Purchase orders are raised for the purchase of goods or services. These can be created based on part shortages (i.e. supply < demand), subcontract requirements (i.e. subcontract work), or manually for non-inventory items (i.e. text POs).

Manually Raising Standard Purchase Orders

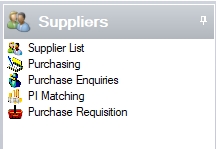

The user can raise purchase orders manually. This method requires the user to enter all the details into the blank purchase order. This can be done via the Purchasing section of Progress, within the Suppliers section. Clicking on the Supplier section will present the following options.

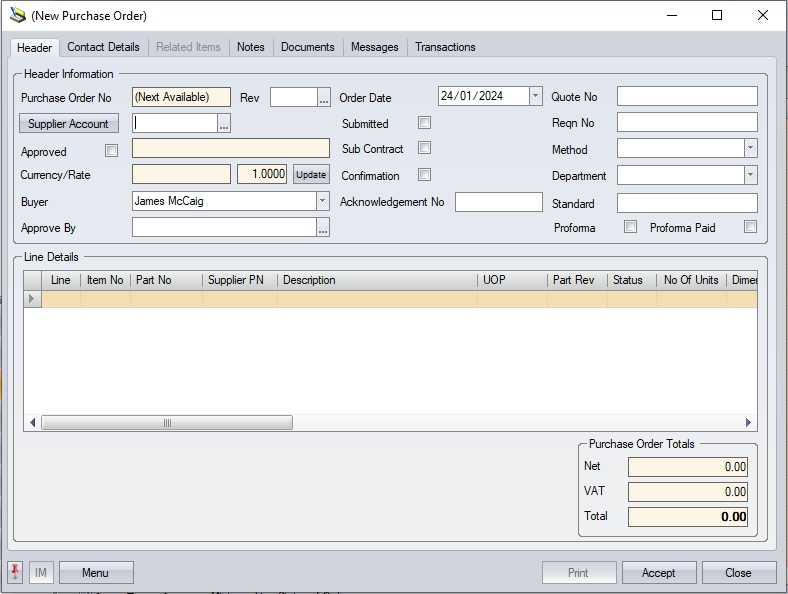

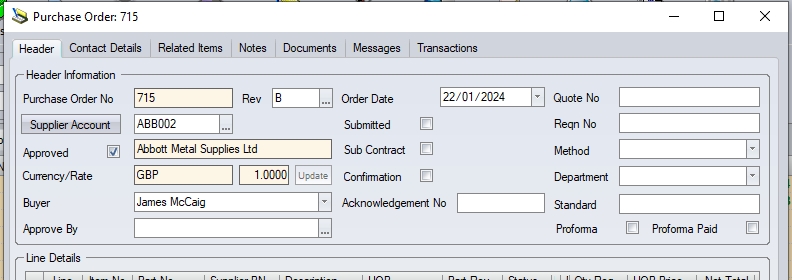

The user must now click on to the NEW option to open a new Purchase Order form.

| Purchase Order No | This is the system maintained purchase order number. The Purchase Order No will be populated on saving the purchase order. |

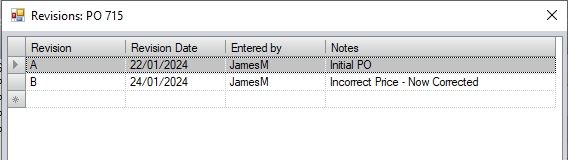

| Rev | This is the revision of the purchase order. This option allows the user to amend the revision of the purchase order, and add notes to explain the changes to the order. |

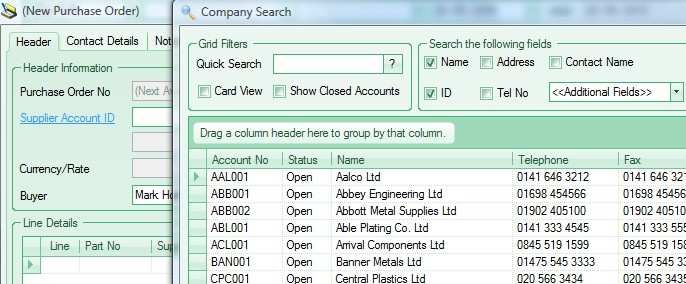

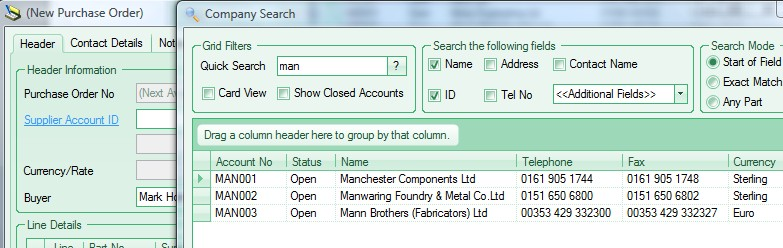

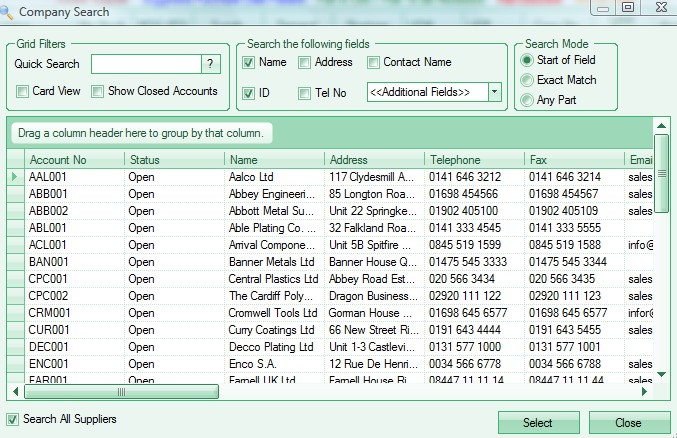

| Supplier Account ID | Who are we raising the purchase order to? The user must select an existing supplier via the Company Search screen. The user can choose to scroll up and/or down to find the required record or alternatively by entering the first few letters of the required company name into the QUICK SEARCH field will narrow down the search. |

(Company Search – No Criteria)

(Company Search – Partial Details Entered)

| Approved | If Progress has been configured to use purchase order approvals, this option allows the user to approve the purchase order if they have authority to do so. If not, the purchase order will have to be approved by an authorised user before being sent to the supplier. |

Currency / Rate This is the default currency set up for this supplier. The rate for foreign currency suppliers will default to the current rate for the supplier's currency as set in Progress.

| Buyer | Who is entering the purchase order? This field will default to the current system user but can be amended by choosing an alternative from the drop-down list. |

| Approve By | This option allows the user to specify an approver for the purchase order if someone specific needs to approve it. The user can select the appropriate person from the drop-down list if required, although this is not mandatory. |

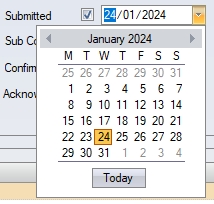

| Order Date | This is the order entry date. This field will default to the current date but the user can select an alternative from the drop-down calendar. |

| Submitted | This option indicates the purchase order has been sent to the supplier. Ticking this option will set/show the associated date to the current date, however, the user can amend the date using the drop-down calendar if required |

| PO Subcontract | This field must be ticked if the purchase order being raised is for a subcontract process (i.e. plating, heat treatment, etc.) required for a works order and not for goods or materials. |

| Confirmation | This options allows the user to indicate the the purchase order has been received and confirmed by the supplier. |

Acknowledgment No This field can be used to record an acknowledgment number from the supplier upon acceptance of the purchase order.

| Quote No | This field can be used for recording a purchase enquiry number. If the purchase order is created from a purchase enquiry within Progress, this will show the purchase enquiry number. |

| Reqn No | This field can be used for recording a purchase requisition number. If the purchase order is created from a purchase requisition within Progress, this will show the purchase requisition number. |

Method This field allows the user to specify how the purchase order was sent to a supplier. The user can choose from the drop-down list available, but this field is not mandatory.

| Department | This field allows the user to assign a department to the purchase order. The user can select a department from the drop-down list if required, but this field is not mandatory. |

Proforma This option allows the user to specify that the purchase order is a proforma order (i.e. needs to be paid up front).

Proforma Paid This option allows the user to mark a proforma purchase order as paid.

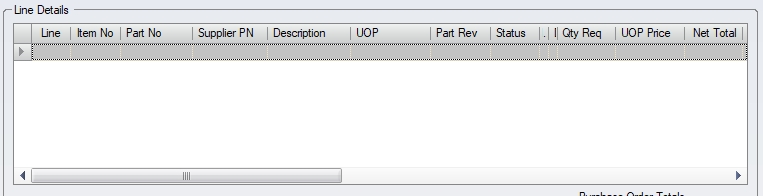

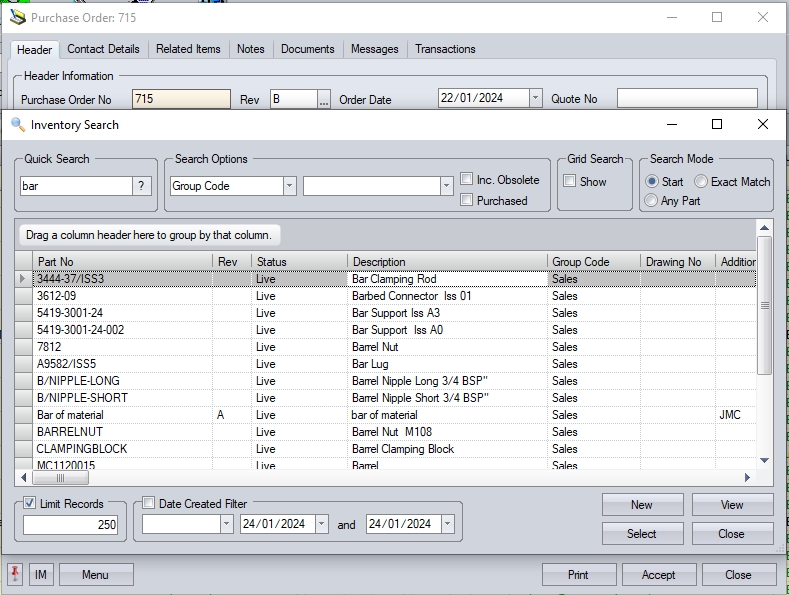

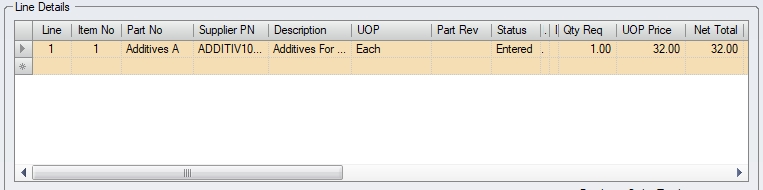

After completing the required fields in the purchase order, the user can proceed to enter details of the items that require to be purchased in the Line Details section. This is where the user specifies the details of the items being purchased.

The user can choose to select an existing part number to include on the order, create a new part if the required item does not exist, or simply type in a description of the item to be purchased.

Purchasing An Existing Part

If the user wishes to purchase a part that already exists in Progress, they can select the item from the inventory list, which will also populate some of teh information on teh PO line based on the part record. This includes, but is not limited to, description, unit of purchase (UOP), supplier part numbers, etc.

| Part No | The user can select an existing part by typing the part number if known into this field, or by via the Inventory Search form. Similar to the other searches within Progress, the user can choose to scroll up and/or down to find the required record or, alternatively, by entering the first few letters of the required item into the QUICK SEARCH field will narrow down the search. |

| If the part required does not already exist, the user can click on the NEW option to create a new inventory part. Once created, the user can select it for inclusion on teh purchase order. |

| Once the user has selected the part required, they will be returned to the purchase order with the part added to the purchase order line. |

| Supplier PN | If the chosen supplier has their own part number set up against the selected part number, it will be displayed in this field. |

| Description | This is the part description of the chosen item as recorded against the part record. |

| Status | This field will display the current order status of this line. When entering a new purchase order this will default to ENTERED. The line status will automatically be updated by the system based on activity associated with the purchase order line (i.e. receipts, supplier returns, purchase invoice matching, etc.) The status may only be changed to The statuses used by Progress are as follows: |

| ENTERED - Order Entered, No Goods Received. |

| PART RECEIVED - Order Entered, Partial Receipt Of Goods. |

| FULLY RECEIVED - Order Entered, All Goods Received. |

| COMPLETE - Order Entered, All Goods Received, Supplier Invoice Purchase Invoiced Matched. The user may manually change the status from FULLY RECEIVED to COMPLETE if purchase invoice matching is not used within Progress. |

| CANCELLED - The line has been cancelled. No goods may be received for this line. Order line can only be manually set to cancelled if no goods have been receipted against the line. |

| UOP | This is the previously defined unit of purchase as stored for this item, however, it can be amended on the order line if its being purchased in a different form. |

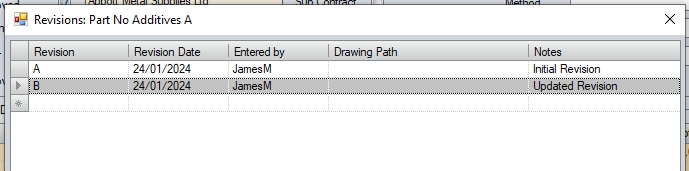

| Revision | This field shows the revision of the selected part number. This will default to the part number's current part revision as set in the inventory record, however, the user can select any valid revision for the part selected. |

| Qty Req | This is the quantity that is to be purchased. This field will default to the purchasing minimum order quantity (MOQ PO) set against the part number, however, the user can set the quantity to any value they wish. |

| UOP Price | This is the price being paid for the item and is based on the unit of purchase. This will default to either the part's purchasing cost, or to a supplier price matrix price if one exists for the selected supplier and part number, however, the user can set this to any required value. |

| NET Total | This is a calculated field based on the quantity order and the UOP price entered. This value will include any discounts or surcharge percentages applied to the order line. |

| Date Required | This is the date that the user is looking for this item to be delivered by. This date will automatically default to the purchase order entry date (usually “today”) plus any Purchasing lead time defined against this part, though the user may choose any date required via the drop-down calendar. |

| Promised Date | This is the confirmed date from the supplier. Initially, this date will be the same as the required date, however, this can be updated once confirmation is received from the supplier. |

| Latest Date | This is the latest confirmed date from the supplier. Initially, this date will be the same as the required date, however, this can be updated to reflect any changes to dates beyond the required and promised date from the supplier. |

| Qty Rec | This is a system maintained field displaying the quantity received for this line. |

| Qty Returned | This is a system maintained field displaying the quantity received for this line then returned to the supplier for whatever reason. |

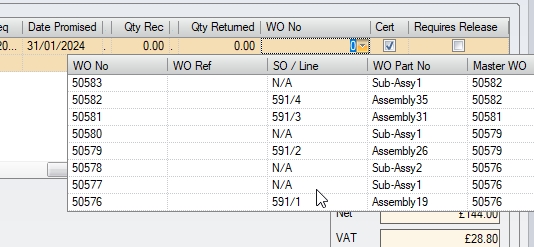

WO No If the part being ordered if for use on a specific work order, the user can link the order line to the work order. The user can select the work order using the drop-down list.

| Cert | This field may be ticked to signify that this order line requires a certificate of conformity from the supplier. If the part number itself has the CofC REQUIRED flag ticked, this will automatically be ticked on the order line when the part is selected. This information can be included on the purchase order layout if desired to indicate a cert is required with the goods. Ticking this field will also highlight the CERT REQUIRED field when booking the items into stock when they are received from the supplier so the employee receiving the goods knows a cert should be provided. |

| Requires Release | This option indicates whether the item being purchased needs to be inspected upon arrival. This option places the receipt onto a temporary hold status when received and requires a user to "release" the goods to stock after they have been inspected. |

Once all the details have been entered, the user can repeat the process for any additional line items they need to add to the purchase order, or click ACCEPT to save the details in the purchase order.

Purchasing a Non-Inventory Item (Text PO)

In some cases the user may want to purchase an item that does exist within Progress and does not require the same traceability levels or stock control of a standard part. For this scenario, the user can raise a text order line.

The top part of the purchase order would be completed by the user just like a standard purchase order; selecting the supplier, settings dates, etc.

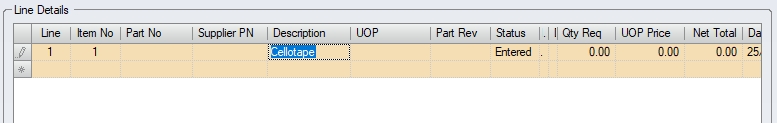

On the Line Details section, the user will not enter or search for any part number, but simply type into the DESCRIPTION field details of the item to be purchased.

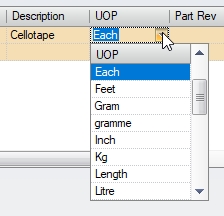

The user must now choose a unit of purchase (UOP) for the item from the drop-down list.

It is essential that a UOP is entered for text purchase order lines. If the item is being ordered has multiple units per unit of purchase (i.e. pack, box, etc.) then the user should select an appropriate UOP as this is what the unit price will reflect. If the required UOP is not available in the drop-down list, then the required UOP must be added to Progress via the Maintenance > List Maintenance > Units Of Measure list first. The user can proceed to enter the QTY REQ, UOP PRICE and DATE REQUIRED in the same manner as a standard PO. The user can also still link the order line to a specific work order if the item being purchased is specifically for that job, but its not mandatory.

Once all the details have been entered by the user, the user can repeat the process if further items are to be ordered, or click ACCEPT to save the order details.

Purchase Order Notes

Further details on the items being ordered, or how they should be delivered can be added by the user via the order notes sections. These can be entered for the order as a whole (i.e. PO notes) or for specific order lines (i.e. PO Line notes).

PO Notes

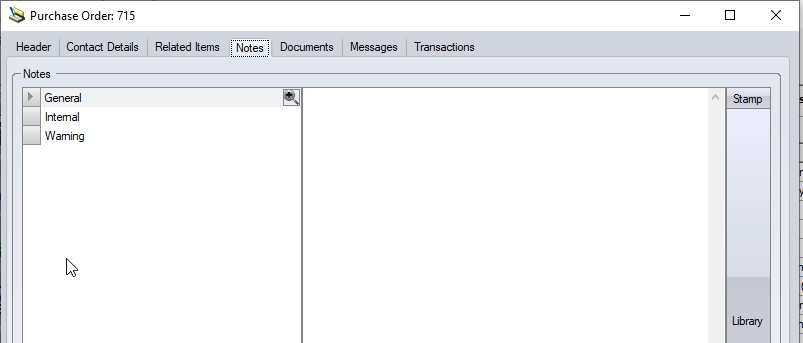

Purchase order notes (i.e. relating to the entire order) are entered via the Notes tab at the top of the purchase order. This tab gives the user a few note fields that can be used.

The notes fields available for the overall order are as follows:

| General | This note field is the main one for relaying information to the supplier and is typically included on the purchase order sent to the supplier. |

| Internal | This note is an internal note and is not included on the purchase order sent to the supplier. This is useful for adding notes that are for internal purposes or reference. |

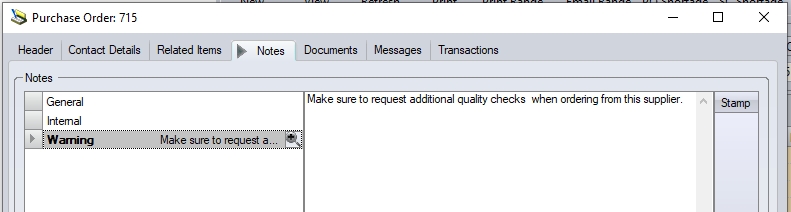

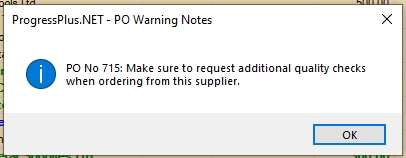

| Warning | This note is a warning note for the order. Any text entered into this field will be displayed as a warning note when someone opens the purchase order. This is useful for relaying information relevant to the order to anyone who looks at the order. |

(Example PO warning note)

(Warning note displayed when opening PO)

The user can manually enter the note required in any of the listed notes fields, or they can select a pre-defined note from the Notes Library, using the LIBRARY option to the right of the notes fields.

PO Line Notes

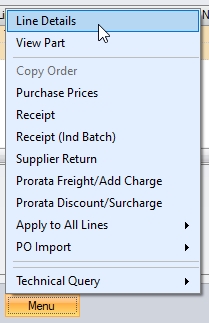

The user can also enter notes relating to individual purchase order lines. The line notes are added via the Purchase Line Details screen in the Notes tab. To add line notes to the order line, the user must open the line details screen, either by double-clicking on the purchase order line, or select the LINE DETAILS option via the purchase order MENU option.

(Accessing order line details via MENU option)

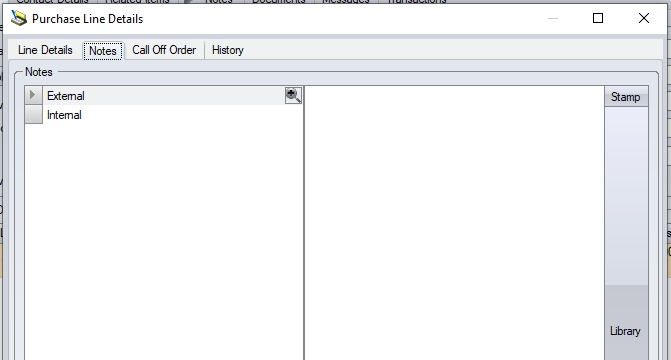

(Order line Notes tab)

The notes fields available for the selected order line are as follows:

| External | This note field is the main one for relaying information to the supplier about the selected line item and is typically included on the purchase order sent to the supplier. |

| Internal | This note is an internal note and is not included on the purchase order sent to the supplier. This is useful for adding line-specific notes that are for internal purposes or reference only |

As per the general order notes described above, the user can manually enter the note required in any of the listed notes fields, or they can select a pre-defined note from the Notes Library, using the LIBRARY option to the right of the notes fields.

Once the user has entered any required notes, clicking the ACCEPT button will save the notes and return the user to the previous screen.

Purchasing Subcontract Services (Subcon POs)

External processes, or subcontract process as they are called in Progress, use a slightly different purchase order format. This is due to them not relating to physical goods. Subcontract purchase orders use subcontract codes to specify whats being ordered (i.e. Paint, Heat Treatment, etc.)

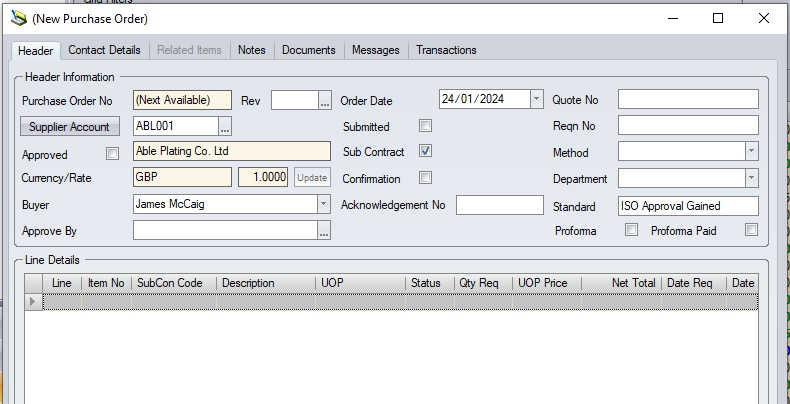

Subcontract purchase orders still require the user to select the supplier details as per standard purchase orders, so this is the same, the only difference being that the user must tick the SUB CONTRACT option to tell the system that its a subcontract purchase order that's being raised.

(New subcontract purchase order)

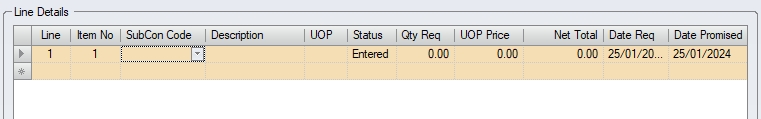

Once the user has indicated that the purchase order being created is a subcontract purchase order, the Line Details section will change to "subcontract" details. Instead of part numbers, this will now be based on subcontract codes and work orders.

| Line | This is a system generated sequential number relating to the order line. |

| Item No | This field defaults to match the Line field above, however, this can be edited by the user to make it show something more relevant. |

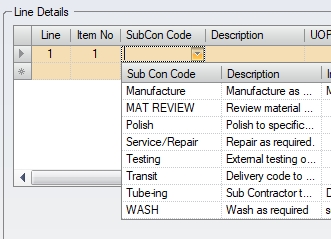

| SubCon Code | Clicking onto this field will display a list of subcontract codes that the user can select from. The user can click on the required process to continue. |

| UOP | This will default to EACH on a subcontract purchase order. |

| Status | This field will display the current order status of this line. New purchase order lines will default to ENTERED status. Subcontract orders use the same order statuses as standard purchase orders. |

| The statuses used by Progress are as follows: |

| ENTERED - Order Entered, No Goods Received. |

| PART RECEIVED - Order Entered, Partial Receipt Of Goods. |

| FULLY RECEIVED - Order Entered, All Goods Received. |

| COMPLETE - Order Entered, All Goods Received, Supplier Invoice Purchase Invoiced Matched. The user may manually change the status from FULLY RECEIVED to COMPLETE if purchase invoice matching is not used within Progress. |

| CANCELLED - The line has been cancelled. No goods may be received for this line. Order line can only be manually set to cancelled if no goods have been receipted against the line. |

| Qty Req | This is the quantity that is to be sent for the subcontract process. |

| UOP Price | This is the price for this subcontract process per unit. The user can simply type a cost into this field. |

| NET Total | This is a calculated value, based on the UOP price and the quantity ordered. This will also take any discounts or surcharges applied to the line into account. |

| Date Req | This is the date that the user is looking for the subcontract item to be returned by. The user can select the date for this order line from the drop-down calendar. |

Date Promised This is the date confirmed the by the supplier. Initially, this will be the same as the required date.

| Qty Rec | This is a system maintained field displaying the quantity received against this line. |

| Returned | This is a system maintained field displaying the quantity returned to the supplier for whatever reason. |

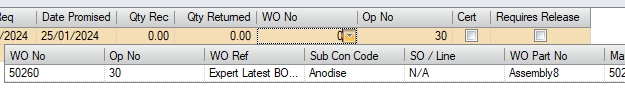

| WO No / Op No | Subcontract purchase orders must be linked to the associated WO No/op. This information is mandatory for subcontract orders. Clicking on this field will display a list of the current outstanding works orders that have a requirement for the selected subcontract code. The user must choose a works order and operation for this subcon process to continue. |

| Cert | This field may be ticked to signify that this order line requires a certificate of conformity from the supplier. This information can then print off on the user’s purchase order layout if desired. Ticking this field will also highlight the Cert Required field when receipting the subcontract items when they are returned from the supplier. |

| Requires Release | This option indicates whether the item needs to be inspected upon arrival. This option places the receipt onto a temporary hold status when received and requires a user to "release" the goods to stock after they have been inspected. |

Once all the details have been entered, the user can repeat the process for any additional subcontract line items they need to add to the purchase order, or click ACCEPT to save the details in the purchase order.

Printing Purchase Orders

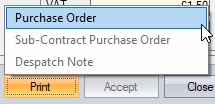

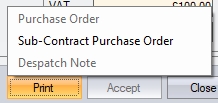

After the purchase order has been completed, and the purchase order has been saved, the user can print the order via the PRINT button at the bottom of the order. The print option has several options available, but these will only be available in the correct order type.

(Printing a standard PO)

(Printing a subcontract PO)

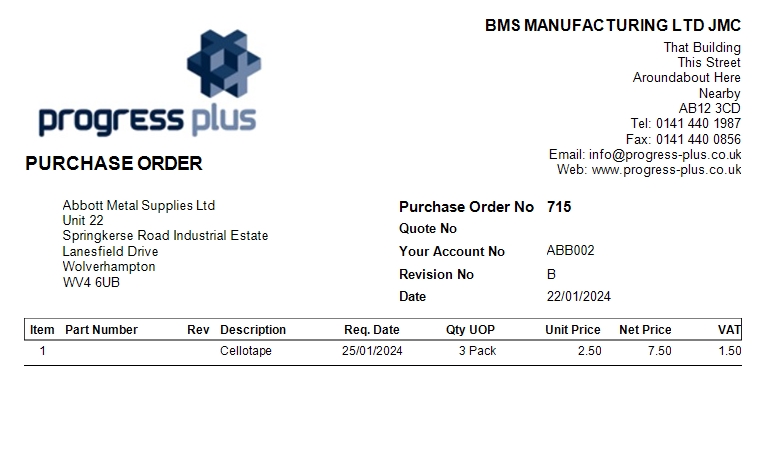

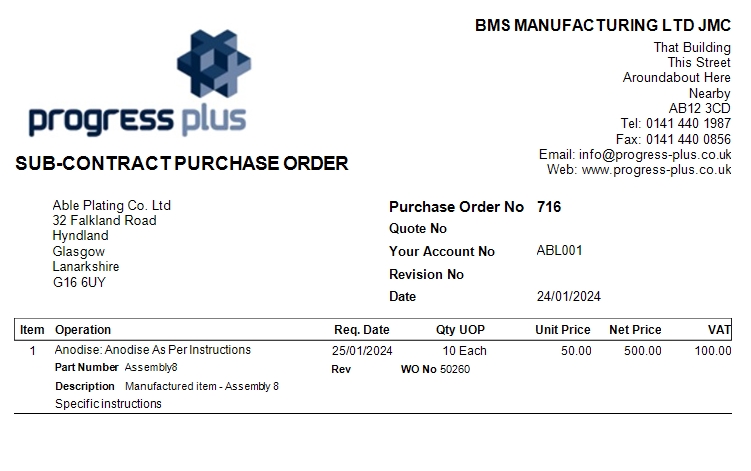

The purchase order will then be displayed on screen.

(Example standard PO)

(Example subcontract PO)

Once displayed, the user can save the document in a number of formats via the SAVE option, print a hard copy of the document on a printer of their choice via the PRINT option, or email the document directly to the customer via the EMAIL option.

Raising Standard Orders Based on Shortages/Requirements

In addition to raising purchase orders manually in the manner previously described, the user can also purchase items based on outstanding shortages/requirements. This method can be access in two ways:

1. Via the Today > To Do > Items To Be Purchased screen

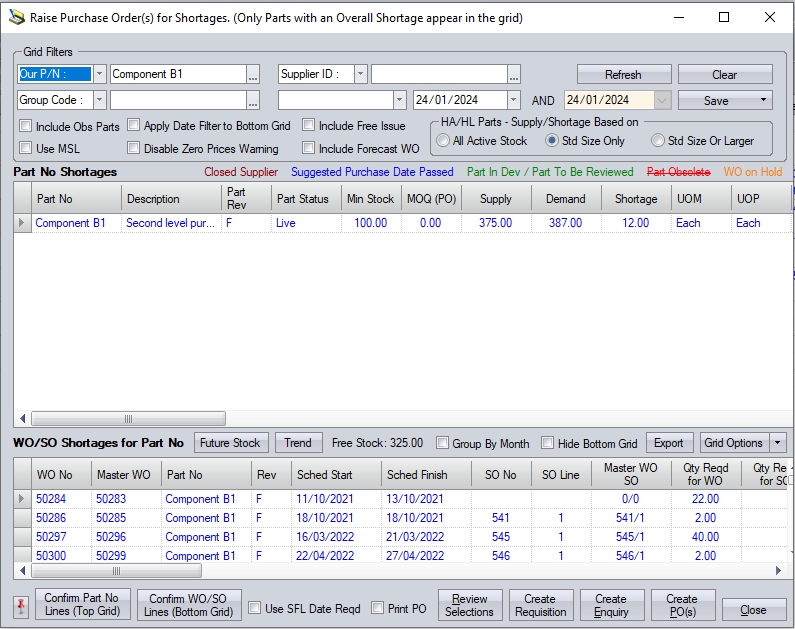

2. Via the Suppliers > Purchasing > PO Shortage option

Ultimately, the user will end up at the same screen (the PO Shortage screen) from which they can raise the required purchase orders.

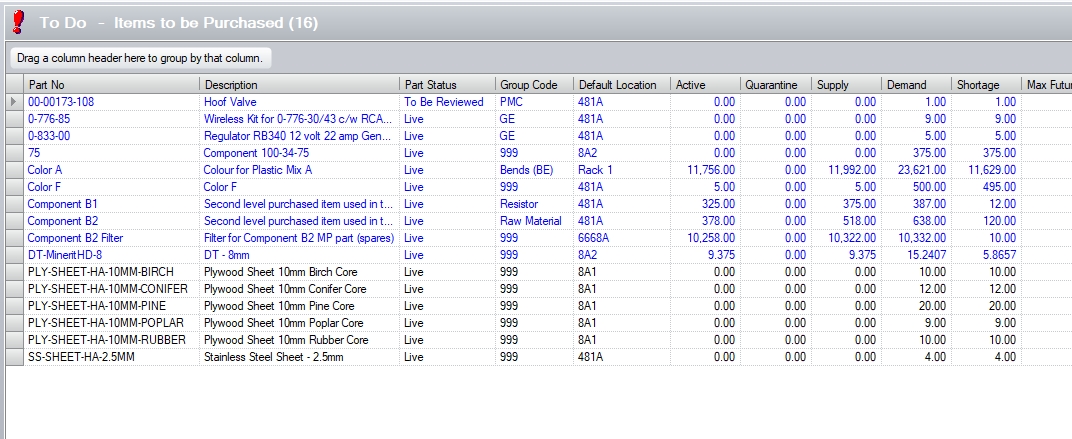

Items To Be Purchased screen

This screen highlights all mainly purchased inventory parts that currently have an overall shortage (i.e. SUPPLY < DEMAND). The screen shows summary figures for the supply and demand of each listed part, current stock and earliest date required, as well as some other supplier related information.

To purchase an individual item listed on the Items To Be Purchased screen, the user must double-click onto the required item. This will open the PO Shortage screen, filtered by the selected part number.

The user can still see all parts that have shortages by simply removing the filtered part number and pressing REFRESH. This will display all purchased parts that have an overall shortage.

PO Shortage screen

Instead of the user going via the Items To Be Purchased screen, the user can go direct to the PO Shortage screen via the Supplier > Purchasing section, using the option at the top of the Purchasing screen.

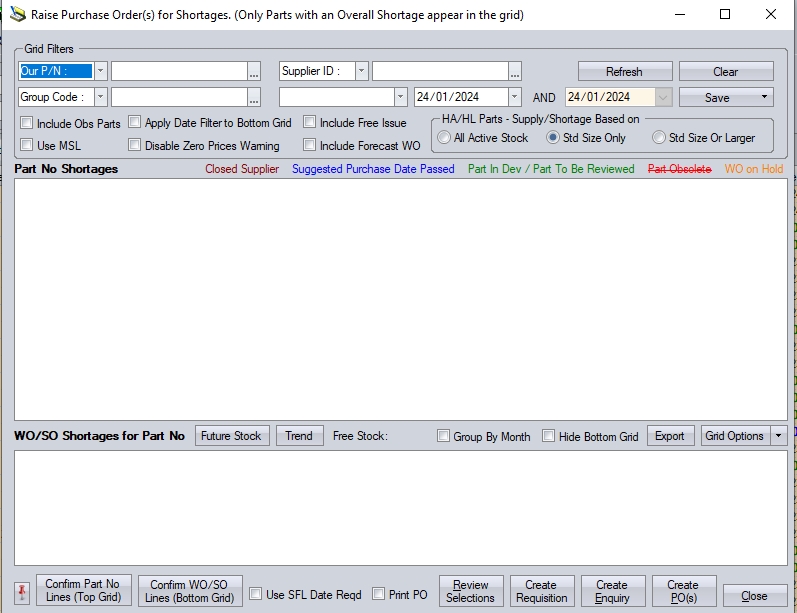

Clicking this option will open the PO Shortage screen.

No filters are applied at this stage, so the user can apply any filters they wish, or simply click REFRESH to see all parts that currently have an overall shortage.

The PO Shortage screen is split into two parts; overall part shortages (top half) and WO/SO specific shortages (bottom half).

Part No Shortages

The top section of this screen will total up all requirements for each part. This option is used when the user wishes to buy to a stock position or wants to raise a purchase order that totals the requirements for a number of works order. This approach will not be linked to any specific job and is more of a general purchase which covers a number of requirements.

WO/SO Shortages For Selected Part No

This option is used when the user wishes to purchase the part(s) for a number of specific works orders and/or sales orders but wishes to have separate lines for each order.

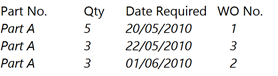

An example of the differences between these options would be as follows:

Part A is required for 3 works orders; WO No.1 requires 5, WO No. 2 requires 3 and WO No.3 Requires 3 - a total requirement of 11.

Using the Part No Shortages (top half) approach would raise a single line order for a total of 11 with no work order association e.g.

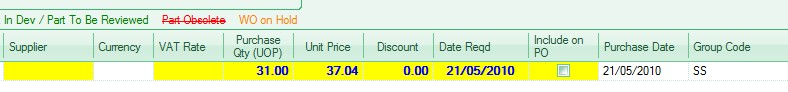

![]()

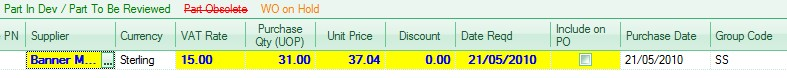

Using the WO/SO Shortages For Selected Part No approach would raise a multi-line purchase order , with each line linked to the relevant work order or sales order.

Once the user has decided how the purchase order needs to be raised, the user can proceed to enter the remaining information essential for raising a purchase order. Both approaches require the same information to be added before the purchase order can be created.

| Supplier | Who are we raising the purchase order against? This field will display the name of any PREFERRED SUPPLIER assigned to the part, however, user can choose a supplier from via the Company Search screen. The user can choose to scroll up and/or down to find the required record, or alternatively, by entering the first few letters of the required company name into the QUICK SEARCH field will narrow down the search. |

(Supplier selection)

| Clicking on the required supplier and pressing the SELECT button will return the user to the previous screen and populate the field with the selected supplier. |

| VAT Rate | This is the default VAT rate set up for this supplier within the supplier record. This can be changed if required. |

| Purchase Qty | This is the quantity that is to be purchased. This field will default to any MOQ PO (purchasing minimum order quantity) that may have been set for this item if the shortage is less than the MOQ PO. The user may chose to override this quantity to suit. |

| Unit Price | This is the price of the individual part. If a supplier price matrix exists for the selected supplier/part combination, this field will default to the relevant price. If no supplier price matrix exists for the supplier/part number combination, then this will default to the part's PURCHASING COST. If no pricing exists within Progress, this will be zero, and the user can enter any price required. |

| Discount | The user can enter any discount expected by percentage. Any discount for this item previously entered in a Supplier Price Matrix would be automatically populated though the user can amend this discount field if required. |

| Date Reqd | This is the date that the user is looking for this item to be delivered by. The user can choose the DATE REQD for this order line from the calendar lookup. This date will automatically default to the purchase order entry date (usually “today”) plus any Purchasing Lead Time defined against this part, though the user may choose any date required. If the user has decided to use the WO/SO Shortages For Selected Part No approach, the DATE REQD field will default to the Works Order Start Date assuming this is in advance of today’s date. If the date required for this item has already passed, this will be highlighted in blue as the suggested date has passed and the DATE REQD will default to today’s date plus any purchasing lead time set against the part. |

| Include On PO | Once the details have been entered, the user must click on the INCLUDE ON PO option for each line that is to be purchased. A purchase order cannot be raised if no items have been selected. |

| Purchase Date | This field will display the suggested purchasing date for an item. It can be useful when using the WO/SO Shortages For Selected Part No option. This will calculate a date based on the works order START DATE minus any purchasing lead time defined against this part. If this date has passed the information will be highlighted in blue. |

| Confirm Part No Lines (Top Grid) | The user must click this button if using the Part No Shortages approach to confirm selection of the items to be included on the purchase order. This adds the selected item(s) on the top-half of the PO Shortages screen to the "shopping list". |

![]()

| Confirm WO/SO Lines (Bottom Grid) | The user must click this button if using the WO/SO Shortages For Selected Part No approach to confirm selection of the items to be included on the purchase order. This adds the selected item(s) on the bottom-half of the PO Shortages screen to the "shopping list". |

![]()

| Print PO | This field can be ticked if the user wants to automatically print off the purchase order on completion. |

| Review Selections | This option will display a list of selected items for the purchase order(s). Basically, this lets the user see their "shopping list" before the purchase orders are created. |

![]()

| Create Requisition | Clicking this option allows the user to create a purchase requisition for all the selected items/suppliers. |

![]()

| Create Enquiry | Clicking this option allows the user to create a purchase enquiry for all the selected items/suppliers. |

![]()

| Create PO(s) | Clicking this option allows the user to create a purchase enquiry for all the selected items/suppliers. |

![]()

Once the user has created their purchase orders, they can click CLOSE to exit the PO Shortages screen and return to the main system. Any purchase orders created will now be listed and accessible via the Supplier > Purchasing screen. If further purchase orders are required, the user can repeat the steps above to create the purchase orders required.