Material can be issued to work orders in a number of ways, but also at a number of stages in the process.

Issuing Material Upon Receipt

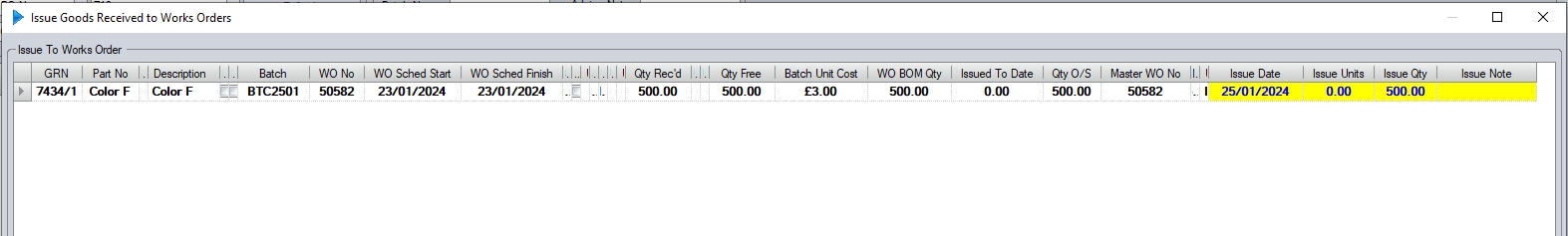

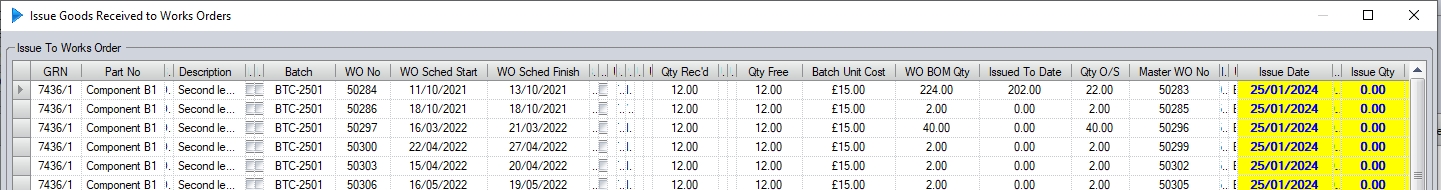

If the system is configured to issue material at the point of receipt, the user can issue material after its been received into stock (i.e. PO receipt, WO receipt, etc.). Once the receipt process is complete, the user is presented with a screen similar to the following, which highlights work orders that are waiting for the item. If the item was purchased for a specific job, the associated work order will be highlighted in bold. If the item was not purchased for a specific job, then all the work orders waiting for the part will simply be listed.

(Issuing PO receipt to WO - Job specific purchase)

(Issuing PO receipt to WO - General purchase)

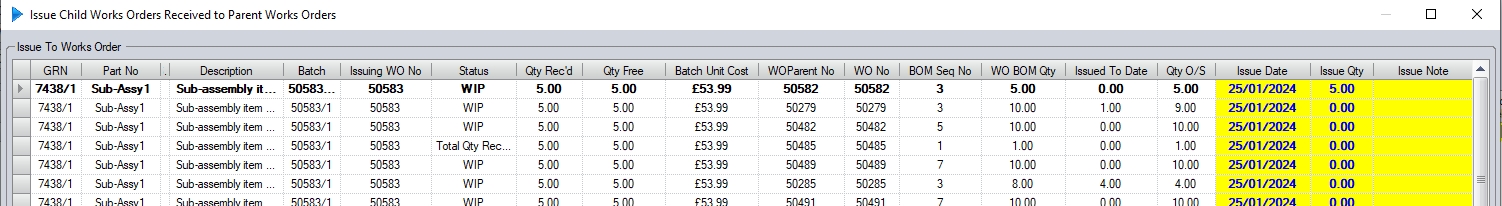

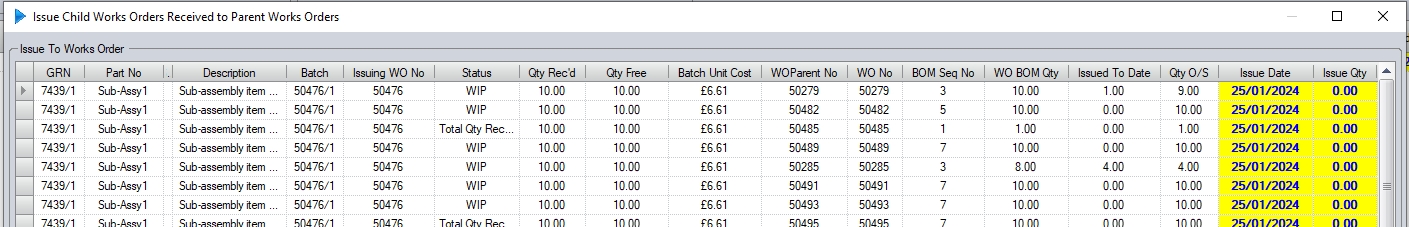

Similarly, receipt of child work orders (i.e. sub-assemblies which are part of a larger assembly) will also prompt the user to issue the part to the parent work order upon receipt. The user will be presented with a screen similar to the issue screen above, but for work order receipts and issues. As per the PO receipt process, if the child work order is linked to a parent WO, then the system will highlight this requirement in bold. If the work order was a general work order (i.e. not for a specific parent WO), then the list of work orders waiting for the part will simply be listed.

(Issuing child WO receipt to parent WO - Job specific)

(Issuing child WO receipt to parent WO - General WO)

Issuing Material from Stock

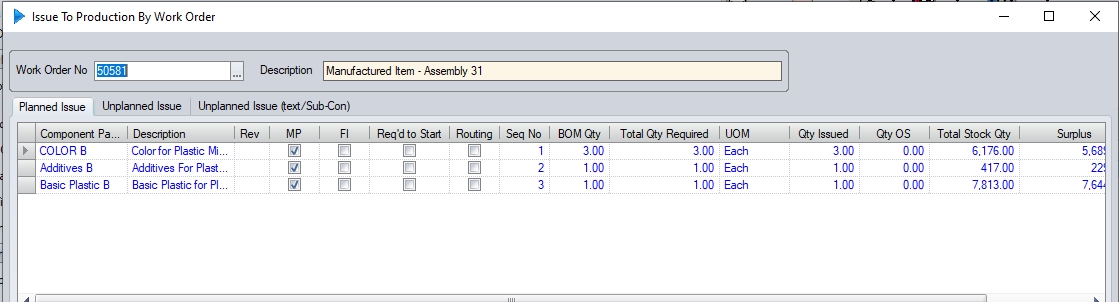

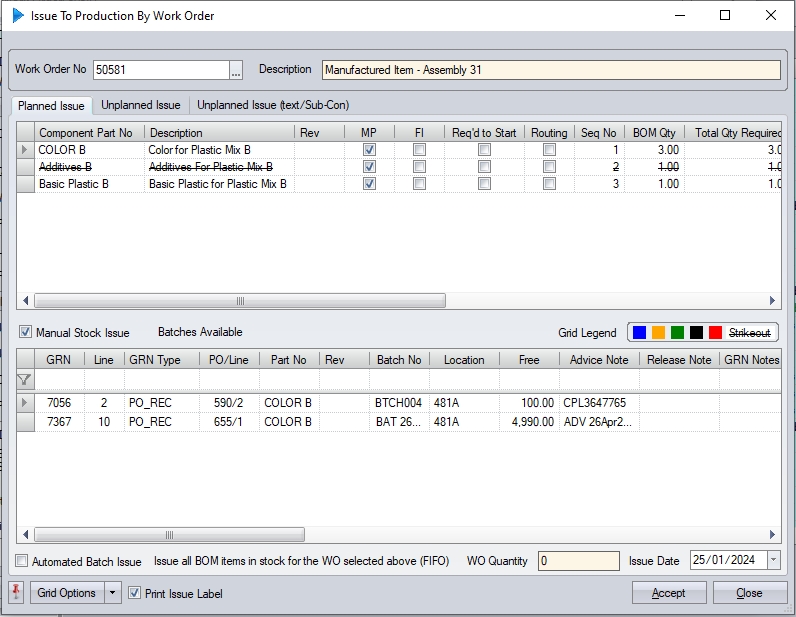

If the parts required by the work order are already in stock, then the user can issue the material using a few options. This is typically done via the Issue To Production By WO screen, which can be access from within the work order itself via the MENU option, or via the Inventory > Issues > Production Issue By WO option. Accessing this from within the work order will automatically filter the screen by that work order. Accessing from the Inventory section will require the user to enter the work order number.

(Issue To Production By WO - From within WO)

(Issue To Production By WO - From Inventory>Issues)

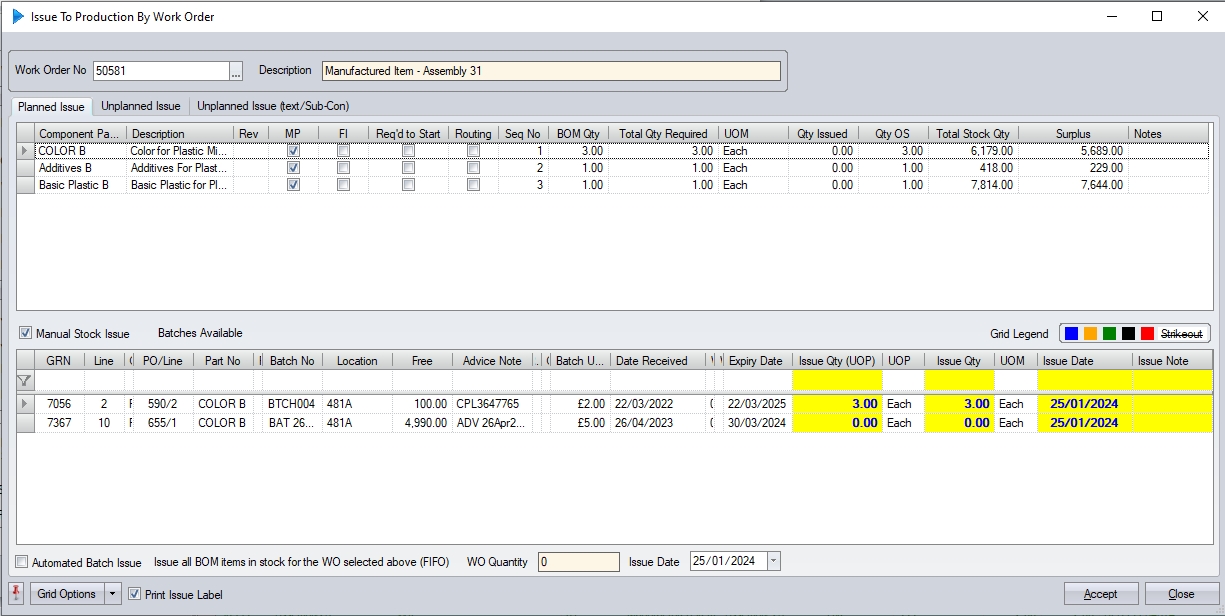

Once the work order has been selected, the screen will be updated to show the associated work order BOM (top half of the screen) and any available stock of the selected part (bottom half of screen).

The user can now choose from three different tabs on this form depending on the type of issue that is required.

| Planned Issue | The user wishes to issue an item that is contained in the WO BOM |

| Unplanned Issue | The user wishes to issue an item than is not contained in the WO BOM |

| Unplanned Issue (Text/Subcon) | The user wishes to issue an item from a text purchase order or a subcon receipt |

The screen will default to the Planned Issue tab, but the user can change this by selecting the tab they require.

Planned Issue

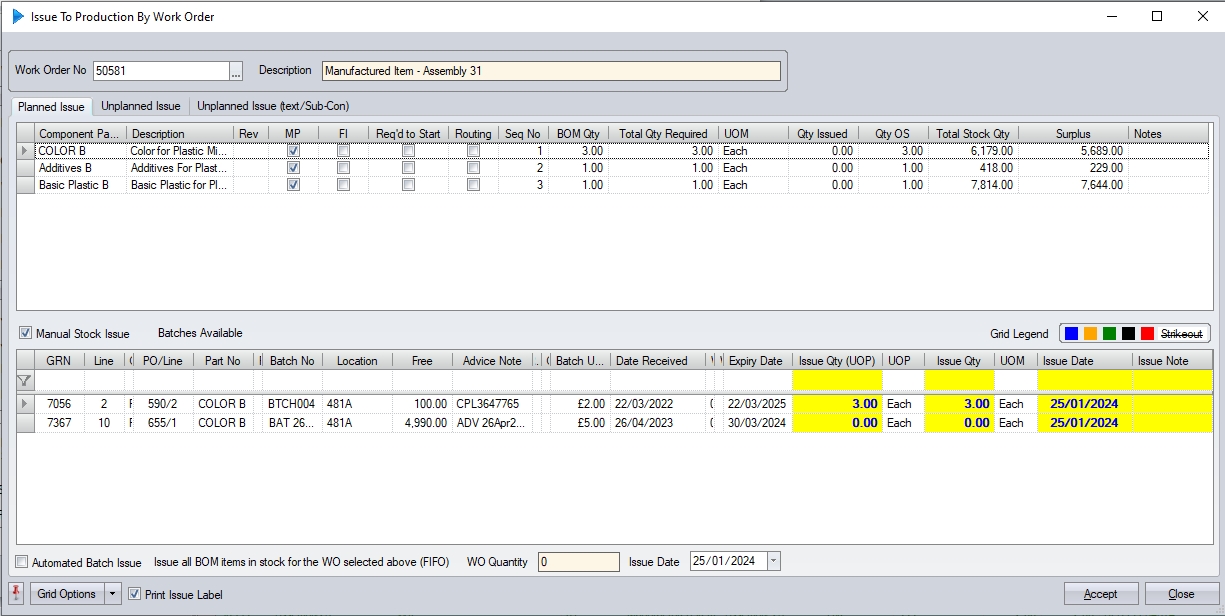

To issue planned material to the work order, the user can select the item to be issued from BOM (top half) and see all available stock (bottom half). The user now has two options; Manual Stock Issue or Automated Batch Issue. These options are selected using the tick boxes provided on the screen

Manual Stock Issue

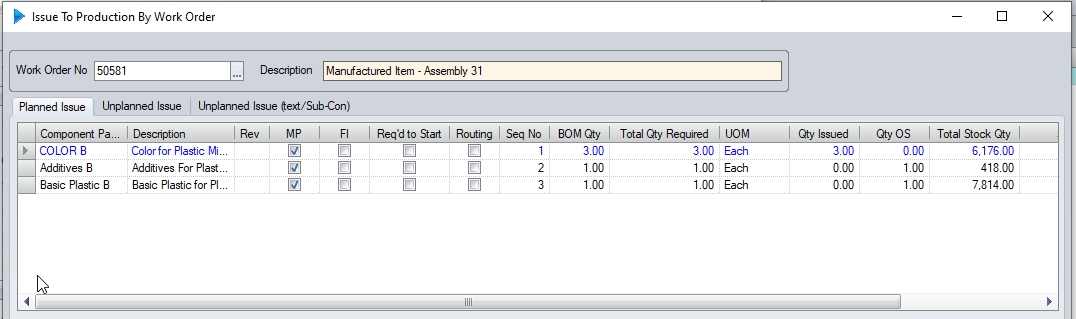

The manual stock issue process requires the user to issue the BOM items individually, selecting each item from the top-half of the screen and selecting the relevant batch in the bottom half to issue to the work order. The system can be configured to auto-select the batches required and automatically populate the ISSUE QTY with the quantity required for the job. If a single batch does not have enough to fulfill the work order requirement, the system would then populate the ISSUE QTY against multiple batches using a FIFO approach (First In, First Out) until there is no more stock, or the work order requirement has been fulfilled. Alternatively, the user can manually select the batch they wish to issue from, and enter the ISSUE QTY against that batch. Once the batch and quantity have been set, clicking ACCEPT will issue the selected part, batch and quantity to the WO. Once the issue is complete, the part will be updated in the top-half of the screen to show whats been issued, whats still outstanding, etc.

If further parts are to be issued, the user can select the next BOM item and repeat the process until all BOM items have been issued.

Automated Batch Issue

This method of issue allows the user to specify a total number of finished units, and the system will issue all BOM items and the total quantities of each item required to make the specified number of finished units.

To use this approach, the user must tick the AUTOMATED BATCH ISSUE option at the bottom of the screen. Ticking this option will automatically default the WO QUANTITY field to the total quantity the work order is for, but the user can amend as required (i.e. they want to issue 20 units worth to a WO for a total of 100 units). The user can also set the ISSUE DATE to be used for the issues too.

![]()

Once the details have been set, the user can click ACCEPT to complete the issues. The system will issue the BOM items to the WO for the specified total quantity, issuing on a FIFO basis until the requirement has been fulfilled or the existing stock has been depleted. The system will then move onto the next BOM item and repeat the process until all BOM items have been processed. Once complete, the top-half of the screen will be updated to reflect the issues made.