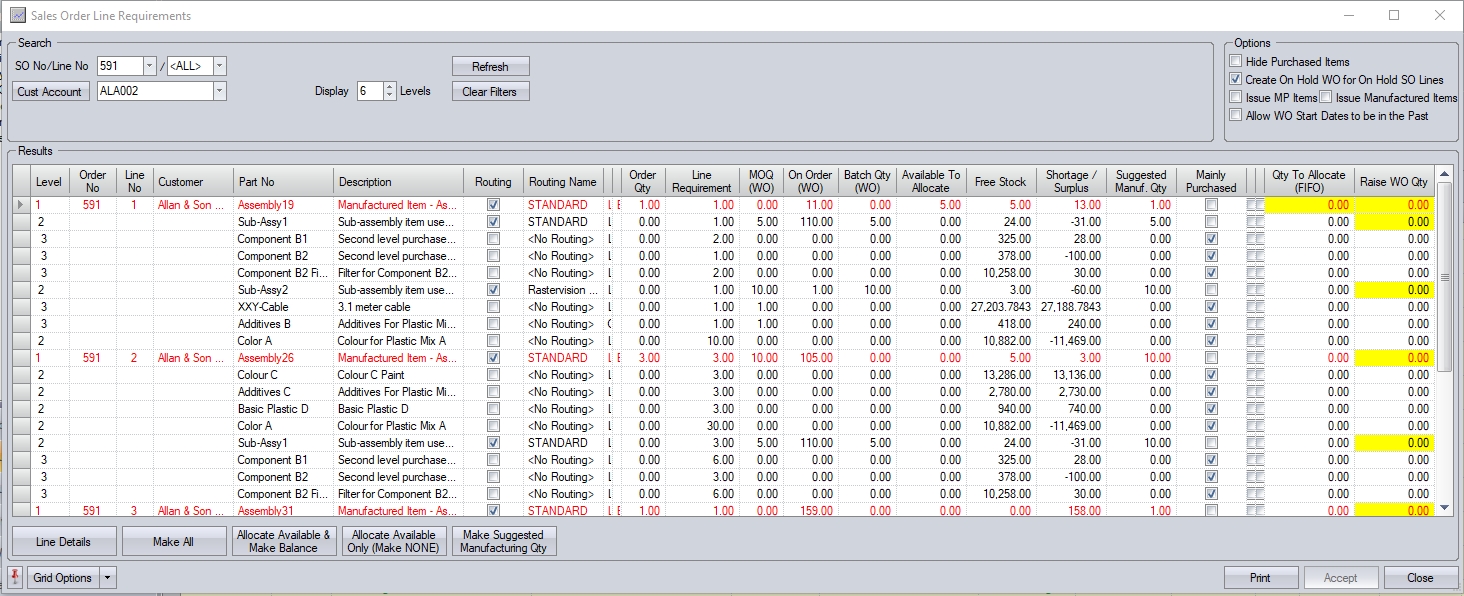

This screen is typically displayed upon creation of a sales order. This screen highlights all sales order lines which have an outstanding requirement (i.e. a quantity to be fulfilled). The SO Line Requirements screen shows a breakdown of the SO line part's BOM, allowing the user to create work orders at all levels of the BOM if required. They user can also allocate any existing stock of the finished product to the order if some already exist.

The screen opens showing all sales order lines that have an outstanding requirement by default, however, the user can focus on a specific SO line by amending the filter at the top of the screen and clicking REFRESH.

The results grid shows the BOMs of all selected sales order lines, along with relevant information for each part number listed, including minimum order quantities, free stock, shortage/surplus figures so the user can make informed decisions on whether they need to raise further work orders to meet their requirements.

The user has two fields, highlighted in yellow, on the grid which determine whether existing stock is allocated (QTY TO ALLOCATE (FIFO) ) and/or work orders are created (RAISE WO QTY).

These fields can be manually completed by the user, or they can use the following options at the bottom of the screen.

![]()

These options provide quick ways to populate the QTY TO ALLOCATE (FIFO) and RAISE WO QTY fields on the grid based on the selected option.

| Make All | Clicking this button will enter the full sales order quantity for this item into the RAISE WO QTY field for all manufactured parts with a routing. This option ignores any free stock of this item that may be available to be allocated to help satisfy this order. |

| Allocate Available & Make Balance | Clicking this button will allocate any available free stock to this order by setting a value into the QTY TO ALLOCATE (FIFO) field up to the quantity required/available. Stock allocations are done on a FIFO (First In, First Out) basis which means the system will allocate batches to the sales order lines from the oldest batch first, then the next batch, and the next, until the SO line requirement has been fulfilled. Any shortfall in the sales order quantity that cannot be fulfilled with existing stock will have a value entered into the RAISE WO QTY field so that a works order can be raised for the remaining quantity required. |

| Allocate Available Only (Make None) | Clicking this button will allocate any available free stock to this order by placing a value into the QTY TO ALLOCATE (FIFO) field, up to the quantity required/available. Again, stock allocations are done on a FIFO (First In, First Out) basis which means the system will allocate batches to the sales order lines from the oldest batch first, then the next batch, and the next, until the SO line requirement has been fulfilled. This option will not raise work orders, even if there is a shortfall, so the RAISE WO QTY field will be zero. |

| Make Suggested Manufacturing Qty | This options populates the RAISE WO QTY field with a calculated quantity, based on the existing sales order line requirements, minimum work order quantity and work order batch sizes. The grid shows a SUGGESTED MANUF. QTY value based on this criteria, so selecting this option populates the RAISE WO QTY field with the calculated values. |

NOTE: Although these options will often produce the works orders and/or allocations required, we suggest the user reviews the quantities set to ensure the results are exactly what they expect. Stock discrepancies can impact the results, especially if stock exists systematically but not physically.

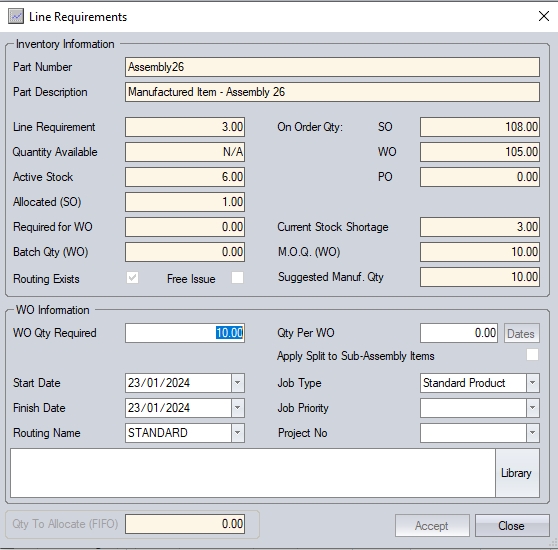

Line Details

This option gives the user more control over the work orders created, allowing them to create batch-sized WOs, each with individual associated work order dates. This can be useful if the customer has ordered a total qty, but has requested the batches are delivered periodically (i.e. one batch a month, etc.) Clicking this option will open a screen similar to the following, displaying details relating to the selected sales order line.

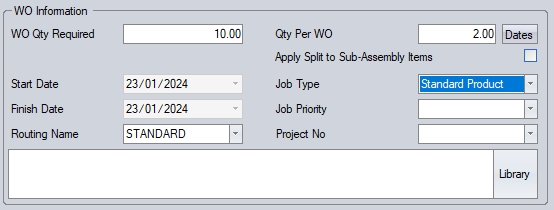

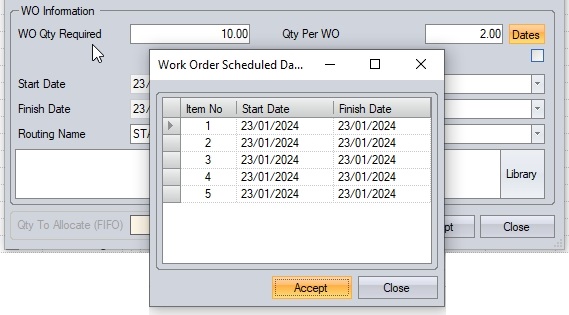

The bottom-half of the screen can be used to raise multiple work orders to fulfill the sales order quantity, and also allow the user to set individual work order dates. The QTY PER WO field allows the user to set the work order quantity required, while the DATES option will allow them to assign individual dates against each work order if required.

(Using QTY PER WO to generate multiple WOs)

(Ability to set individual WO dates)

Once the user has specified how they wish the work orders to be generated, clicking ACCEPT on the SO Line Requirement screen will proceed to create all work orders requested and/or allocate any stock available based on the details entered by the user.

If the system is configured to automatically generate and print the associated work order documents (i.e. WO Job Card, Material List, Operations List) then these will be sent to the user's printer.

If the system is configured to issue material/sub-assembly items to the work orders created, then this will be done at this stage too.

Once the system has finished processing the sales order, the SO Line Requirements screen will close.