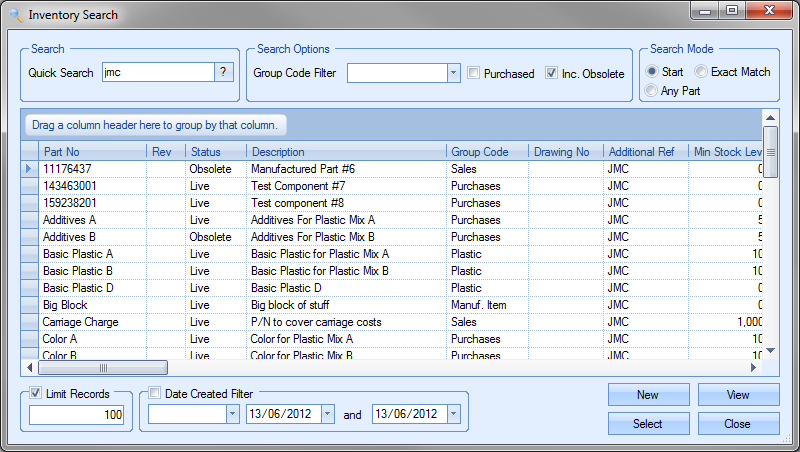

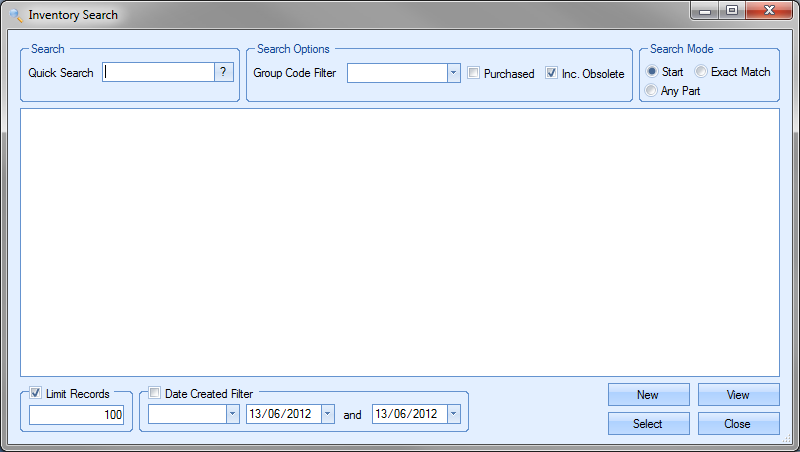

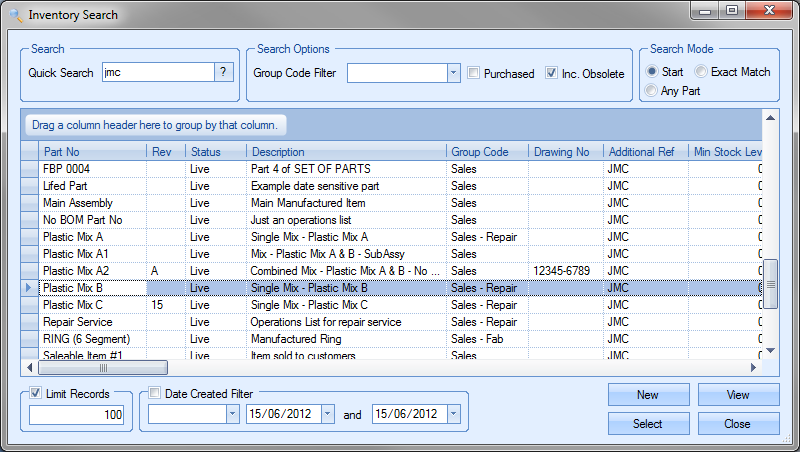

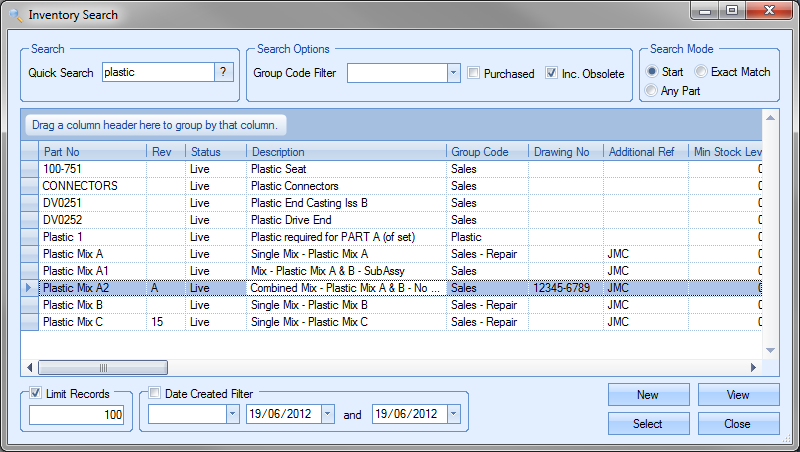

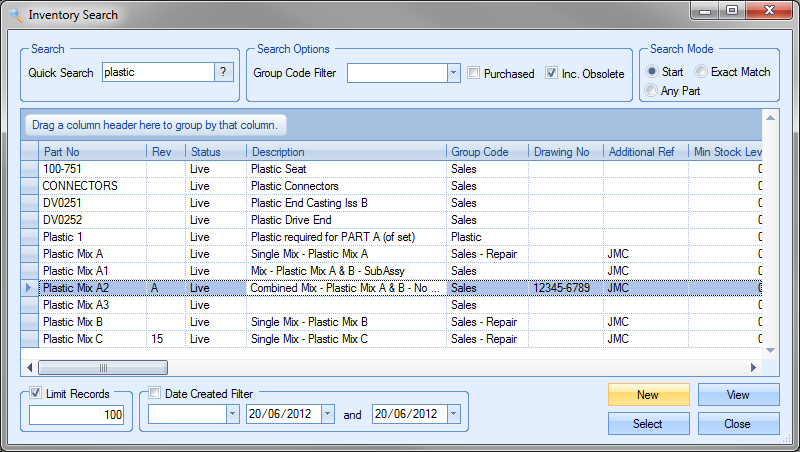

The filters at the top of the screen allow the user to search and display all parts based on the search criteria entered.

The Quick Search option allows the user to enter a piece of text to search for. This can be a specific part number, part of a part number or description, drawing number, etc. Progress will search for all instances of this text based on the Search Mode selected and present a list of all parts which meet the search criteria.

There are three Search Modes available:

| START | This will display all parts where the search text is at the start of a field text. |

| EXACT MATCH | This will display all parts where a field text matches exactly the search text entered. |

| ANY PART | This will display all parts where the field text contains the search text at any point. |

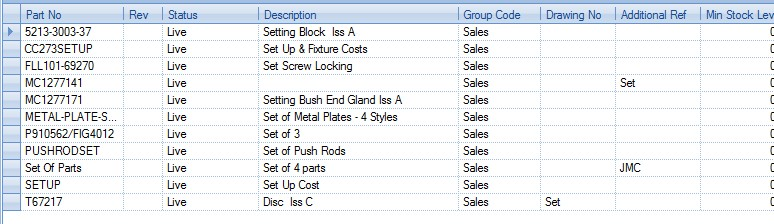

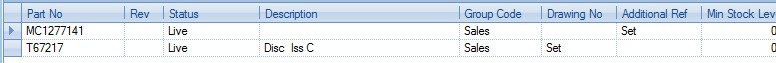

(Example #1: Searching for “set” with a Search Mode of “START”)

(Example #2: Searching for “set” with a Search Mode of “EXACT MATCH”)

(Example #3: Searching for “set” with a Search Mode of “ANY PART”)

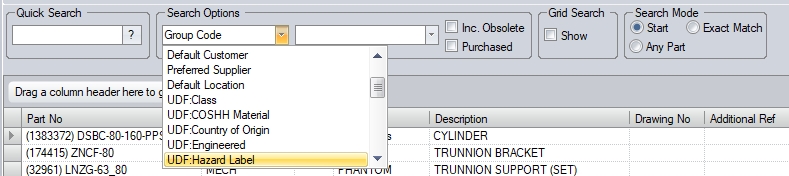

The user also has option to filter the parts list by specific fields, including user defined fields, and also options for including obsolete parts, or for restricting the search to only purchased parts.

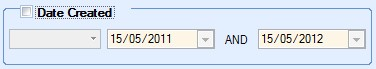

In addition to the filter options above, the user can also filter the parts list by the creation date of the part itself using the date filter at the bottom of the screen.

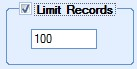

The user can also set the maximum number of part records to be displayed on the grid using the LIMIT RECORDS option.

The default value of this option is set in the system options and is useful when large amounts of data are held in Progress as this limits the amount of data being displayed. The limit can be removed by the user if necessary by simply unticking the option, or they can simply increase the limit quantity to a more suitable value. The number of parts shown in the grid is also summarised at the bottom of the screen. This gives a total count of the parts shown.

If any filters have been specified, the user can click the REFRESH option at the top of the screen or the user can click on the ![]() option at the end of the Quick Search field to update the part list based on the filters chosen.

option at the end of the Quick Search field to update the part list based on the filters chosen.

View

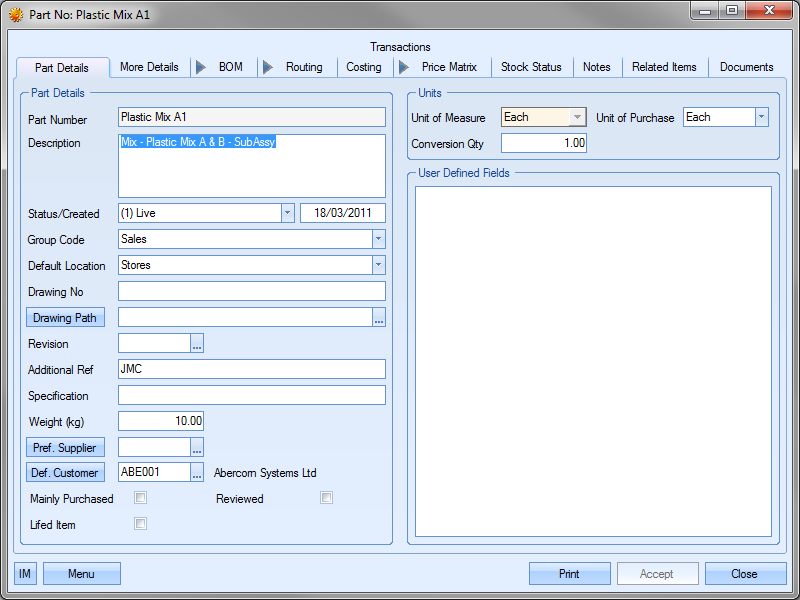

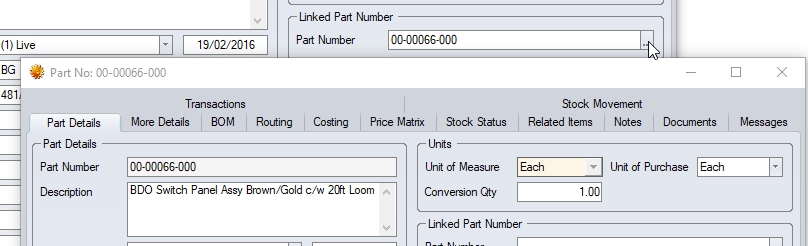

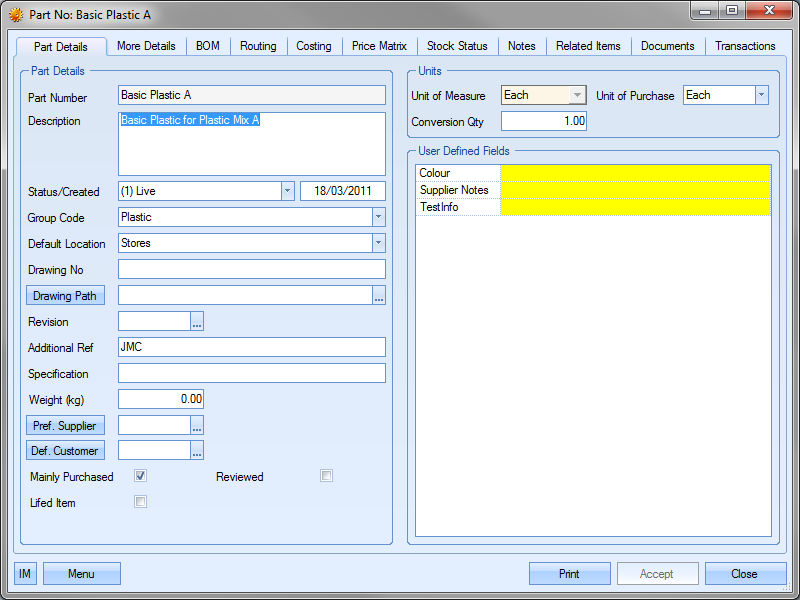

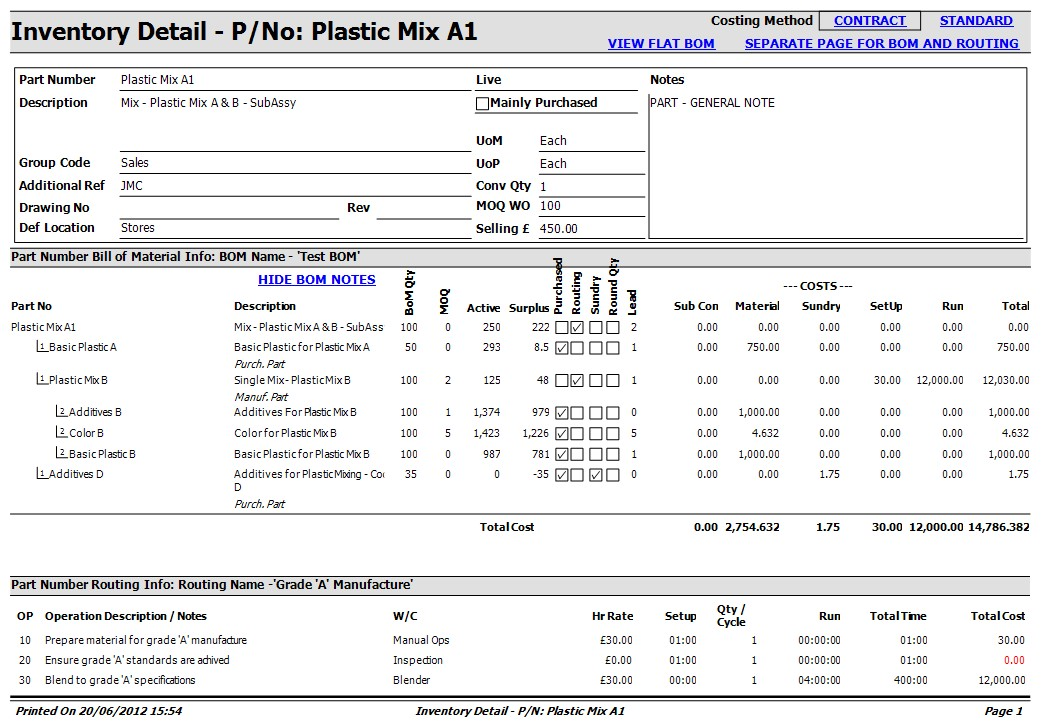

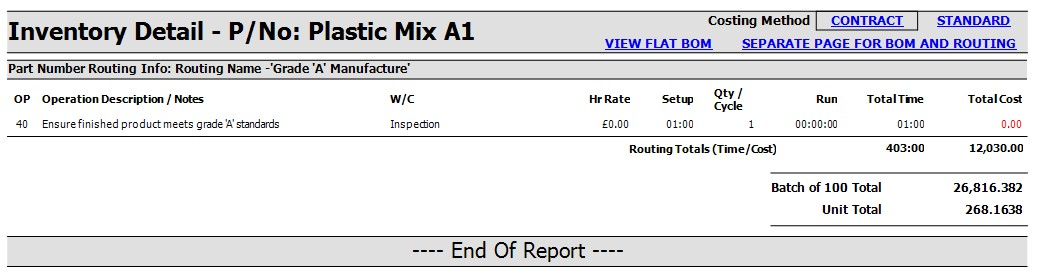

The user can view the details of any selected part record by highlighting the part required in the grid and clicking the View option above. Alternatively, the user can view the details of a part record by double-clicking on the required part directly on the grid. Either method will present the user with the following screen.

The user can now view or amend the details of the selected part as required. Clicking ACCEPT will save any changes made.

NOTE: The Part Number and the Unit of Measure (UoM) fields cannot be changed once the part has been created. If either of these fields has been entered incorrectly, the user must change the part status to an "obsolete" status and create a new part number.

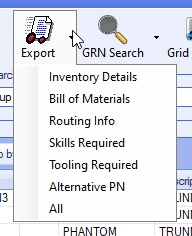

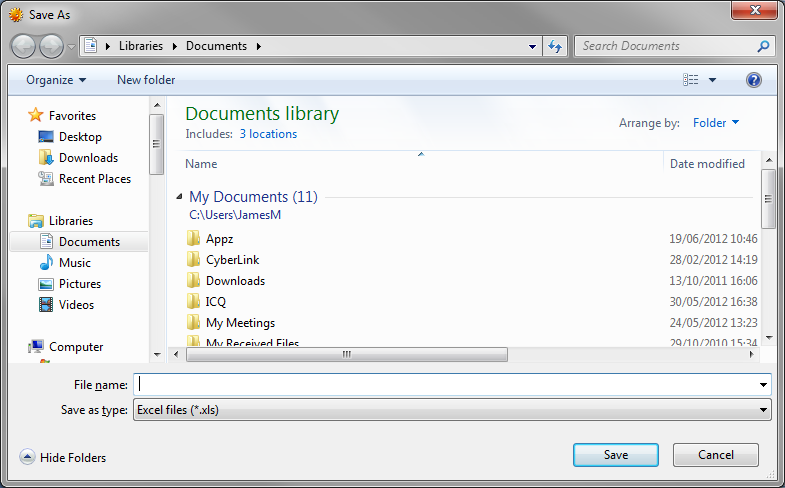

Export

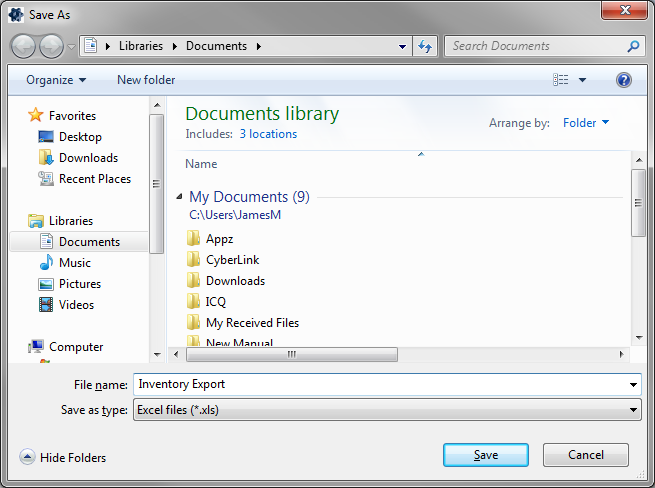

This option allows the user to export out the details of the parts listed on the grid to a spreadsheet. The export spreadsheet can contain one (individual options) or more elements of the selected parts.

If the user selects the ALL option, the spreadsheet generated will contain the part details as well as all other information associated with the parts. Selecting any other option will generate a spreadsheet with just the selected details of the parts.

The contents of the spreadsheet is based on the list of parts currently displayed on the Parts List screen. The user can use the filter option on the Parts List screen to identify the parts they are interested in and then choose the required Export option.

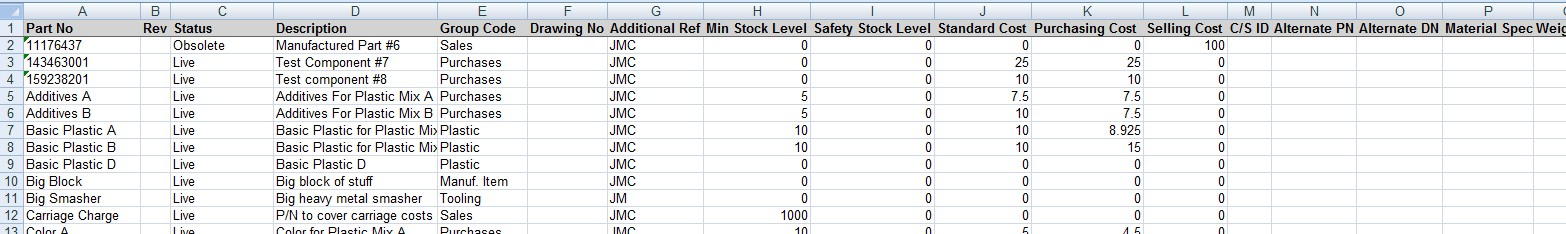

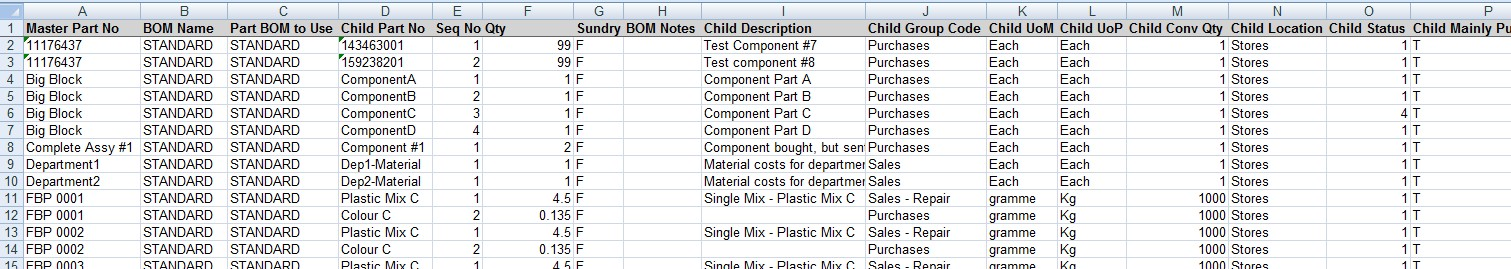

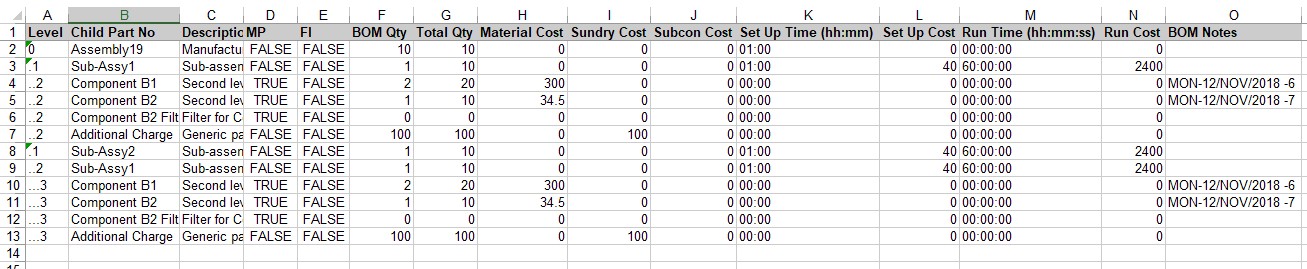

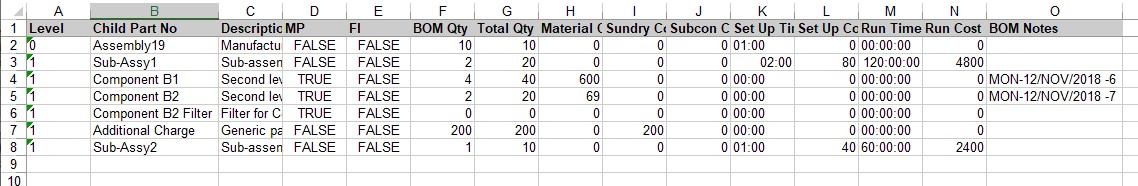

Once the spreadsheet is generated, it will open in Excel. The spreadsheet contains the sheet(s) of information, each labelled according to the information they contain.

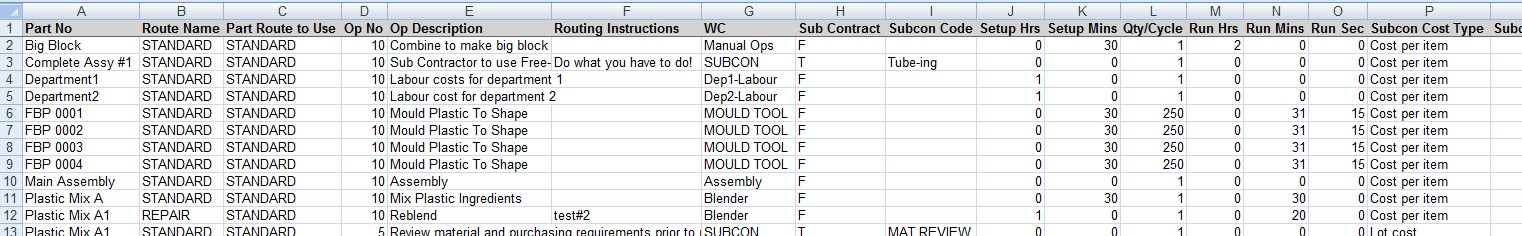

(Example INVENTORY DETAILS sheet)

(Example BILL OF MATERIALS sheet)

(Example ROUTING INFO sheet)

NOTE: The spreadsheet produced is generated using the templates required for the import processes associated with inventory parts, BOMs and routings. These sheets contain all the columns, column names and specific sheet names required for the Import process of inventory parts and the BOM or routing information associated with these parts. Any changes to the templates WILL result in issues when trying to import information to Progress using the modified sheets.

For more information on importing part information into Progress, please refer to the Tools section of this manual.

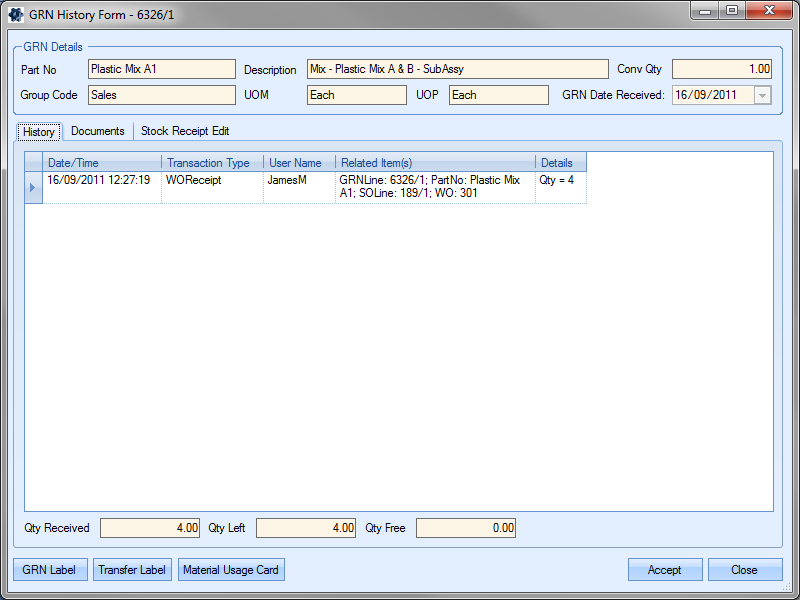

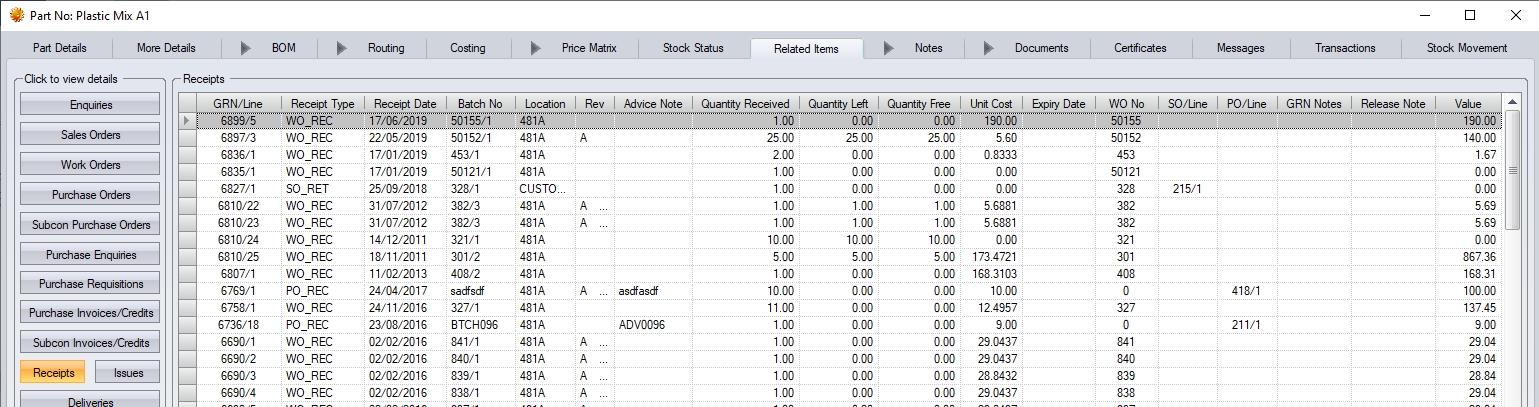

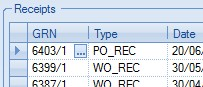

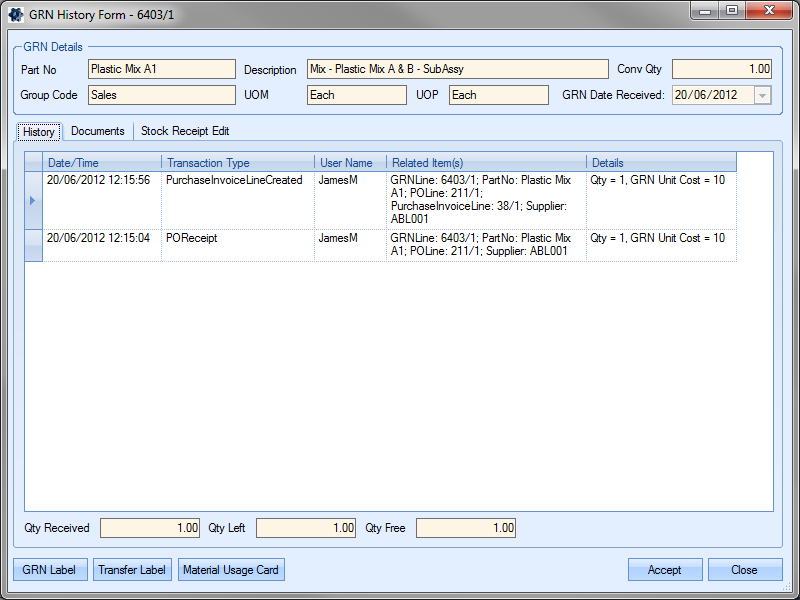

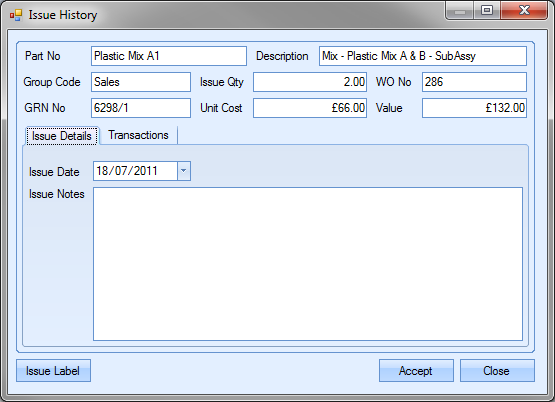

GRN Search

This option allows the user to search for specific receipts or issues, as well as edit these records if required. For more information on these options, please refer to the GRNs (Receipts and Issues) section of the manual.

Parts - Creating New

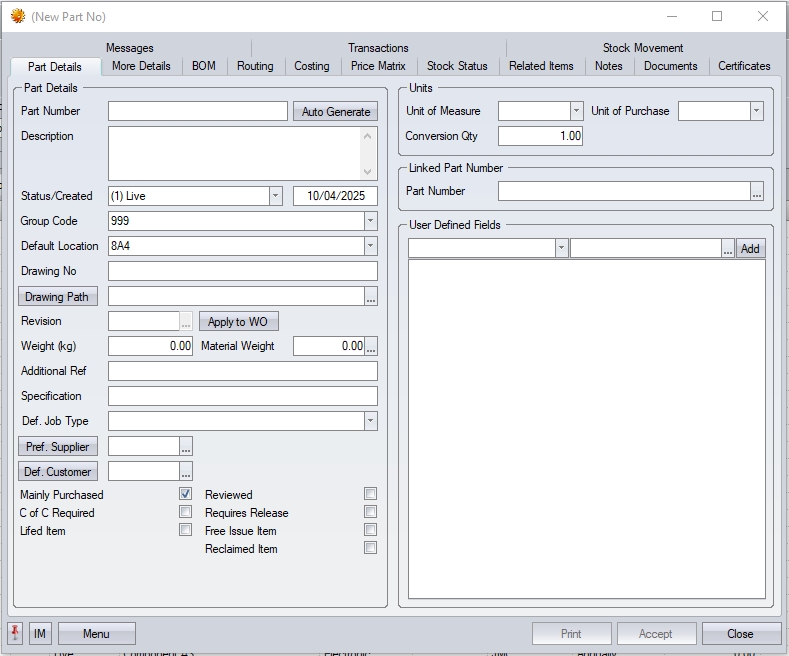

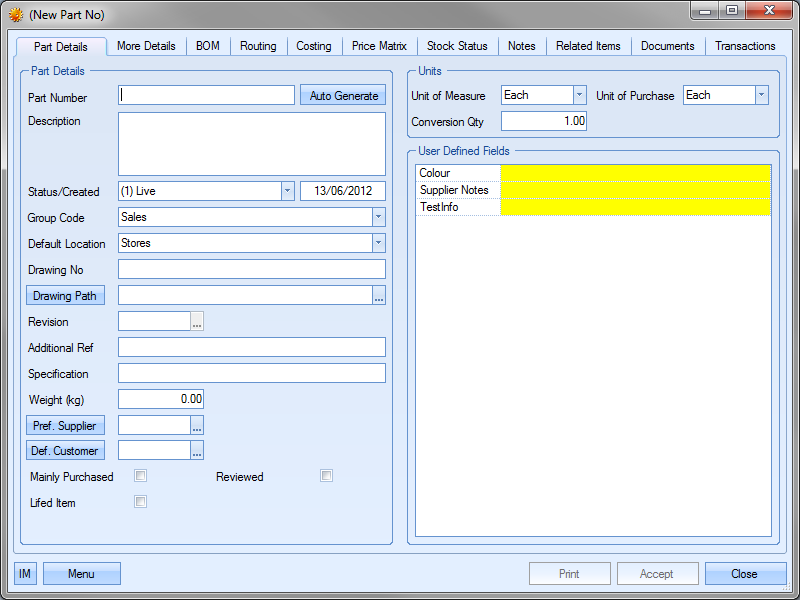

The NEW option allows the user to create new parts in Progress. Clicking this option will present the user with the New Part No screen.

Part Details

This section of the inventory record contains the main information about a part.

| Part Number | This is the unique identifier of the part. Every part that is manufactured or bought requires a part number. The user can enter a specific part number, choose for the system to auto generate a part number using the AUTO GENERATE option or use a combination of them both. |

![]()

Example 1 – Manual part number

Once the user clicks the ACCEPT option, and assuming the part number has not already been used, the part is created with the exact part number entered by the user.

![]()

Example 2 – Auto generated part number

Once the user clicks ACCEPT option to record the part details, Progress will allocate the next available numerical number as set in the system numbers as the part number. In this example, 2.

![]()

Subsequent auto generated numbers will continue this sequence.

![]()

Example 3 – Combination of both options above

The user can enter any prefix text they wish to use as well as click the AUTO GENERATE option. Once the user clicks the ACCEPT option to record the part details, Progress will add the next available four-digit number to the end of the part number entered.

![]()

| Description | This is the full text description of the part up to a maximum of 255 characters. |

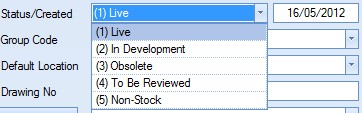

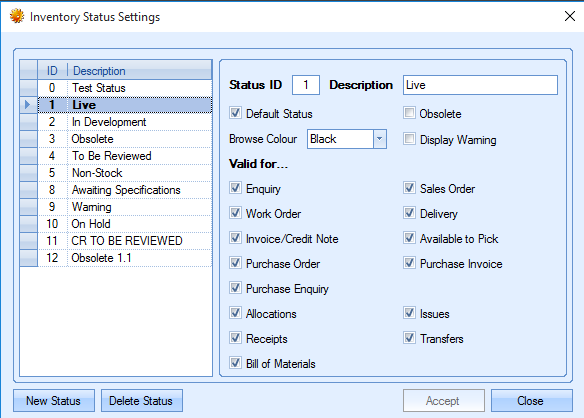

| Status/Created | This is the status of the part. This field will default to whatever status has been assigned as the default in the Maintenance > Inventory Status list. The user can change the status of the part by selecting from the drop-down list. |

This drop-down list can be populated from the Maintenance section of Progress in the Inventory Status list as shown in the screen below.

More information on this screen can be found in the Maintenance > Inventory Status section of this manual.

The date field shown next to the part status field is the date the part was created. This defaults to the current date and cannot be changed.

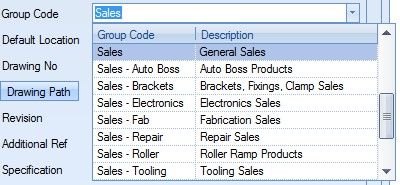

| Group Code | This field allows the user to specify a group code for the part. All parts MUST have a group code specified. The user can select the required group code from the drop-down list. |

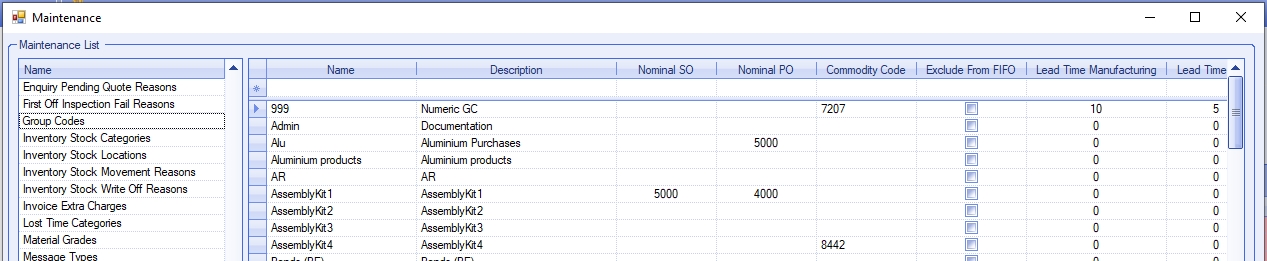

This drop-down list can be populated from the List Maintenance section of Progress in the Group Codes list as shown in the screen below.

For more information on maintaining lists and the List Maintenance section of Progress, please refer to the List Maintenance section of this manual.

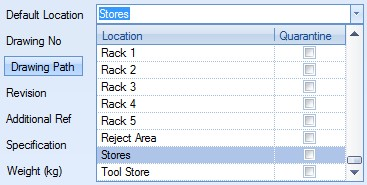

| Default Location | This field allows the user to set the default stock location to be used for this part. The user can select a stock location from the drop-down list. |

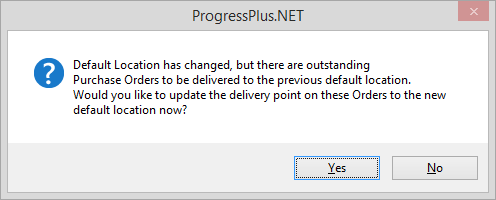

This will be the default location whenever the part number is being receipted on a purchase order or on a work order. If the user changes the default location against a part, the system will prompt the user to update the location recorded against any outstanding purchase order lines for the selected part (the default location is recorded against PO lines when initially created).

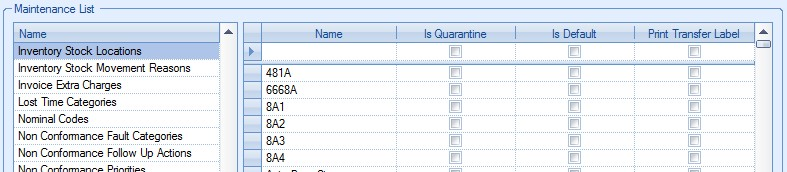

The drop-down list of locations is populated from the List Maintenance section of Progress in the Inventory Stock Locations list as shown in the screen below.

For more information on maintaining lists and the List Maintenance section of Progress, please refer to the List Maintenance section of this manual.

| Drawing Number | This field allows the user to record a drawing number for the part if applicable. |

![]()

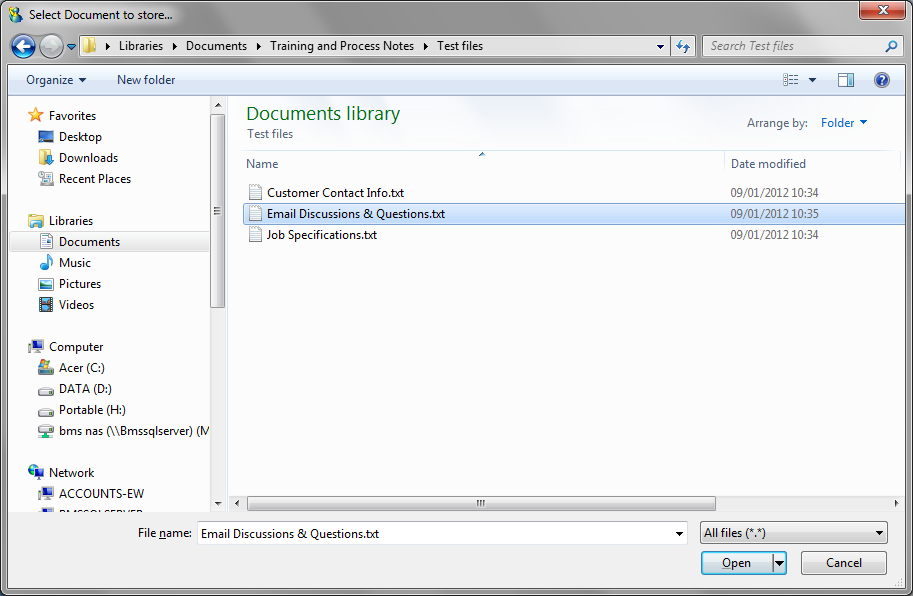

| Drawing Path | This field allows the user to link the part directly to the drawing document or file specified above. This can even be an online web address. |

![]()

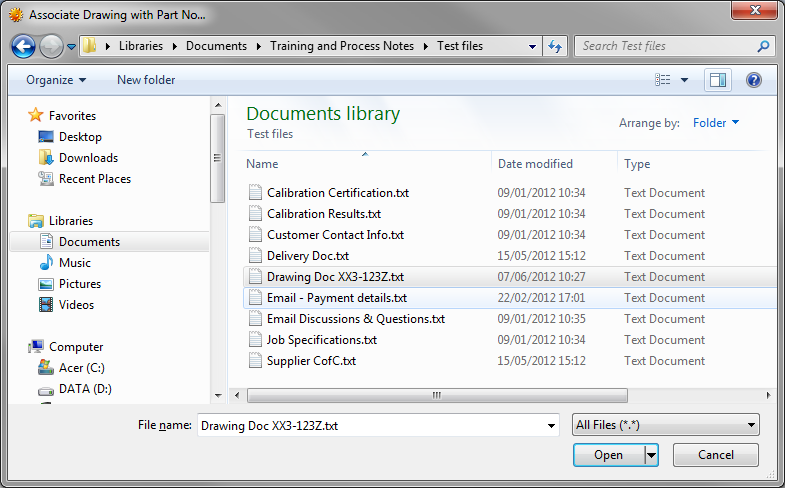

The user can select the required document by clicking on the ![]() option at the end of the field. This will present the user with the following screen which they can use to locate and select the file.

option at the end of the field. This will present the user with the following screen which they can use to locate and select the file.

Once the file has been selected, the file path is recorded in the field.

![]()

| If the user wishes to record a web address, they can simply paste the URL into the DRAWING PATH field. |

The DRAWING PATH button at the start of this field allows the user to open the specified file/URL directly from the part record, assuming they have an application suitable for viewing the specified file type.

| Revision | This field allows the user to specify the part revision. |

![]()

When a part is initially being set up, the user can specify a revision number or character if this is required.

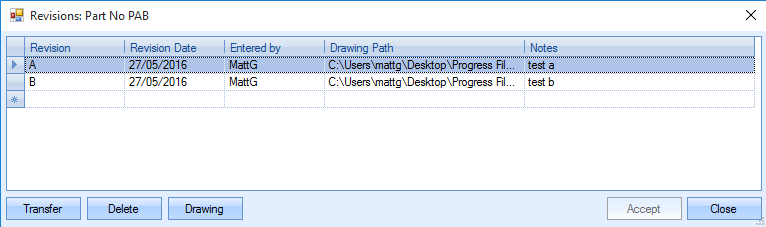

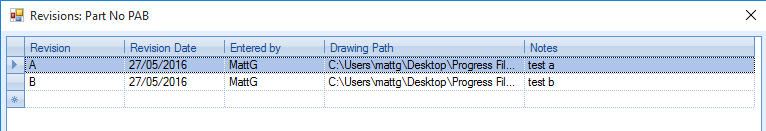

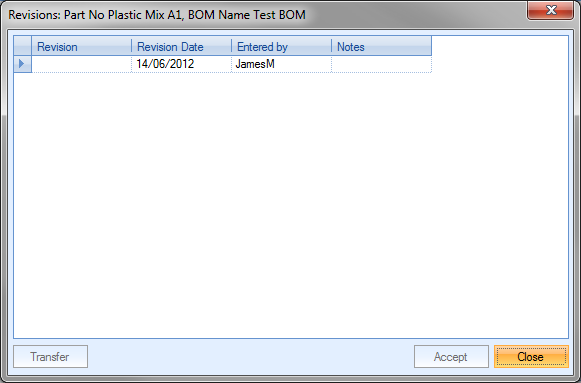

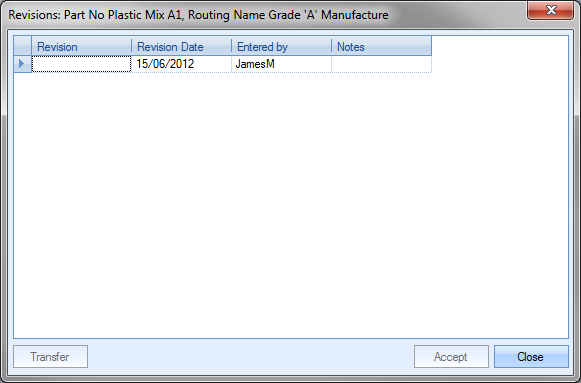

Once a part has been created, the user has the ability to increase the part’s revision, as well as record the date of the change and who done it. Users can add additional revisions and see the revision history by clicking on the ![]() option at the end of the field. This presents the user with the following screen.

option at the end of the field. This presents the user with the following screen.

The user can add additional revisions by completing the blank line available at the bottom of any listed revisions. The Revision Date and Entered By information will default to the current date and user ID. The drawing path can be selected for that specific revision by using the ![]() button in the Drawing Path column. Once the details have been entered, the user can save the changes by clicking on the ACCEPT option.

button in the Drawing Path column. Once the details have been entered, the user can save the changes by clicking on the ACCEPT option.

To select a revision the user must highlight the required revision and click on the TRANSFER option to return the selected revision to the part record. This will update the revision to the selected revision and change the drawing path accordingly.

![]()

The user can also delete a revision by highlighting the line and selecting the Delete button.

The Drawing button will open the drawing of the revision highlighted, providing there is a suitable drawing path for that revision.

| Additional Ref | This field allows the user to add an alternative reference for the part being created. |

![]()

| Specification | This field allows the user to enter specification details for the part being created. |

![]()

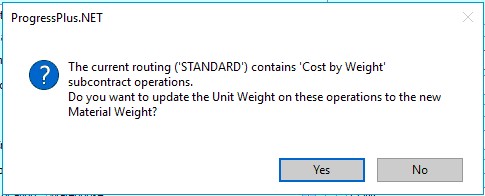

| Weight (kg) | This field allows the user to record a weight against the part. This is used typically for INTRASTAT purposes and commercial invoices, but can be included on delivery documents if required. If the part is an assembly and has subcontract operations on its routing that are priced based on weight, the system will default the part's weight onto the subcontract operations. If the user updates the part weight value, and the part has subcontract operations on its routing that are priced by weight, the system will prompt the user to ask whether they want the subcontract operation weight values to be updated. |

Clicking YES will update the weight values on all relevant subcontract operations.

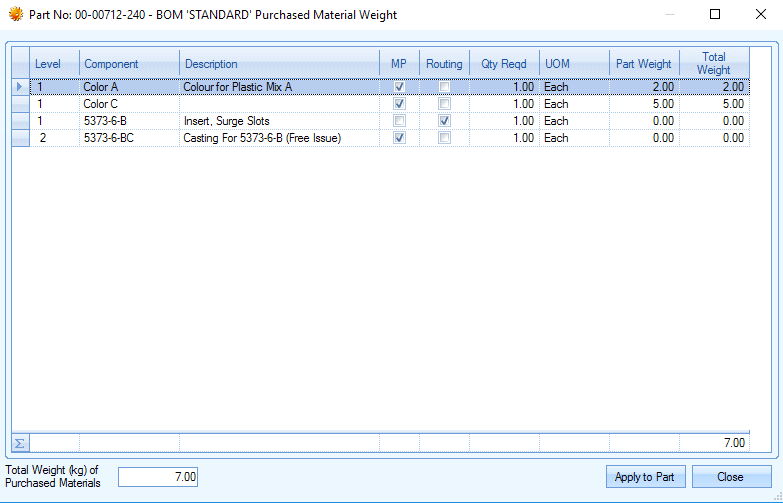

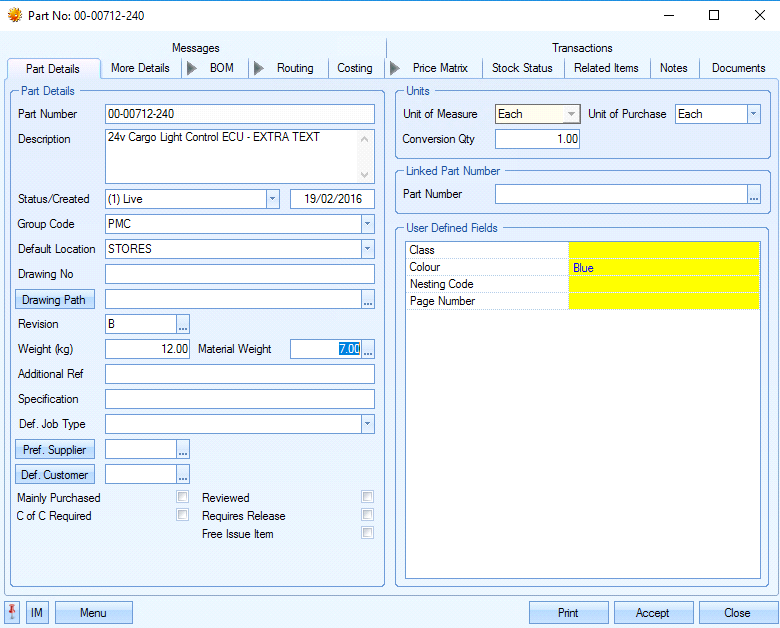

| Material Weight | This field allows the user to record the total material weight of the part. This can be manually entered or, if an assembly part, be calculated based on its BOM components' weights. |

![]()

This can be done by clicking on the three dots against the field which will present the user with the following screen.

| This screen will allow the user to view the component parts on the BOM of the top level part. If there is a weight in the Part Weight field, the system will add these weights together and total them in the bottom left and right of the screen. |

| The use can simply click the APPLY TO PART button and the system will roll up the individual part weight's and shows these as a total weight figure against the top-level part. |

![]()

| This will now display the MATERIAL WEIGHT of the BOM items on the part record as shown below. |

(Updated Top-Level Part)

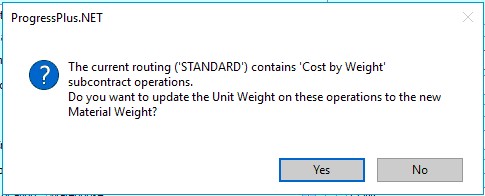

| If the part has subcontract operations on its routing that are priced by weight, changes to this field will ask the user whether they wish to update the subcontract operations with the new value. |

Clicking YES will update the subcontract operation weights.

| By default, any subcontract operations on the part's routing which are costed based on weight will default the weight value to the PART WEIGHT value, however, if the user would prefer to use the Material Weight value, this can be configured in the system settings. |

![]()

| For more information on this option, please refer to the system options section of this manual. |

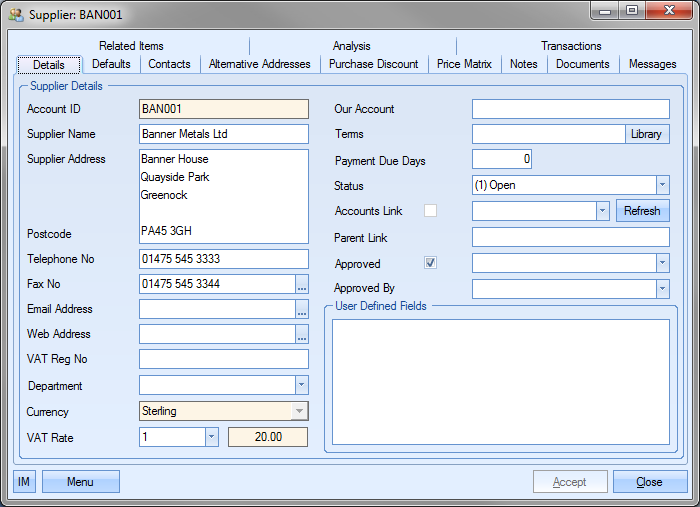

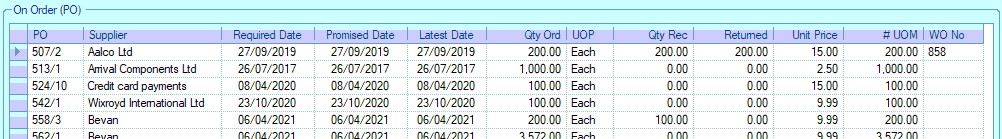

| Pref. Supplier | This field allows the user to choose a preferred supplier for this item from a list of previously entered suppliers. This field is used for entering a supplier against mainly purchased items. Supplier information will default to the preferred supplier specified when the part appears on the PO shortage screen. |

![]()

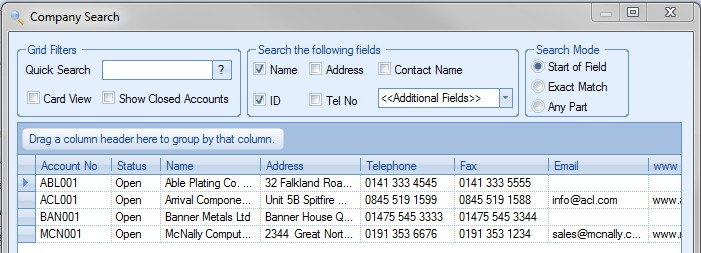

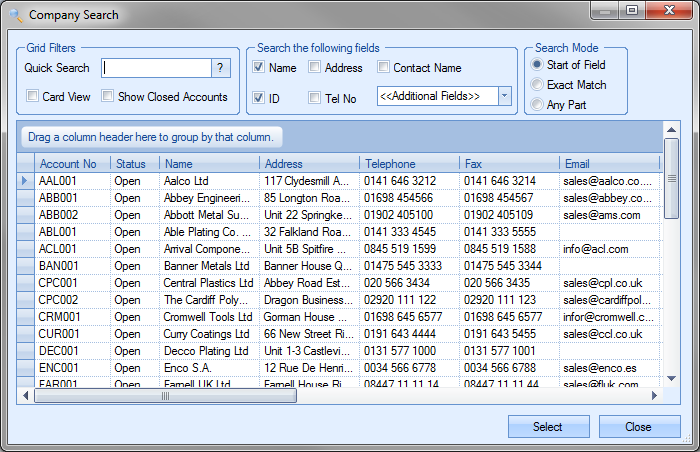

The user can select a preferred supplier by clicking on the ![]() button at the end of the field. This will present the user with the supplier list to choose from. If the APPROVED SUPPLIER filter is in use, the screen will present a list of approved suppliers for the user to select from.

button at the end of the field. This will present the user with the supplier list to choose from. If the APPROVED SUPPLIER filter is in use, the screen will present a list of approved suppliers for the user to select from.

![]()

If the APPROVED SUPPLIER option is not in use, the user will be presented with every supplier currently available in Progress.

![]()

For more information on approved suppliers option, please refer to the Administrator Functions section of this manual.

The user can select the required supplier from the list and click the SELECT option to return to the part record.

![]()

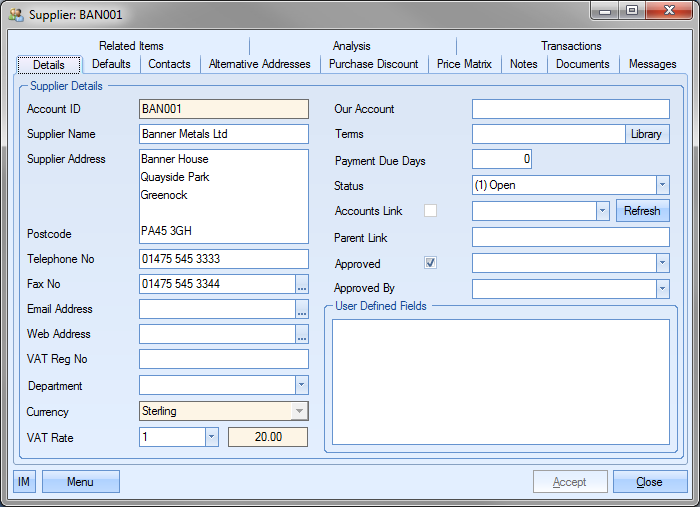

Once a supplier has been selected for a part, the user can view the supplier details directly from the part record by clicking on the PREF SUPPLIER button. This will open the supplier record for the user to view.

The user can view or amend the supplier details if their access allows.

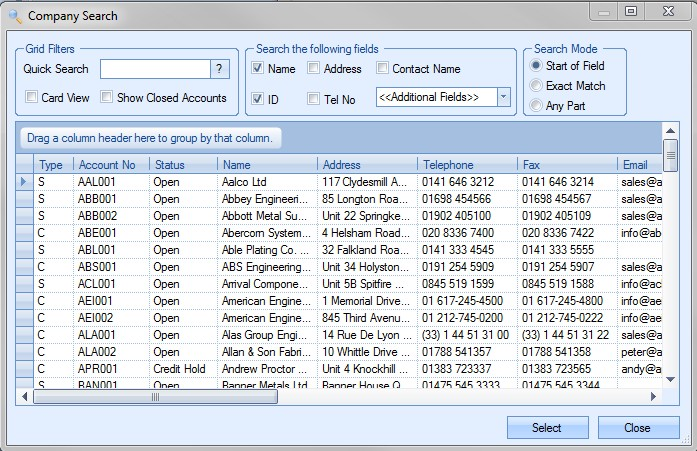

| Def. Customer | This field allows the user to choose a default customer for this item from a list of previously entered customers. Specifying a default customer allows the user to filter some inventory reports to view customer specific parts and can be used for both mainly purchased and manufactured parts. |

![]()

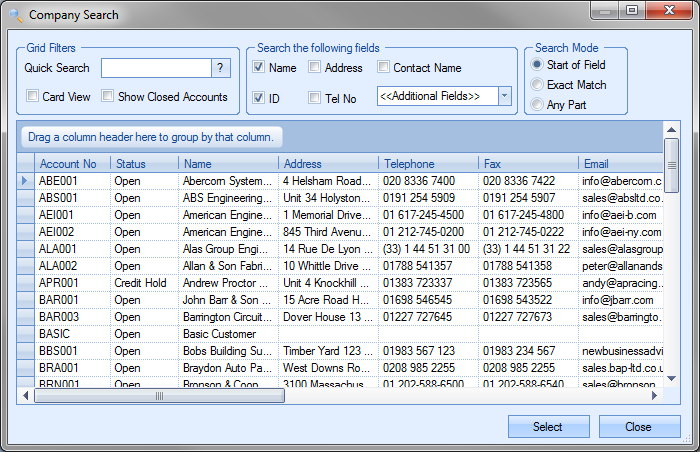

The user can select a customer by clicking on the ![]() button at the end of the field. This will present the user with the customer list to choose from.

button at the end of the field. This will present the user with the customer list to choose from.

The user can select the customer from the list and click the SELECT option to return to the part record.

![]()

Once a customer has been selected for a part, the user can view the customer details directly from the part record by clicking on the DEF CUSTOMER button. This will open the customer record for the user to view.

The user can view or amend the customer details if their access allows.

| Mainly Purchased | This option allows the user to specify whether the part is a purchased part from a supplier or a manufactured item. |

![]()

Sometimes a part will be mainly purchased but if the user has more time he may choose to manufacture the item in-house. If this item is in turn used on the BOM for other parts the system requires to know if the part is Mainly Purchased so it can suggest raising a purchase order for any shortfall or if it is not mainly purchased it will suggest that the user should raise a works order to satisfy requirements. The user may choose however to ignore a purchase order suggested by the system and choose to manufacture the part if desired. If this box is not ticked the system will assume that it is a manufactured item and treat it accordingly.

| Reviewed | This option allows the user to specify whether the part has been reviewed. This is used as a visual indicator only. |

![]()

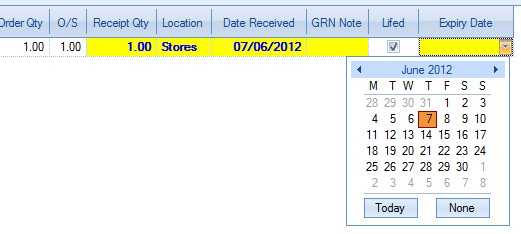

| Lifed | This option allows the user to specify whether the part has a shelf life or expiration date. |

![]()

If the option is ticked receipt of the item, whether it’s via a purchase order or a work order, will expect the user to specify an expiration date as part of the receipt information. This information is recorded against the GRN record.

Inventory with expiration dates can be monitored via the Today > To Do screen using the Parts Due To Expire section. This highlights any inventory where the expiration date falls within the specified number of days. For more information on the To Do screen, please refer to the Today section of this manual. If lifed items are not used within the business, the inventory option can be removed completely by ensuring the following inventory admin option is unticked.

![]()

For more information on the inventory admin options, please refer to the Miscellaneous & Inventory system options section of the manual.

CofC Required This option indicates that the part requires a CofC from a supplier (if purchased), or a CofC should be provided to the customer (if sold).

![]()

| If this option is ticked, the CofC Required option will be ticked on purchase order lines and/or sales order lines when the part is added to either. |

| From a purchasing perspective, this can be used to indicate to a supplier that a CofC is to be provided upon delivery and also to highlight to those receiving the goods that one should be present. |

| From a sales perspective, this can be used to highlight to both sales and despatch departments that a CofC is to be sent with the goods. |

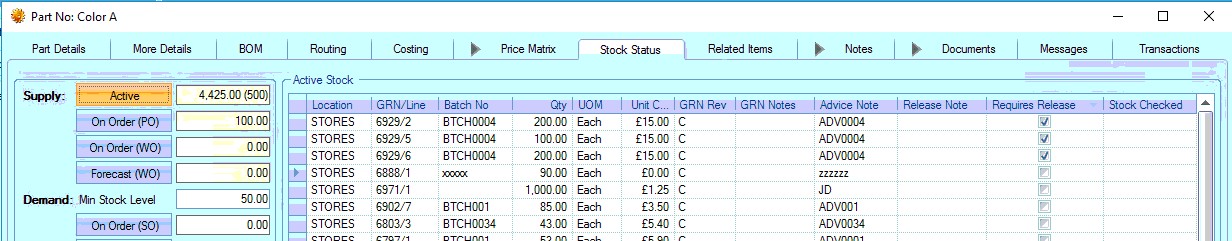

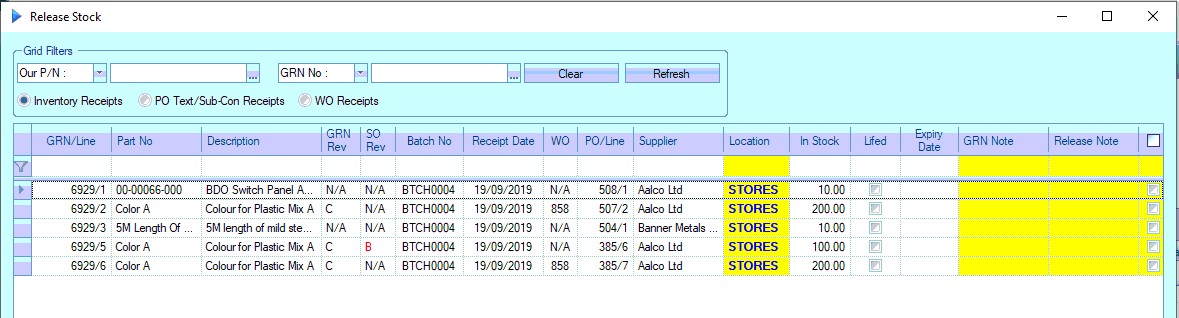

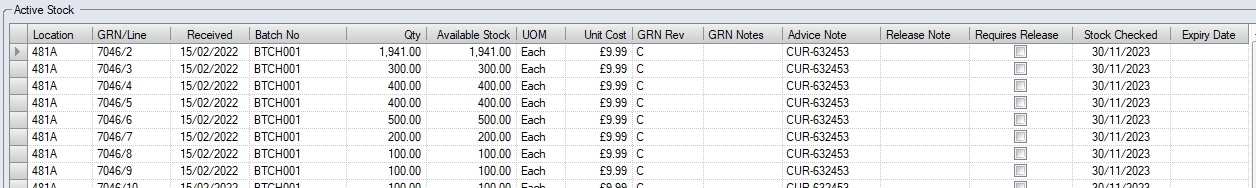

| Requires Release | This option determines whether batches/GRNs of this part are placed on automatic hold when receipted into stock and applies to all receipt types. |

![]()

| Having this option ticked will automatically tick the REQUIRES RELEASE option on all receipt screens for this part. Leaving this unticked will default the REQUIRES RELEASE option on all receipt screens as unticked, however, the user will be able to tick it if that specific batch is to be placed on hold. |

Any batches received into stock and placed on hold will show against the part's ACTIVE stock figure however the "requires release" quantity will show in brackets next to the total. Each batch will also be highlighted as being "requires release" too on the grid to the right.

Any batch that is "on hold" can be released into available stock using the Requires Release screen which can be found in the Inventory section of Progress. Please refer to the section of the manual for this screen for further information.

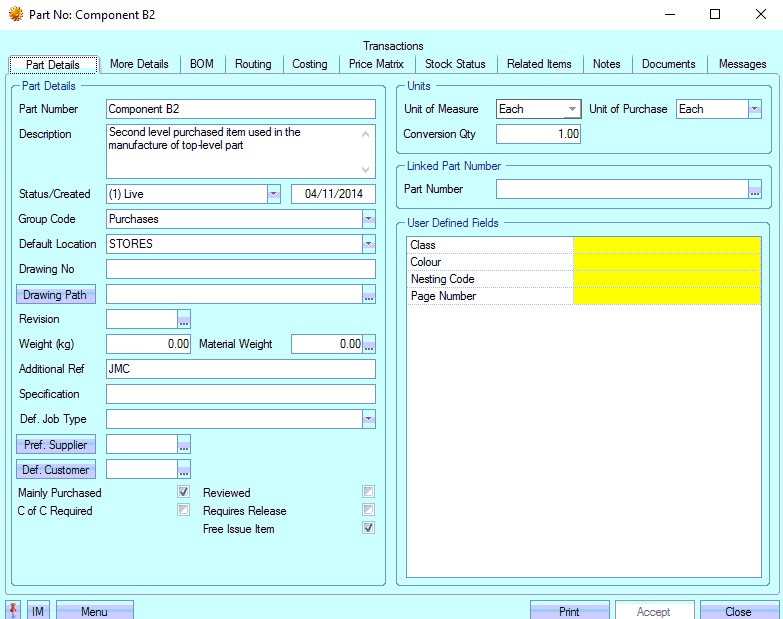

| Free Issue Item | This option allows the part to be marked as a FI (free issue) part. This is used to indicate that a part will be supplied by another party, typically the customer. |

![]()

| This allows the part to be included in BOMs but not generate demand for the purchasing or production departments to action (i.e. no POs or WOs required). It will also remove any associated costs from job costing calculations in the system (i.e. because its not a cost you will incur). For assembly items, this flag will do the same but will result in all costing calculations associated with the part to ignore any labour, subcon or material costs that are set up on its BOM or ROUTING. |

| This FI flag is shown alongside the part throughout the system for the user's reference, appearing on all relevant screens. These include the BOMS, SO Line Requirements, WO Demand, PO Shortage and Below MSL screens with most having an option for FI items to be filtered out. |

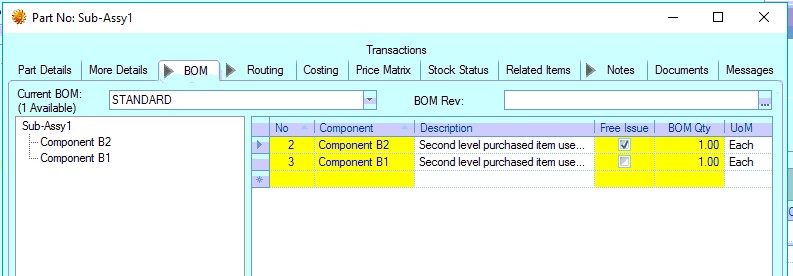

| If the part is added to a BOM for an assembly item, the flag will default against the BOM item based on the master part record. This can be edited on the work orders BOM details if it needs to be different to the default FI setting on the part number. |

(Component FI part)

(Assembly BOM with Component FI Part)

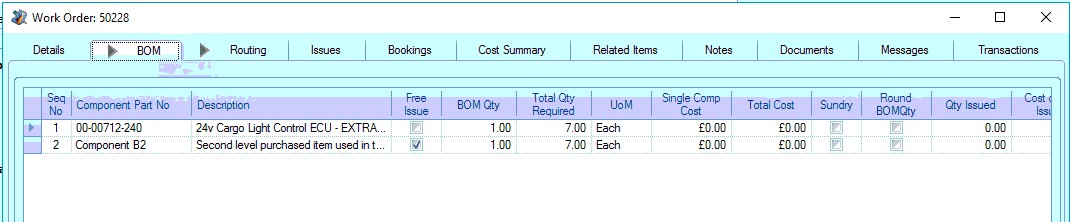

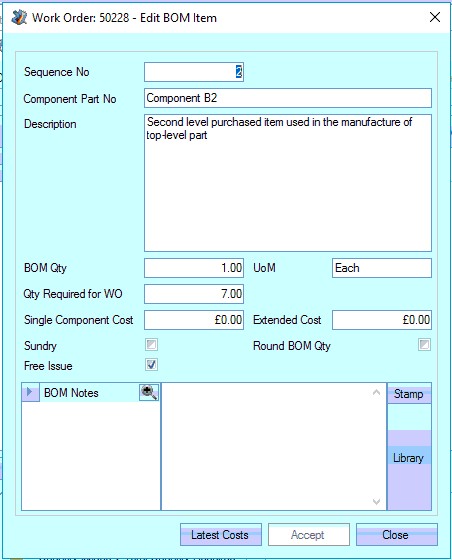

| Similarly, when a WO is raised for an assembly part, the WO BOM items will pull through based on the assembly part's BOM. Any component or sub-assy part on the top-level assemblies BOM will be marked accordingly on the WO BOM. |

(WO BOM for Assembly with FI Component)

| Again this can be changed at the WO level if different from the assembly's default configuration for the specific job. This can be done in the WO BOM item's details. |

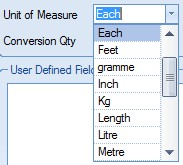

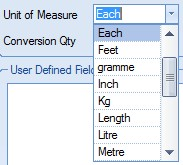

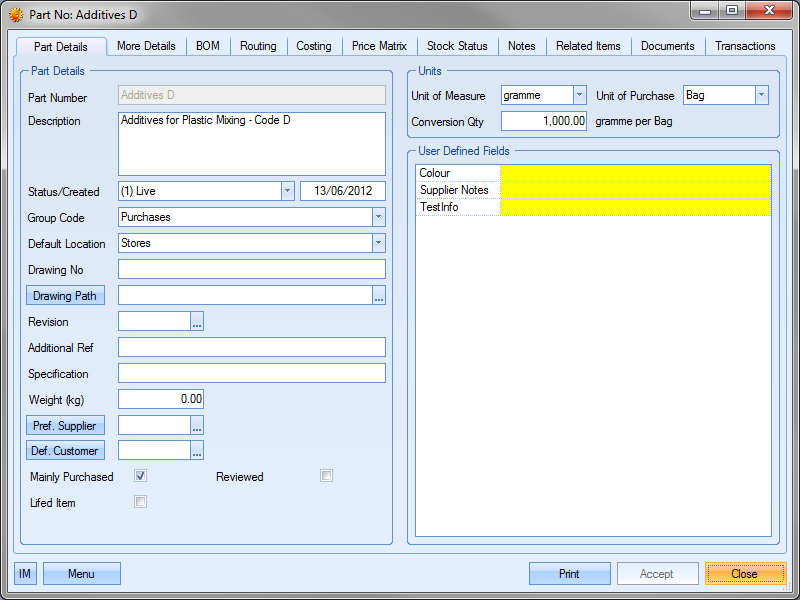

| Unit of Measure | This field allows the user to specify the measurement by which the parts is recorded and used within Progress. The Unit of Measure (UoM) is used when referring to all part quantities within Progress EXCEPT on purchase orders. |

![]()

The user can specify the measurement used for UoM by selecting from the drop-down list.

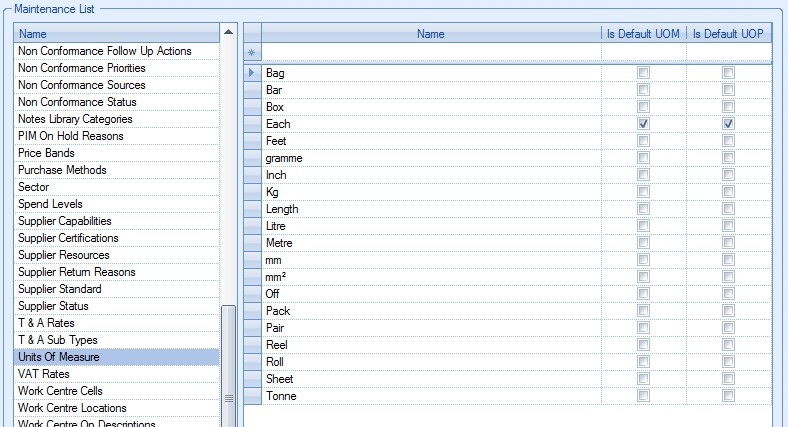

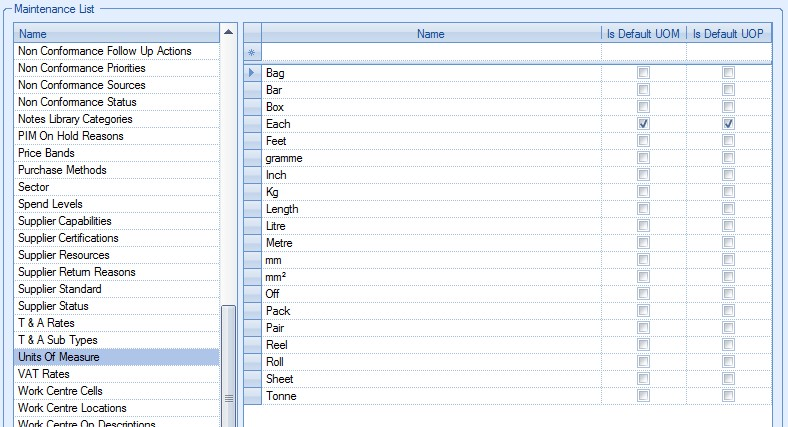

This drop-down list is populated from the List Maintenance section of Progress in the Units of Measure list as shown in the screen below.

For more information on maintaining lists, please refer to the List Maintenance section of this manual.

| Unit of Purchase | This field allows the user to specify the measurement by which the part is purchased from the supplier. The Unit of Purchase (UoP) is used when referring to part order quantities on purchase orders. |

![]()

The user can specify the measurement used for UoP by selecting from the drop-down list.

All items, whether they are purchased or manufactured in-house, will have a UoP. If the user does not enter a UoP, the system will default to “Each”. The drop-down list is populated from the List Maintenance section of Progress in the Units of Measure list as shown in the screen below.

| Conversion Qty | This is the quantity used to convert between the Unit of Purchase (UoP) and the Unit of Measure (UoM) upon purchase order receipt. |

![]()

For example, screws are bought in boxes of 500, but they are used individually in the manufacturing process. Our PO would specify the number of boxes we want to buy but, upon purchase order receipt, we want to see the quantity in stock as the number of screws, so our Conversion Qty would be set to 500. Therefore, for every box received from the supplier on a purchase order, we would see 500 screws in inventory.

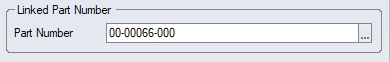

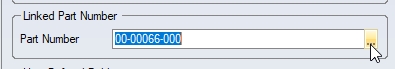

| Linked Part Number | This field allows the user to link the part number to another part number. This can be useful if the new part is a replacement part for an existing one, and provides quick access to its previous incantation for historical reference. |

| If a part is linked, clicking the box at the end will open the linked part number for the user to see. |

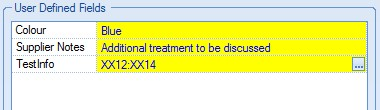

| User Defined Fields | If any user defined fields have been configured for the parts records, they will be listed in the section shown below. |

For more information on user defined fields, please refer to the Maintenance section of the manual.

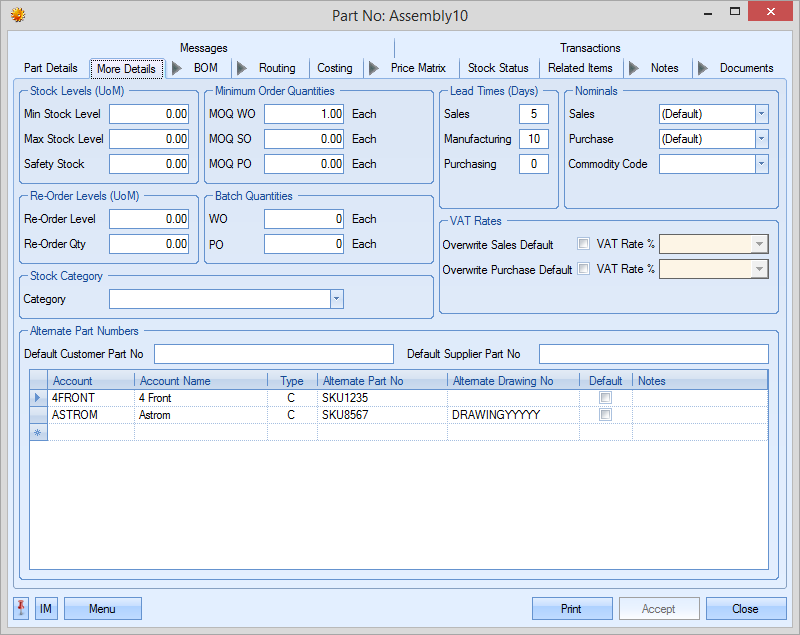

More Details

This section of the inventory record contains the additional information about a part.

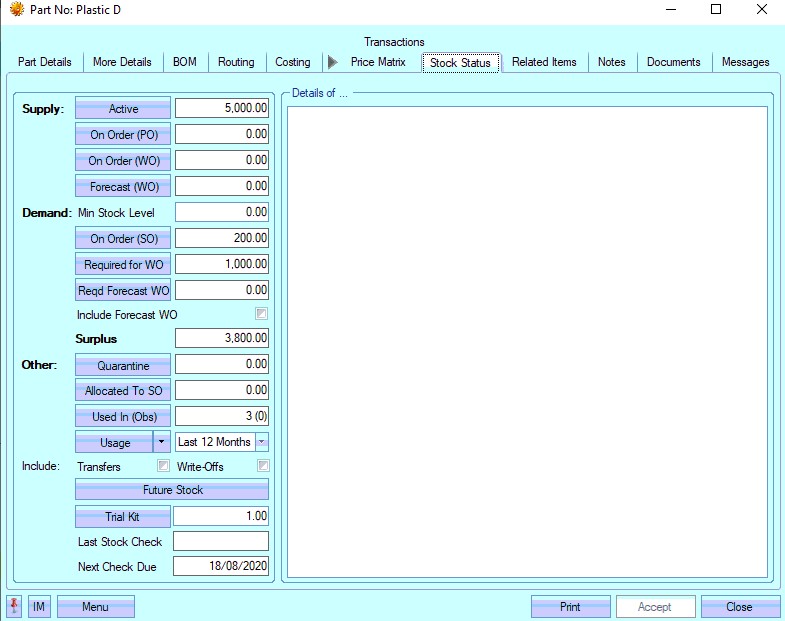

| Min Stock Level | This is the minimum stock level that the user wishes to hold of this item at any time. |

![]()

Should the projected quantity of this item held in stock fall below this level this item will appear on the Stock Shortages Report within the Reports section of Progress and on the Stock Status screen as a shortage. The values entered into this field should relate to the UOM.

| Max Stock Level | This in the maximum stock level that the user wishes to hold of this item at any time. |

![]()

| This is used as a reference for the part but will not affect any purchases or shortages for that part. |

| Safety Stock | This is the stock level that the user wishes to hold to maintain normal production requirements – usually a figure higher than that of the Minimum Stock Level. |

![]()

It is not used within the system for any calculations but is there as a visual aid. The values entered into this field should relate to the UOM.

| Re-Order Level | This is the level held of this item at which the user wishes to re-order this item to maintain a sufficient stock level e.g. re-order level equates when stock of this part reaches this level the user wishes to replenish his stock of this item either by raising a purchase order or a works order for this item. The values entered into this field should relate to the UOM. |

![]()

| Re-Order Qty | This is the batch quantity that the user prefers to purchase this item in. The values entered into this field should relate to the UoP. |

![]()

| MOQ WO | This field allows the user to specify the minimum quantity to manufacture on a work order. This may be due to minimum customer order quantities or due to the cost ineffectiveness of manufacturing smaller quantities. The quantity entered relates to the UoM. |

![]()

| MOQ SO | This field allows the user to specify the minimum quantity to sell on a sales order. This may be due to minimum quantities that can be supplied to the customer or because it’s not cost effective to sell quantities less than this value. The value entered relates to the UoM. |

![]()

| MOQ PO | This field allows the user to specify the minimum quantity to be ordered on a purchase order. This may be due to minimum quantities that can be supplied by the supplier or because it’s not cost effective to buy in smaller quantities. The value entered relates to the UoP. |

![]()

| Batch Quantity WO | This field allows the user to set batch quantity for creating Work Orders. This will affect the suggested quantity when using the Below MSL screen and Sales Order Line Requirement screen. The value entered relates to the UoM. |

| Batch Quantity PO | This field allows the user to set batch quantity for creating Purchase Orders. This will affect the suggested quantity when using the PO shortage screen. The value entered relates to the UoP. |

| Sales Lead Time | This is the number of days lead time to be taken into consideration when a sales order is raised for this part. The SO line requirement date will default to the current date plus any sales lead time specified against the part. |

![]()

| Manuf. Lead Time | This is the number of days lead time taken to manufacture the part. This value is used to calculate the work order start date from the sales order requirement date. This value is used in conjunction with any margins of error that have been set up for work order start and finish dates. |

![]()

For more information on manufacturing lead times and margins of error in relation to work order dates, please refer to the System options for work orders.

| Purch. Lead Time | This is the number of days lead time taken to purchase the part. This value is used to calculate the date by which the purchased material needs to be ordered to ensure it’s received by the work order start date. |

![]()

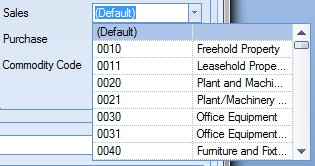

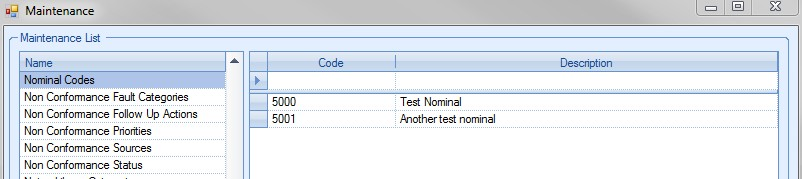

| Sales Nominal | This field allows the user to select a specific accounts nominal for the part. |

![]()

The user can select the nominal from the drop-down list.

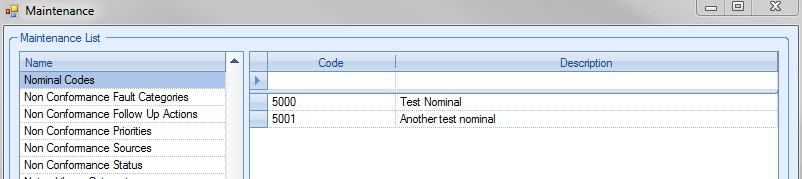

If Progress is linked to an external finance package, the nominal list will show all available nominals set up in the accounts package. If Progress is not linked to an external accounts package, the drop-down list will show all nominals set up in the List Maintenance section of under the Nominal Codes section.

Selecting a specific nominal against the part will override any nominal associated with the Group Code of the part. When left as (DEFAULT) the nominal will default to the nominal set up against the chosen Group Code. If no sales nominal has been set up against the Group Code, then the nominal will default to that of the customer the part is being sold to. If no nominal has been set up against the customer then the nominal will default to the default sales nominals set up in the System Accounts Link options.

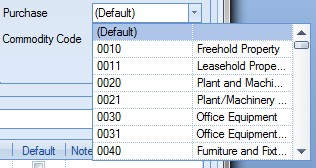

| Purchase Nominal | This field allows the user to select a specific accounts nominal for the part. |

![]()

The user can select the nominal from the drop-down list.

If Progress is linked to an external finance package, the nominal list will show all available nominals set up in the accounts package. If Progress is not linked to an external accounts package, the drop-down list will show all nominals set up in the List Maintenance section of under the Nominal Codes section.

Selecting a specific nominal against the part will override any nominals associated with the Group Code of the part. When left as (DEFAULT) the nominal will default to the nominal set up against the chosen Group Code. If no purchasing nominal has been set up against the Group Code, then the nominal will default to that of the supplier the part is being bought from. If no nominal has been set up against the supplier then the nominal will default to the default purchasing nominals set up in the System Accounts Link options.

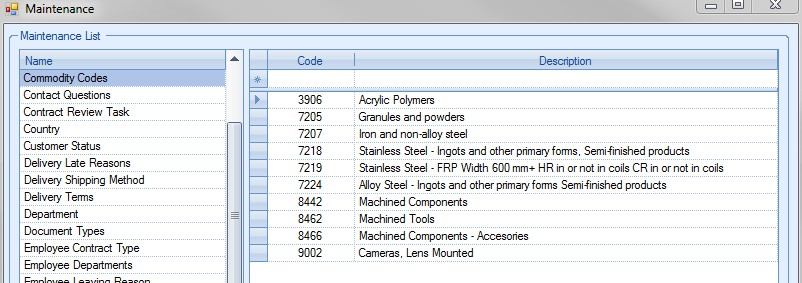

| Commodity Code | This field allows the user to specify a commodity code group for the part. |

![]()

The user can select a commodity code from the drop-down list. The drop-down list is populated from the List Maintenance section of Progress in the Commodity Codes list as shown in the screen below.

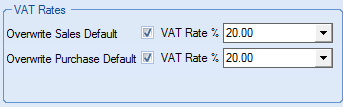

| VAT Rates | These options allow the user to set an overriding VAT rate for sales orders and purchase orders when the part is added to the respective order. This value will override the customer or supplier's VAT rate. |

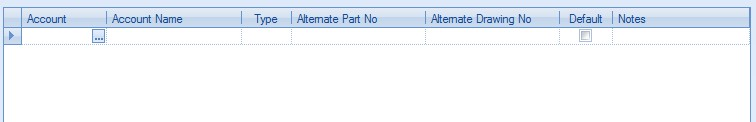

| Default Cust Part No | This field allows the user to specify a default customer part number. This can be used where the Progress part number is not the same as the customer part number or where the customer specifically wants to see their part number on documents generated by Progress. |

![]()

| Default Supp Part No | This field allows the user to specify a default supplier part number. This can be used where the Progress part number is not the same as the supplier part number or where the supplier specifically wants to see their part number on documents generated by Progress. |

![]()

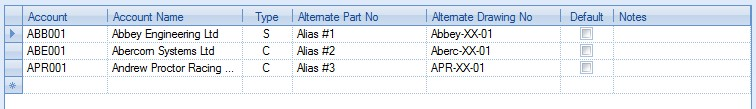

In the event that the part being created has multiple different aliases depending on the customer or supplier being used, the user can set up multiple references to the part specific to the suppliers and customers in question. This can be done using the grid below.

The user can select a supplier or customer by clicking on the ![]() option at the right of the Account column. This will present the user with a list of all customers and suppliers to choose from.

option at the right of the Account column. This will present the user with a list of all customers and suppliers to choose from.

The user can select the supplier or customer required and press SELECT to return to the part screen. This can be repeated for as many different references as required for the part.

These aliases can then be used to reference the correct supplier or customer part number for any documentation.

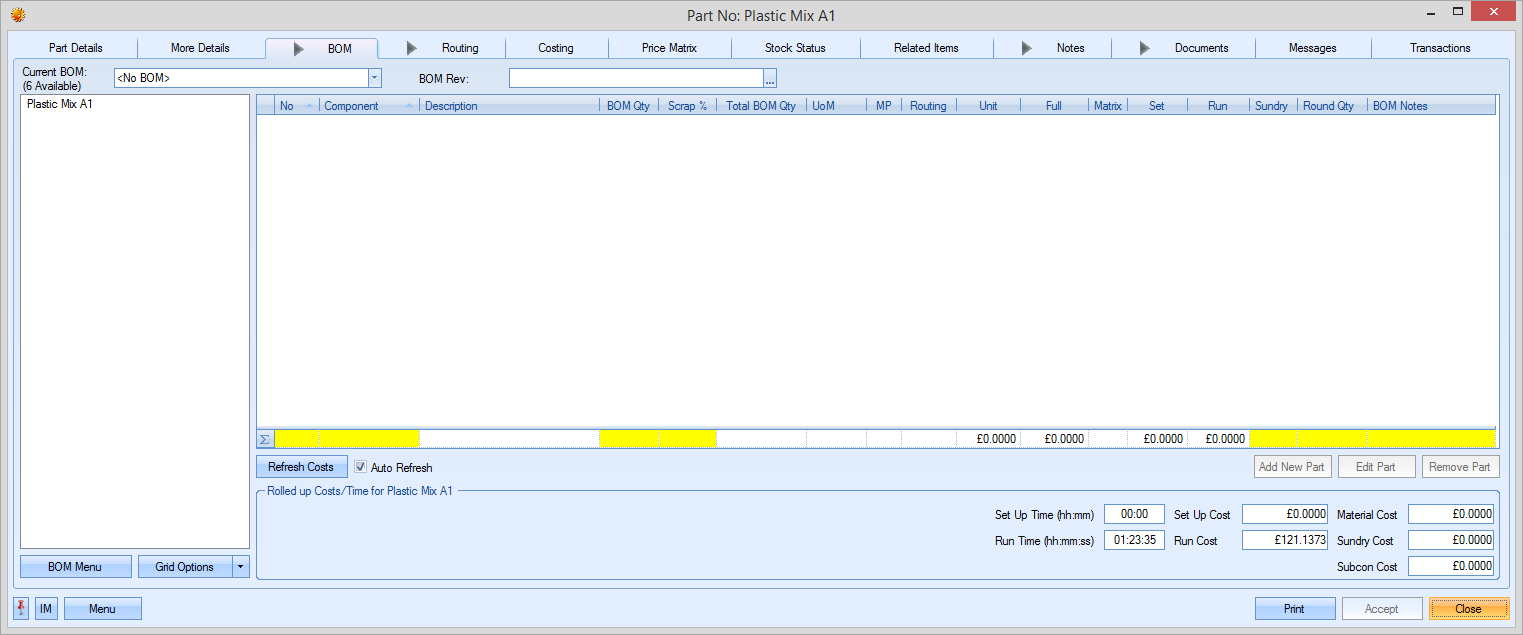

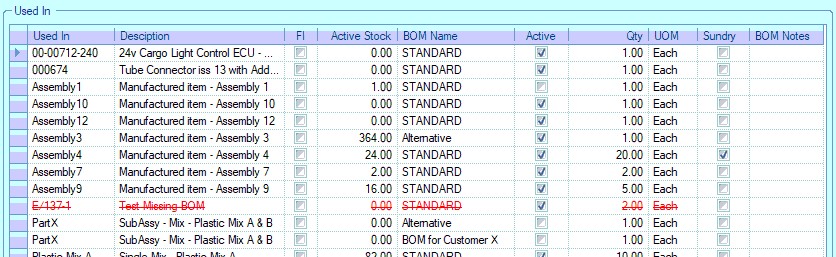

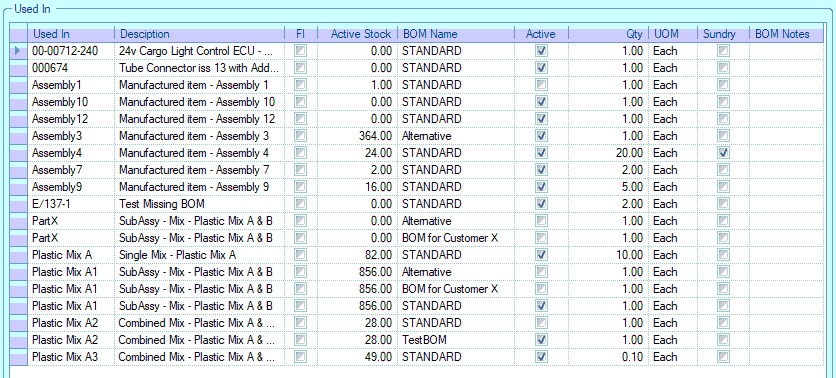

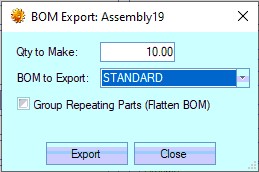

BOM

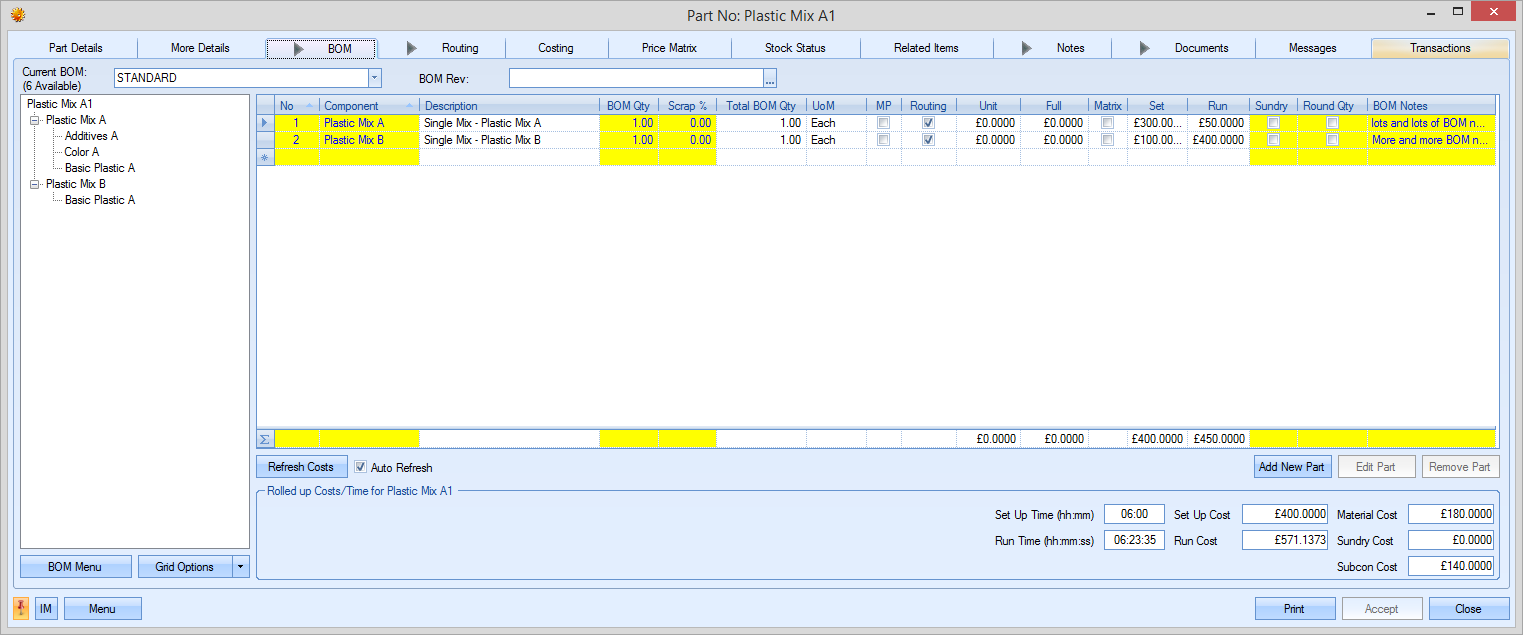

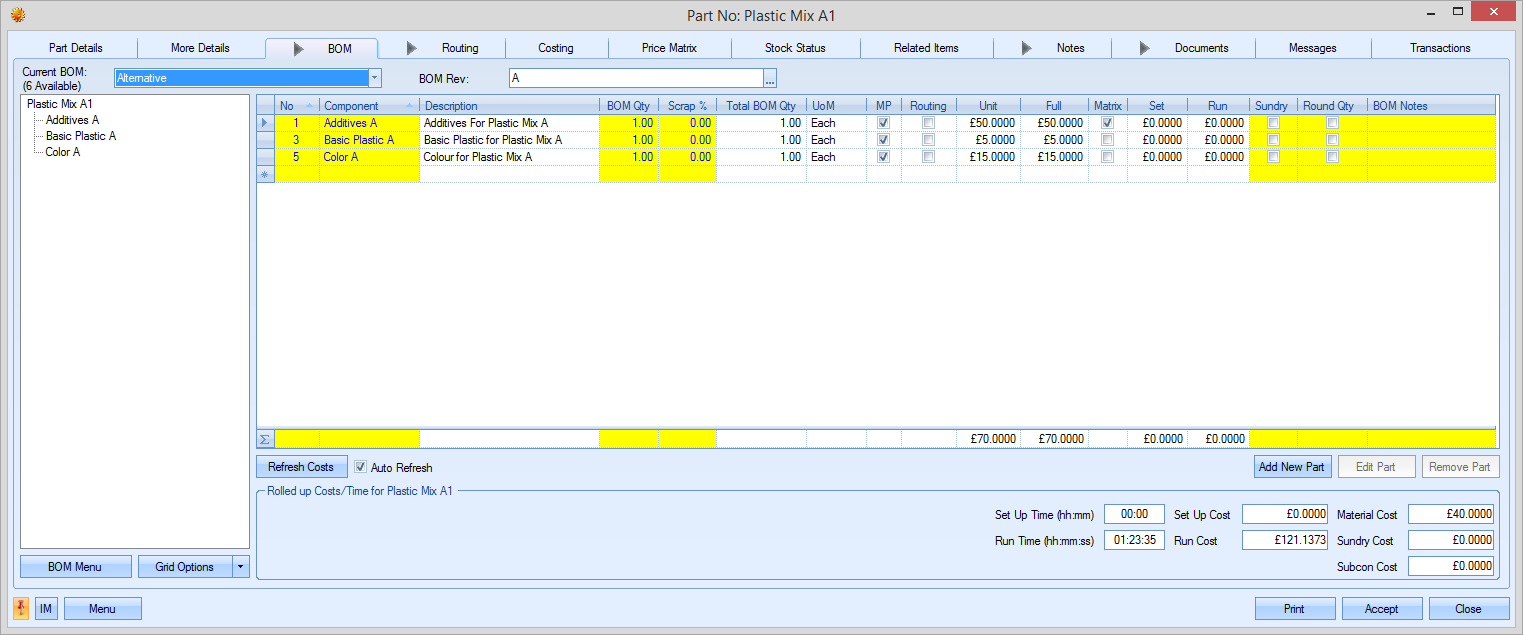

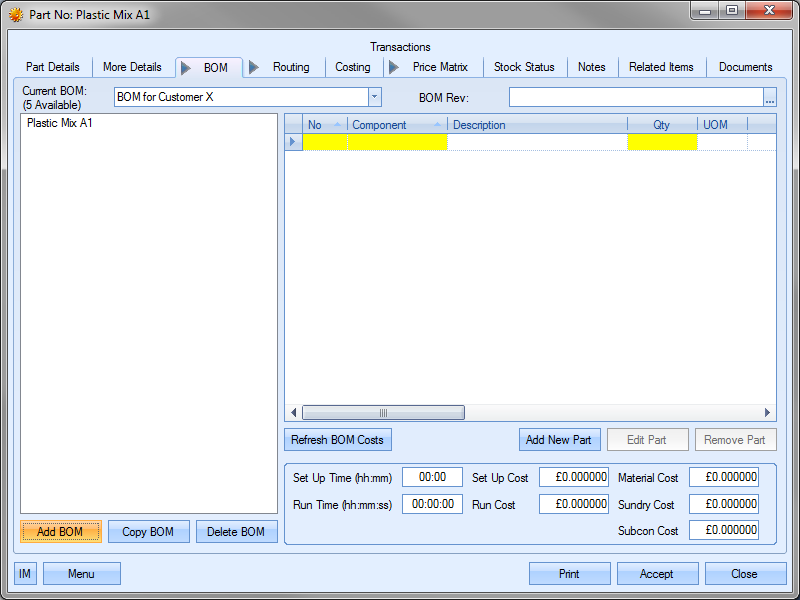

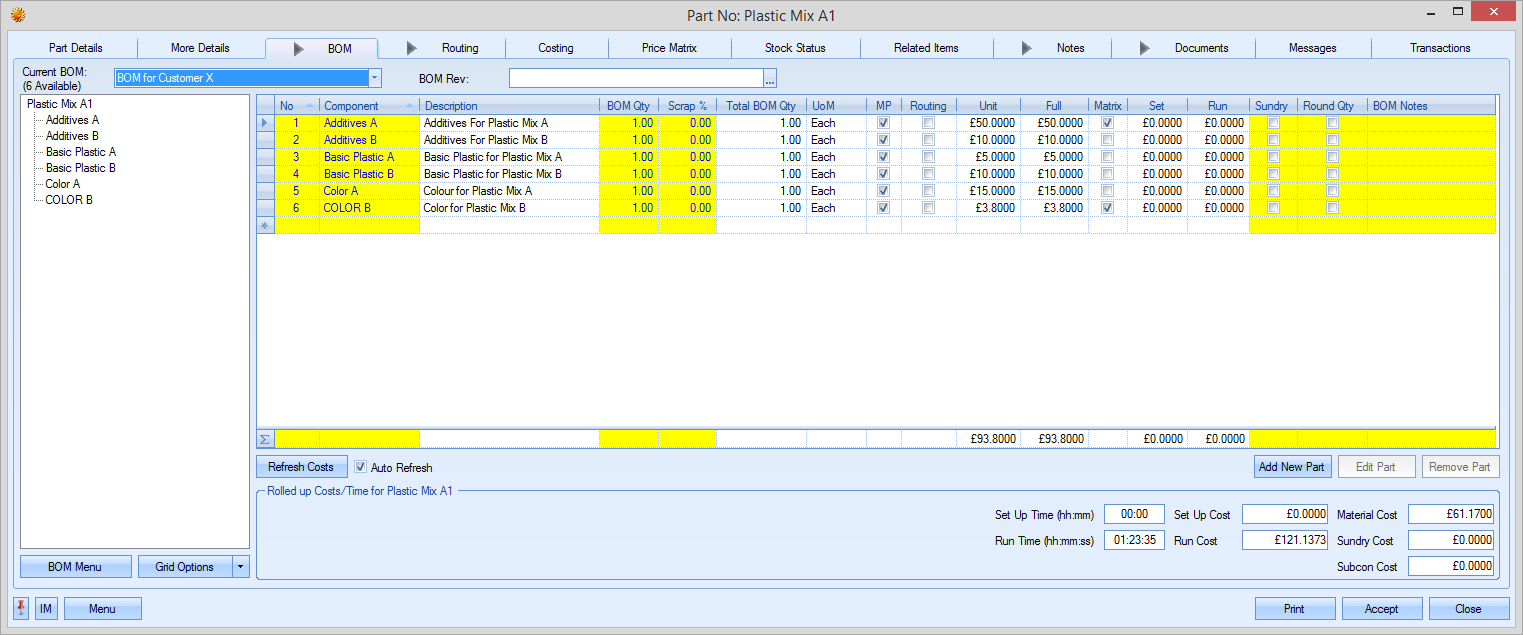

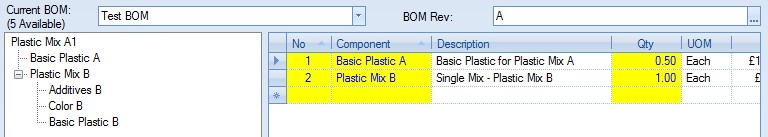

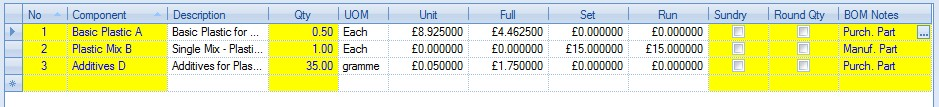

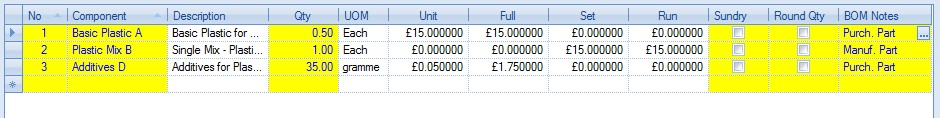

This screen allows the user to list any purchased or sub-assembly items used in the manufacture of the current part.

For purchased parts, this screen will be left empty as there will be no component parts for a purchased item. For a manufactured part, this screen allows the user to specify one or more component lists that can be used for the manufacture of the item. An example manufactured part is shown in the screen shot above.

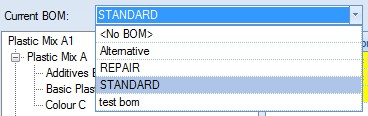

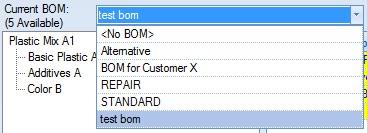

The drop-down list at the top of the screen allows the user to select the BOM to be used for the part. By default, the first BOM is labeled “STANDARD”. Subsequent BOMs can be labeled however the user desires.

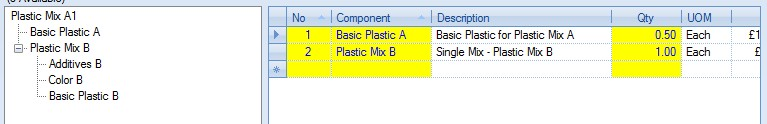

Selecting an alternative BOM will result in the details on the screen being updated accordingly as shown below.

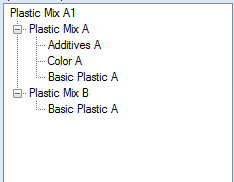

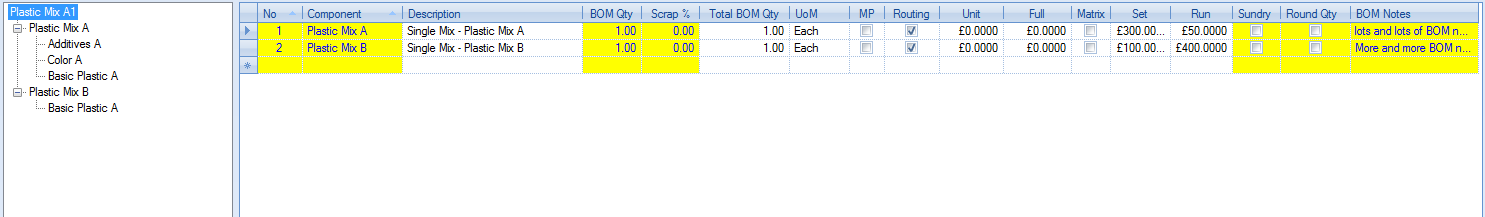

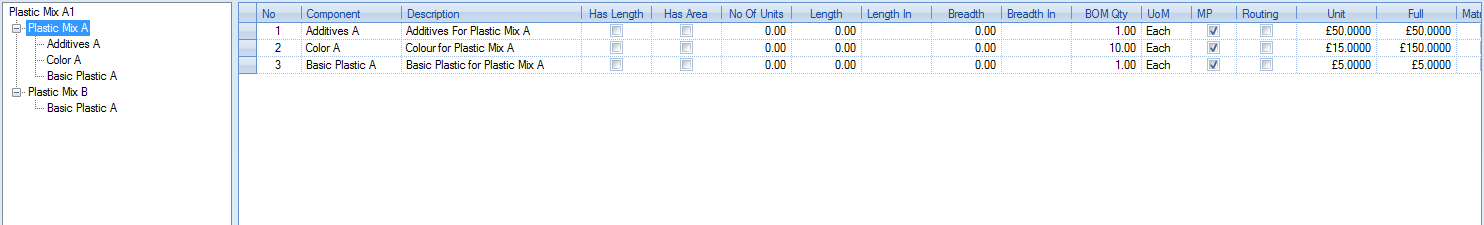

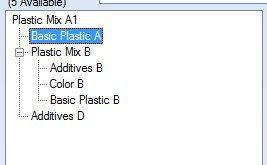

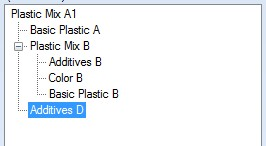

The current selected BOM is shown as a “tree view” in the box to the left of the screen. This shows the different BOM levels contained within the BOM.

Selecting different parts within the “tree view” results in the component details being shown in the box to the right. By default, the details of the first level of the BOM are shown.

Selecting one of the sub assembly components lists the component parts for that part in the right hand section of the screen.

BOM Management

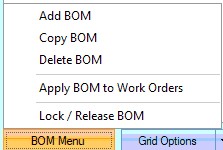

Manufactured part’s BOMs can be created, copied, amended or deleted from this screen using the various options. The options in the BOM Menu option at the bottom left of the screen allow the user to create new BOMs, copy existing BOMs from other manufactured parts or delete existing BOMs. The user can also lock BOMs so they cannot be edited.

Add BOM

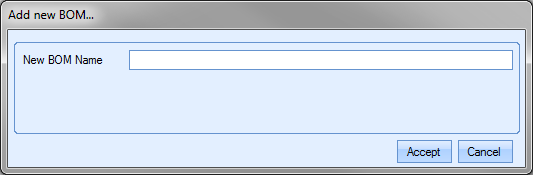

The user can create additional BOMs for the selected part by clicking on the ADD BOM option. When selected, the user is asked to provide a name for the new BOM.

The name provided can be anything, but it’s often used to indicate the purpose of the additional BOM; a customer reference or reference to a particular component part or material that is used. Once entered the BOM screen is updated with the new BOM which, by default, will be blank. The user can then add the purchased and/or sub-assembly parts required for the BOM. The new BOM name can also be seen in the CURRENT BOM drop-down list at the top of the BOM screen too.

To add new components to the BOM, the user can either click on the highlighted yellow “component” box in the grid to select existing Progress part numbers or click on the ADD NEW PART option immediately under the grid to add new parts not currently available on Progress. For more information on adding component parts to a BOM, please refer to the BOM Component Maintenance section of this manual.

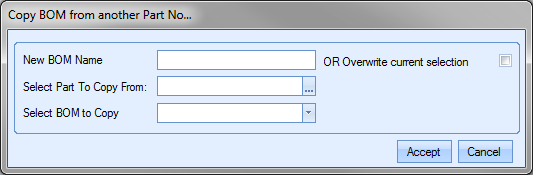

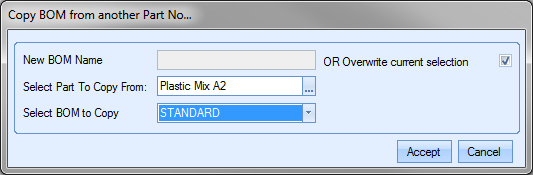

Copy BOM

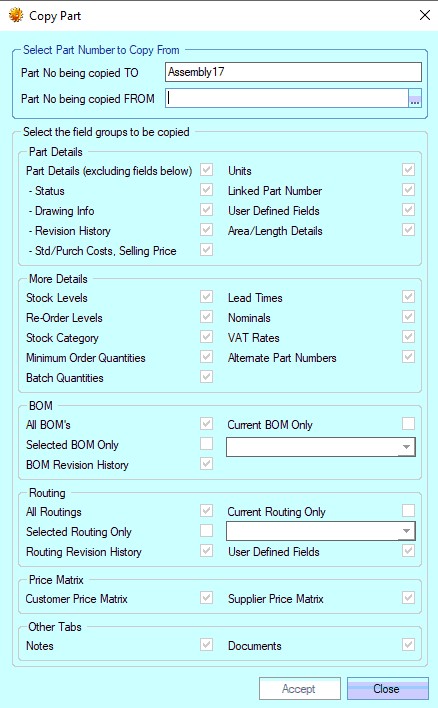

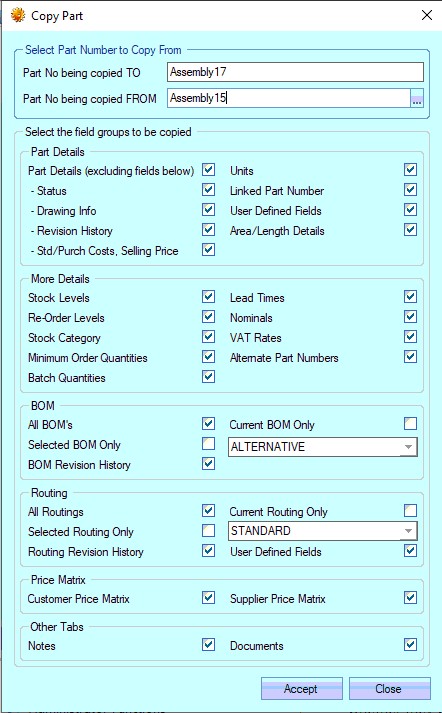

This option allows the user to copy an existing BOM from another part in Progress. This is particularly useful when large-scale BOMs are used and there are similarities between manufactured items. When the user selects the COPY BOM option, the following screen is displayed.

The user can choose to create a new BOM by entering a name for the new BOM or overwrite the currently selected BOM by ticking the overwrite option. The user must then select the part number that has the required BOM. They can do this by clicking on the ![]() option at the end of the field. This will present the user with the Inventory Search window. The user can then search for the part number required.

option at the end of the field. This will present the user with the Inventory Search window. The user can then search for the part number required.

Once the user has identified the part required, clicking the SELECT option will return the part to the COPY BOM screen.

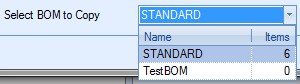

Finally, the user can select the BOM using the drop-down list.

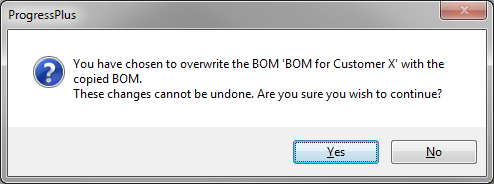

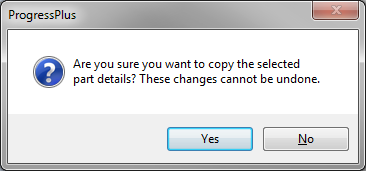

Once selected, clicking the ACCEPT option prompt the user to confirm the change before pulling the BOM details through to the BOM screen.

The user can now make additional changes to the BOM quantities or components as necessary. Once finalised, the user must click the ACCEPT option to save the new BOM details. The new BOM is now ready for use.

Delete BOM

This option allows the user to delete existing BOMs from the manufactured part. This option could be used if older BOMs have become obsolete and the user chooses to remove them from the part. To delete a BOM, the user must firstly select the BOM from the drop-down menu at the top.

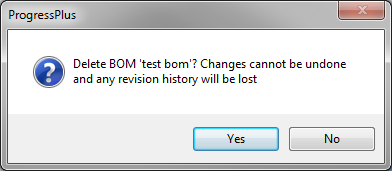

Once the BOM to be deleted has been selected, the user can click the DELETE BOM option. The user will be prompted to confirm the deletion.

Once the user confirms, the BOM information will be cleared from the screen and the part will default to the <NO BOM> option.

The user can now select the BOM the wish to use going forward from the drop-down list at the top of the screen or create a new BOM if required. Again, clicking the ACCEPT option will save the changes made.

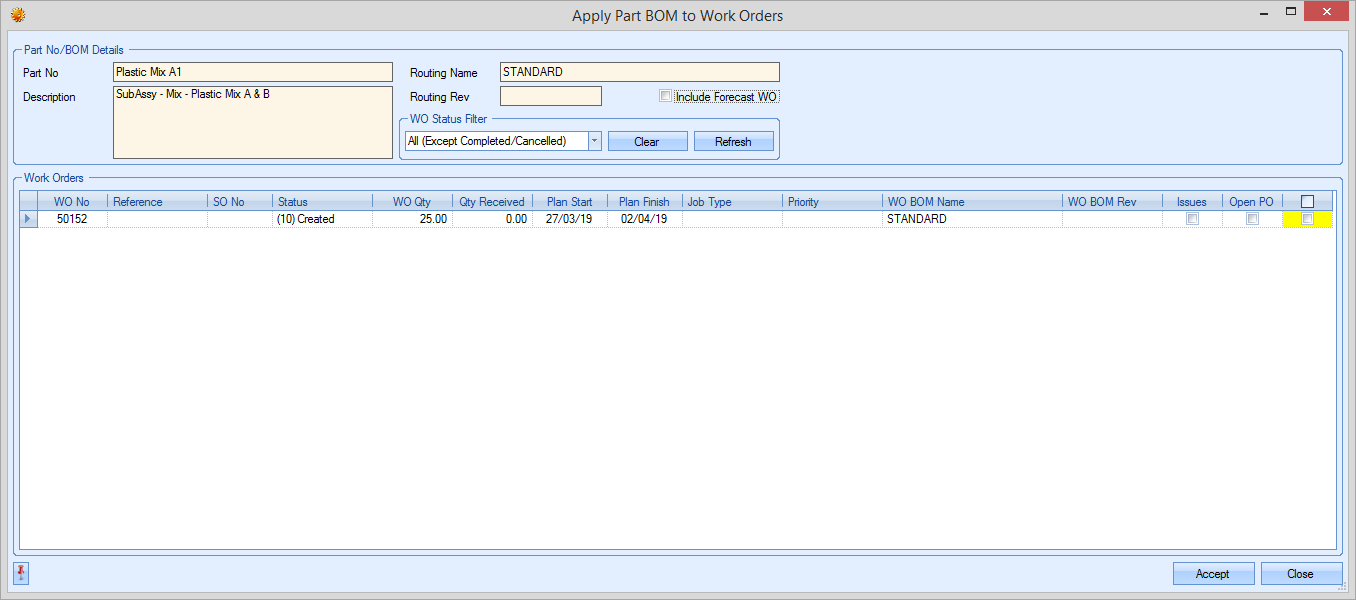

Apply BOM to Work Orders

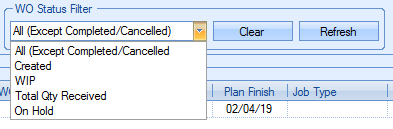

This option allows the user to push amendments to BOMs to existing WOs. The user will be prompted to select the WOs to be updated as shown below.

The user can use the status filter to narrow down the list of WOs that are to be updated. By default, the system will suggest all WOs (except cancelled or complete WOs), although this can be changed. Clicking REFRESH will update the list of WOs shown.

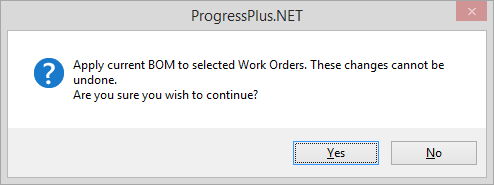

Once the user has selected the WOs to be updated, clicking ACCEPT will prompt the user to confirm the update before updating the selected WOs.

Lock/Release BOM

This option allows permitted users to lock a BOM so it cannot be edited. This is a user permission and is set against the user's access permissions in the Admin section of progress. This option will only be available to users who have this permission. When a BOM is locked, a small padlock icon will be displayed against the BOM tab to indicate such. The BOM can be viewed but cannot be edited until its unlocked by an authorised user.

![]()

BOM Revisions

The user can record revision history against each BOM in the system using the BOM Revision field at the top of the screen.

![]()

The user can record revisions against the BOM by clicking on the ![]() option at the end of the field. This will present the user with the following screen.

option at the end of the field. This will present the user with the following screen.

The user can record the revision ID and any notes associated with the revision. The date will default to the current date and the user to the current Progress user. Once the details have been added, the user can select the revision by highlighting the required revision and clicking on the TRANSFER option. This will return the user to the BOM screen and attach the selected revision.

Once the user has added a revision to the BOM, they can save the changes by clicking the ACCEPT option. Additional revisions can be added and selected as and when required.

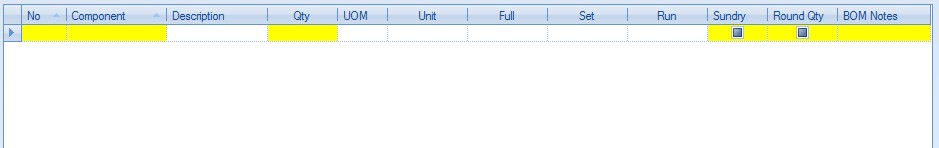

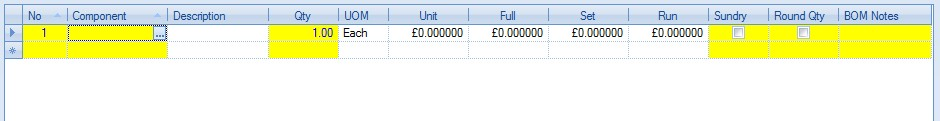

BOM Component Management

BOM parts, manufactured and purchased, can be added, amended or deleted from this screen using the various options available. Existing Progress parts can be selected directly via the BOM grid or the user can use the following options.

![]()

Adding Existing Progress Parts to a BOM

If the user wishes to add an existing Progress part to a BOM, they can add it via the BOM grid.

Clicking on the yellow Component field presents the user with the ![]() option that will allow them to search for the part number required.

option that will allow them to search for the part number required.

Clicking on the ![]() option opens up the Inventory Search window from which the user can search.

option opens up the Inventory Search window from which the user can search.

Once the required part has been identified, clicking the SELECT option will return the part to the BOM grid.

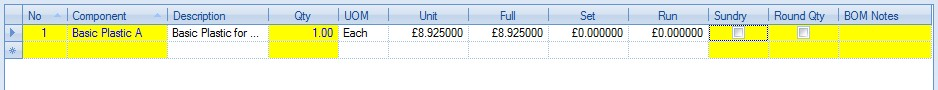

The information in the grid is as follows:

| No | This is the BOM sequence number. This is a sequential number generated by Progress, although this can be amended by the user if required. |

| Component | This is the Progress part number selected for the BOM. |

| Description | This is the description recorded against the selected part in the inventory record. |

| Qty | This is the BOM quantity and is the qty of the component required to manufacture one unit of the manufactured item. |

| UoM | This is the unit of measure (UoM) of the component part. |

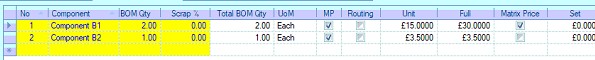

| Unit | This is the unit cost of one unit of the selected part. For manufactured parts, i.e. sub-assemblies, this will always be zero. For purchased parts, this will either be the STANDARD COST or the LAST PRICE of the part depending on how the costing options have been configured in the system options. |

For more information on these options, please refer to the Costing Defaults section in the Admin section of the manual.

If the system is configured to use the LAST PRICE option, the system will display either the part's purchasing cost or a price matrix price if one is set. If a suitable price matrix is set up for the part in question, then the relevant price matrix price will be displayed and highlighted using the PRICE MATRIX flag against the BOM item.

| Full | This is the full cost of the purchased part based on the UNIT cost and the BOM quantity entered. |

| Set | This is the set up cost associated with the part. For purchased parts, this will always be zero. This is only associated with manufactured parts on the BOM i.e. sub-assembly items. This is calculated based on the cost per hour of the sub-assembly work centres and the set up times associated with them. |

| Run | This is the run cost associated with the part. For purchased parts, this will always be zero. This is only associated with manufactured parts on the BOM i.e. sub-assembly items. This is calculated based on the cost per hour of the sub-assembly work centres and the run times associated with them. |

| Sundry | This option allows the user to specify whether this part has a one-off cost associated with the BOM or whether the cost increases based on the manufactured quantity. |

| Round Qty | This option allows the user to specify whether the BOM quantity is rounded up to the nearest full unit of purchase (UoP) quantity when calculating part shortages and costs. Full cost of BOM item will reflect this even though the BOM quantity may only be a fraction of what is being purchased. This ensure the system includes the cost of a full bar, sheet, etc. if not able to purchase an exact quantity required. |

| Subsequent WOs created will also increase the BOM requirement to the full UOP quantity to ensure enough material is ordered. |

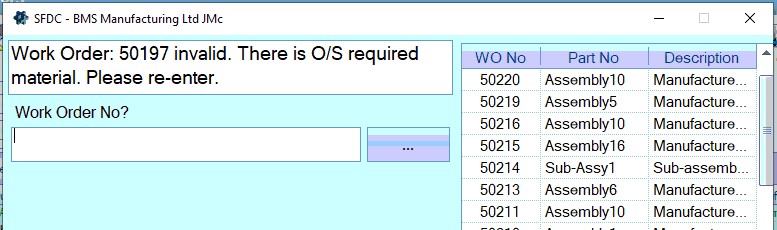

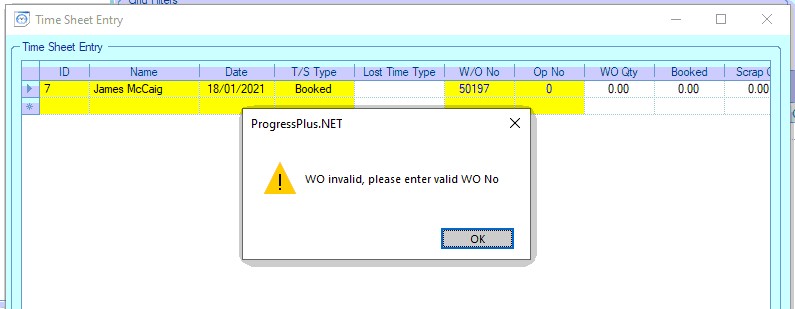

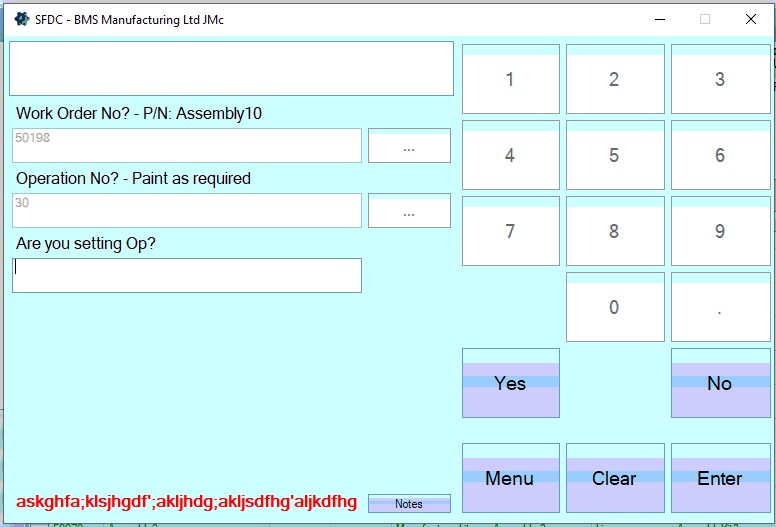

| Req'd To Start | This option allows the user to indicate that the component part is required for the WO to start. This option needs to be switched on in the Inventory > BOM system options. Please refer to the relevant section of the Administrator Functions section of the manual. When this option is ticked, the system will not allow an employee to job on to/create a timesheet against any WOs for an assembly where the component part has not been fully issued to the WO. Attempting to job onto a WO or create a manual timesheet will result in the following messages being displayed. |

(Jobbing on via SFDC)

(Creating manual timesheet)

| In addition to this, the Work To List screen also shows a flag to indicate that there is outstanding material against the WO that will stop the job being started. |

|

This indicates that material(s) that have been marked as required for the job to start have not been issued in full to the WO.

| BOM Notes | This field allows the user to specify specific notes for the part on the BOM. This could be directional notes or instructions but can be used for any notes the user wishes to add. The user also has the option of selecting notes from the Notes Library. This can be accessed by clicking on the |

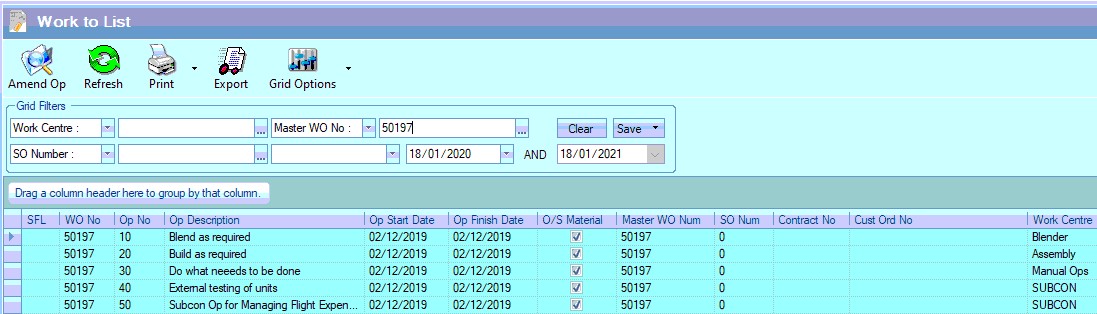

The screen below shows an example BOM with one purchased part and one manufactured part.

Adding New Progress Parts to a BOM

If the user wishes to add a part to the BOM which does not already exist in Progress, they can do this using the ADD NEW PART option.

![]()

Selecting this option will present the user with a new part record for the user to complete.

The user can complete the details of the new part as required.

For more information on creating new parts in Progress, please refer to the Creating New Parts section of the manual.

Once the details have been added, the user can click the ACCEPT option to save the details and then the CLOSE option to return the part to the BOM grid. The user can then specify the BOM quantity required.

Again, once the user has added the part(s) to the BOM, they can save the changes by clicking the ACCEPT option on the BOM screen.

Editing Parts on an Existing BOM

The user also has the ability to make changes to the parts already listed on a BOM. To do this, the user simply needs to click on the part in the “tree view” box on the left hand side of the screen and then click on the EDIT PART option under the BOM grid.

![]()

This will present the user with the inventory record for the selected part.

The user can then make the necessary changes to the part before saving the changes by clicking the ACCEPT option. This will not only save the changes against the inventory record, but will update the BOM screen accordingly. The following shows the updated BOM grid after the purchasing cost was increased for the part shown above.

Deleting Parts on an Existing BOM

The user can remove parts from an existing BOM by selecting the part in question and clicking on the REMOVE PART option.

![]()

The selected part will be removed from the BOM and the screen updated to reflect the change.

Once the user has removed the part from the BOM, they can save the change by clicking the ACCEPT option.

BOM Costs

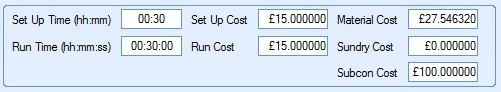

A summary of costs and times associated with the selected BOM are shown at the bottom of the screen.

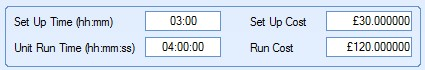

| Set Up Time (hh:mm) | This is the total planned set up time of the routing operations required in the manufacture of one unit of the current part. |

| Run Time (hh:mm:ss) | This is the total planned run time of the routing operations required in the manufacture of one unit of the current part. |

| Set Up Cost | This is the cost of the total planned set up time based on the times and hourly rates entered against the work centres and routing operations. |

| Run Cost | This is the cost of the total planned run time based on the times and hourly rates entered against the work centres and routing operations. |

| Material Cost | This is the total material cost of all purchased parts required for the manufacture of one unit of the current part. |

| Sundry Cost | This is the total cost of all sundry parts required for the manufacture of one unit of the current part. |

| Subcon Cost | This is the total cost of all subcon operations required for the manufacture of one unit of the current part. |

These values and times are reflective of the current BOM and all subsequent BOM levels. Any changes made to the current BOM via the EDIT PART option will result in these values and times being updated accordingly after the change has been saved. If changes are made to the component parts out with the current part’s BOM screen, the user can refresh the values shown using the REFRESH BOM COSTS option, although these values are calculated afresh whenever the part record is opened.

![]()

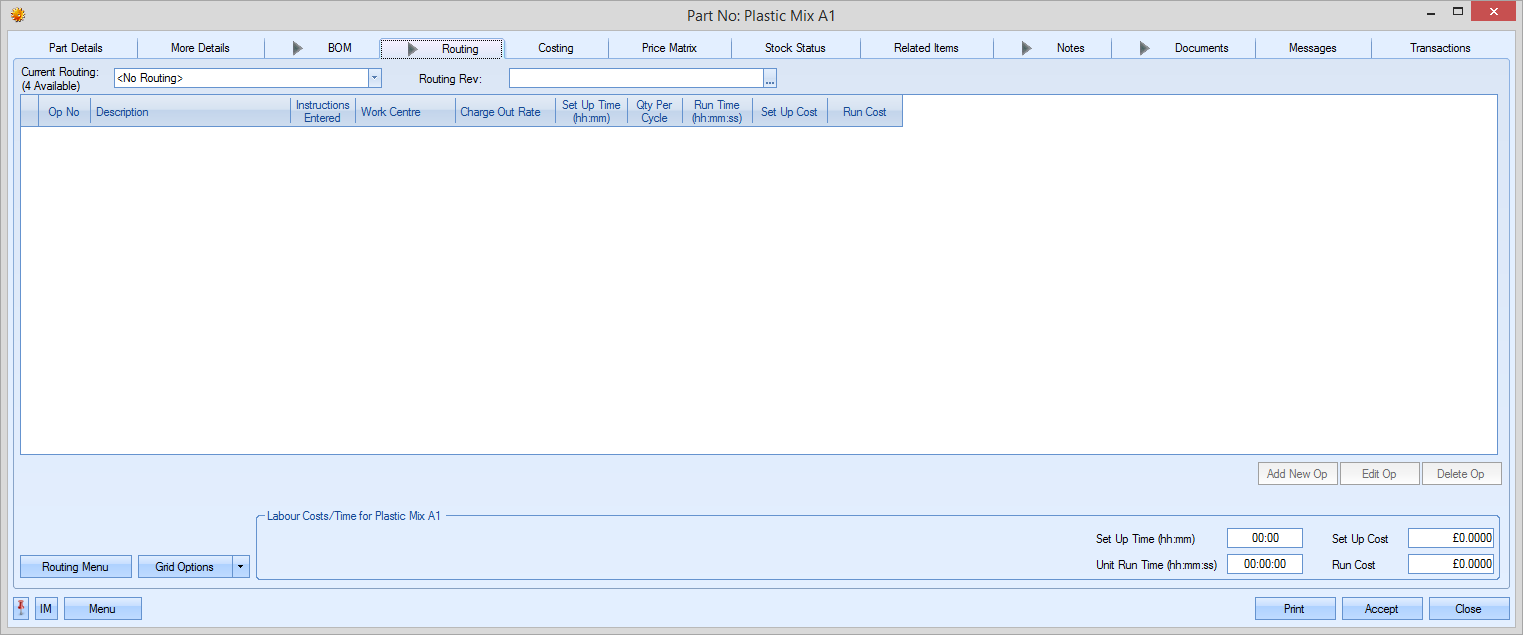

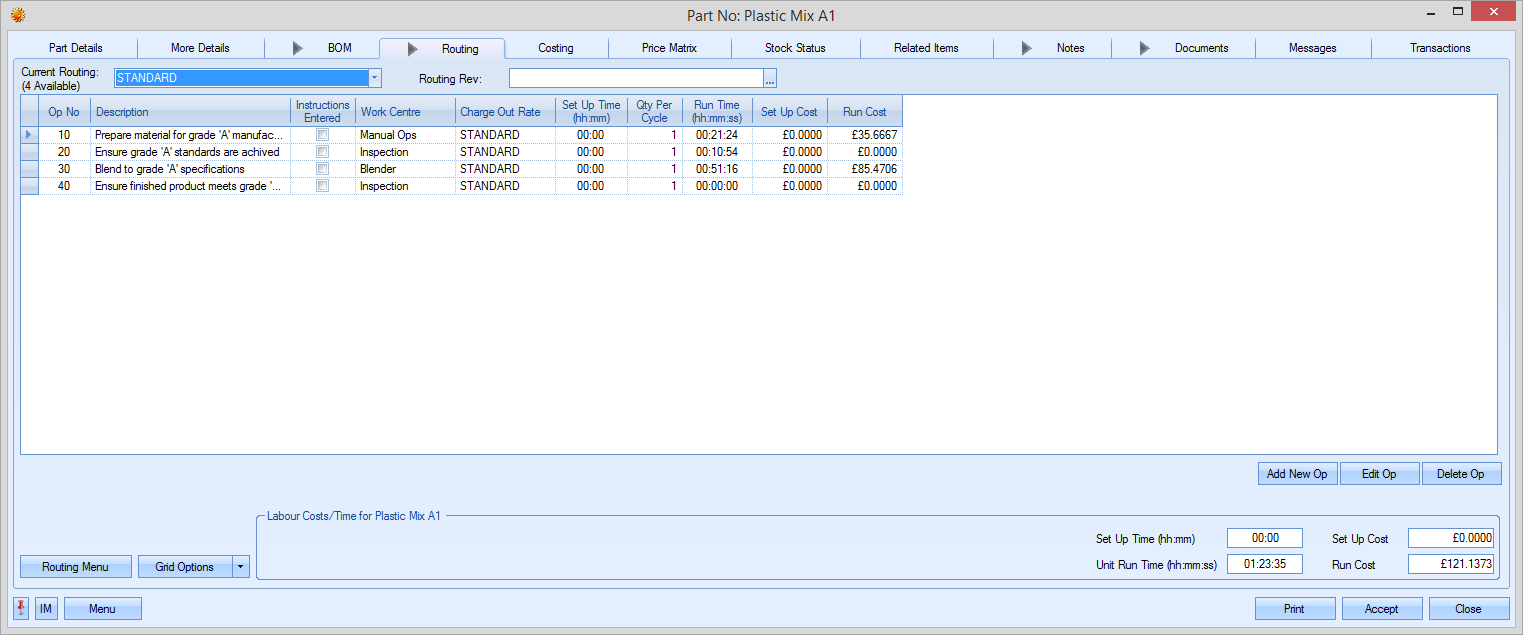

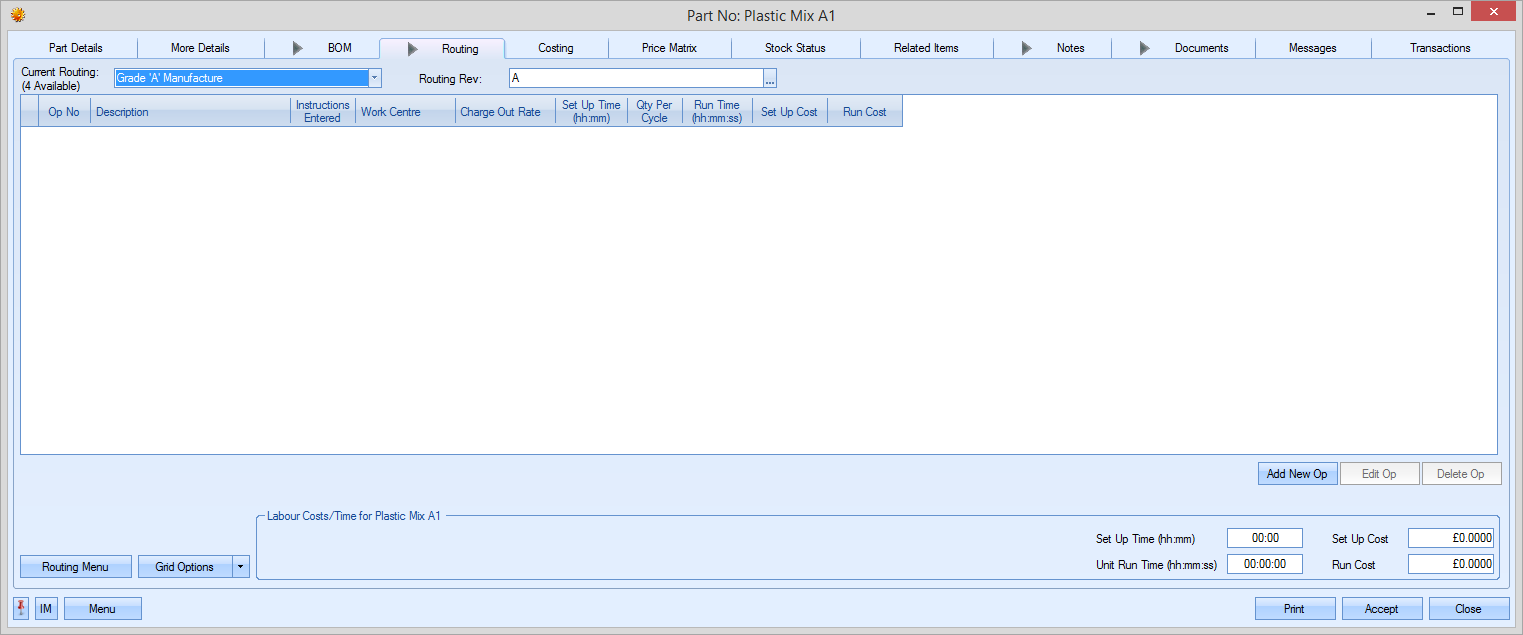

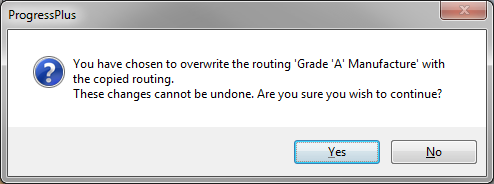

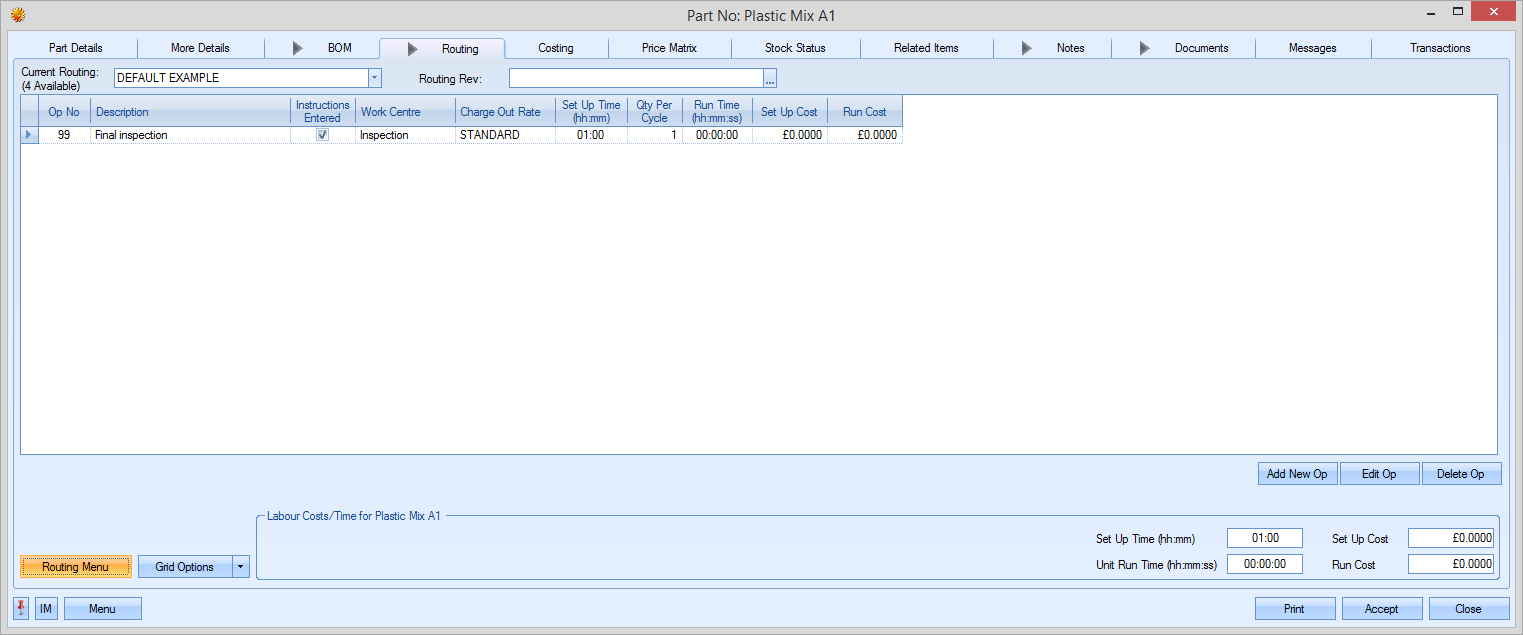

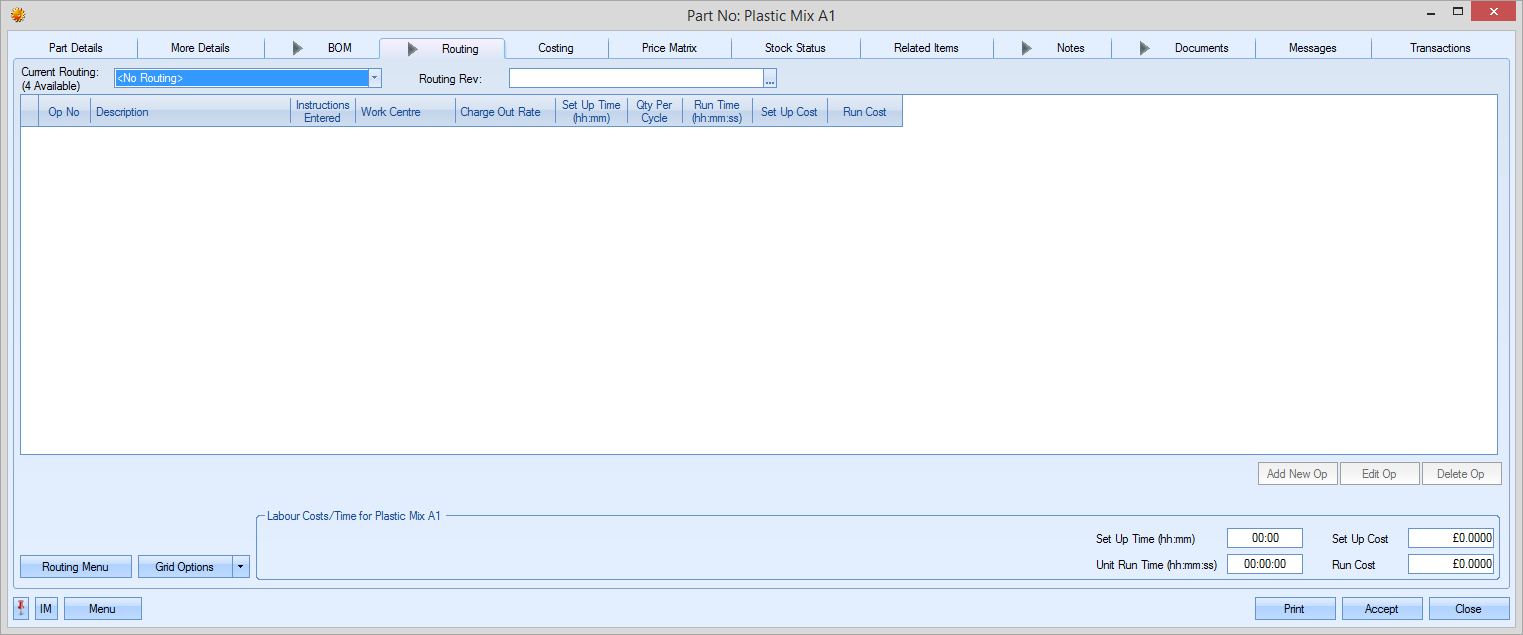

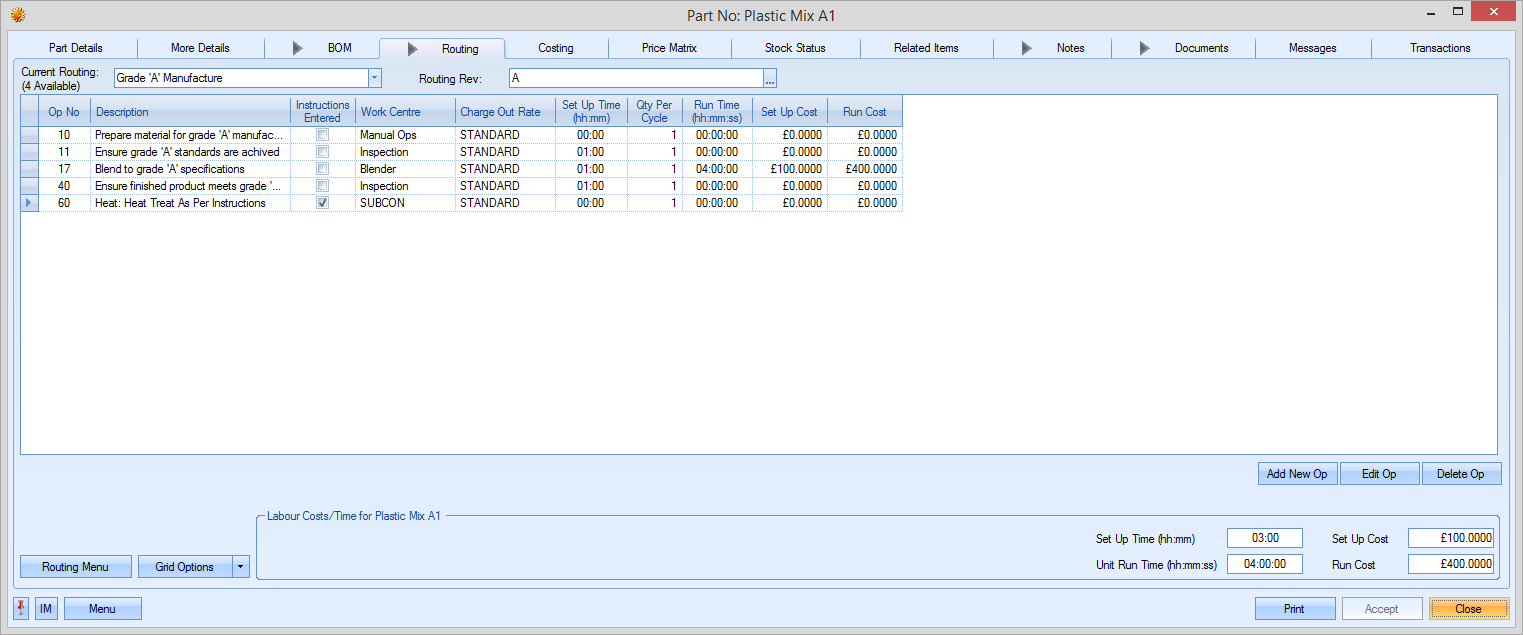

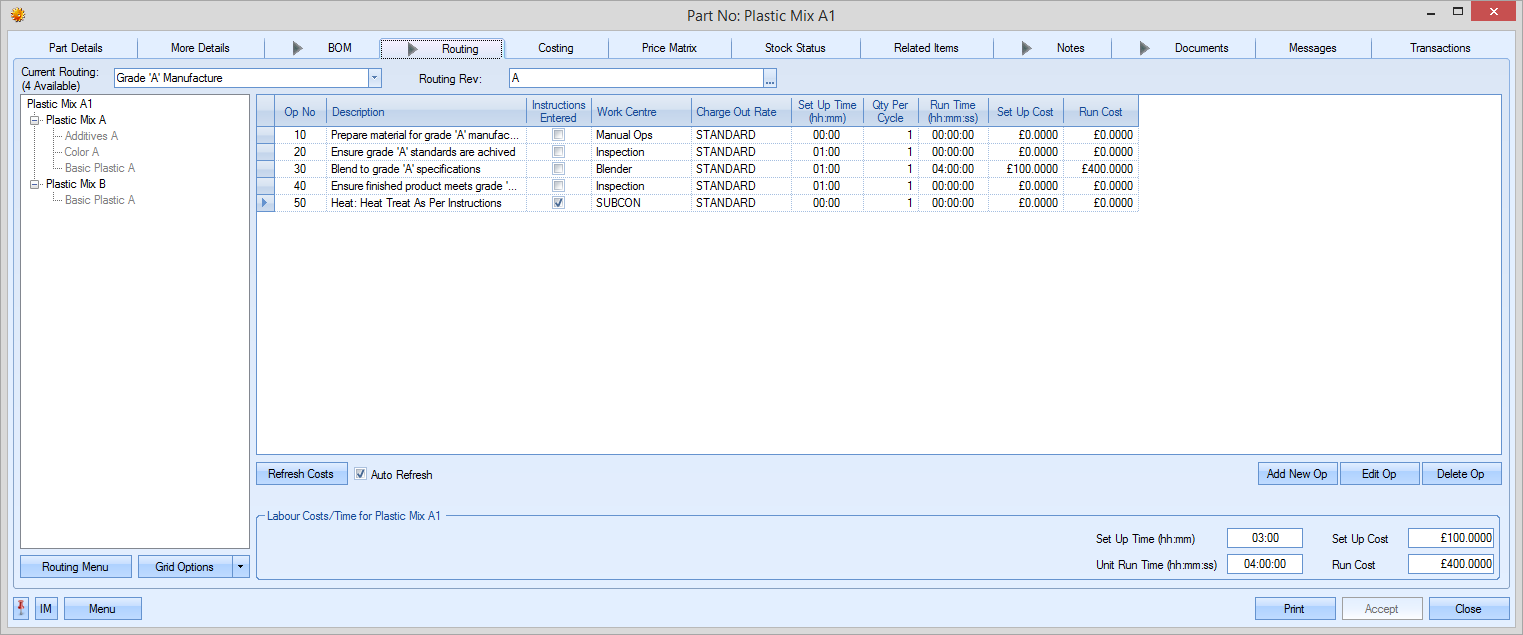

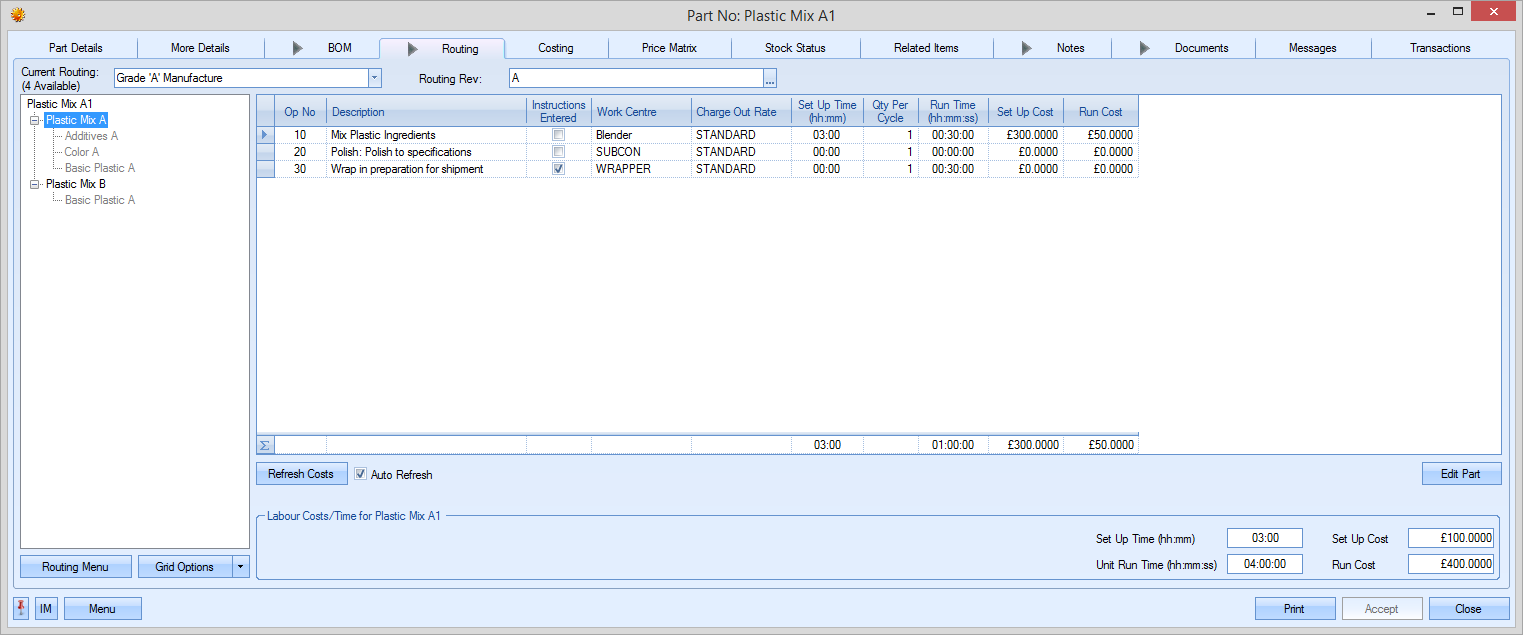

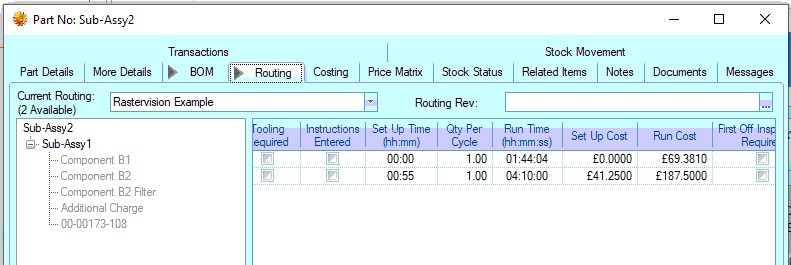

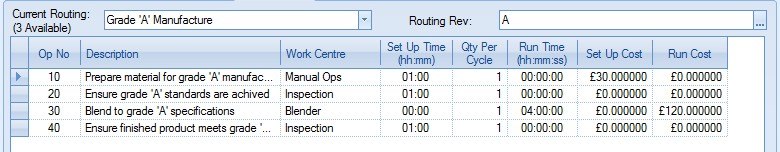

Routing

This screen allows the user to list any internal or sub-contract operations carried out along with the associated work centres in the manufacture of the current part.

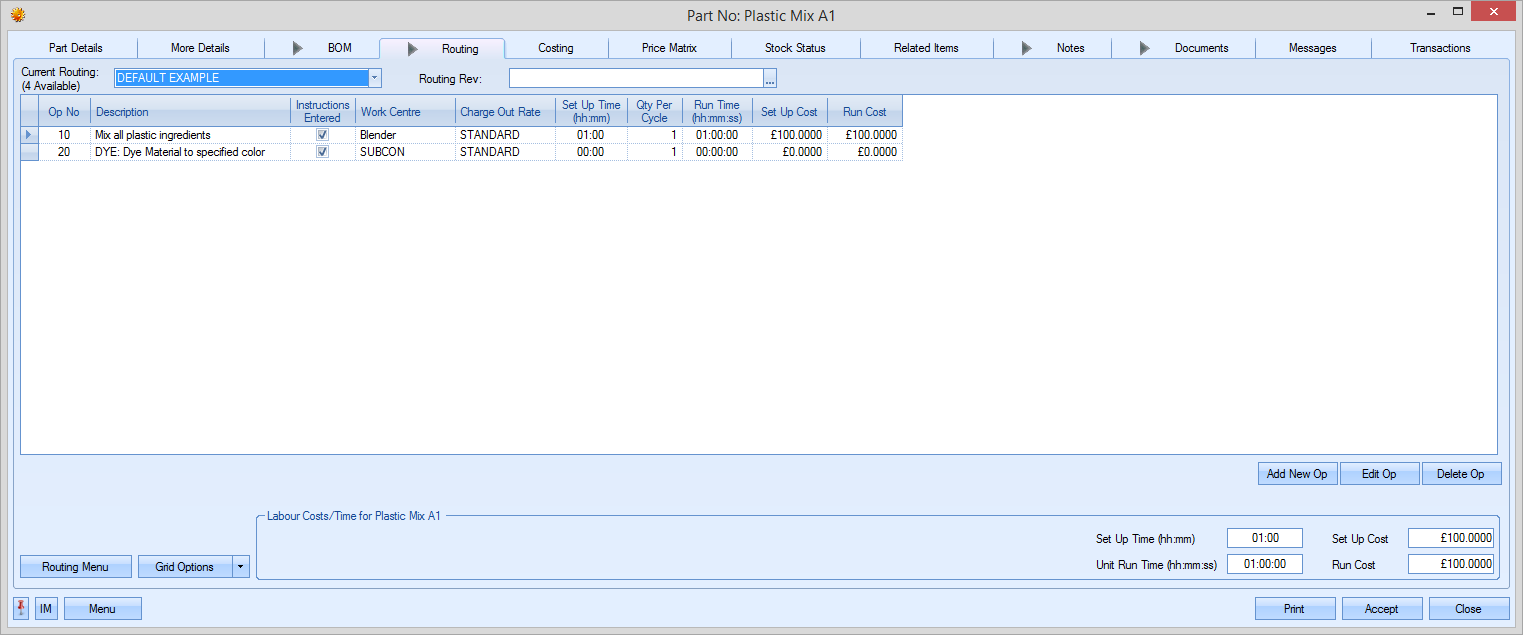

For purchased parts, this screen will be left blank as there will be no operations for a purchased item. For a manufactured part, this screen allows the user to specify one or more operation lists that can be used for the manufacture of the item. An example manufactured part is shown below.

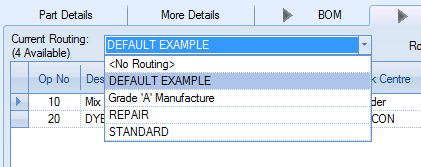

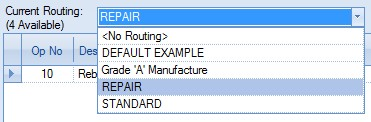

The drop-down list at the top of the screen allows the user to select the routing list to be used for the manufactured part. By default, the first routing is labeled “STANDARD”. Subsequent routings can be labeled however the user desires.

Selecting an alternative routing will result in the details on the screen being updated accordingly as shown below.

The bottom of the screen has summarised time and cost values for the selected routing.

These give the total set up and unit run times and the associated costs based on all the operations listed in the selected routing. Any changes to the routing operations will result in these values being updated to reflect the amended information.

Routing Operations Management

Routing operations, internal or sub-contracted, can be added, amended or deleted from this screen using the options available.

![]()

Adding New Internal Operations to a Routing

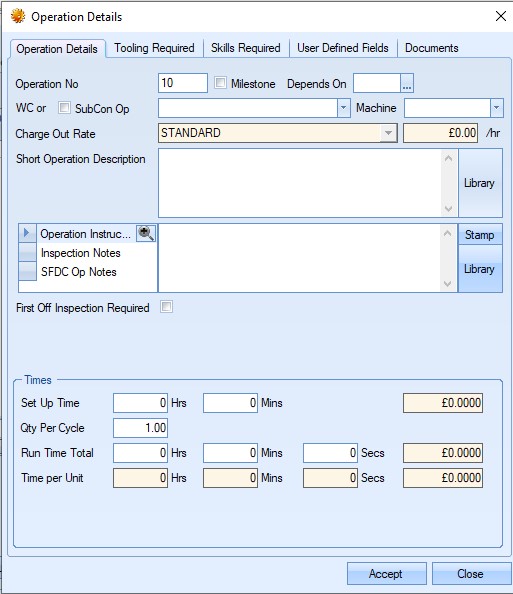

If the user wishes to add an operation to a routing, they can add it using the ADD NEW OP option. Clicking on this option presents the user with the following operation screen.

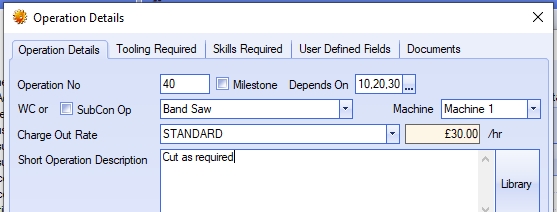

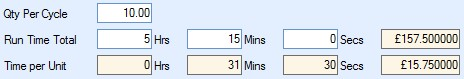

Operation Details

This tab contains all the main details regarding the operation and either the internal work centre required or the external subcontract requirement.

The user can then proceed to complete the information regarding the operation on this screen.

| Operation No | This is the routing operation number. This defaults to 10 for the first operation and then increases in multiples of 10 for subsequent operations, however, this number can be edited by the user. |

| Milestone | This option allows the user to mark the operation as a "milestone" operation. This means the operation has to be marked as "complete" before employees can continue on to subsequent operations. |

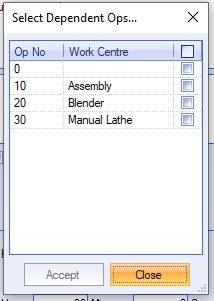

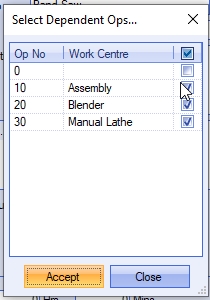

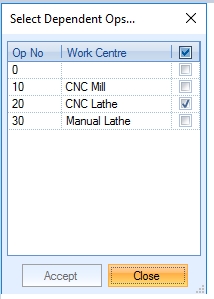

| Depends on | This option allows the user to specify dependent operations. This is often referred to as "parallel operations" as it allows different operations to run alongside others or set operation(s) which must be done prior to another operation starting. |

| NOTE: This functionality is not switched on by default. Please contact progress Plus to have this done. |

| The easiest way to manage this is to add all the relevent operations to the part's routing and then set the dependencies as required. Clicking this option once the operations have all been added will present the user with a list of operation that the current op can be made dependent on. The user will be presented with a list of current operations. |

| The user can select the operations the current operation is dependent on. These will be operations that need to be completed before the current operation can be started. |

| Once the user has selected the relevant operations, clicking ACCEPT will set the dependencies for the current operation. |

| This process allows the user to set up dependent operations, but also allows them to set up "parallel" operations, where different operations can run alongside each other. In this scenario, you would simply have multiple operations with the same dependencies or starting point. |

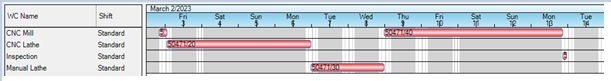

| From a planning/scheduling perspective, no dependencies will assume the operations of the routing are sequential, each following the previous op. Using dependencies will schedule the operations accordingly. |

| Example: |

| When no dependencies are set up, the system will automatically sequence the operations based on the operation number. From a scheduling perspective, the system will sequence the ops accordingly. |

| When dependencies are set, the system will schedule the operations in the way the dependencies have been set. In the example below both operation 30 and 40 are dependent on operation 20. Both these operations will have the following dependency set. |

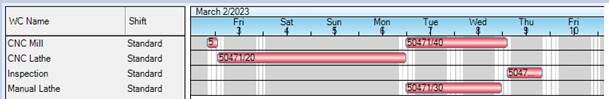

| When the job is scheduled, the user would see something similar to the following: |

| For more information on planning/scheduling within Progress Plus, please refer to the Shop Floor Loading (SFL) section. |

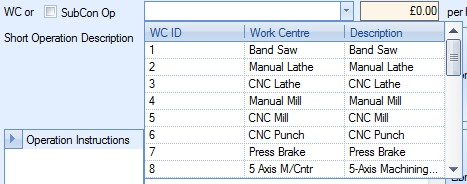

| WC or SubCon Op | This is where the user specifies whether the operation is an internal or external operation. For internal operations, the user must select the existing work centre associated with the required operation from the drop-down list. |

This drop-down list is populated from the Work Centres section of the Maintenance options and lists all work centres currently listed with a LIVE status. For more information on work centres and their creation, please refer to the Maintenance Menu section of the manual.

Once the user selects an existing work centre for an internal operation, the work centres, the associated hourly rate is displayed to the right of the work centre drop-down list.

![]()

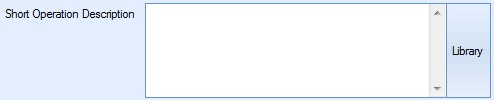

| Short Op. Description | This field allows the user to provide a short operation description regarding the operation. The user has the option of choosing a description from the Notes Library section of Progress, or manually entering the details. |

If the user manually enters a description not currently held in the Notes Library, Progress will prompt the user

To use the Notes Library, the user can click on the LIBRARY option. This will present the user with the Notes Library window, from which they can choose the required description. For more information on using the Notes Library section of Progress, please refer to the Notes Library section of the manual.

| Operation Instructions | This field allows the user to enter more detail instructions relating to the operation. This note will copy across to the WO operation whenever a WO is created. Again, the user has the option to select notes from the Notes Library if they require, or manually enter the details. To use the Notes Library, the user can click on the LIBRARY option. This will present the user with the Notes Library window, from which they can choose the required description. For more information on using the Notes Library section of Progress, please refer to the Notes Library section of the manual. |

| Inspection Notes | This field allows the user to enter inspection notes against a specific operation. This note will copy across to the WO operation whenever a WO is created. Again, the user has the option to select notes from the Notes Library if they require, or manually enter the details. To use the Notes Library, the user can click on the LIBRARY option. This will present the user with the Notes Library window, from which they can choose the required description. For more information on using the Notes Library section of Progress, please refer to the Notes Library section of the manual. |

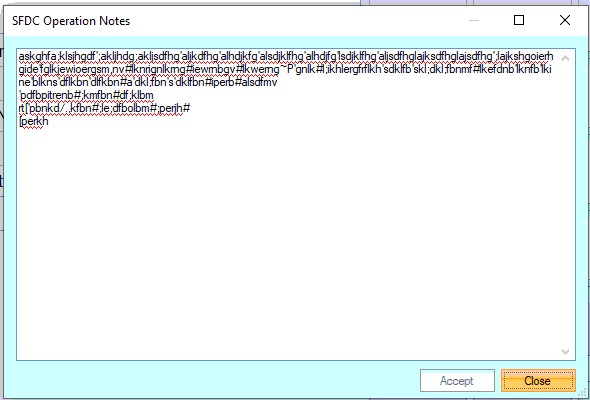

| SFDC Op Note | This field allows the user to enter specific SFDC notes against a specific operation. This note will copy across to the WO operation whenever a WO is created. When the employee jobs onto the operation via the SFDC station, the note is displayed on screen for the employee to see. The employee also has a NOTES option that allows them to expand the note to see if in full. |

Again, the user has the option to select notes from the Notes Library if they require, or manually enter the details. To use the Notes Library, the user can click on the LIBRARY option. This will present the user with the Notes Library window, from which they can choose the required description. Formore information on using the Notes Library section of Progress, please refer to the Notes Library section of the manual.

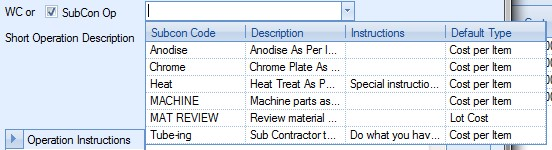

| Set Up Time | These fields allow the user to specify the set up time in hours and minutes for the operation. This is the initial set up or preparation time required before the operation can start. |

![]()

Once the user enters a time, Progress calculates the associated cost based on the work centre’s hourly rate. An example is shown below.

Work Centre: BLENDER Hourly Rate: £30 p/h

![]()

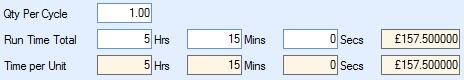

| Qty Per Cycle | This field allows the user to specify the number of units that can be done in a single run time period. |

![]()

| Run Time Total | This is the total run time required to produce the quantity specified in the Qty Per Cycle field above. The user can enter the run time in hours, minutes and seconds |

![]()

Once the user enters a time, Progress calculates the associated cost based on the work centre’s hourly rate. An example is shown below.

| Work Centre: BLENDER | Hourly Rate: £30 p/h |

![]()

| Time Per Unit | These fields are calculated based on the Qty Per Cycle and Run Time Total values entered by the user. These fields show the individual run times per unit. Typically, where the Qty Per Cycle has a value of 1, the Run Time Total and Time Per Unit will match. |

Where the Qty Per Cycle has been entered as a value greater than one, Progress will calculate the run time per unit and display it in these fields.

Once all the details have been entered, the user can save the new operation by clicking the ACCEPT option. The user will be returned to the routing screen with the new operation now displayed in the operations list.

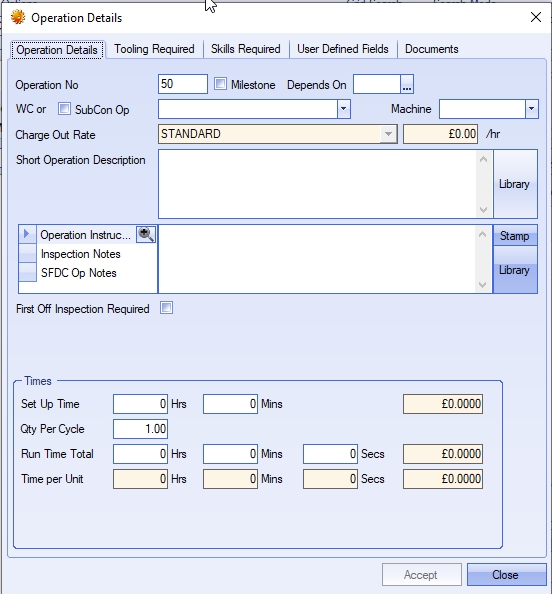

Adding New External Operations to a Routing

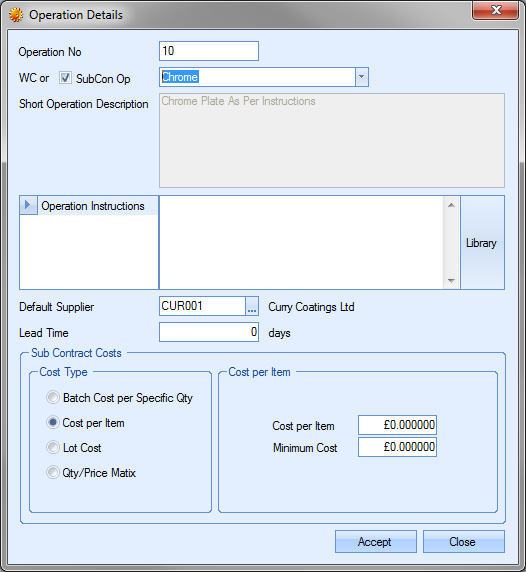

If the user wishes to add a sub-contract operation to a routing, they can add it using the ADD NEW OP option. Clicking on this option presents the user with the following operation screen.

The user can then proceed to complete the information regarding the sub-contract operation on this screen.

| Operation No | This is the routing operation number. This defaults to 10 for the first operation and then increases in multiples of 10 for subsequent operations, however, this number can be edited by the user. |

| WC or SubCon Op | This is where the user specifies that the operation is a sub-contract operation. For sub-contract operations, the user must tick the SubCon Op tickbox. This changes the drop-down list from a list of internal work centres to a list of external sub-contract codes. |

This drop-down list is populated from the Sub-Contract Codes section of the Maintenance options and lists all sub-contract codes currently listed with a LIVE status. For more information on sub-contract codes and their creation, please refer to the Maintenance Menu section of the manual.

Once the user selects the sub-contract code required, the operation screen changes to accommodate the details of the sub-contract requirement.

| Short Op. Description | For sub-contract operations, this field defaults to the description entered against the selected code in the Sub-Contract Code record. This field cannot be changed by the user. |

| Operation Instructions | This field allows the user to enter more detail instructions relating to the operation. If specific instructions have been recorded against the sub-contract code, these will be pulled through from the sub-contract code record. Again, the user has the option to select notes from the Notes Library if they require, or manually enter the details. |

To use the Notes Library, the user can click on the LIBRARY option. This will present the user with the Notes Library window, from which they can choose the required description. For more information on using the Notes Library section of Progress, please refer to the Notes Library section of the manual.

| Default Supplier | This field allows the user to specify the supplier who will carry out the sub-contract task. If a supplier has already been specified against the sub-contract code, this will be pulled through to the operation screen. The user can specify the supplier if known at this stage or can leave this blank for the supplier to be specified at the purchase order stage. |

![]()

| Lead Time | This field allows the user to specify the lead time of the sub-contract operation. If the lead time is specified against the sub-contract code, this field will default to that lead time. The user can change this value if a different lead time is to be applied. |

![]()

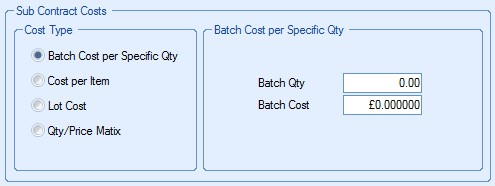

| Sub Contract Costs | The next section allows the user to specify how the sub-contract operation is to be costed. The user has 4 options available to choose from. |

| Again, the costing method will default to the selection made against the sub-contract code, but can be changed if necessary by the user. The options available are as follows: |

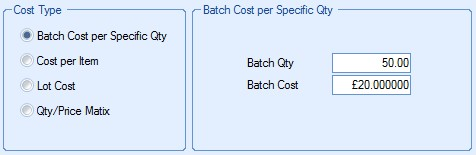

Batch Cost per Specific Qty This option permits the user to enter a batch size and cost for that specific batch. The following example has a Batch Qty of 50 and a Batch Cost of £20.

If the user were to send a batch of 200 items for subcontract work the cost would therefore be £80 (200/50 x £20).

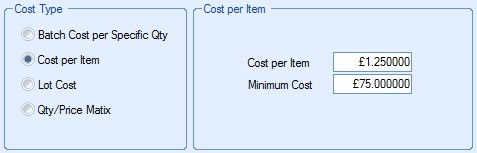

| Cost Per Item | This option allows the user to enter a cost per item for the sub-contract cost and can be used in conjunction with a specified minimum order quantity. The following example has a Cost Per Item of £1.25 with a minimum charge of £75. |

The system would cost any quantity up to 60 (£75/£1.25 = 60) as costing the minimum charge of £75 i.e. to plate 1 item = £75, 15 = £75, 42 = £75 etc as these quantities do not fulfil the minimum charge. Any quantity greater than 60 would be costed at Minimum Charge + Cost per Item e.g. a quantity of 80 would be costed at £100 (£75 + 20 x £1.25).

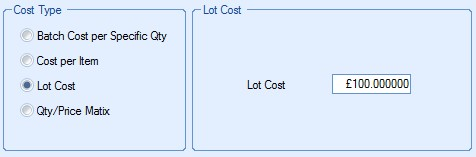

| Lot Cost | This option allows the user to enter a single cost for the sub-contract requirement. This is used when a fixed fee has been agreed with the supplier. The example below shows a fixed fee of £100. This would be the same whether the quantity being sub-contracted was 1 or 1000. |

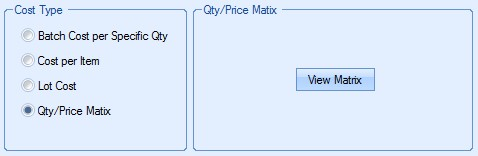

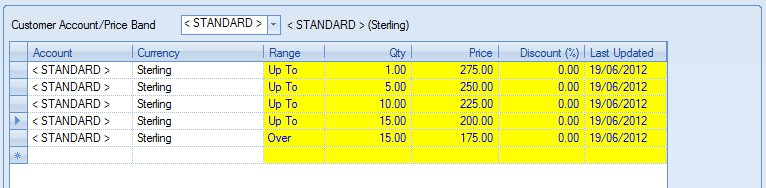

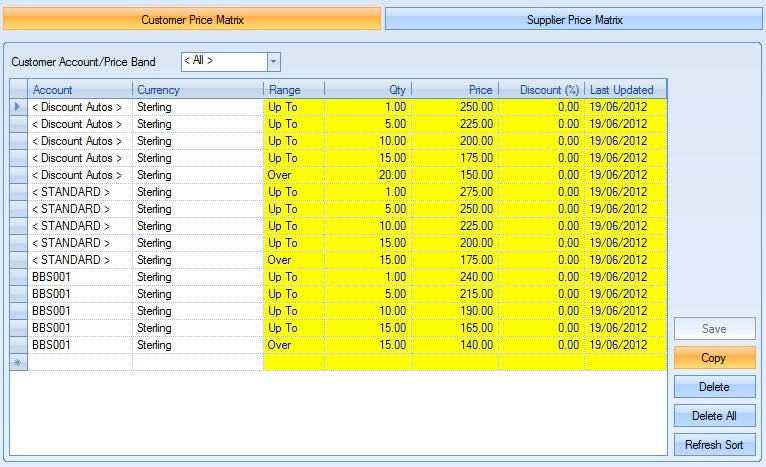

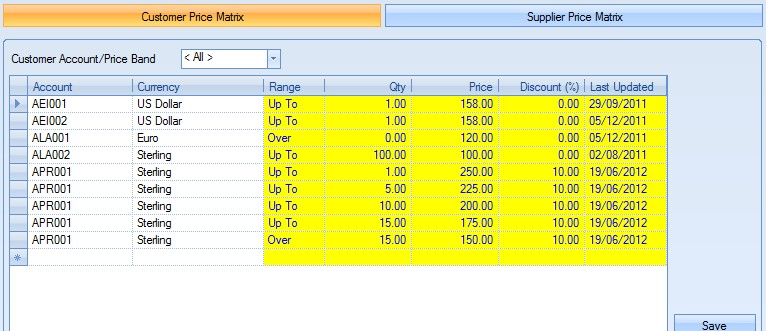

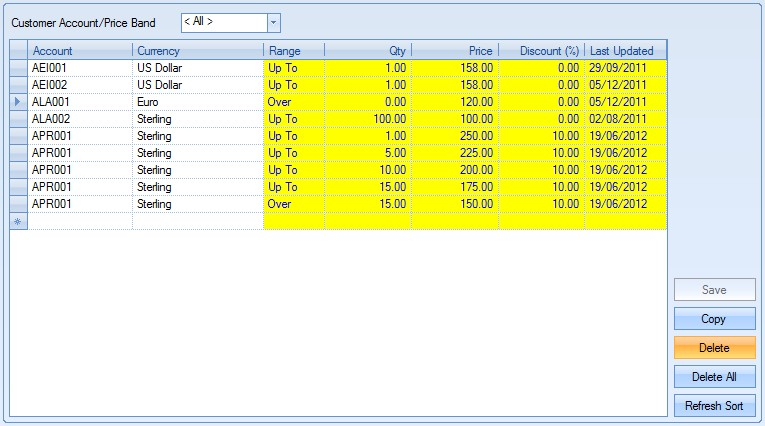

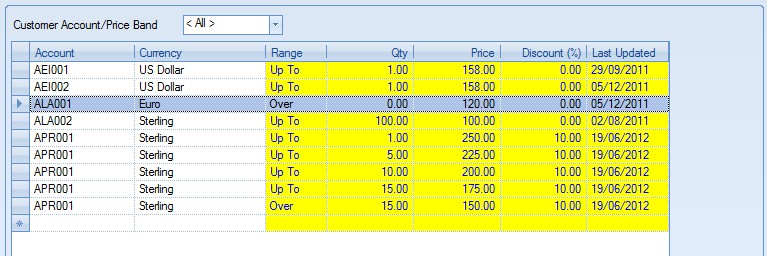

| Qty/Price Matrix | This option allows the user to record price breaks against different quantities. |

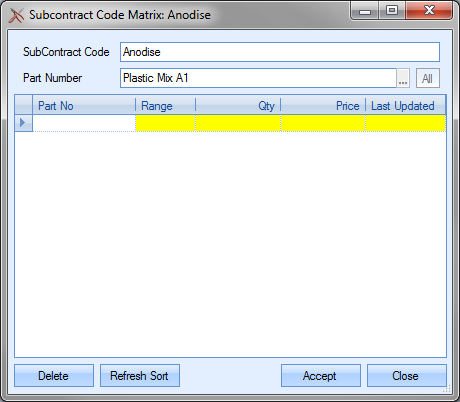

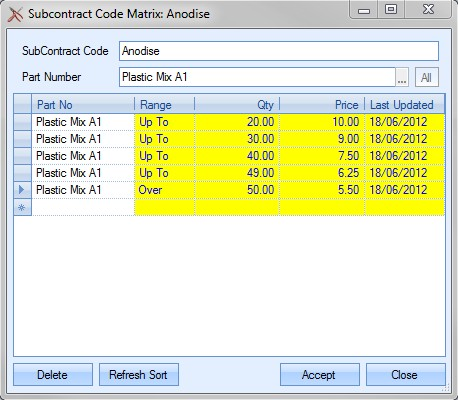

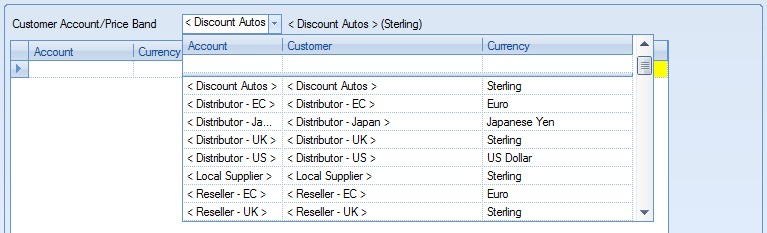

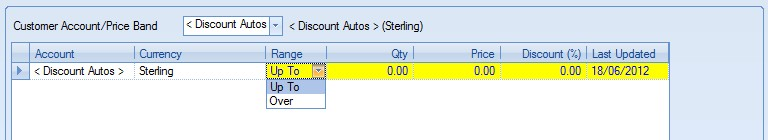

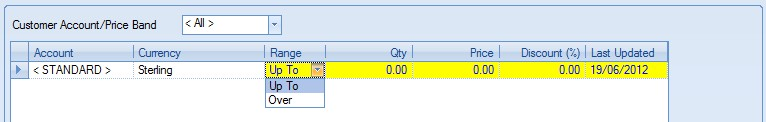

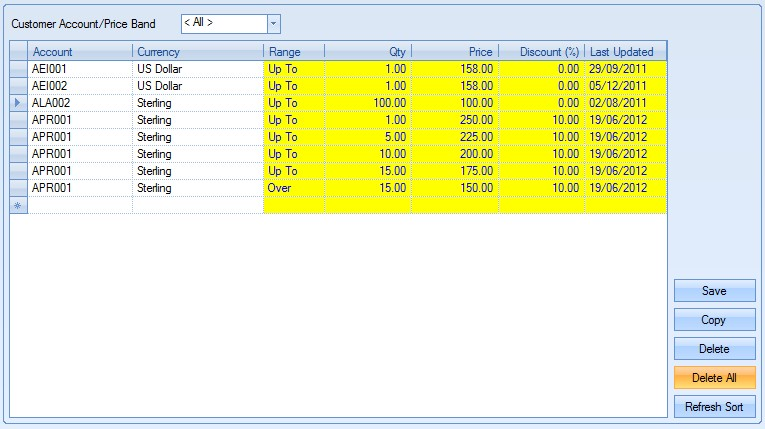

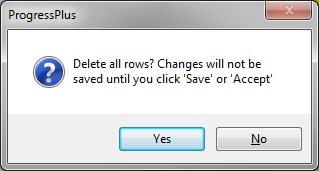

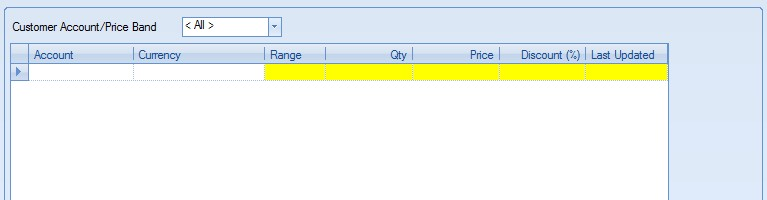

The user can add the price breaks for this sub-contract operation by clicking on the VIEW MATRIX option. The user will then be presented with the following screen.

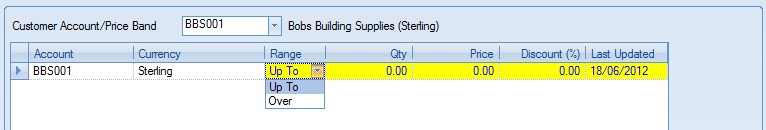

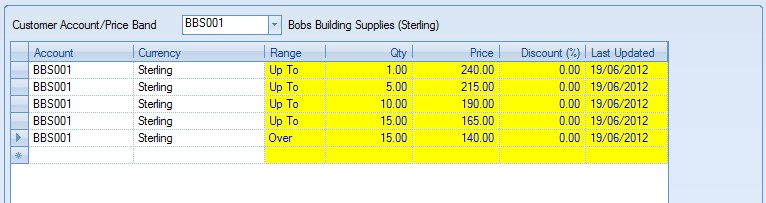

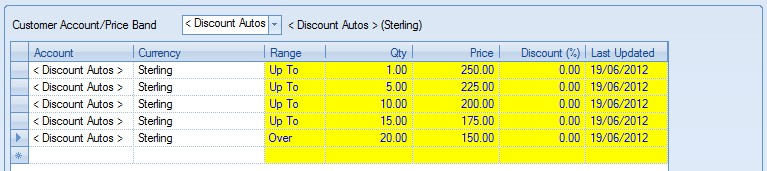

The user may then click onto the Range field (in yellow) and choose either “Over” or “Up To”. A “Qty” and “Price” each may also be entered into the appropriate yellow fields. An example is shown below.

e.g. for a Qty (quantity) “Up To” 10, the Price is £10.00 each,

for a Qty (quantity) “Up To” 20, the Price is £9.00 each, etc

until a maximum quantity is reached e.g. 49. The user may then choose the “Over” option from the Range field i.e. any quantity required greater than 49 would cost £5.50 as shown in the next screen.

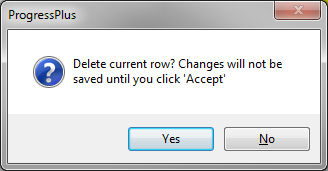

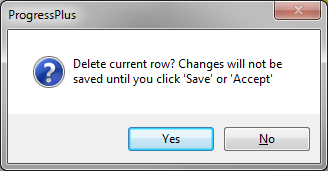

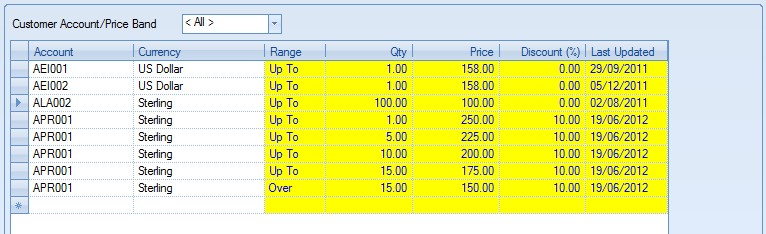

If any price breaks are entered in error, the user can delete them by highlighting the erroneous entry and click the DELETE option. The user will be prompted to confirm the deletion.

Clicking YES will complete the deletion. Clicking NO will return the user to the Matrix screen.

The REFRESH SORT option allows the user to refresh the entries by quantity sequence. This can be used after changes have been made to reorder the information entered.

![]()

Once the user has made the required changes, they can save the changes by clicking on the ACCEPT option. The costing of the sub-contract operation would then use the price matrix details entered for calculating the planned costs associated with the sub-contract operation.

| Once all the details have been entered, the user can save the new operation by clicking the ACCEPT option. The user will be returned to the routing screen with the new sub-contract operation now displayed in the operations list. |

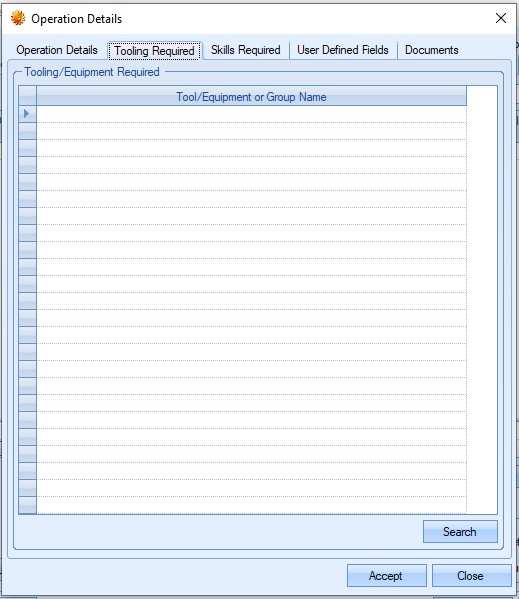

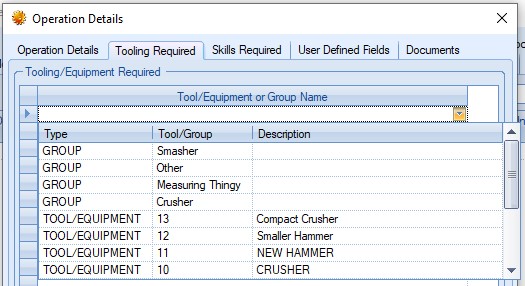

Tooling Required

NOTE: This section is only available if Progress has the additional Quality module.

This section allows the user to specify specific tooling required for the operation. The user can select the tools/equipment from the list set up in the Quality > Tooling & Equipment section.

The user can select the tools required for the operation using the drop-down list. The user can select a specific tool or a group of tools for the operation.

Once the required tools/tool groups are selected, the user can save the information by clicking ACCEPT. This information will default to any work orders that are created for the part number and feed into the Tooling & Equipment Issue/Return functionality that's available.

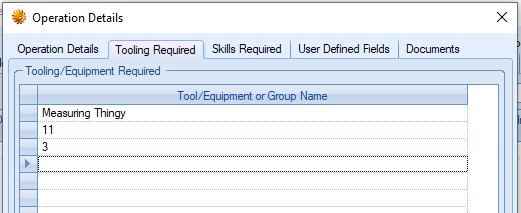

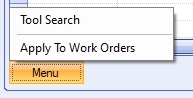

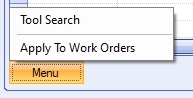

The user also has the ability to select multiple tooling for addition to the routing operation. This can be done via the MENU > TOOL SEARCH option.

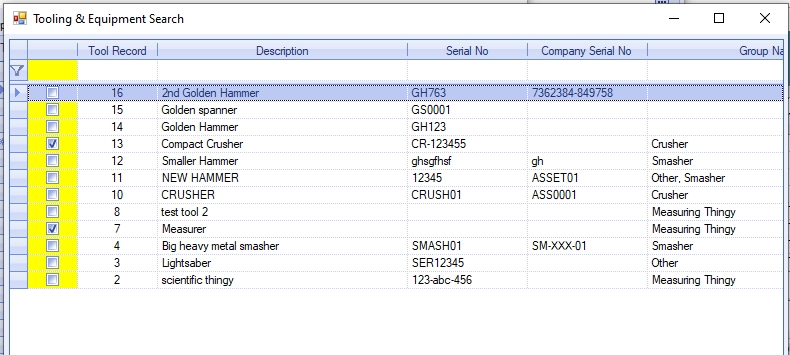

Selecting this option will present the user with a list of all tools to select from.

The user can tick multiple tools to be added from the list. Clicking ACCEPT will add all the selected tooling to the routing operation.

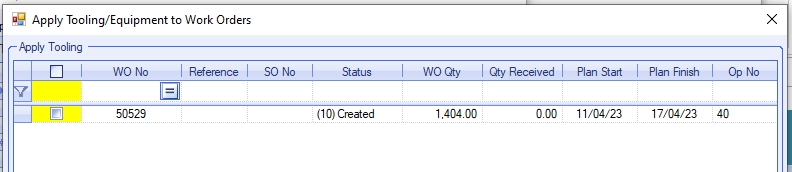

The user also has the ability to push any changes to the routing operation's tooling to any existing work orders. This can be done via the MENU > APPLY TO WORK ORDERS option.

Selecting this option will display a list of all work orders for the current part number.

Again, the user can tick individual work orders, or click the column heading to select all work orders listed. Clicking ACCEPT will update all the selected work orders with the new part routing tooling.

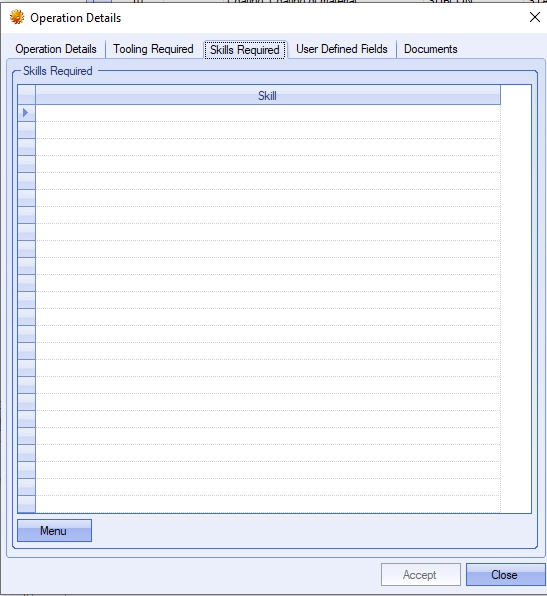

Skills Required

This section allows the user to specify any particular employee skills required for the operation. Setting skills against the operation ensure only employees with the correct skills can carry out the operation.

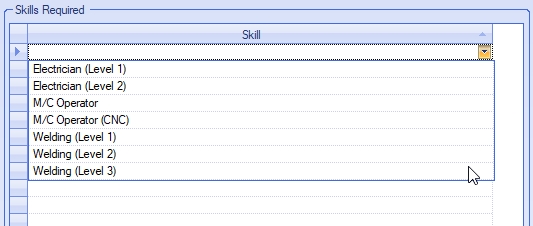

Skills can be added manually to the operation using the drop-down list.

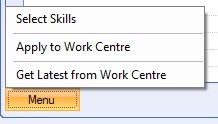

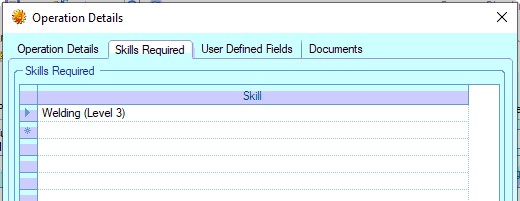

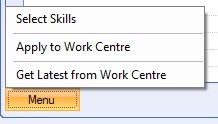

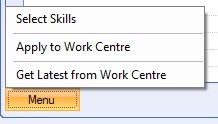

They can also be added via the MENU > SELECT SKILLS option.

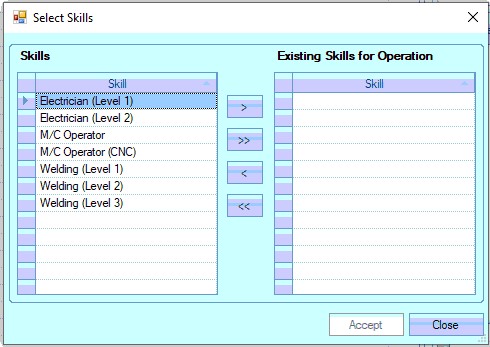

This presents the user with a list of all skills and allows them to be added/removed individually or as multiples, using the single and double arrows respectively.

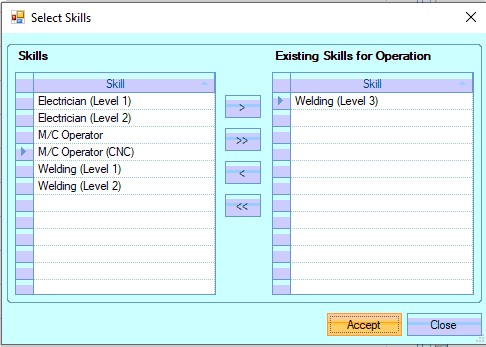

Once selected, the user can click ACCEPT to add the selected skills to the routing operation.

Once all skills have been added, clicking ACCEPT will save the skills. These skills will then become a default requirement of the employee to ensure only the correct employees carry out the operation.

Updating Master Work Centre Skills

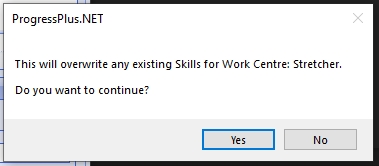

The user also has an option to update the master work centre with the currently selected skills. This can be useful if the requirements have been update on the part and are now to be the default set of skills for the work centre. THis can be done via the MENU > APPLY TO WORK CENTRE option.

Selecting this, the user will be asked to confirm the updating of the work centre.

Clicking YES will proceed to update the master work centre. Clicking NO will return the user to the part routing.

Updating Existing Work Orders

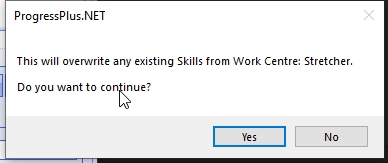

The user also has an option to update the current operation with the part routing operation work centre's current skills. This is useful if the master work centre has been updated and the current part also needs to be update. This can be done via the MENU > GET LATEST FROM WORK CENTRE option.

Clicking this option will prompt the user to confirm the updating of the skills from the master work centre.

Selecting YES will update the current part routing operation with the latest skills set in the master work centre record. Selecting NO will stop the uipdate and return the user to the operation skills.

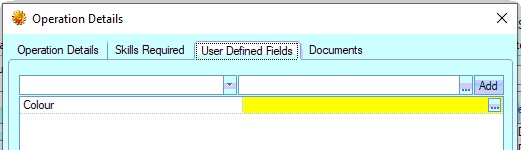

User Defined Fields

This section allows completion of any user-defined fields (UDFs) set up against routing operation.

For more information on setting up UDFs, please refer to the Maintenance > User Defined Fields section of the manual.

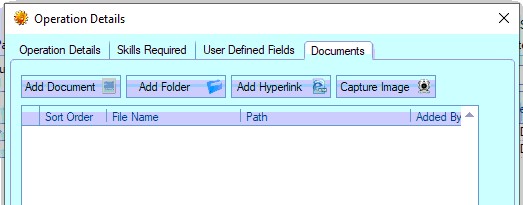

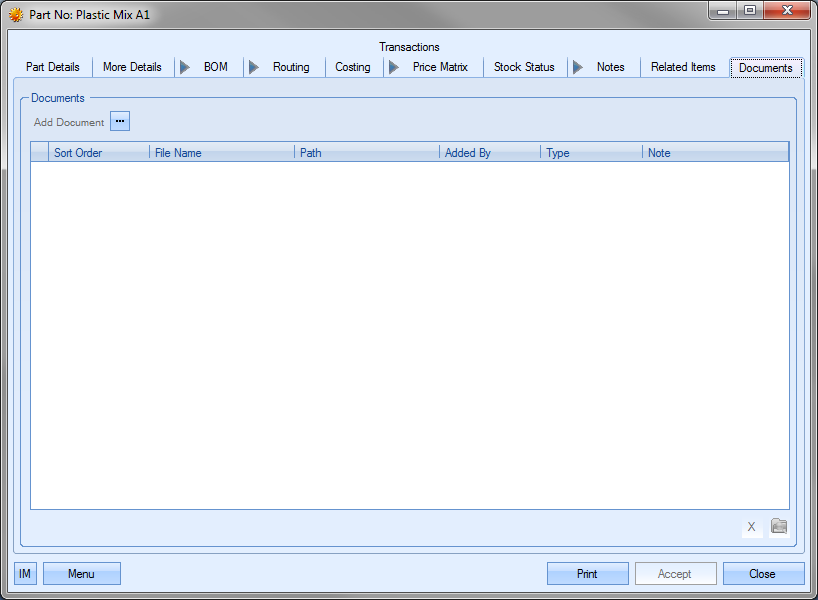

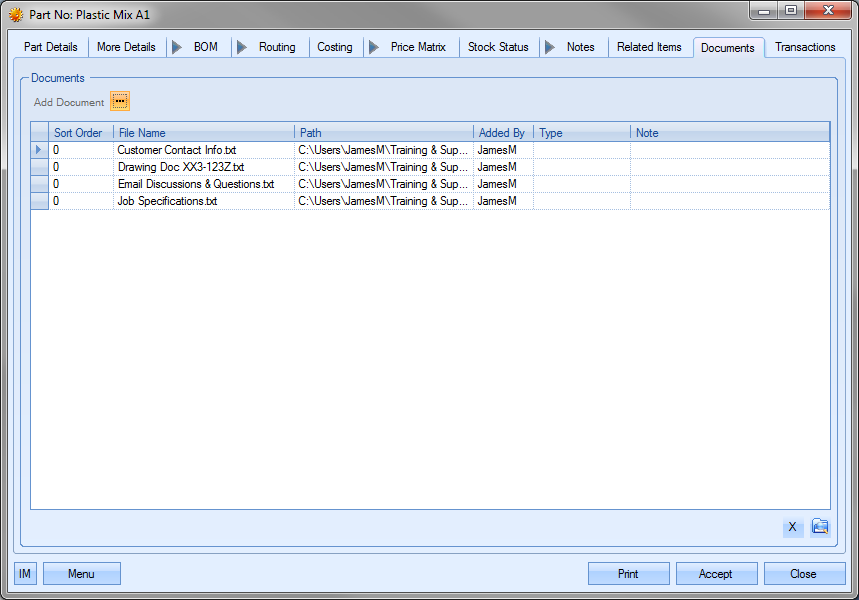

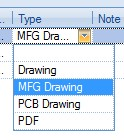

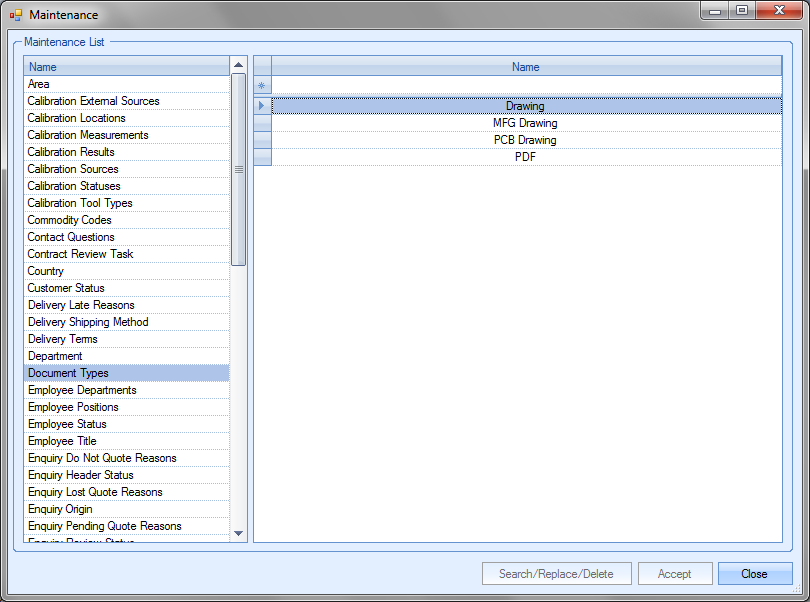

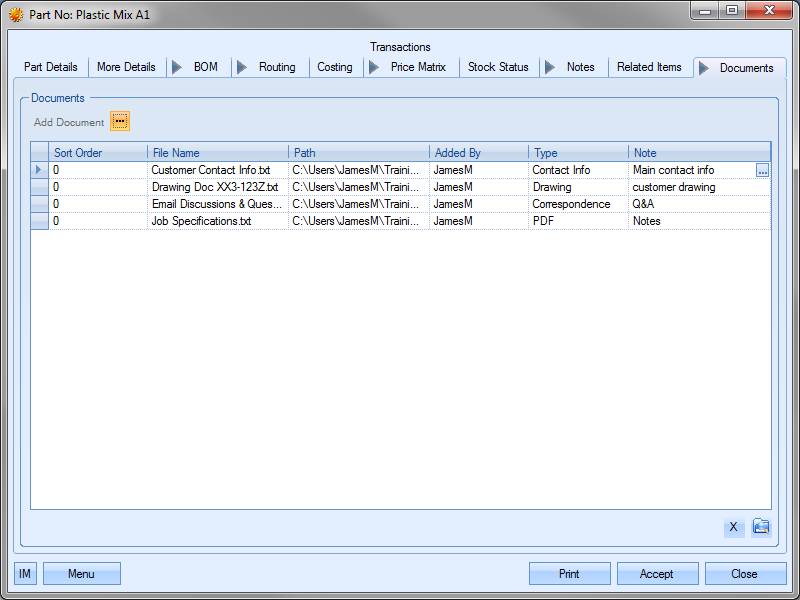

Documents

This section allows the user to add documents, files, images, etc. to the routing operation.

The options allow the user to add individual documents, specific folders, hyperlinks or captured images on suitable devices to the operation. Once all items have been added, the user should click ACCEPT to save them.

NOTE: To ensure all employees are able to access the attached items, the user should ensure these are saved to a suitable shared location, have internet access, etc. otherwise the items might not be accessible.

Editing Existing Routing Operations

The user can edit any existing operations by clicking on the EDIT OP option.

![]()

This presents the user with the operation details screen as described above. The user can then make any changes required. Once the changes have been made the user can click the ACCEPT option to save the changes.

Deleting Routing Operations

The user can remove any existing operations from the routing by highlighting the operation to be removed and clicking on the DELETE OP. This will remove the operation from the routing list.

![]()

Once any changes have been made to the routing screen, the user can click the ACCEPT option to save the changes made.

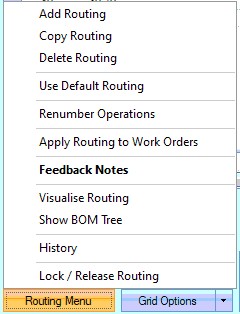

Routing Management

Manufactured part’s routings can be created, copied, amended or deleted from this screen using the various options. The ROUTING MENU option at the bottom left of the screen contains several options to allow the user to create new routings, copy existing routings from other manufactured parts, set the routing to the system default routing or delete existing routings as well as renumber existing routing operations.

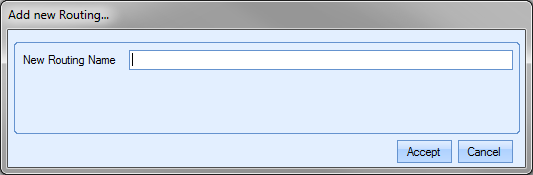

Add Routing

The user can create additional routings for the selected part by clicking on the ADD ROUTING option. When selected, the user is asked to provide a name for the new routing.

The name provided can be anything, but it’s often used to indicate the purpose of the additional routing; a customer reference or reference the reason for the alternative, i.e. Repair, or reference to the material that is used in the manufacturing process. Once entered, the routing screen is updated with the new routing name which, by default, will be blank. The user can then add the routing operations required. The new routing name can also be seen in the CURRENT ROUTING drop-down list at the top of the screen too.

To add new operations to a routing, the user can click on the ADD NEW OP option immediately under the grid to add new operations. For more information on adding operations to a routing, please refer to the Routing Maintenance section of this manual.

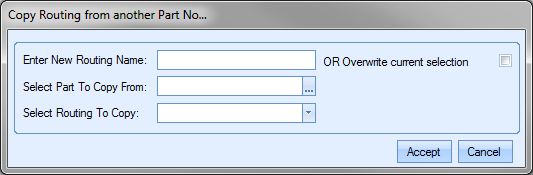

Copy Routing

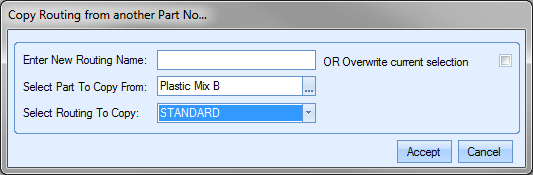

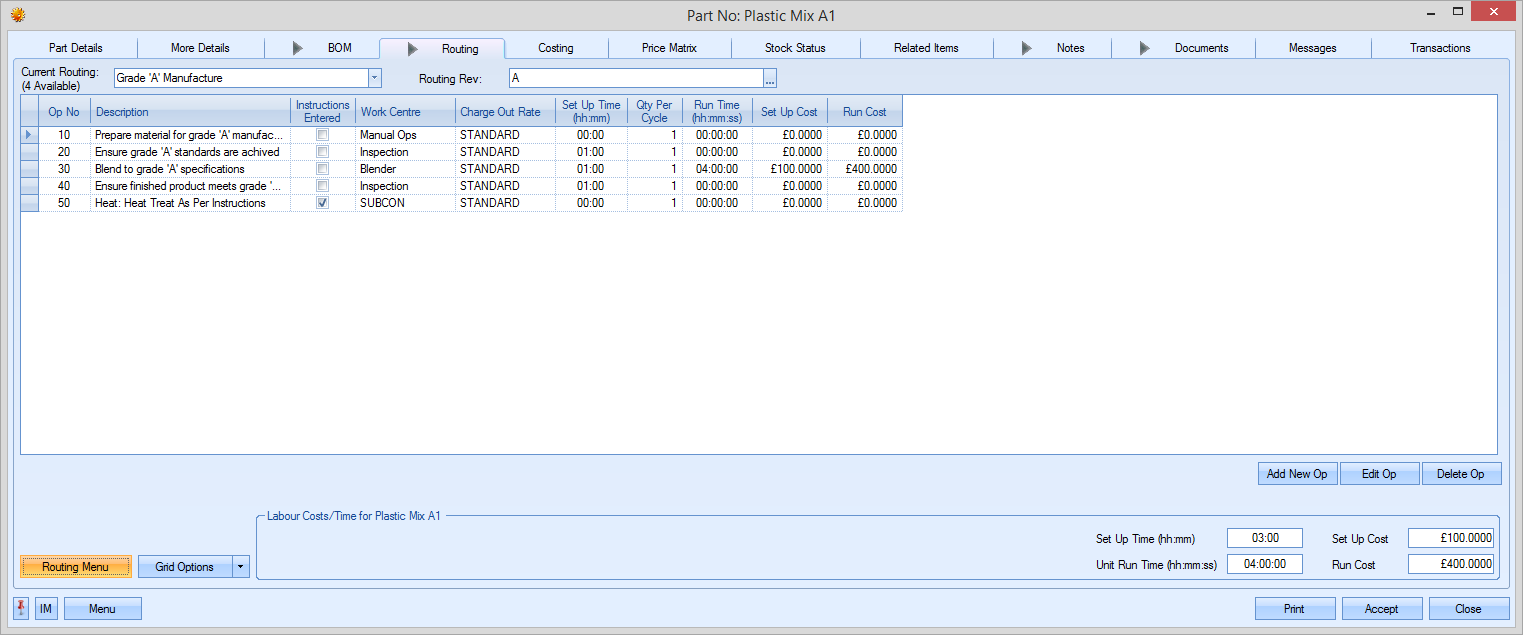

This option allows the user to copy an existing routing from another part in Progress. This is particularly useful when large-scale routings are used and there are similarities between manufactured items. When the user selects the COPY ROUTING option, the following screen is displayed.

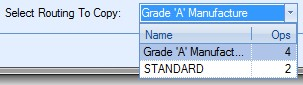

The user can choose to create a new routing by entering a name for the new routing or overwrite the currently selected routing by ticking the overwrite option. The user must then select the part number that has the required routing. They can do this by clicking on the ![]() option at the end of the field. This will present the user with the Inventory Search window. The user can then search for the part number required.

option at the end of the field. This will present the user with the Inventory Search window. The user can then search for the part number required.

Once the user has identified the part required, clicking the SELECT option will return the part to the COPY ROUTING screen.

Finally, the user can select the routing required using the drop-down list.

Once selected, clicking the ACCEPT option prompt the user to confirm the change before pulling the BOM details through to the BOM screen.

The user can now make additional changes to the routing operations to fine tune if required. Once finalised, the user must click the ACCEPT option to save the new routing details. The new routing is now ready for use.

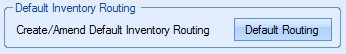

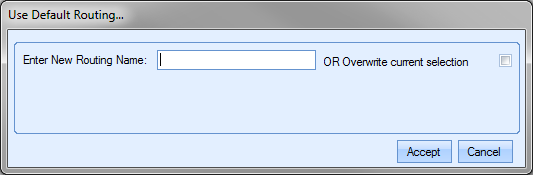

Use Default

This option allows the user to update the current routing to that of the system default routing. If all manufactured items have similar operations or share common operations, a default routing incorporating these can be created to provide the user a quick means of adding these operations into routings. A default routing is created within the system options under the Miscellaneous & Inventory options.

For more information on creating a default routing, please refer to the Default Inventory Routing section of the system options.

When the user clicks on the USE DEFAULT option, they are prompted to confirm whether a new routing is being created or whether they are updating the currently selected routing.

Once the user had decided how they wish to proceed, clicking the ACCEPT option, the routing screen is updated. If a new routing was entered, the routing screen displays the new routing with the default routing operations listed. If the user chose to overwrite the existing routing, the existing routing is updated to show the default routing operations.

The user can now make any additional changes to suit their requirements or simply click the ACCEPT option to save the routing operations.

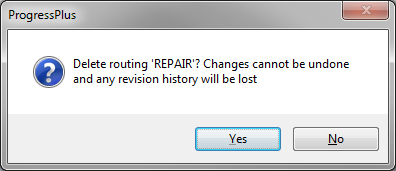

Delete Routing

This option allows the user to delete existing routings from the manufactured part. This option could be used if older routings have become obsolete and the user chooses to remove them from the part. To delete a routing, the user must firstly select the routing from the drop-down menu at the top.

Once the routing to be deleted has been selected, the user can click the DELETE ROUTING option. The user will be prompted to confirm the deletion.

Once the user confirms, the routing information will be cleared from the screen and the part will default to the <NO ROUTING> option.

The user can now select the routing the wish to use going forward from the drop-down list at the top of the screen or create a new routing if required. Again, clicking the ACCEPT option will save the changes made.

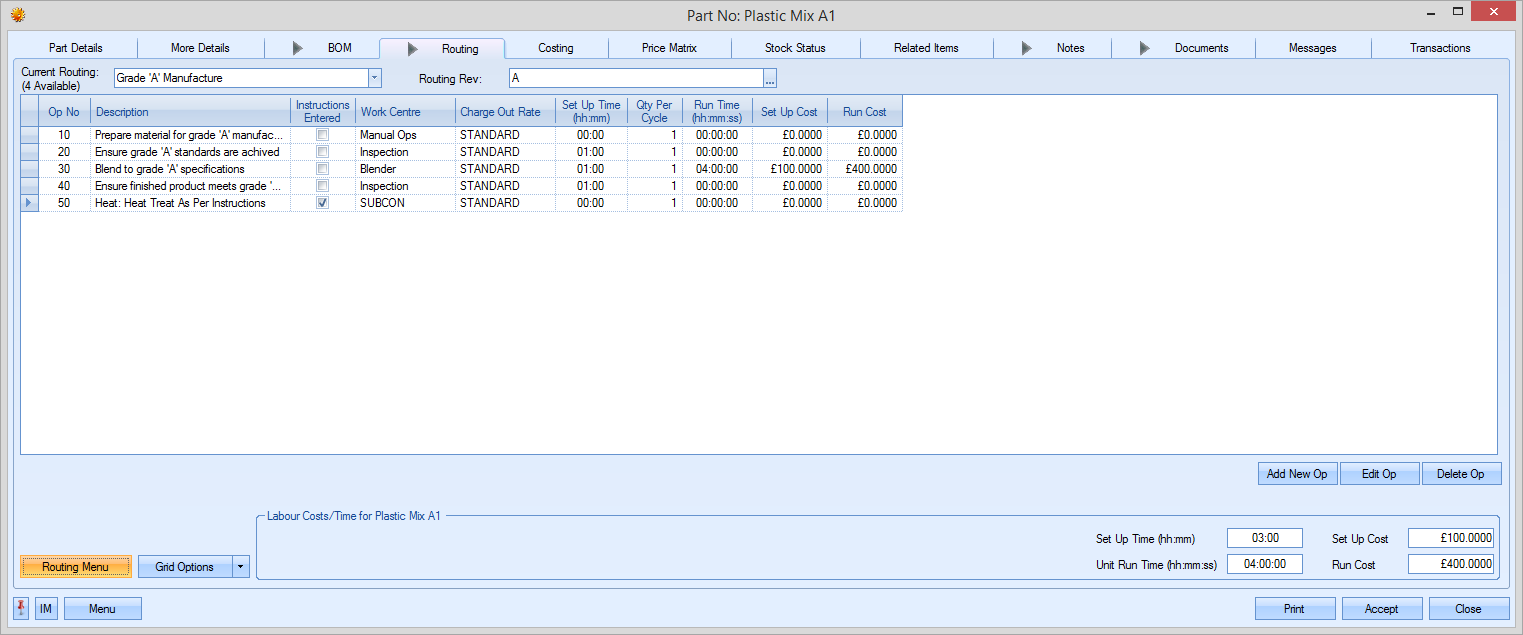

Renumbering Operations

The user has the option of "tidying up" the operation numbers of the selected routing. This option resets the listed operations in a 10, 20, 30... sequence. This can be useful if the selected routing has been edited to add new operations in between existing operations.

Selecting the RENUMBER OPERATIONS option results in the following:

Apply Routing to Work Orders

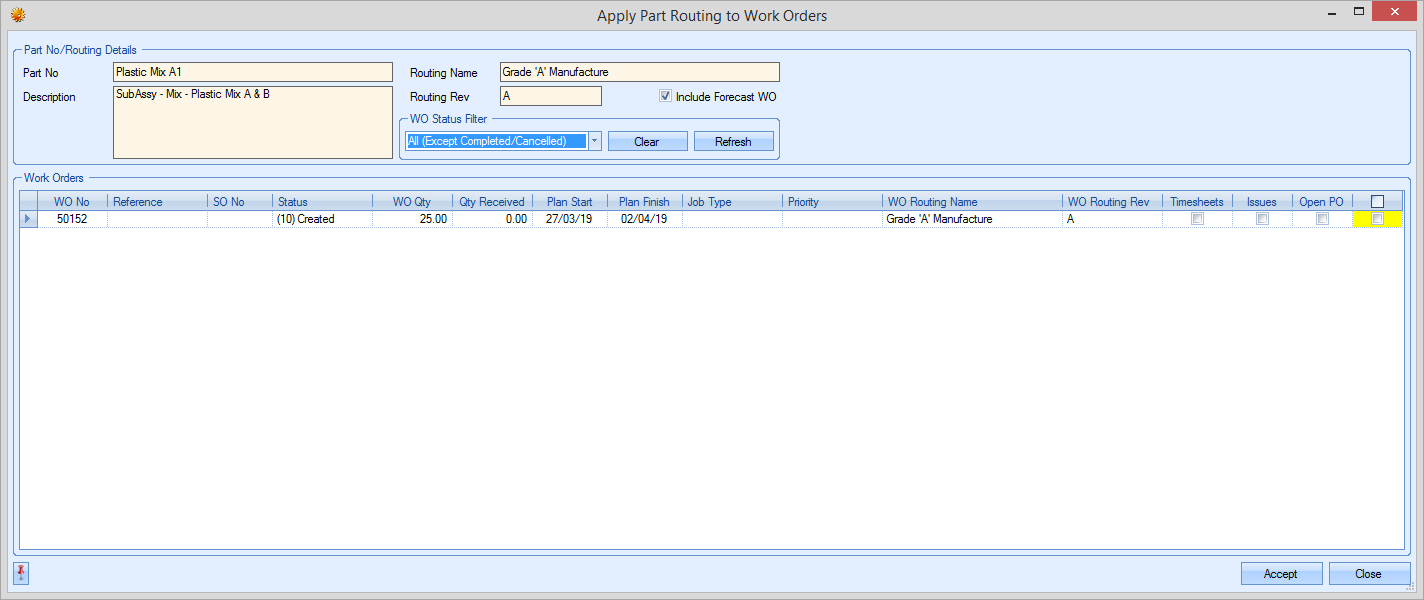

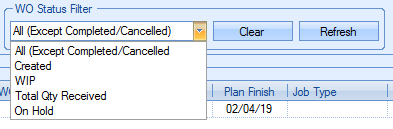

This option allows the user to push amendments to routings to existing WOs. The user will be prompted to select the WOs to be updated as shown below.

The user can use the status filter to narrow down the list of WOs that are to be updated. By default, the system will suggest all WOs (except cancelled or complete WOs), although this can be changed. Clicking REFRESH will update the list of WOs shown.

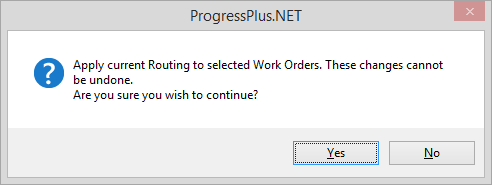

Once the user has selected the WOs to be updated, clicking ACCEPT will prompt the user to confirm the update before updating the selected WOs.

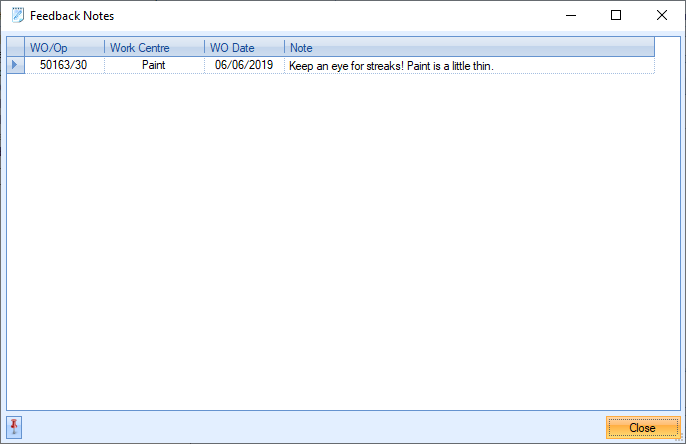

Feedback Notes

This option displays any feedback notes that have been recorded against any operations on work orders for the current part. This option is only available if feedback notes have been entered against any WO operation and provides a convenient method of seeing all these notes together.

Show BOM Tree

This option allows the user to view operations of sub-assembly parts contained in the BOM without the need to drill into the sub-assembly part itself. This option adds a similar tree view to the BOM tab as shown below.

Each manufactured part on the BOM tree is highlighted. Selecting any of these will result in the routing ops for the selected part being displayed on screen for the user to see as shown below.

Unticking this option will show only the immediate operations of the current part number.

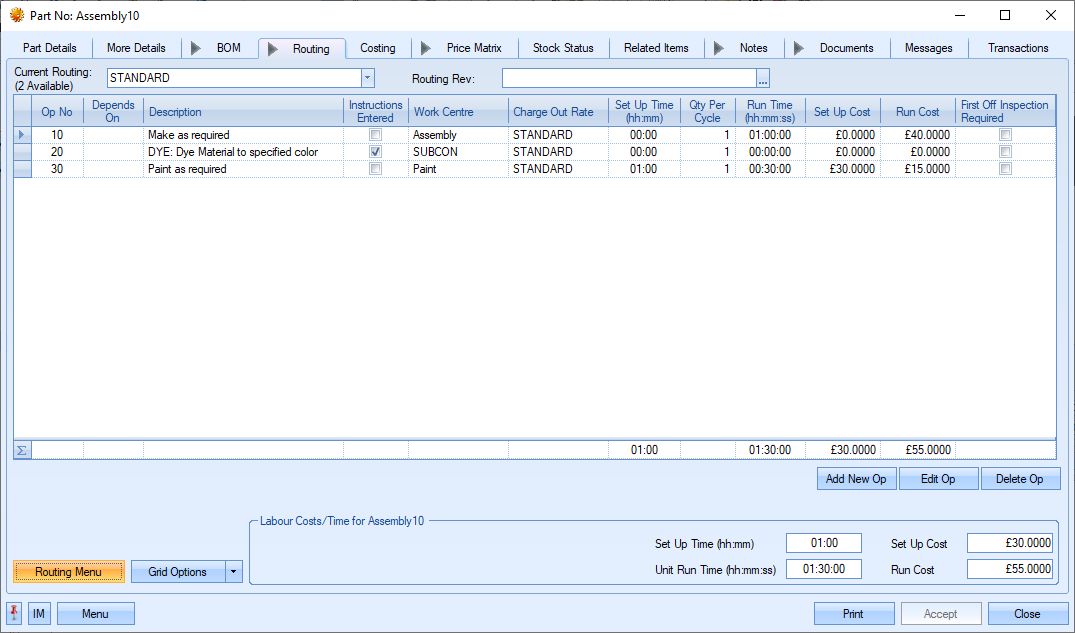

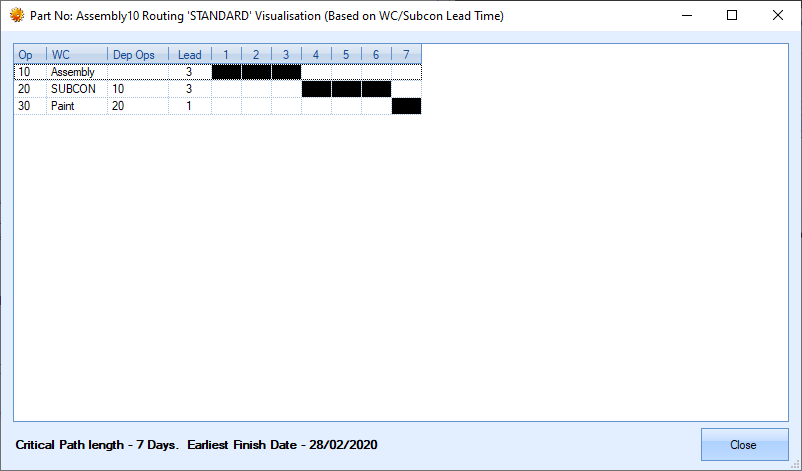

Visualise Routing

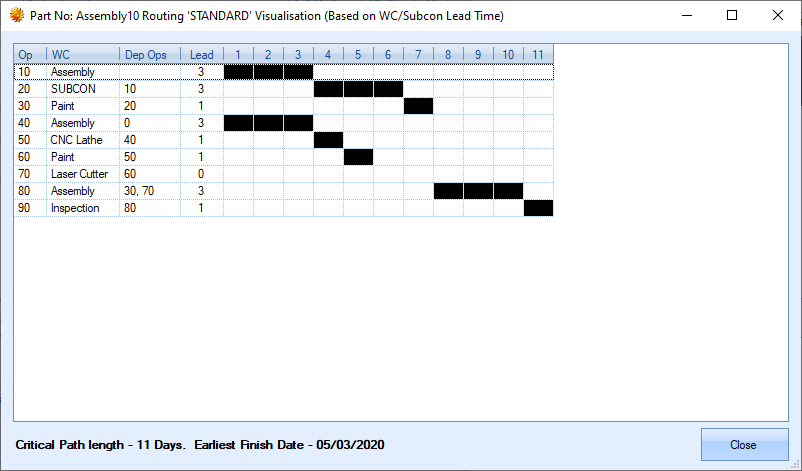

This option generates a visual representation of the current part's immediate routing. Using the work centre and subcontract lead times, the user is presented with a screen showing the operations and how they interact with each other. Primarily designed for use when using parallel operations, the screen shows which operations are dependant on others as well as informs the user of the total number of days to complete and the earliest finish date based on the current date. The screen shot below shows an example of a standard sequential routing where each operation is dependant on the previous operation.

Using parallel operations allows multiple operations to run along side each other. This is often used when two or more aspects of a job can be worked on at the same time. An example of this is shown in the screen shot below.

As can be seen above, operations 10 and 40 can start at the same time with both processes having their own dependent operations, however, operation 80 requires all these previous operations to be complete before it can start.

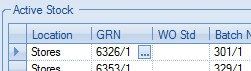

History

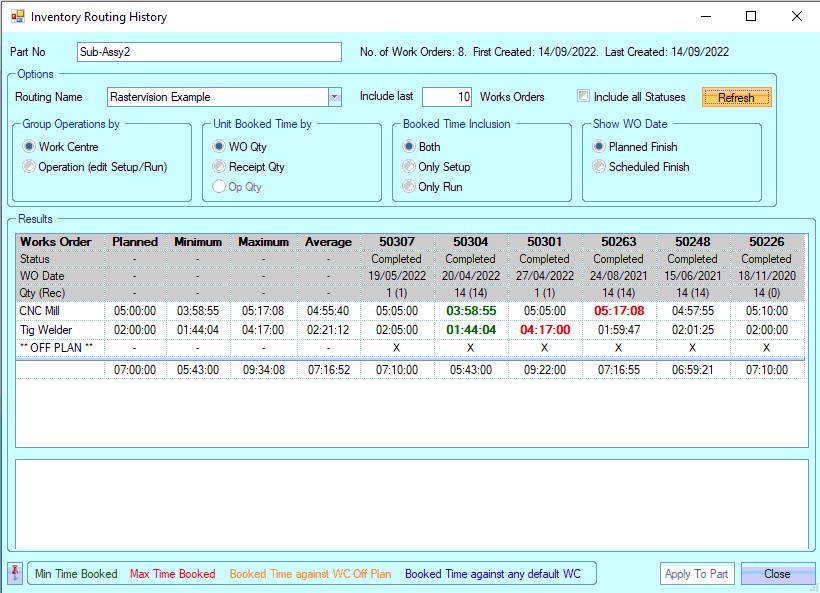

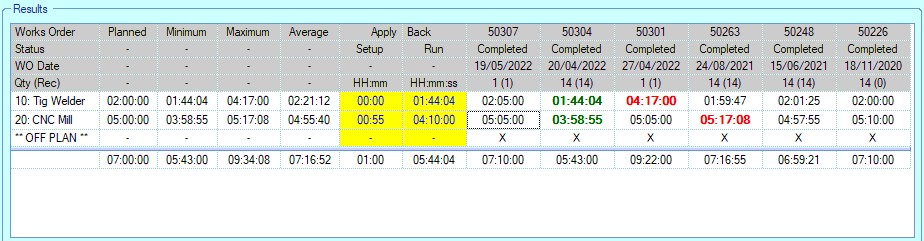

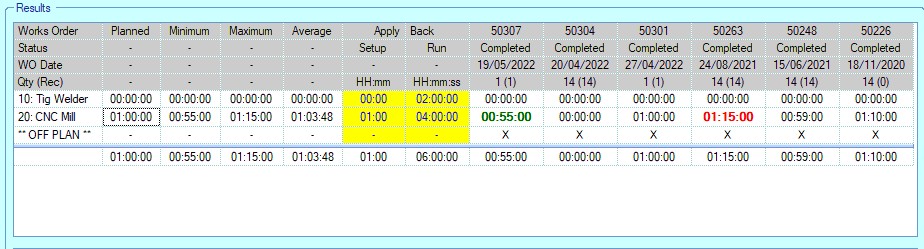

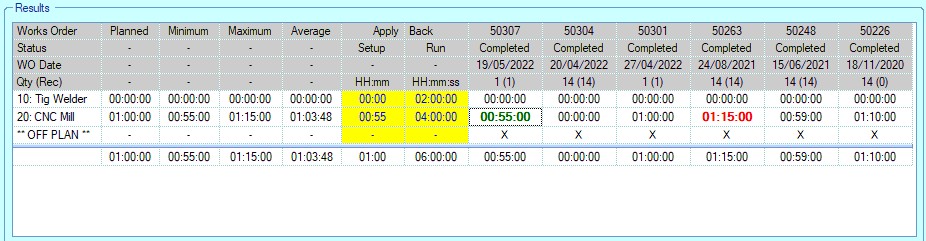

This option shows a historical summary of the current part and the selected routing.

The user can see the history of the part and its routings across a number of work orders, including the individual times against each of the planned operations. By default, only completed work orders are shown, although the user can tick the INCLUDE ALL STATUSES option if they wish to include work orders at other statuses.

Any time recorded against work centres/operations that are not part of the planned routing is shown as ** OFF PLAN **. Highlighting any cell also shows any associated timesheets at the bottom of the screen so the user can see where this information comes from.

The screen also summarises the maximum, minimum and average times across the operations or work centres. The coloured legend at the bottom of the screen indicates what each of the highlighted colours represent.

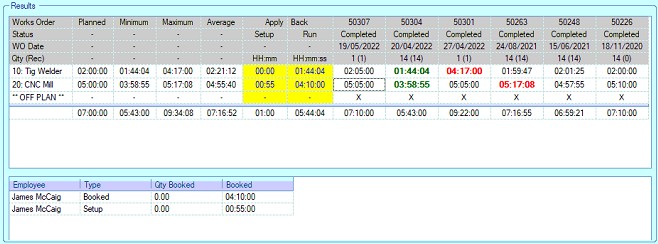

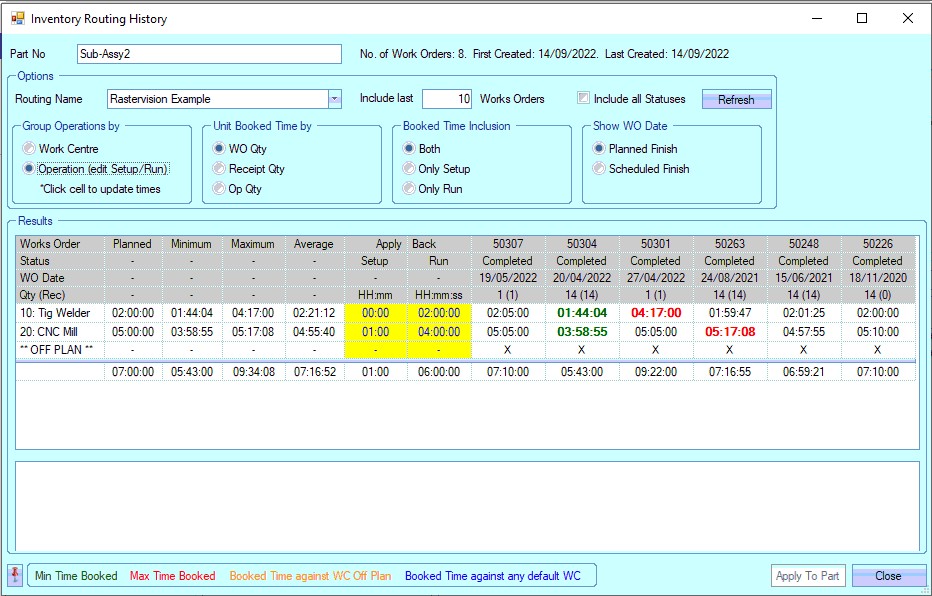

The user has a variety of options available to them in how they wish to view this info; it can be viewed by work centre or by operation (shown below), but can also be restricted to setup time or run time if necessary.

When viewing the routing history by operation, the user can also update the existing planned routing based on the previously recorded times. The APPLY BACK values are those that will be applied to the existing routing. These values can be manually set, or set based on selection of previous times.

The user can set the APPLY BACK times based on previous work order performance by selecting the time shown against any previous work order.

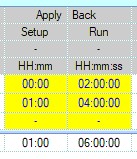

(BEFORE: APPLY BACK shows the existing planned routing times)

(AFTER: APPLY BACK shows the new times after selecting the 50304/10 time and the 50307/20 time)

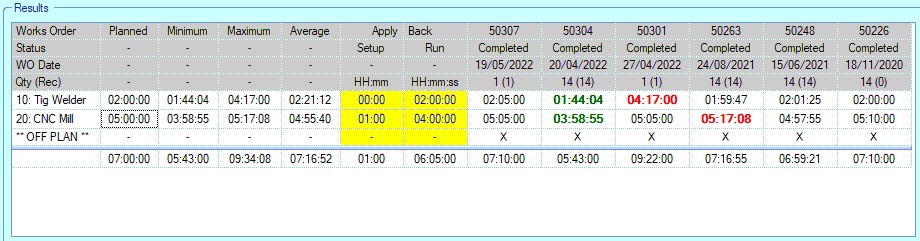

If the user is only looking at set up or run time (Booked Time Inclusion options), the same can be applied, but only thee selected type's times will be selected and updated. The example below shows the result when only SETUP TIME is being considered.

(BEFORE: APPLY BACK shows the existing planned routing times)

(AFTER: APPLY BACK shows the new Op 20 set up time after selecting the 50307/20 time)

Once the new times have been set, the user can update the existing planned routing with the new times by clicking the APPLY TO PART option at the bottom of the screen. Once done, the planned routing will reflect the selected times.

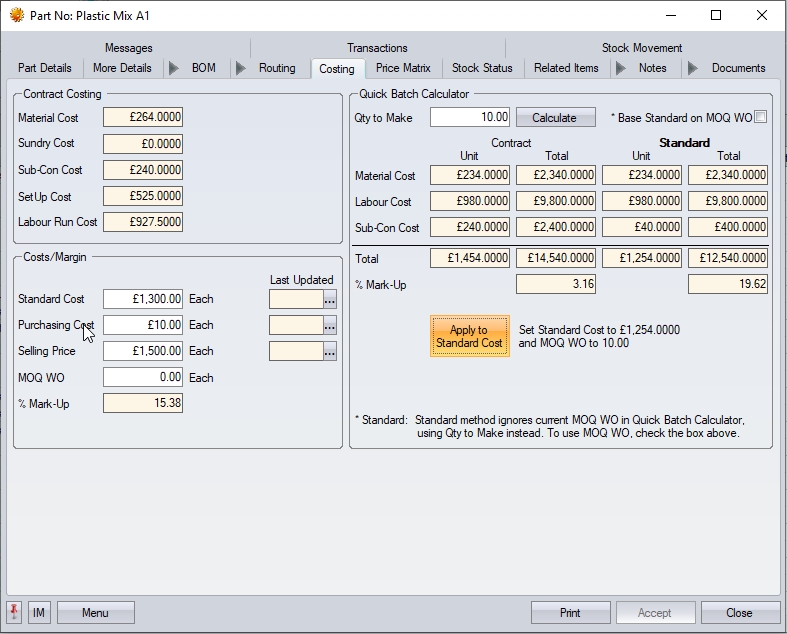

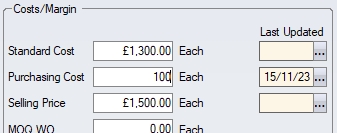

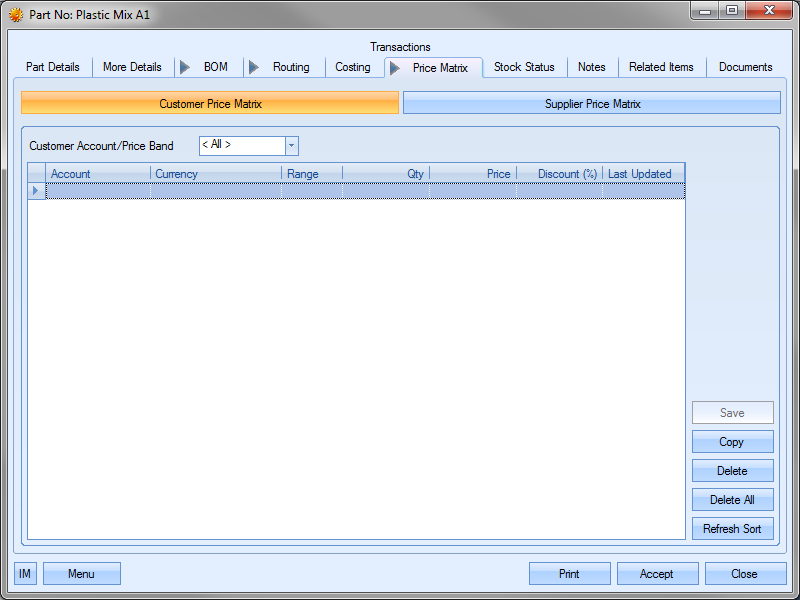

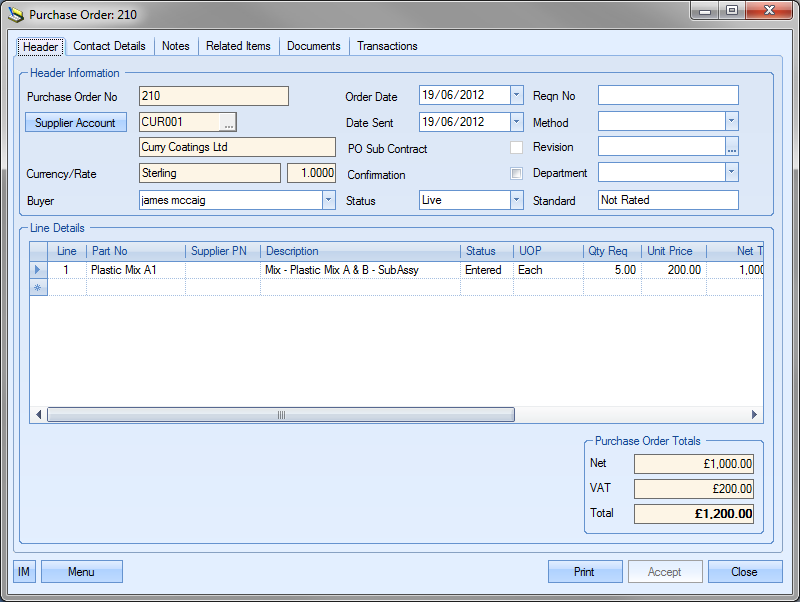

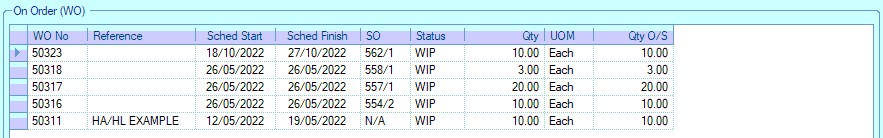

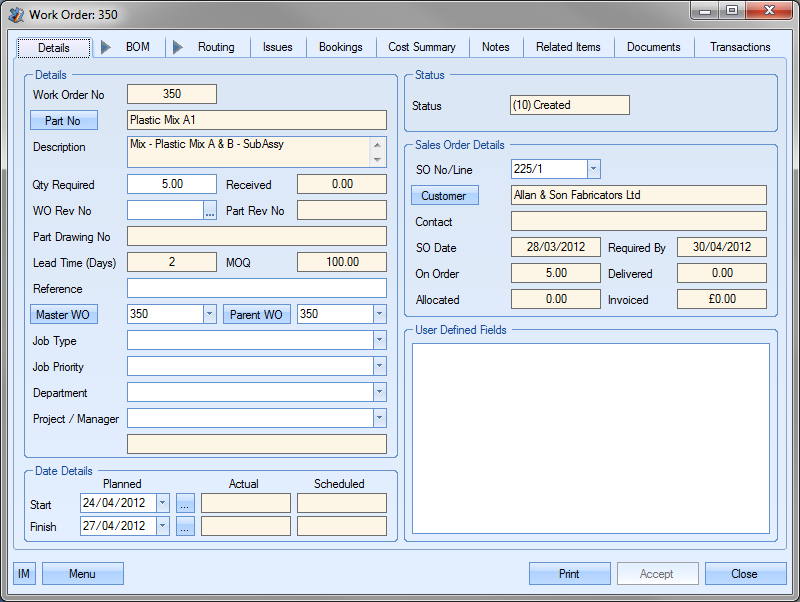

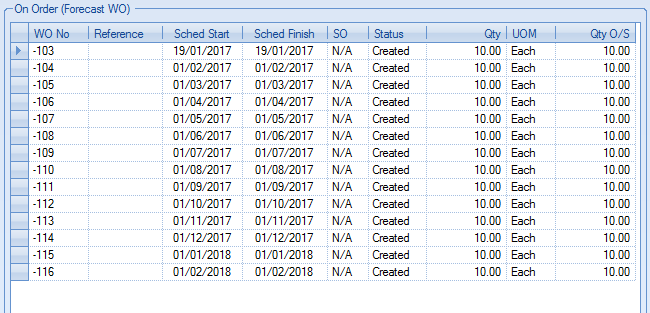

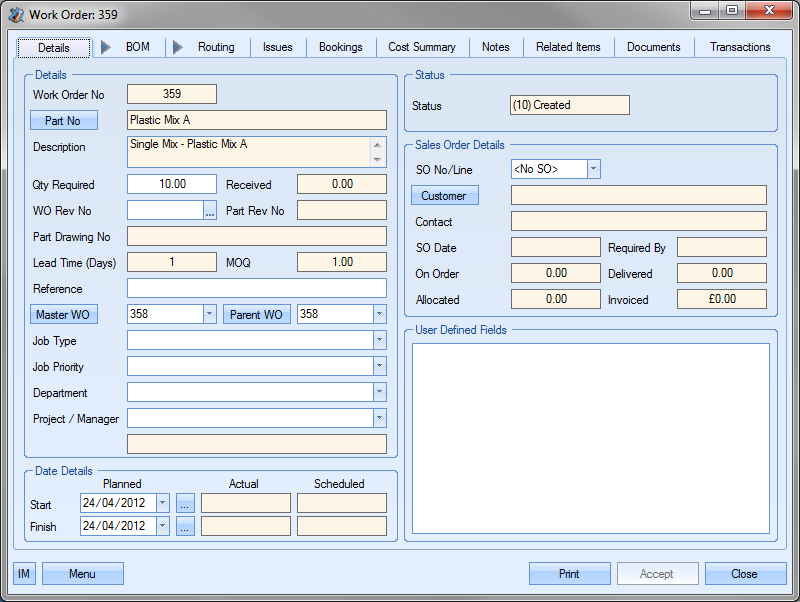

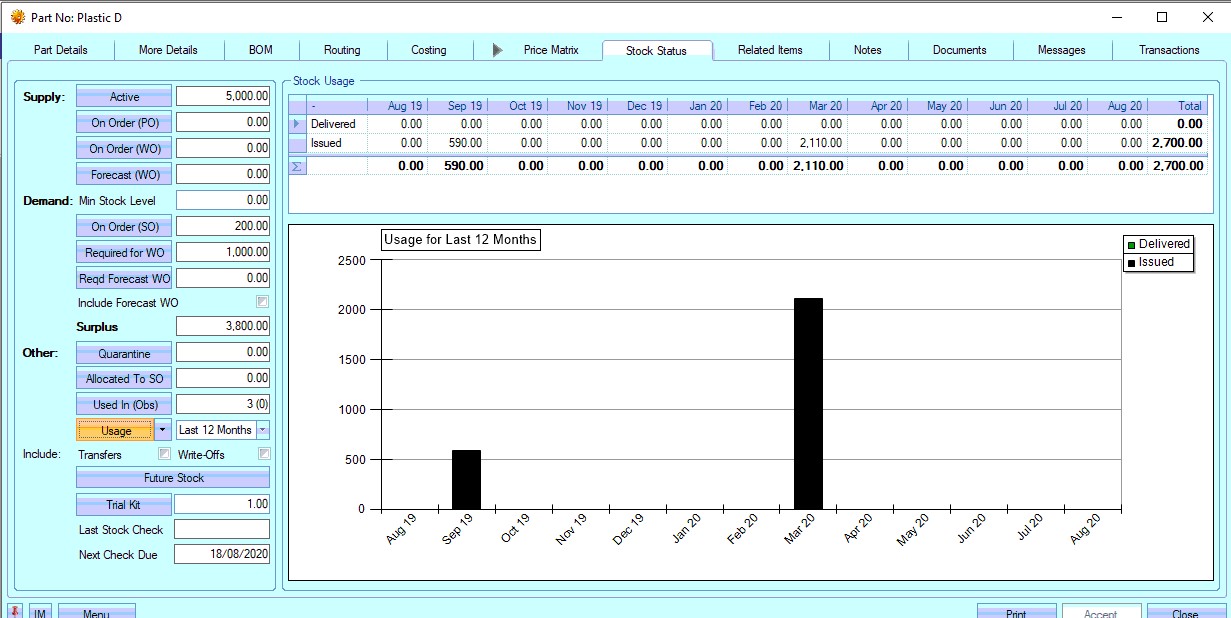

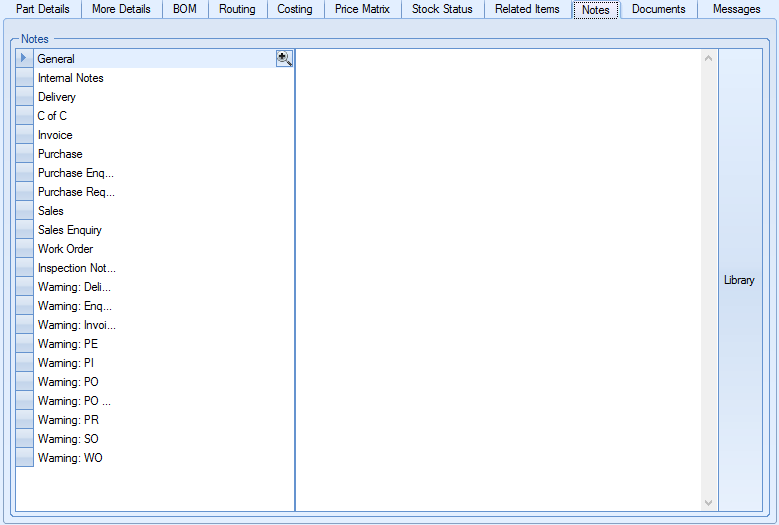

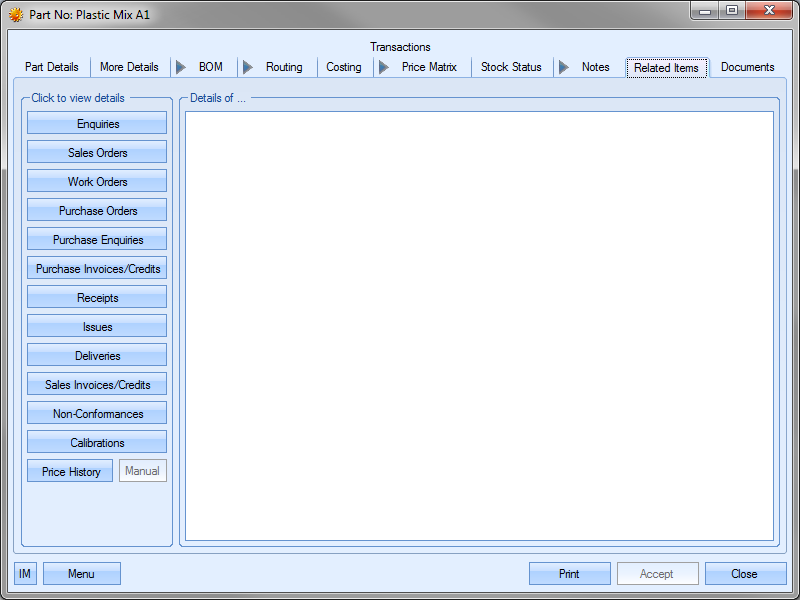

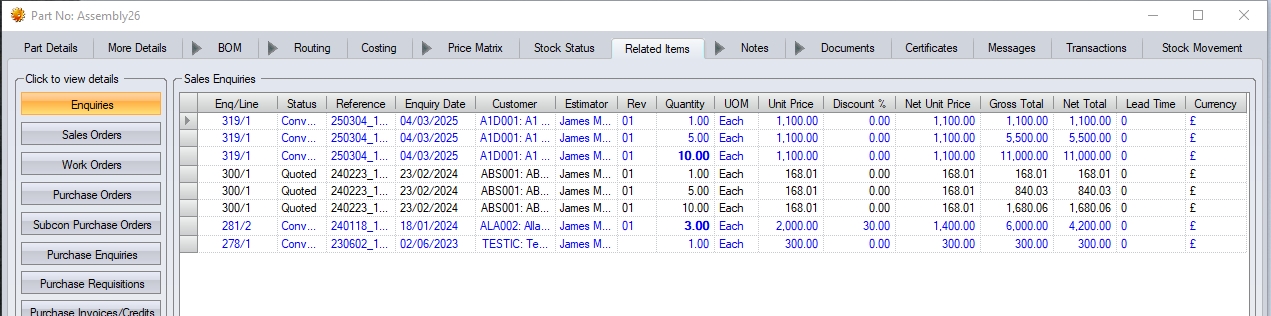

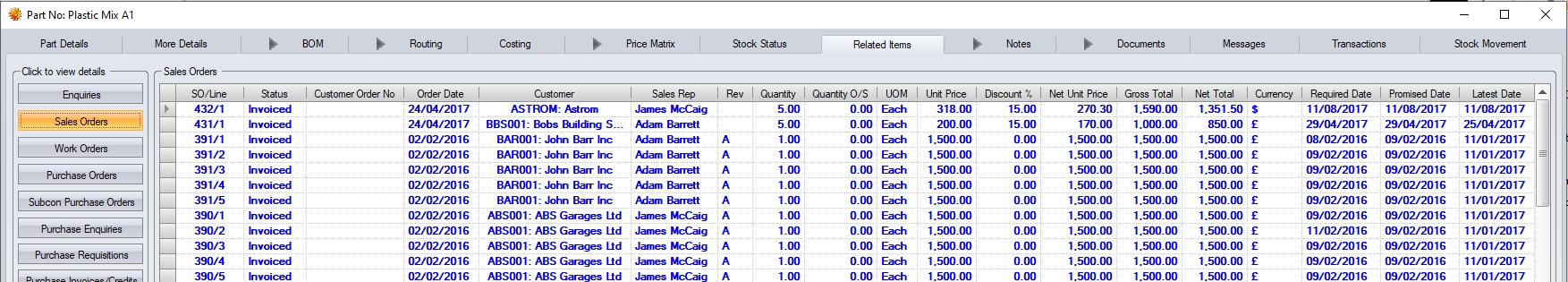

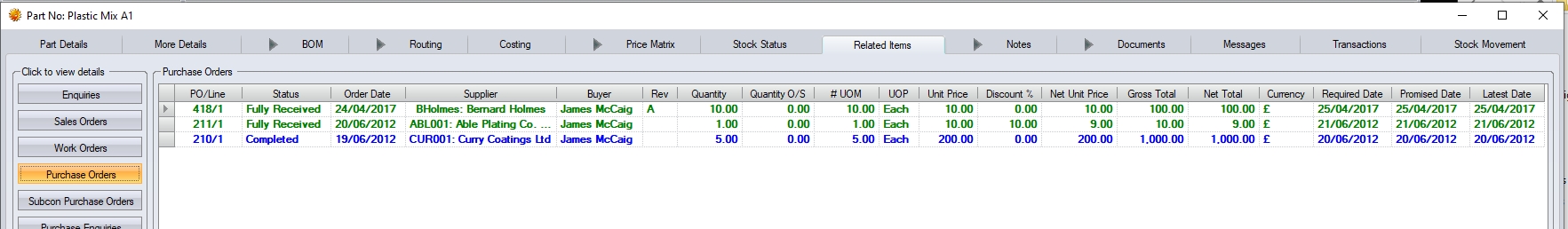

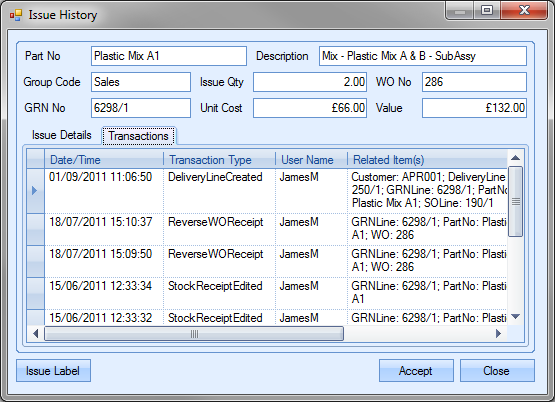

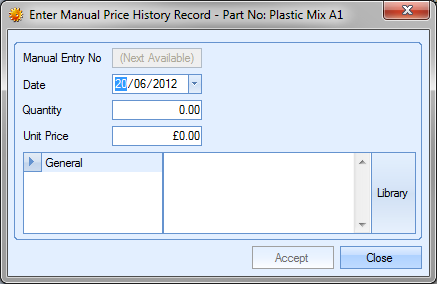

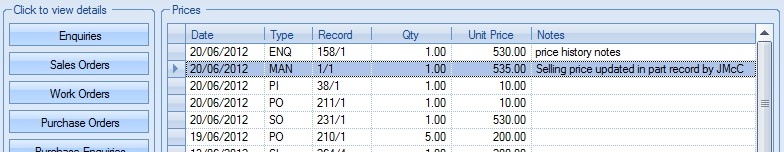

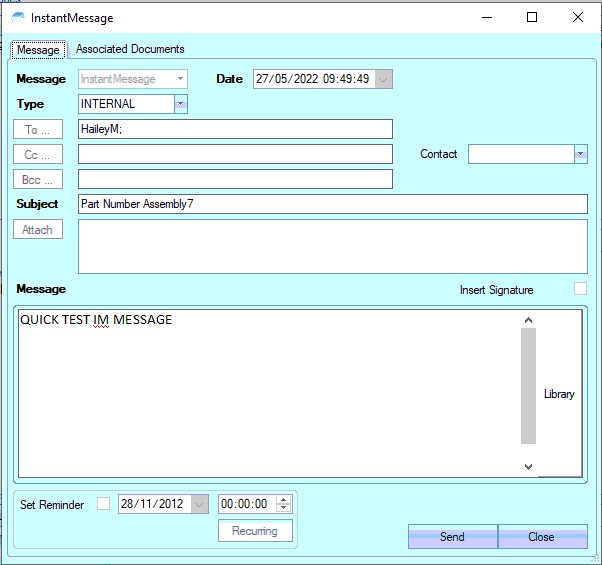

Lock/Release Routing