When a work order is finished and the units being made are complete, the work order needs to be receipted into stock. This is done via the WO Receipt screen. This screen can be access from within the work order itself, via the MENU option, or via the Inventory > Receipts section. Like the PO Receipt screen previously mentioned, both methods will take the user to the same screen, the only difference being that accessing from the work order itself will automatically filter the screen for that work order. Accessing from the Inventory section will require the user to enter the work order.

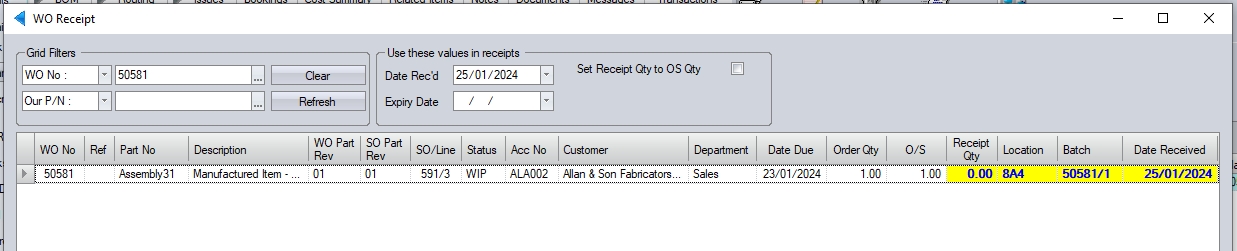

(Initial WO Receipt screen via WO)

(Initial WO Receipt screen via Inventory section)

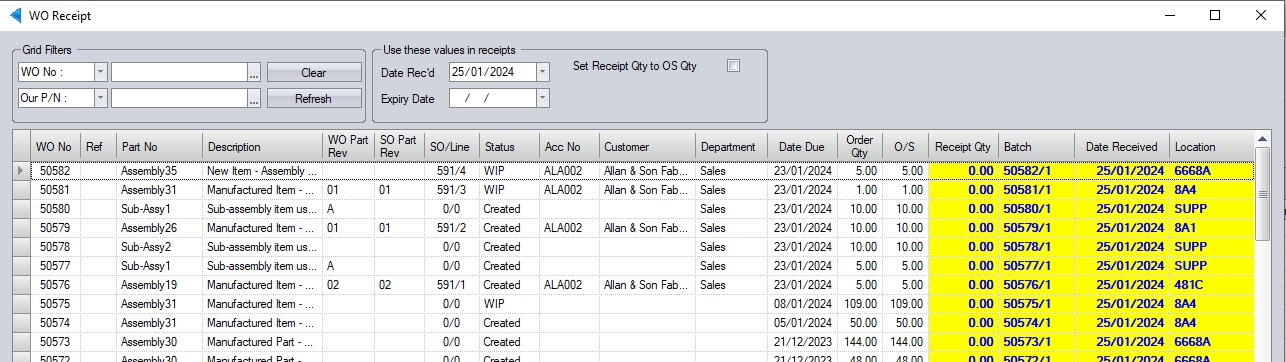

The user can apply any specific filters they need (i.e. WO number, SO No, etc.) using the grid filters at the top of the screen or, alternatively, click REFRESH to see everything that's outstanding.

Once the work order details are displayed, the user can enter the quantity to be booked into stock against their work order on the grid. The main information required on this screen is as follows:

| Receipt Qty | This is the number of finished units being receipted into stock. This is a mandatory field. |

| Batch | This is the batch number of the finished units. This will default to the work order number and receipt number (i.e. XXXX/YY, where XXXX is the WO number, and YY is the receipt number against the order) however, the user can set any batch number they prefer. |

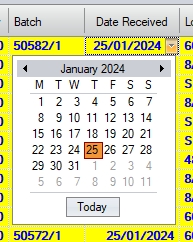

| Date Received | This is the date of the receipt. This will default to the current date, but can be changed using the drop-down calendar if required. |

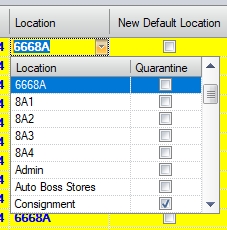

| Location | This is the stock location that the units will be receipted into. This will default to the work order part's default location but, again, the user can amend by selecting an alternative location from the drop-down list. |

| Requires Release | This option allows the user to place the receipted goods on a temporary "on hold" status. If the master part record has the REQUIRES RELEASE option ticked, then all receipts of the part will automatically have this option ticked, however, the user can tick/untick this as required for this individual receipt. |

GRN/Release Notes These fields allow the user to add notes to the receipt. These will be recorded against the GRN created by the receipt.

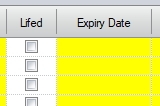

| Expiry Date | If the item being received has a shelf life and is configured as a LIFED item, this will be highlighted on the grid and the user will be expected to enter an EXPIRY DATE for the batch in the field provided using the drop-down calendar |

Once the user has entered all the details against their work order(s), clicking ACCEPT will complete the receipt(s) and generate GRN numbers for all batches booked into stock. If the system is configured to generate GRN labels for the receipts, these will be generated and printed.

If any of the work orders received are linked to parent work orders (i.e. the parts are on the parent WO BOM), the system will give the user the option of issuing the units to other work orders (as shown in the Issuing Material To A Work Order section of the Quick Start Guide).

If the receipted work orders are directly linked to sales orders, then the receipted units will be allocated to the sales order lines for delivery. If the quantity received is greater than the outstanding requirement of the associated sales order, the system will allocate the outstanding units to the sales order line and place the additional units in stock.