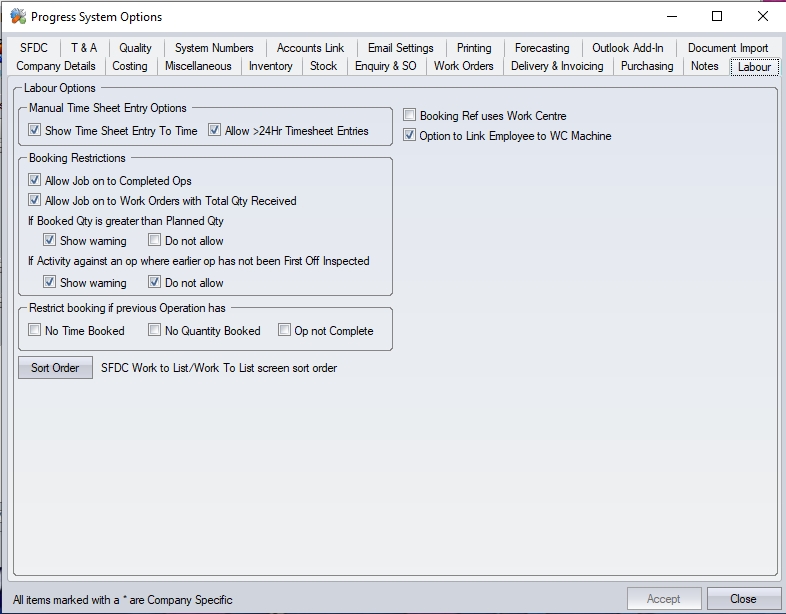

These system options relate to the recording of timesheets against work order operations, whether its via the SFDC module or manually via the Timesheets screen.

Manual Time Sheet Entry Options

Show Time Sheet Entry To Time

Within the Labour section of the standard progress plus system users can enter manual timesheets without the requirement for the additional SFDC module. These timesheets are labour recordings for time spent on activities such as jobs, lost time, rework etc. but not for time attendance.

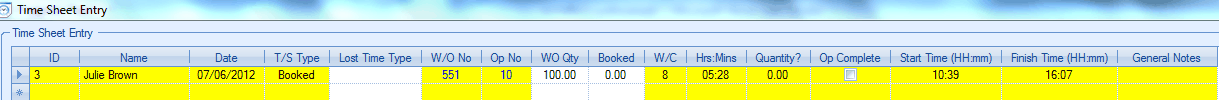

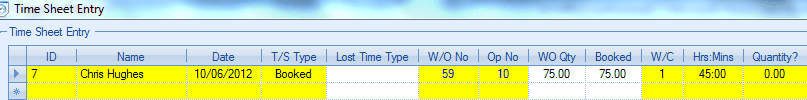

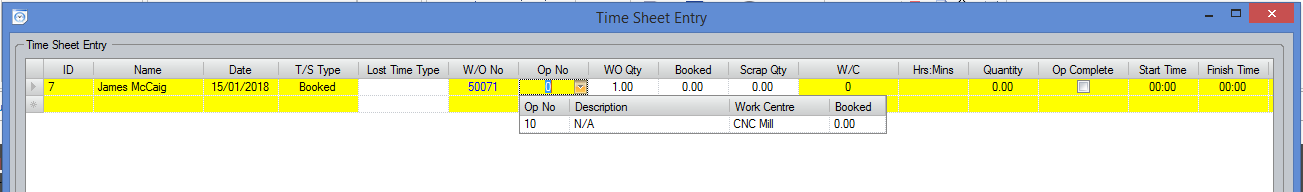

The Show Time Sheet Entry To Time when activated displays an extra 2 columns on this the Time Entry Screen enabling the user to enter a Start Time and a Finish Time for this time booking. The system will then calculate the time spent on this activity and display the result in the Hrs:Mins field as shown above.

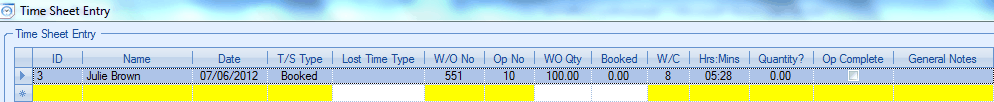

Without this option activated the user can simply enter the time spent on this activity directly into the Hrs:Mins field as shown above.

Allow > 24hr Timesheet Entries

This option permits the user to enter more than 24 hours against an employee in a single day when entering manual time sheets for activities such as jobs, lost time, rework etc. into the Time Entry Screen. This facility can be useful in the scenario that employees work offsite and wish to enter a ‘lump’ time spent against a works order instead of entering daily totals.

Booking Restrictions Options

Allow Job On to Completed Ops

The administrator if desired can permit employees to log more time to works order operations that have previously marked as complete. If this option is activated then the user can Job On to the required operation in the normal manner.

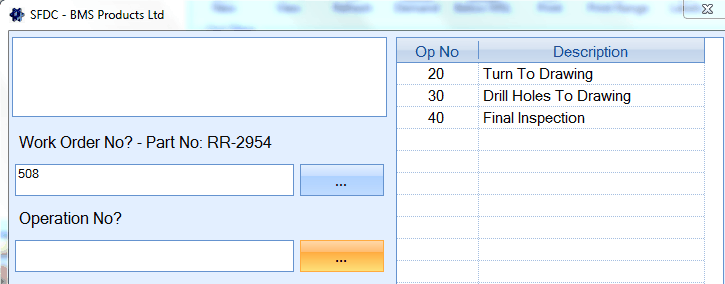

If this option is not selected then the employee may only choose from a list of uncompleted operations for the selected works order. In the following example Op No 10 for Work Order No 508 has previously been marked as having been completed and as such does not appear in the list.

An operation can have the Complete status amended by removing the check box set against the operation within the Routing for this Works Order. Please refer to the relevant section of the manual for more information.

Allow Job On To Work Orders with Total Qty Received

Similar to the option above, this option will restrict the ability to job onto any work orders which have already been fully received (status = Total Qty Received).

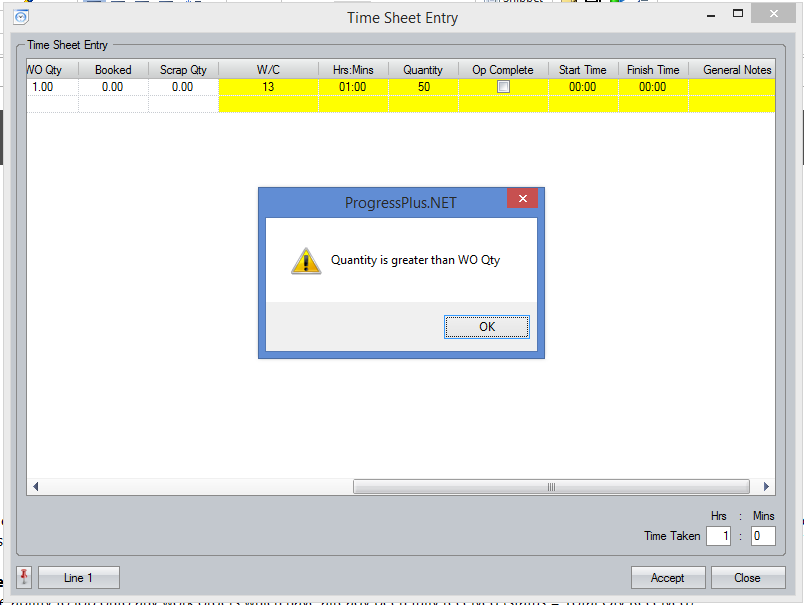

If Booked Qty Is Greater Than Planned Qty - Show Warning/Do Not Allow

These options allow the user to dictate what happens when an employee tried to record a quantity against a work order operation which is greater than the WO quantity. The user has the option to simply show a warning but also has an option to stop the booking being recorded.

If the system is configured to only warn the user, the system will warn and then proceed with the quantity entered. If the system is configured to warn and block the booking, then the QUANTITY field will be reset to allow the user to re-enter the value.

If Activity Against An Op Where Earlier Op Has Not Been First off Inspected - Show Warning/Do Not Allow

These options allow the user to dictate what happens when an employee attempts to book time against an operation when a previous "First Off" operation has not been marked as "inspected". Again, the user can specify whether a warning is displayed and the booking accepted or whether the booking is rejected. System checks all previous operations of the specified WO to check that any operations marked as "First Off Inspection Required" (shown below) have been updated to "First Off Inspected". If not, the relevant warning and/or rejection of the booking is done.

![]()

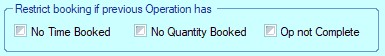

Restrict Booking If Previous Operation Has No Time/Qty Booked - No Time Booked/No Quantity Booked/Op

These options dictate whether the employee is able to record time against a WO operation if the previous operation has had no activity logged. The options here allow the Admin user to set the restriction based on time, quantity or whether the previous op is complete.

With these options applied, the system will only allow bookings against operations which meet the criteria above (time booked, quantity booked or is complete). Manual time sheets will only allow the user to record against valid operations too.

Sort Order (SFDC Work To List/Work To List Screen sort order)

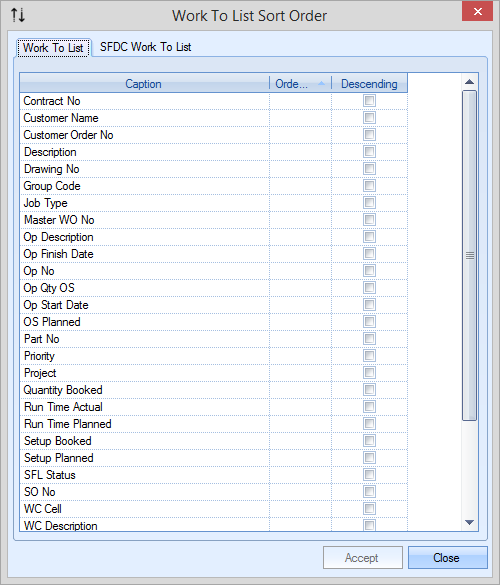

This option allows the user to set the sequencing and sort options of the Work To List displayed within Progress Plus as well as the one displayed in the SFDC module.

The user can sequence the fields on both Work To Lists by entering a sequential number, starting at 1, against each of the fields they are interested in. The option to list the items in descending order is also available using the DESCENDING tick boxes.

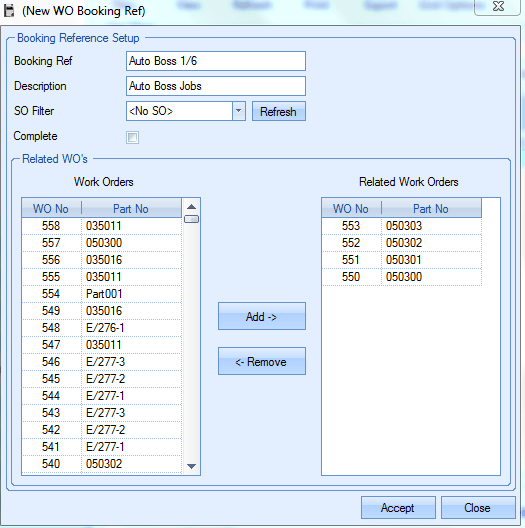

Booking Ref uses Work Centre

Within the Works Order section of the system, there is a facility to group similar type jobs together for the purposes of time recording e.g. a sheet metal company may be cutting 5 or 6 different jobs together on the one machine at the same time. The Booking Ref allows the user to group these jobs together in order to enable the employee to ‘job on’ a single booking reference instead of having to log on onto 5 or 6 works orders.

When employees ‘job off’ the time spent is then allocated pro rata against all the works orders assigned to that booking reference. For a Booking Ref to be successful all works orders allocated to the reference must have the same work centre in their routings or share the same work centre location. There must also be planned time greater than 0 against these operations as the booking reference function allocates time spent to jobs not completed quantities. The time for each job does not have to be of equal amounts nor does the works order operation number have to match.

Example

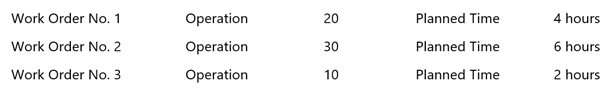

Booking Ref 123 is for 3 different works. All 3 works order require a turning operation to be complete on a CNC Lathe. We are planning to do these 3 turning jobs together.

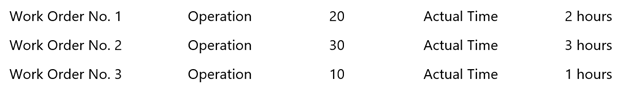

If an employee should log 6 hours of time against Booking Ref 123 the time would be allocated as follows

The time allocated is done on a pro rata basis based on the planned time of the operation.

For more information regarding time bookings and works orders please refer to the relevant sections of the Labour and Works Order manuals.

The most common way of using the booking reference facility is with the Booking Ref uses Work Centre activated.

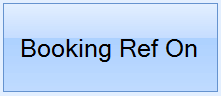

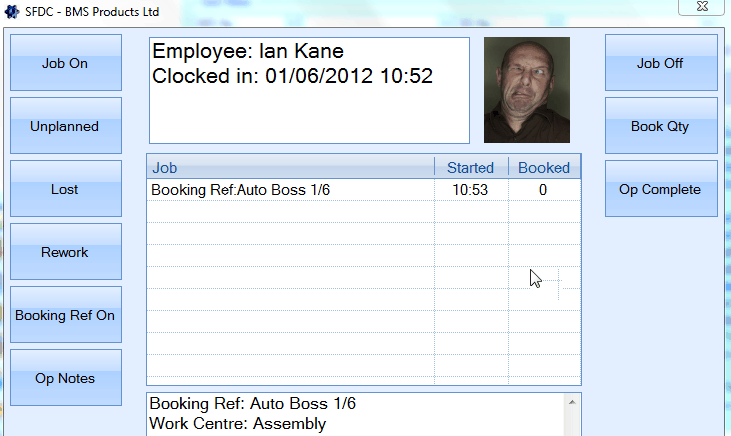

After the user has created a booking reference within the Works Order section – similar to that to that shown in the diagram opposite – an employee is then able to able to access the SFDC module and choose to click on the Booking Ref On option to proceed with clocking onto a Booking Ref.

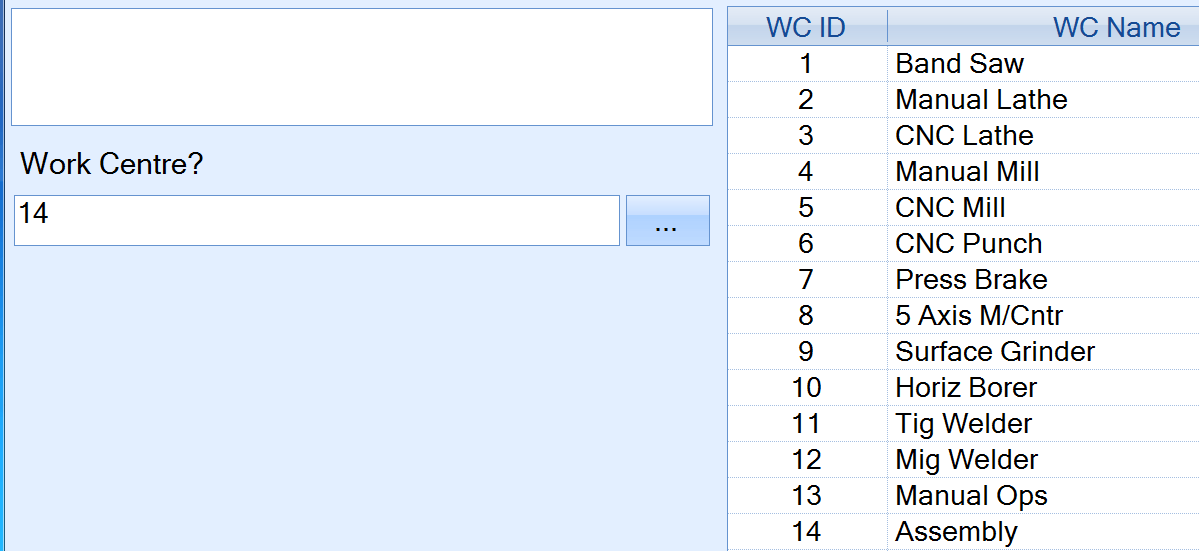

With the Booking Ref uses Work Centre activated the employee will be required to select the relevant work centre – as shown in the following example – to continue.

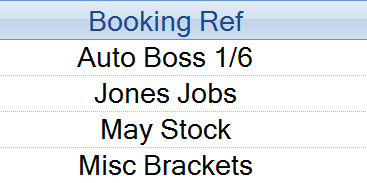

After choosing the desired work centre the employee can then select from a list of current booking references to clock onto.

Details of the booking reference will then be displayed to the employee on the SFDC screen.

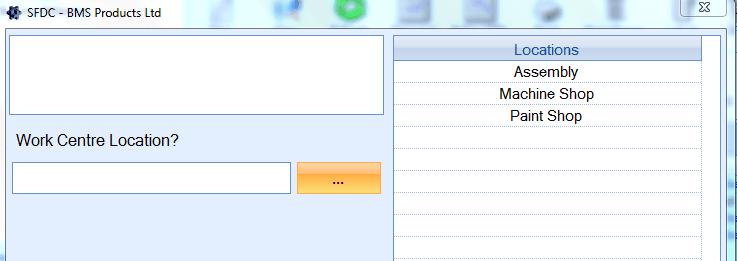

With the Booking Ref uses Work Centre option deactivated, the process for logging onto a booking ref is different. The main difference is that the employee must log onto a Work Centre Location instead of an individual work centre itself.

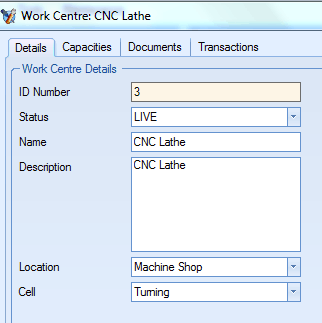

The work centre locations are entered within the Maintenance section and can be applied to each work centre. In the above example the CNC Lathe has be assigned to the Machine Shop location.

On clocking off the Booking Ref the time spent by the employee will be apportioned across all operations that appear on the routings for the works orders that have a work centre within the selected Work Centre Location. The time spent on this booking reference will be allocated in the pro rata method previously mentioned to the relevant works orders.

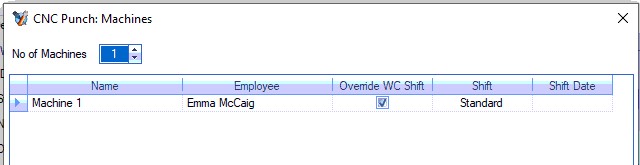

Option To Link Employee to Work Centre

This option allows the user to assign specific employees to individual work centre machines. Linking them will adjust the capacity of the work centre if the linked employee is on holiday.

Ticking this option adds an employee option against the individual work centre machines, allowing a specific employee to be linked.