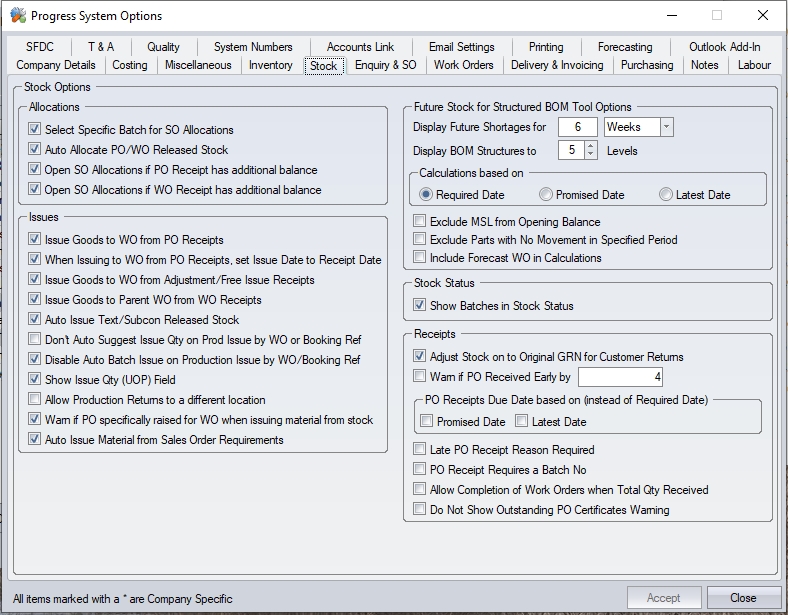

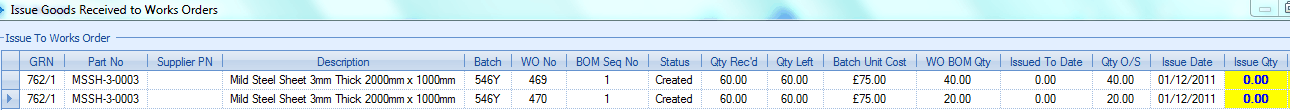

These options all relate to stock control; receipts, issues and allocations as well as some default reporting options.

Allocation Options

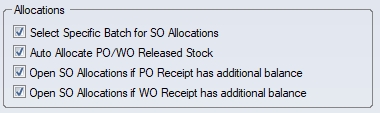

Select Specific Batch For SO Allocations

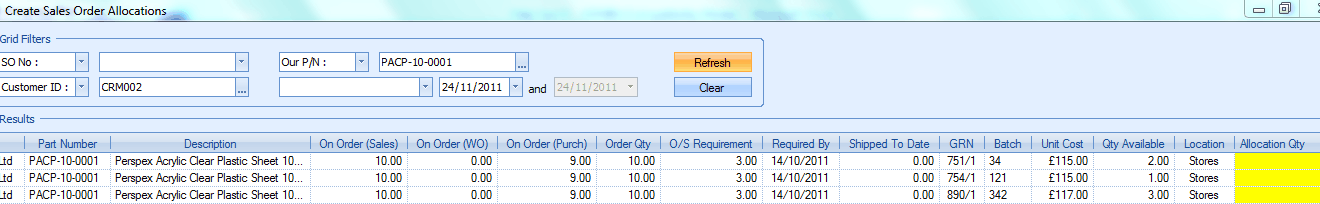

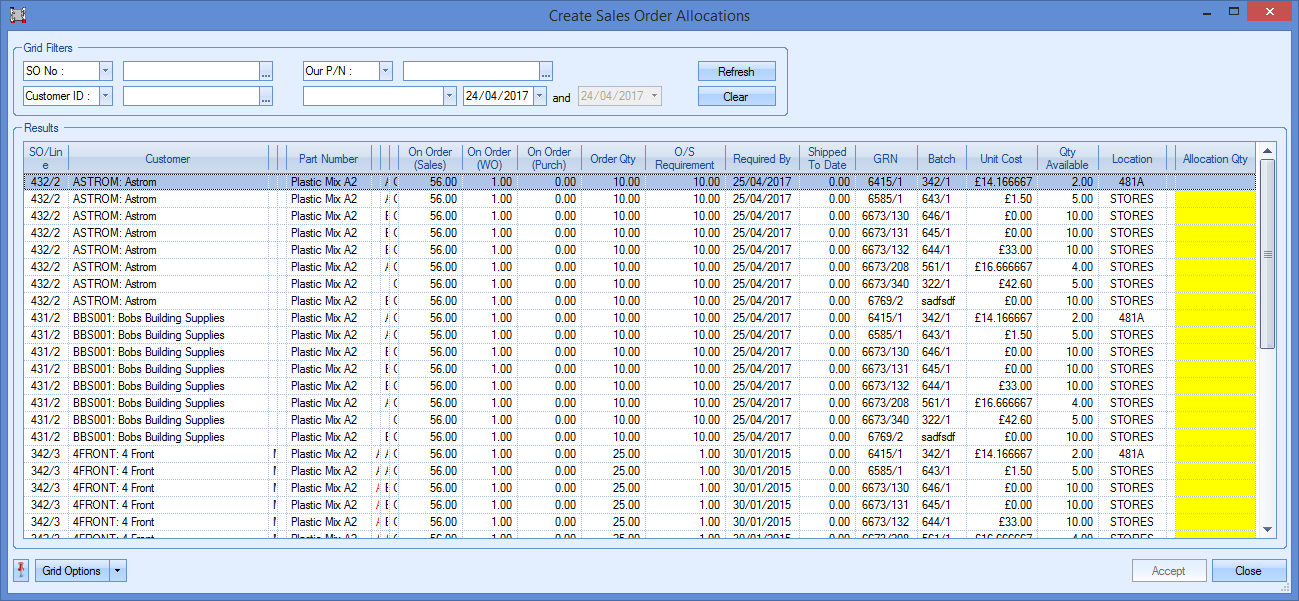

This option enables the user to select a specific batch for a manual sales order allocation within the Create SO Allocations option within Inventory. Users may choose to create a manual sales order allocation from stock in order to choose a specific batch of an item to deliver to the customer instead of using the system default of FIFO (first in, first out).

The following example is using the Select Specific Batch for SO Allocations option. The batch details of the items held in stock that are available are displayed

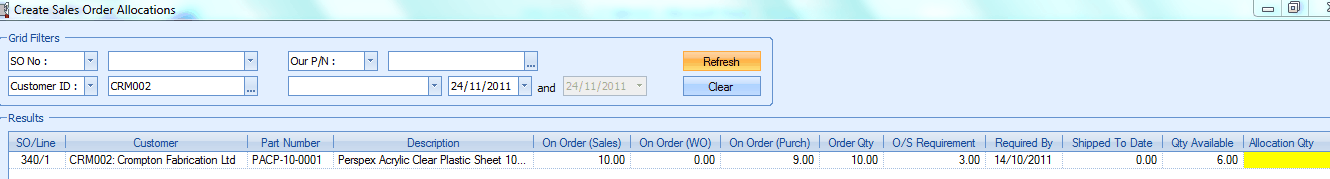

The following example is not using the Select Specific Batch for SO Allocations option. Only the totals held in each location for this item are displayed. Any stock allocated would be done on a first in, first out basis

For more information on sales order allocations please refer to the Customers – Sales Orders section of the manual.

Auto Allocate PO/WO Released Stock

This option will automatically allocate any released PO or WO stock to the associated SO upon release from the temporary hold status. If unticked, releasing the stock will release it to ACTIVE stock.

Open SO Allocations Form If PO Receipt Has Additional Balance

This option dictates whether any additional inventory receipted from a PO is highlighted and allows the user to assign it to other SO requirements. When ticked, the user is presented with the following screen which allows them to assign the extra inventory to other orders which require it.

Once the stock has been assigned, clicking ACCEPT will allocate the goods to the sales order.

Open SO allocations form if WO receipt has an additional balance

Similar to the option above, this option will present the user with the Create Sales Order Allocations screen to allocate any additional units received against a WO to any other sales orders that are awaiting stock of the same part. This takes away the need to manually allocate the stock afterwards. If unticked, any additional units will go straight to stock and would require manual allocation.

Issue Options

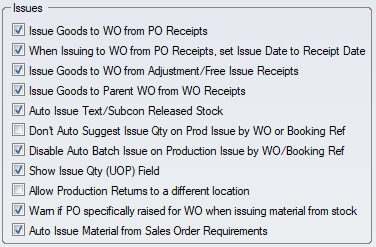

Issue Goods to WO from PO Receipt

The Issue Goods To WO (works orders) From PO (purchase orders) Receipt permits the user to view a screen on receipting items from a purchase order and issue them to works orders that may require them. This option may not be desired by some users mainly due that to the fact that goods issued to works orders via this screen are no longer considered by the system as being in stock (they will not be included in any stock valuation report) but instead the value of these goods will be included in Works In Progress reports and cost calculations (WIP).

With this option activated a screen similar to the above Issue Goods Received to Works Orders would be displayed on receipting a purchase order. In the above scenario some mild steel sheet has been purchased and receipted into stock. The system has determined that 2 works orders (WO No.469 & 470) have an outstanding requirement for this material.

![]()

If the user wishes to continue with the issue of material to works orders he or she has a choice of 2 options both located at the bottom left of the screen.

When Issuing To WO from PO Receipts, set Issue Date to Receipt Date

This option will default the issue date of the transaction to match that of the receipt date of the PO when the goods are issued to the associated WO directly from the PO receipt screen.

Issue Goods to WO from Adjustment/Free Issue Receipts

This option will allow the user to issue any stock received via adjustment or free issue receipts to WOs where required just like the PO receipts. Once the goods are received, the system will open the Issue Goods Received to Works Orders window to allow the user to indicate where the goods have to be issued to.

If the user wishes to continue with the issue of material to works orders he or she has a choice of 2 options both located at the bottom left of the screen.

![]()

Issue Goods to Parent WO from WO Receipts

This option allows the user to issue received WOs to other WOs which are waiting for inventory. Typically, this would be used for sub-assy parts being manufactured then issued to their parent WOs. Like the options above, once the WO is received, the system will present a window which will allow the user to issue the received goods to other WOs.

If the user wishes to continue with the issue of material to works orders he or she has a choice of 2 options both located at the bottom left of the screen.

![]()

Auto Issue Text/Subcon Released Stock

This option will automatically issue received text or subcon PO items to their associated WO upon release from the temporary hold status. If unticked, releasing the stock will release it to ACTIVE stock.

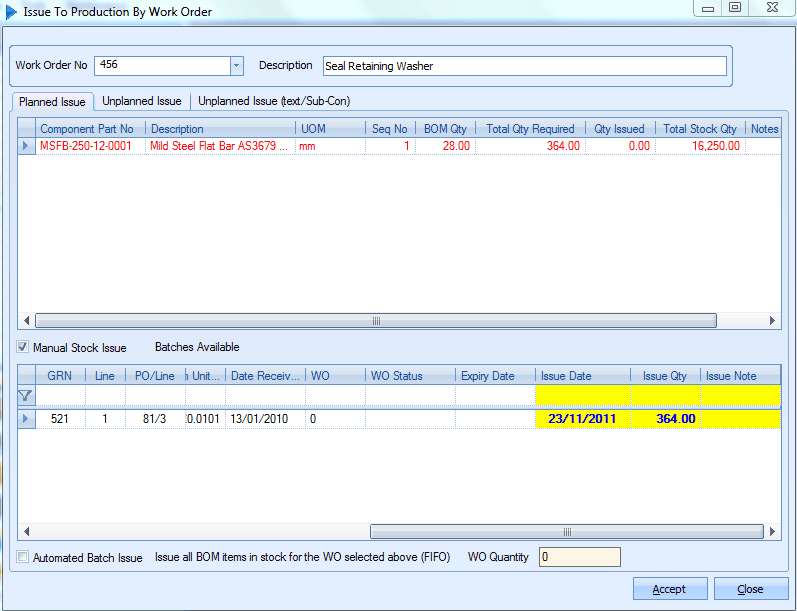

Don’t Auto Suggest Issue Qty On Production Issue By WO or Booking Ref

This option deals with the process of suggesting to the user quantities of material required to be issued to satisfy works order requirements. When issuing material to a works order the user is normally prompted by the system as to the quantity of material required to satisfy a works order's requirement.

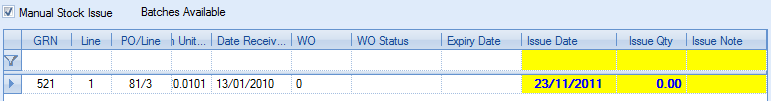

With this option unticked, the system will suggest the quantity and batch to be issued, based on FIFO. If this option is ticked, then no quantities or batches will be suggested, so the user will have to manually fill in the quantity against the batches to be issued.

In the following example with the Don’t Auto Suggest Issue Qty option turned off works order 456 requires a quantity of 364mm of a mild steel bar to satisfy its requirements to manufacture a quantity of finished product. This quantity required is displayed in the ISSUE QTY on the following screen.

The user can now amend the ISSUE QTY if required, and press the ACCEPT button to issue this material to the works order. With the Don’t Auto Suggest Issue Qty option turned on, the ISSUE QTY is left at zero, requiring the user to enter the quantity of material used and press the ACCEPT button to issue this material to the works order.

This system option also applies to the Production Issue By Booking Ref screen, working in the exact same way. Leaving the system option unticked will auto-fill the quantity against the available batches for issue, while having the system option ticked will leave all quantities as zero, so the user themselves can complete the details.

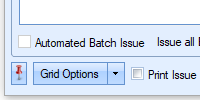

Disable Auto Batch Issue on Production Issue By WO/Booking Ref

This option removes the ability to use the AUTO BATCH ISSUE option on the Production issue By WO screen.

![]()

With this option switched on, the Auto Batch Issue option is not available as shown below.

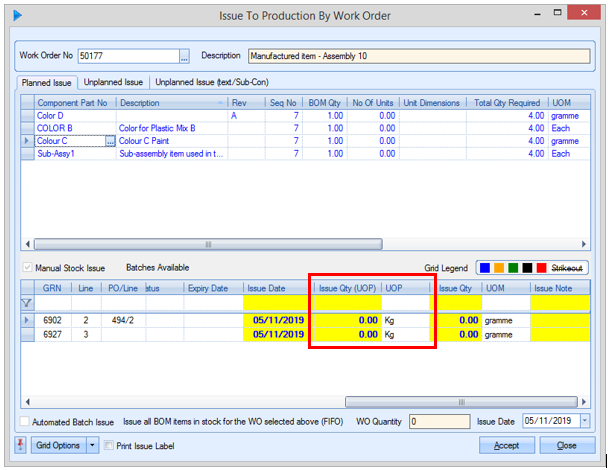

Show Issue Qty (UOP) Field

This option switches on some additional fields on the Production Issue By WO screens and allows the user to issue quantities based on the part's UOP.

![]()

When issuing material, the user will see the additional fields that allow the issues to be done by UOP quantity. For example, issuing boxes of screws instead of 20 individual screws.

The user still has the option of issuing material based on the part's UOM but now has the additional option of issuing by the UOP, which might be more convenient for some parts. The part's stock will be reduced accordingly regardless of which method the user selects to use.

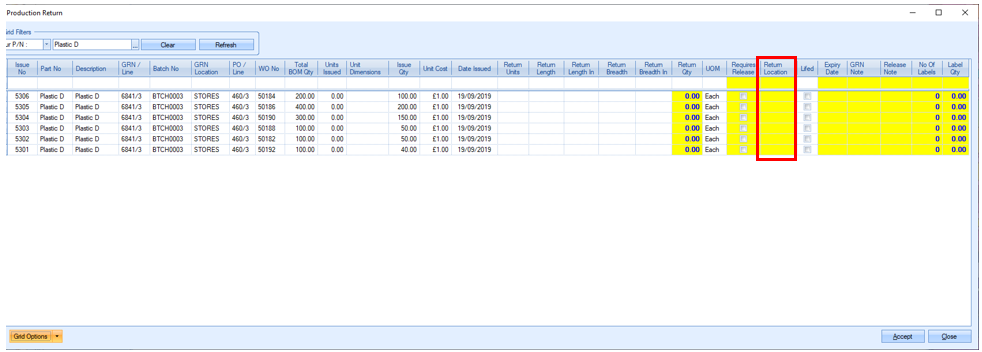

Allow Production Returns To A Different Location

This option allows users to select a different stock location when returning goods from a WO to stock.

With this option turned off, the user will not have an option to select a location when doing a production return and the stock will return to previous GRN location. With this option switched on, the system will allow the user to select a new location for the returned stock to go.

If a partial return of a GRN is done, the system will return the stock to the original location and then do a stock transfer to create the new GRN number. This will be shown as two transactions in the system - a production return and a stock location transfer.

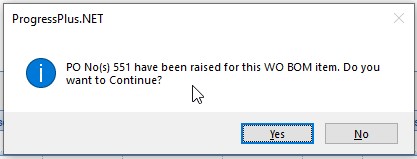

Warn if PO Specifically Raised for WO When Issuing Material from Stock

This option will display a warning to the user when they are issuing material to a WO where a PO has already been raised and is linked to the WO for the part number being issued. The warning will be displayed when the user clicks the ACCEPT option on the Production Issue By WO screen.

The user can click YES to proceed with the issue or NO to cancel the issue.

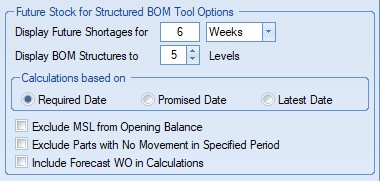

Future Stock for Structured BOM Tool Options

This allows the user to set the default settings for the Future Stock For Structured BOM tool which is available via the Tools menu in Progress.

The user can set the default number of weeks, the default number of BOM levels to drill down to and also the default date to be used. There are additional options for excluding MSL and parts with no movement, and an option to include forecast WOs in calculations too.

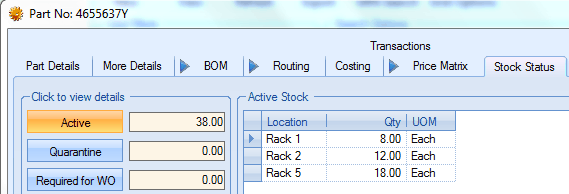

Stock Status Options

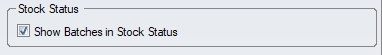

Show Batches In Stock Status

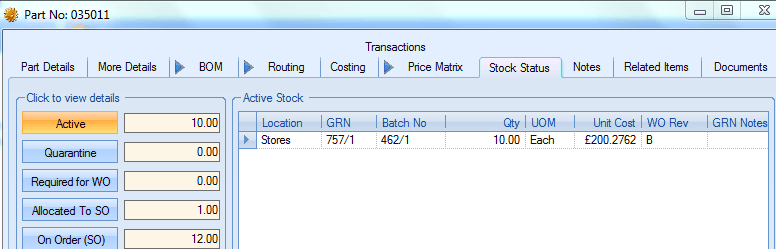

This option enables the user to view details of batches in stock for a specific part when accessing the Active or Quarantine option from within the Stock Status tab in Inventory. The following example is using the Show Batches in Stock Status option.

In the above screen there is an Active stock of 38. The details of the batches are displayed. It is normal to have this option activated.

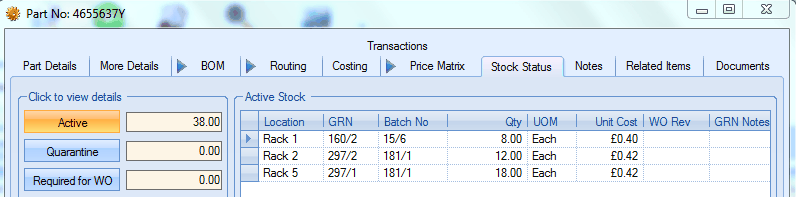

The following example is not using the Show Batches In Stock Status option. Only the totals held in each location for this item are displayed.

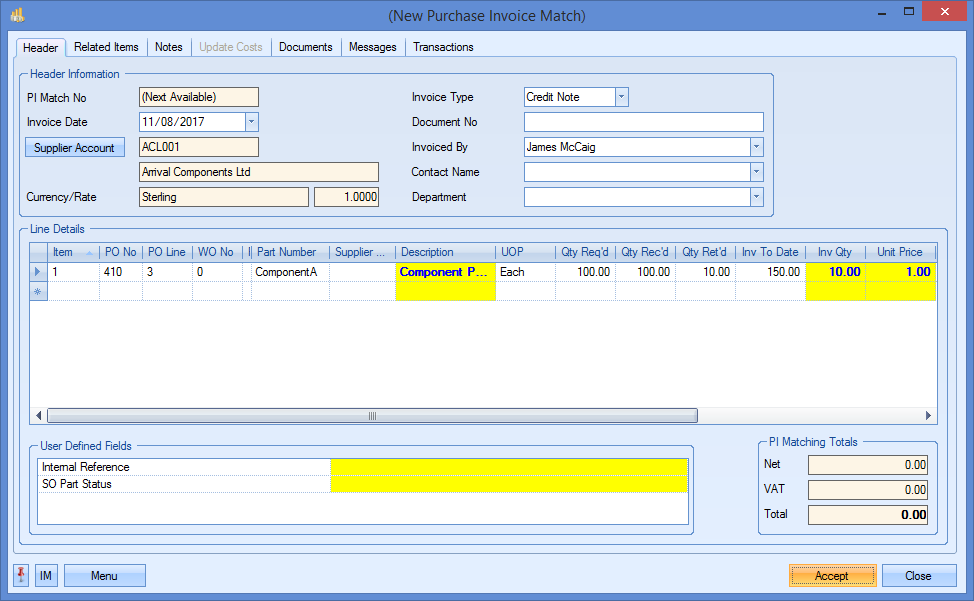

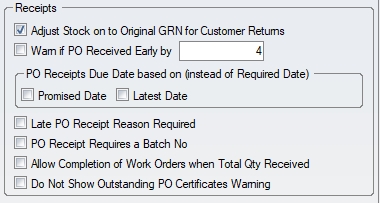

Receipts Options

Adjust Stock on to Original GRN for Customer Returns

This option affects the way items that have been returned from customers are booked back into stock. The user has the option to book any item received back from a customer back onto the same GRN (Goods Receipt No.) from which it was originally issued. It this facility is not activated any items returned from customers will receive a new GRN on receipt. It is normally advisable to have this option switched on as it aids with traceability.

The following example deals with the standard way a customer return will be updated on the system.

There is currently an Active stock of 10 of the above part receipted under GRN 757/1.

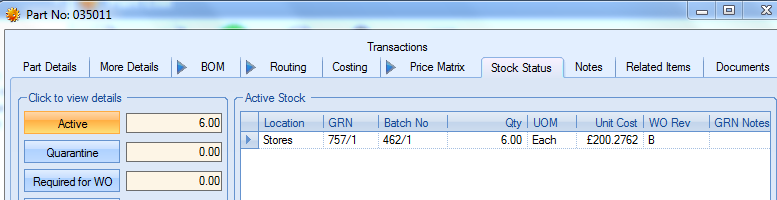

A sales order is entered for this item and a quantity of 4 are subsequently delivered. There is now an Active stock of 6 under GRN 757/1

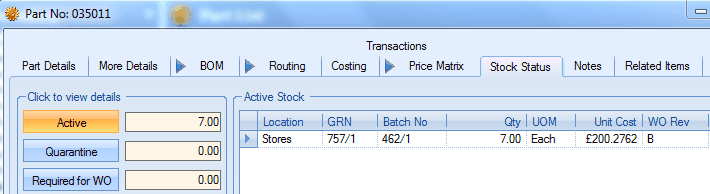

One of these delivered items is eventually returned from the customer and booked into stock via the Customer Returns facility within Inventory. With the Adjust Stock on to Original GRN for Customer Returns option activated the Active stock figure is updated to show a quantity of 7 against GRN 757/1 as shown above.

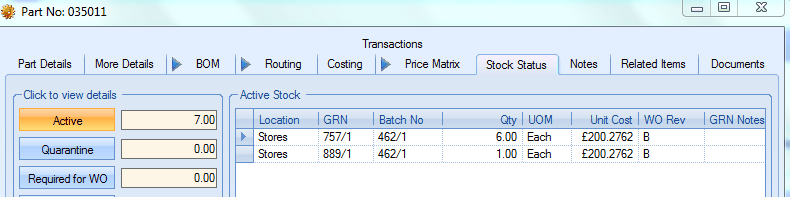

If the same scenario occurred with the Adjust Stock on to Original GRN for Customer Returns option turned off the Active stock figure would be updated to show a quantity of 7 but we would now have 2 GRNs for this item – 6 against GRN 757/1 and 1 against GRN 889/1 (the next GRN system number when the item was booked in) as shown below.

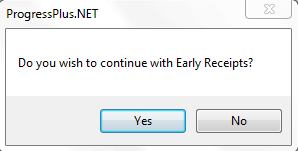

Warn If PO Received Early By...

If ticked this option allows the user to control deliveries from suppliers, possibly for financial control reasons or due to restricted stores space. If the Early by days is set at e.g. 4, and the date the goods are receipted from a purchase order is earlier than 4 days, the following message will appear.

The user can then choose to continue booking in the goods received or can choose to cancel the receipt process. Please refer to the Suppliers Purchasing manual for more details on raising and receipting purchase orders.

Use Promised as Due Date on PO Receipts (instead of Required Date)

This option allows the user to set the PO line Promised Date as the due date instead of the the Required Date.

Late PO Receipt Reason Required/Use Promised Date For Late POs

These two options are in relation to late receipts of purchase orders. The first option, Late PO Receipt Reason Required, forces the user to enter a reason as to why the PO is late. This reason is specified on the PO Receipt screen and is selectable from a drop-down list which can be maintained via the List maintenance section.

The second option, Use Promised Date For Late POs, will measure the lateness of a PO line based on the Promised Date instead of the Required Date.

PO Receipt Requires A Batch No

This option makes the BATCH NO field mandatory when receipting POs. The user will not be able to proceed with the receipt unless a batch number is entered. Also applies to PO Receipt (Ind) receipt option too.

Allow Completion of Works Orders when Total Qty Received

This option allows the user to auto-complete the WOs when they reach Total Quantity Received (TQR) status. This can only be done within the main system and is not possible via SFDC clients. All the usual checks and validations must be met for the completion of the WO to be done (i.e. rules on all material being issued, ops marked as complete, etc.).

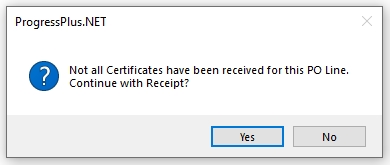

Do Not Show Outstanding PO Certificates Warning

This option is related to the Enhanced PO Certification functionality in Progress Plus, and determines whether the user is shown a warning relating to outstanding PO certificates. If this option is left unticked, the user will be warned (as shown below) about outstanding certificates (i.e. certificates not yet received from the supplier). If the option is ticked, then the user will not be warned that there are outstanding certificates associated with the PO line, and the items will be booked into stock regardless.

For more information on the Enhanced PO Certification functionality, please refer to the relevant section in the Purchasing section of the manual.