These settings deal with the way Progress Plus handles works order information when creating / completing work orders.

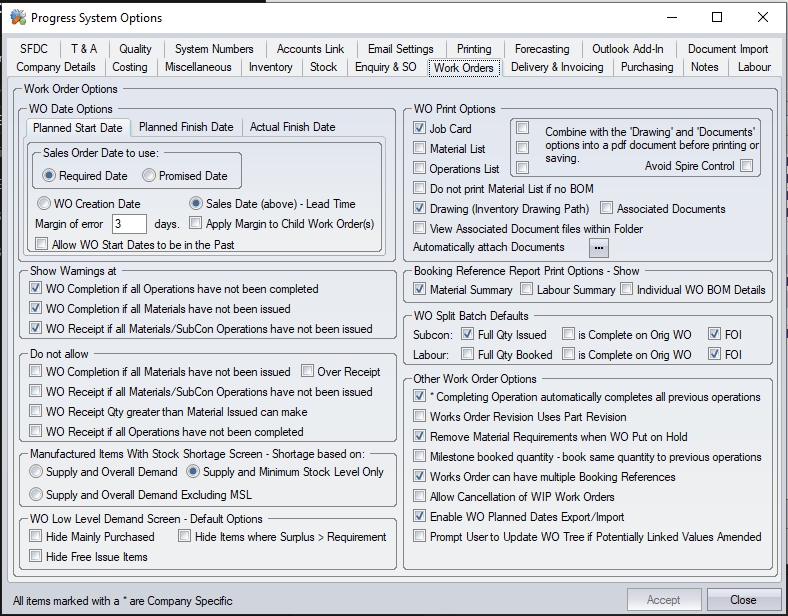

Work Order Options

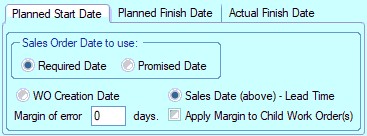

Planned Start Date

These settings determine which date the system will plan for a works order to finish on dependent on what is selected. We can use the following example to see the different affect these options have.

Example

We have a requirement to sell a manufactured item - Part No 123.

Part No 123 has a manufacturing lead time of 5 days set in the Inventory section.

Within the Customers section we have entered a Sales Order with a required date of 31st May.

The date the Sales Order was entered was 23rd May and a Works Order was created at the same time

With the Works Order Creation Date option chosen and no Margin of Error entered, the system would suggest a start date of 23rd May

With the Works Order Creation Date option chosen and a Margin of Error of 1 day entered, the system would suggest a start date of 23rd May as the system would not automatically suggest a start date in the past.

With the Sales Order Required Date - Lead option chosen and no Margin of Error entered, the system would suggest a start date of 26th May if we are using Lead Times – Include Weekends option

With the Sales Order Required Date - Lead option chosen and no Margin of Error entered, the system would suggest a start date of 24th May if we are not using Lead Times – Include Weekends option

With the Works Order Creation Date option chosen and a Margin of Error of 1 day entered, the system would suggest a start date of 25th May if we are using Lead Times – Include Weekends option

With the Sales Order Required Date - Lead option chosen and no Margin of Error entered, the system would suggest a start date of 23rd May if we are not using Lead Times – Include Weekends option

The Apply Margin to Child Works Order(s) setting permits the user to apply any Margin of Error entered to subsequent child works orders created for multi-level assemblies. For more information regarding Works Orders please refer to the relevant section of the manual.

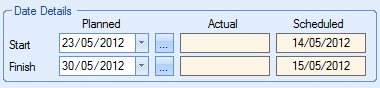

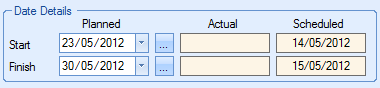

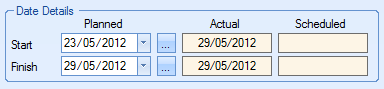

The calculated Planned Start date would be populated in the Date Details section of the works order.

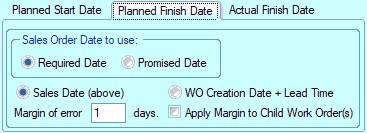

Planned Finish Date

These settings determine which date the system will plan for a works order to finish on dependant on which option is selected. Using the same example as previously described.

Example

We have a requirement to sell a manufactured item - Part No.123.

Part No.123 has a lead time of 5 days set up for it in the Inventory section.

Within the Customers section we have entered a Sales Order with a required date of 31st May.

The date the Sales Order was entered was 23rd May and a Works Order was created at the same time

With the Sales Order Required Date option chosen and no Margin of Error entered, the system would suggest a finish date of 31st May

With the Sales Order Required Date option chosen and a Margin of Error of 1 day entered, the system would suggest a finish date of 30th May

With the Works Order Creation Date + Lead Time option chosen and no Margin of Error entered, the system would suggest a start date based on whatever Works Order Scheduled Start Date we have chosen plus the manufacturing lead time for the item and then take into consideration the Lead Times – Include Weekends option

With the Works Order Creation Date + Lead Time option chosen and a Margin of Error of 1 day entered, the system would suggest a start date based on whatever Works Order Scheduled Start Date we have chosen plus the lead time for the item plus 1 day and then take into consideration the Lead Times – Include Weekends option

The Apply Margin to Child Works Order(s) setting permits the user to apply any Margin of Error entered to subsequent child works orders created for multi-level assemblies. For more information regarding Works Orders please refer to the relevant section of the manual.

The Planned Finish date would be populated in the Date Details section of the works order.

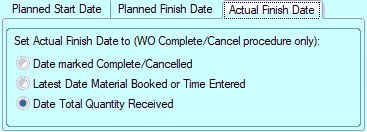

Actual Finish Date

These settings determine which date the system will mark a works order as finished in the Works Order section dependant on which option is selected.

With the Date Marked Complete / Cancelled option selected, the system will use the date that the works order was manually declared as complete by the user as the actual completion date.

With the Latest Date Material Booked or Time Entered option selected, the system will use the date of the latest time booking or the last date material was issued to the works order (whichever is the latest) as the actual completion date of the works order.

With the Date Total Quantity Received option selected, the system will use the date of the last receipt quantity booked in for the works order as the actual completion date of the works order.

The Actual Finish date would be populated in the Date Details section of the works order.

For more information regarding Works Orders please refer to the relevant section of the manual.

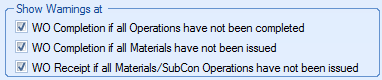

Show Warnings At... Options

These options allow the user to set up system warnings when WOs are completed or received. The options available are shown below.

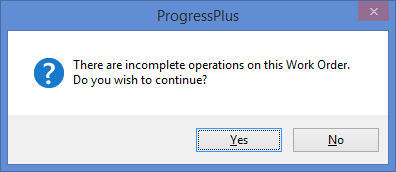

WO Completion If All Operations Have Not Been Completed

When the user completes a WO, they system will warn if there are still uncompleted operations in the routing as shown below.

The user can proceed with the WO completion by clicking YES or can cancel the completion by clicking NO.

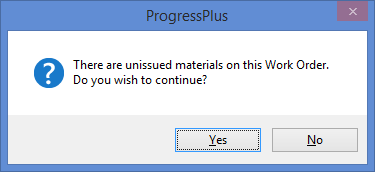

WO Completion If All Materials Have Not Been Issued

When the user completes a WO, the system will warn if there is outstanding material still to be issued as shown below.

The user can proceed with the WO completion by clicking YES or can cancel the completion by clicking NO.

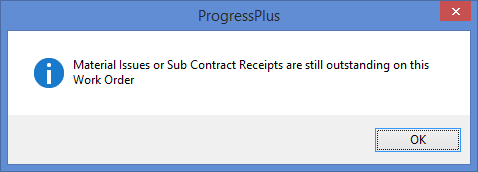

WO Receipt If All Materials/SubCon Operations Have Not Been Issued

When the user attempts to receipt the WO into stock, this warning will inform the user that there is outstanding material and subcontract issues as shown below.

Again, this is just a warning and will allow the user to proceed with the receipt if required.

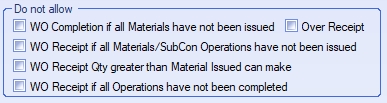

Do Not Allow Options

These options will stop specific activities against the WO if particular criteria is not met.

WO Completion if all materials have not been issued

This option will stop the WO being marked as complete if the full material requirement has not yet been issued to the WO. The system will check the BOM requirements for all BOM items to see if they have been fully issued. If not, the WO cannot be completed.

Over Receipt

This option stops any work order being receipted for more than the WO quantity.

WO Receipt if all Materials/Subcon Operations have not been issued*

This option will stop receipt of the finished goods if all material and subcon items have not been fully issued to the WO. The system will check the BOM requirements for all BOM items and also the subcon requirements of the WO to see if they have been fully issued. If not, the WO cannot be receipted into stock.

WO Receipt Qty greater than Material Issued can make*

This option will stop receipt of a specified quantity of finished goods if the total material issued is not enough to make the specified quantity. The system checks the BOM requirements for the specified quantity and stops receipt if any component part has had less issued than required. Having this option ticked will also provide the user with an option on the WO Receipt screen to default the WO receipt quantity to match the issued material quantity.

Note: User needs to be careful applying this option, especially when material is issued to work orders using booking refs and/or group on due to the issue quantities being pro-rata'd. This can result in WO receipt quantities that are fractional ( i.e 14.000027, etc.). This can impact sales order allocations and stock.

WO Receipt if all Operations have not been completed

This option stops receipt of the work order if all operations have not been marked as complete.

*NOTE: The options to stop receipt if material/subcon has not been issued in full and the option to receipt a quantity greater than the issued material CANNOT both be applied at the same time.

Manufactured Items With Stock Shortage Screen Default Options

These settings determine how shortages are calculated in the Below MSL screen within the Works Order section. This screen calculates and suggests works order quantities to be raised for manufactured items that currently have a shortage. This shortage may be due to this part currently being below its minimum stock level or there is a requirement from a customer for this item but not enough stock or current works orders being manufactured to satisfy this requirement or a mixture of both.

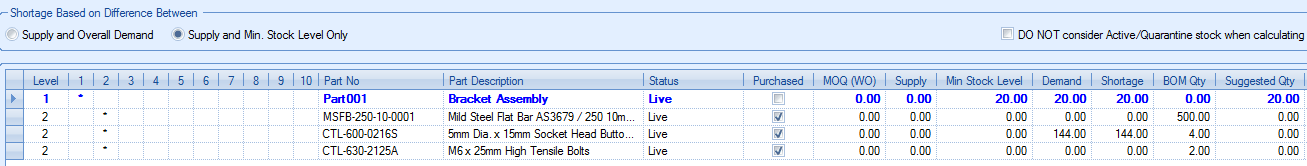

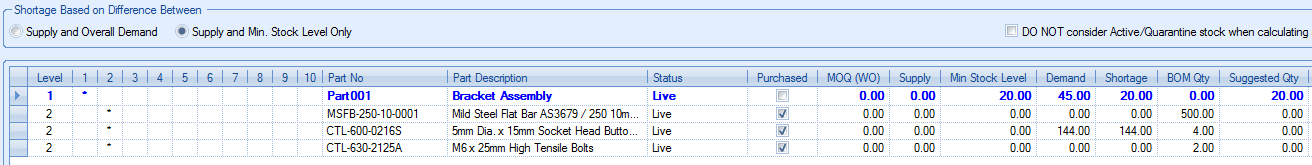

In the following example we have a manufactured item – Part001. This item has had a minimum stock level of 20 set against it in the Inventory module. At present we have none in stock. There are currently no outstanding works orders going through the system. There are currently no customer requirements for this item.

If we should access the Below MSL screen and calculate our requirement the system would give us a Suggested Qty of 20 to be manufactured regardless of whether we choice to use Supply and Overall Demand or Supply and Minimum Stock Level Only to calculate our shortage.

E.g. Minimum Stock Level = 20, no other demand, only manufacture enough to bring stock back to required level.

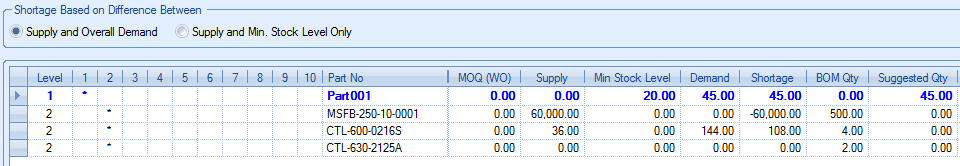

If we should however receive a requirement (sales order) for a customer for a quantity of 25 we will have a different Suggested Qty depending what option is chosen.

Using the Supply and Overall Demand option the system would suggest that we manufacture a quantity of 45. This equates to the 25 required for the customer plus the 20 required to bring the item up to the minimum stock level.

Using the Supply and Minimum Stock Level Only option the system would suggest that we manufacture a quantity of 20. This equates to the 20 required to bring the item up to the minimum stock level only.

For more information regarding the Below MSL screen please refer to the Works Orders section of the manual.

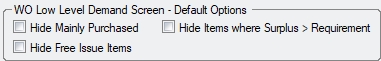

WO Low Level Demand Screen - Default Options

These options allow defaults to be set against the options which appear on the WO Demand screen.

When these default options are applied, they will automatically be applied to the WO Demand screen when a user opens it.

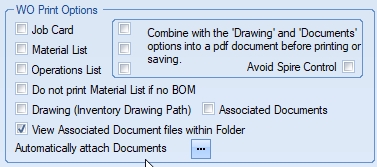

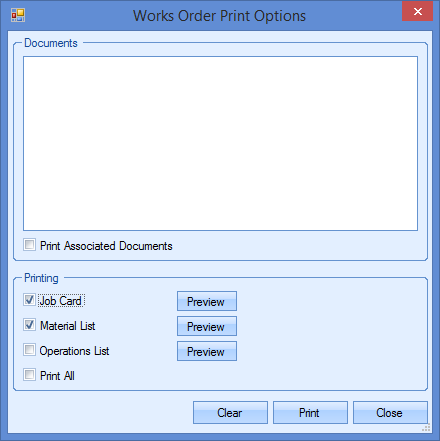

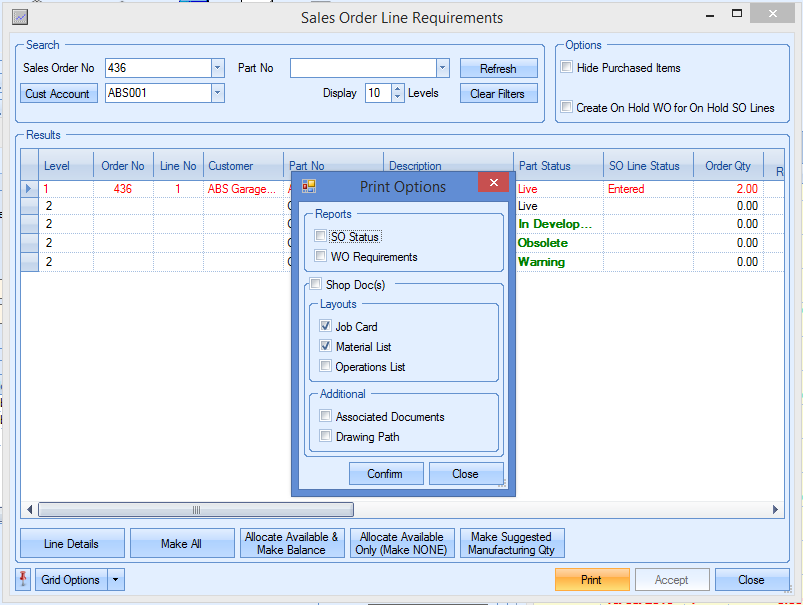

WO Print Options

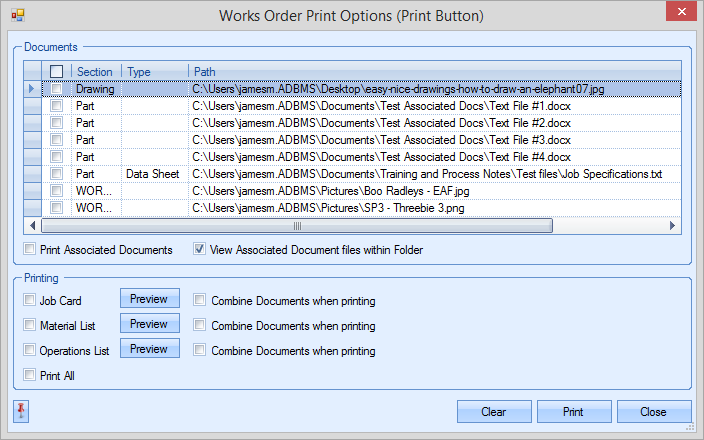

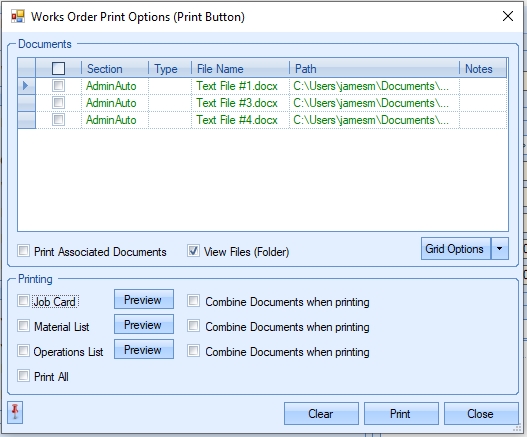

These options allow the user to set the default print options for works orders.

These options will default on both the work order printing option as well as the sales order line requirements screen (both shown below).

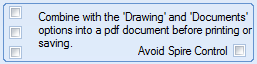

Additional options have been added which allow the user to combine multiple documents into a single document prior to printing - useful if they are printing duplex to condense the amount of paper being used.

These Combine... options are often used to include drawings or associated documents as part of the system-generated documents (i.e. job card). Although this will give more control over the printing of these documents as part of the overall document package for the job, some larger sized documents must be printed separately due to their size. Having the Avoid Spire Control option ticked will allow the printing of larger sized documents but will rely on printing them from the associated program instead of being combined with the system-generated documents first.

View Associated Document Files Within Folder

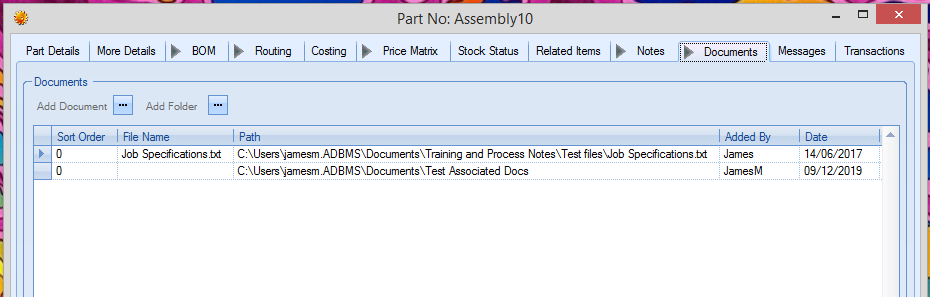

This option allows the user to view all files within a specified folder when printing WO documents.

![]()

If a folder has been associated in the Documents tab of the part, WO and/or routing, this option will present all the files in that folder for printing along with the selected WO documents.

When the user prints from a WO, all the files from the specified folder will be presented as associated documents.

The user can then include any of these in the printing process.

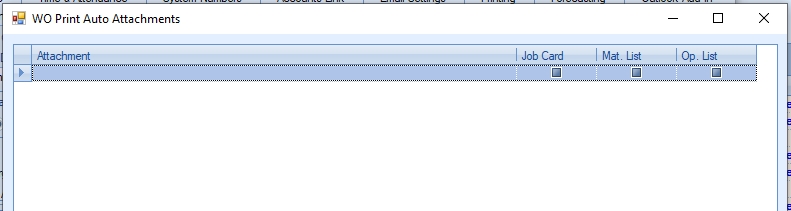

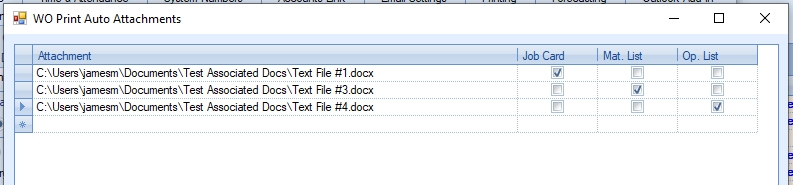

Automatically Attach Documents

This option allows the user to specify documents that need to be generated along with the work order documents (i.e. job card, material list and operations list). This can be set up by clicking on the ![]() option, which will present the user with the following screen.

option, which will present the user with the following screen.

From here, the user can select files under the attachment column, and then select which of the work order documents its to be generated with.

Once the documents have been added, the user can click ACCEPT to save the changes.

When the work order documents are being printed from within a work order, the auto-attach documents will be shown alongside any other Associated Documents listed.

When the user selects the PRINT option, the selected document(s) will be printed along with the associated auto-attached documents too.

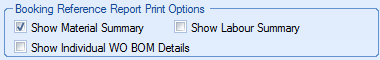

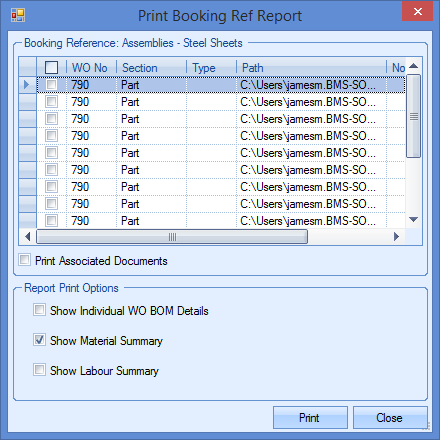

Booking Reference Report Print Options

These options allow the user to set the default printing options for booking references.

These options are displayed when the user prints booking reference documents as shown below.

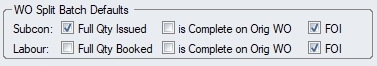

Work Order Split Batch Defaults

These options allow the administrator to set default actions for the WO Split Batch screen. These defaults determine how subcontract issues and labour booked quantities are handled when a new split batch WO is created from an existing WO.

Subcon: Full Qty Issued

This option defaults the subcontract issue quantity, transferring to the new split batch WO, as the full quantity of the WO being created.

Subcon: Is Complete On Original WO

This option automatically completes all subcontract operations on the new WO which are marked as complete on the original WO, regardless of whether fully issued or not.

Subcon: FOI

This option will automatically carry across any first off inspection (FOI) records for the subcontract operation to the new split batch WO being created.

Labour: Full Qty Booked

This option defaults the booked quantity of the operation, transferring to the new split batch WO, as the full quantity of the WO being created.

Labour: Is Complete On Original WO

This option automatically completes all operations on the new WO which are marked as complete on the original WO, regardless of whether fully booked or not.

Labour: FOI

This option will automatically carry across any first off inspection (FOI) records for the internal operation to the new split batch WO being created.

For more information on the work order Split Batch functionality, please refer to the Work Order section of the manual.

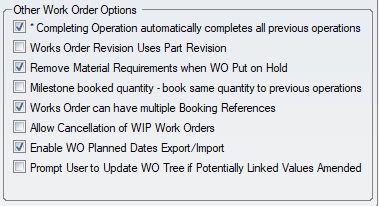

Other Work Order Options

The following system options are also available to help configure the work order aspect of the system.

Completing operation automatically completes all previous operations

This option will update all previous operations upon completion of an operation. This is useful if completing the final operation of a WO, however, completing operations means that they are not available for employees to job on to unless the system is configured to allow this.

Works Order Revision Uses Part Revision

This option will use the part revision as the starting point for the work order revision.

Remove Material Requirements when WO Put On Hold

This option will remove all material requirements for a works order if the works order status is changed to "On Hold". This means the PO Shortage screen would not include the selected work order requirements in the calculations for the overall requirements of the parts. If this is unticked, the system will continue to include the material requirements for the on hold work order in the requirements calculations.

Milestone Booked Quantity - Book Same Quantity to Previous Operations

This option will automatically record the same booked quantity against all previous operations when the quantity is recorded against a milestone operation. If this is left unticked, only the milestone operation quantity will be updated.

Works Orders can have Multiple Booking References

This option allows a work order to be available for selection against multiple booking references. If left unticked, the work order can only be included in a single booking reference.

Allow Cancellation of WIP Work Orders

This options allows a work in progress (WIP) works order to be canceled. If this is left unticked, the work order would be updated to "complete" only.

Auto Issue Material from Sales Order Requirements

This option will automatically issue any existing stock of required material to new work orders when they are generated from the SO line requirements screen. Leaving this unticked would require the material to be issued manually. This includes purchased and manufactured parts.

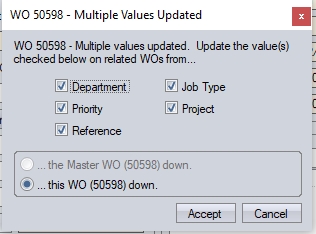

Prompt User To Update WO Tree if Potentially Linked Values are Amended

This option will update all associated work orders with changes to the job type, priority, department, reference and project on a work order. If this option is not ticked, changes will only be applied to the work order being amended. If the option is ticked, the user will be prompted to ask if the same changes are to be made to all associated work orders.

When prompted, the user can select which of the information thats changed is cascaded. They also have the option of cascading the changes from the top-level master WO to all associated lower-level WOs, or they can cascade from just the current WO that are amending (i.e. if changes made to a sub-assy WO, the system can cascade to just that WOs lower level WOs).