These options relate to the entry and control of purchase orders and purchase order related functionality.

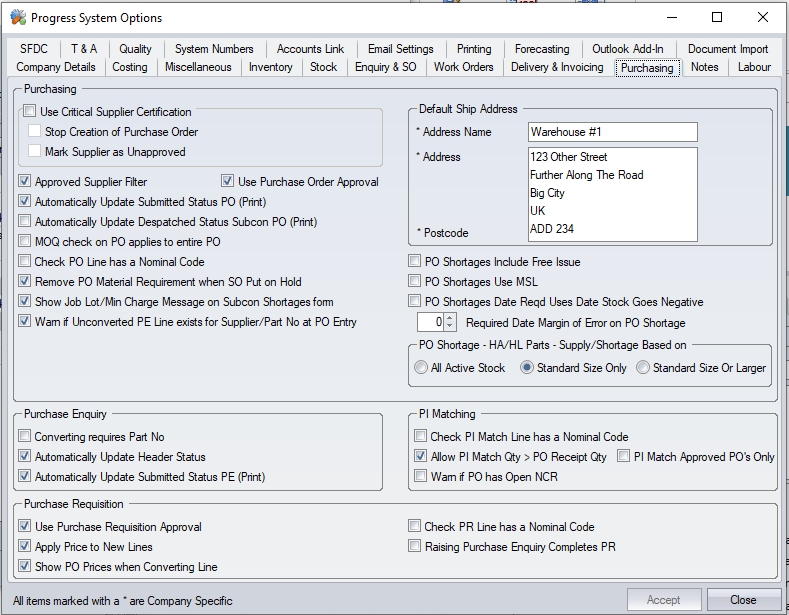

Purchasing Options

Use Of Critical Supplier Certification

This set of options allows the user to determine what happens when a supplier's critical certification expires.

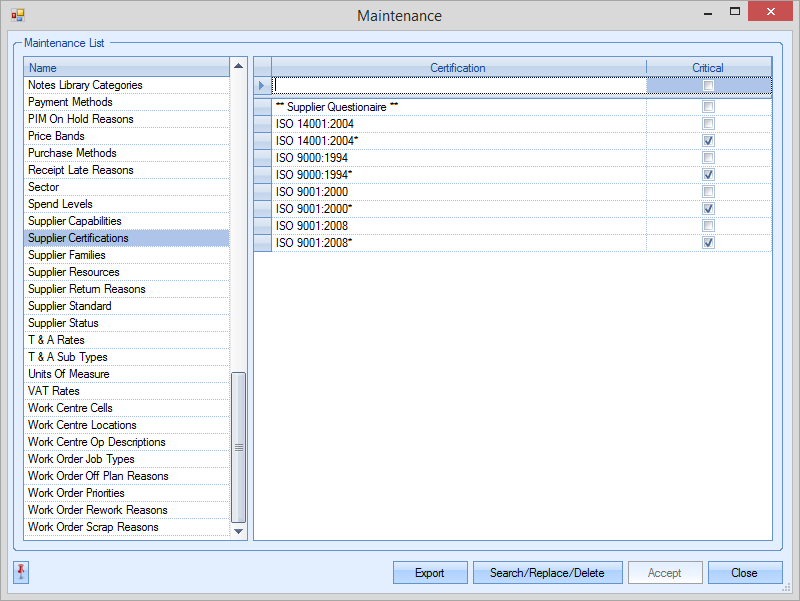

The certifications list is initially set up in the List maintenance section.

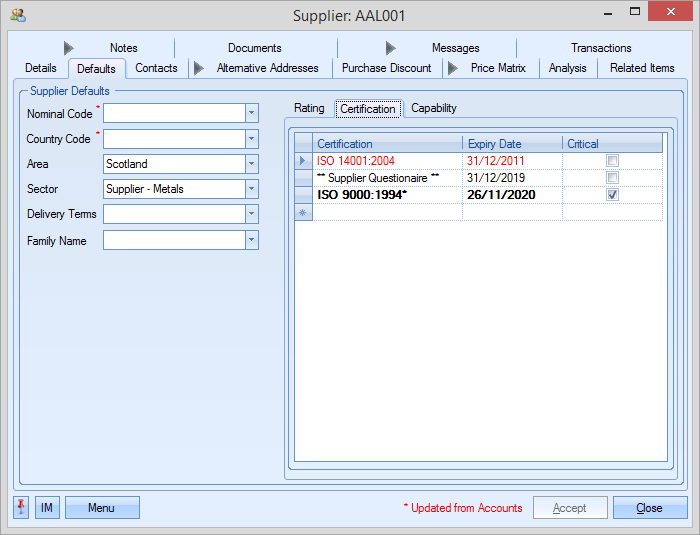

These can then be assigned to suppliers via the DEFAULTS tab of the supplier record.

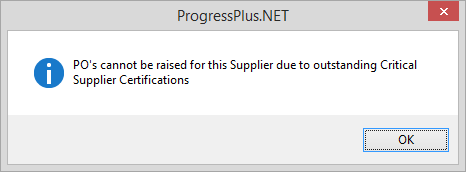

The system options allow the system to stop the creation of a PO for any supplier who has an expired critical certificate and/or automatically mark the supplier as an unapproved supplier.

This would require new certificates to be provided by the supplier and the supplier re-approved for use.

Approved Supplier Filter

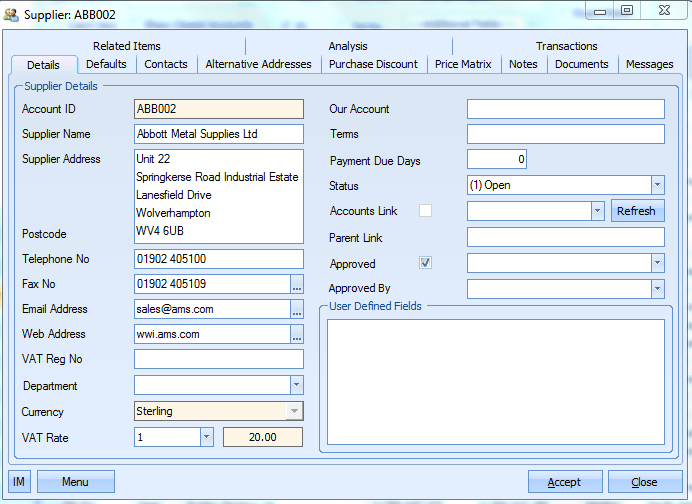

If this option is ticked the user will be restricted to only pick suppliers that have been marked as approved when they are raising a purchase order. The details of unapproved suppliers will not be shown when entering purchase orders. A supplier is marked as approved in the Supplier Details screen. Please refer to the appropriate section of the manual for more details.

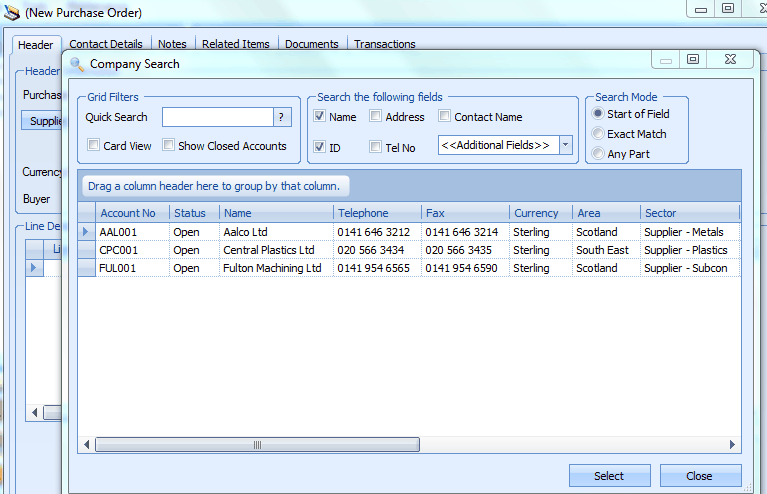

As previously mentioned with this option activated the user will only be able to choose from the list of previously approved suppliers when creating a purchase order. The supplier search when creating a purchase order will only display approved suppliers as in the following example.

Use Purchase Order Approval

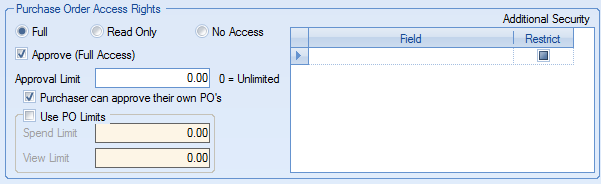

This option activates the PO approval settings in Progress. These settings allow users to have approval limits against POs in which they can raise and approve POs up to their own specified limit, however, they would require further approval from another suitable user if it exceeds their approval limits.

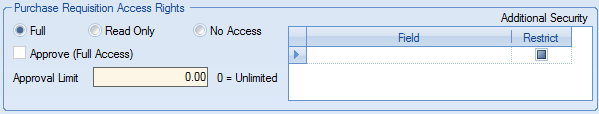

Activating this option allows you to amend the user access rights to indicate whether the user has the ability to approve POs and what their approval limit is when it comes to authorising POs.

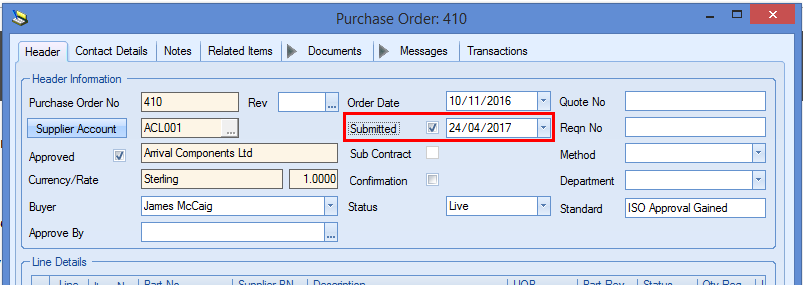

Automatically Update Submitted Status PO (Print)

This option dictates whether the SUBMITTED field on a purchase order is updated automatically when the user prints the PO. If switched on, the SUBMITTED field will be ticked and the date defaulted to the current date.

Automatically Update Despatched Status Subcon PO (Print)

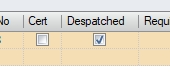

This option dictates whether the subcontract purchase order line is automatically marked as "Despatched" when the subcon despatch note document is generated from within the PO.

![]()

If this option is ticked, printing the subcontract purchase order despatch note will automatically tick the DESPATCHED option against the PO line to indicate that the items have been sent to the supplier.

MOQ Check On PO Applies To Entire PO

This option determines whether part MOQ quantities are enforced on a line-by-line basis on a PO or across the entire purchase order.

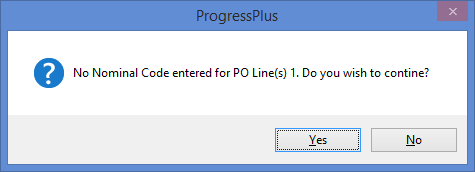

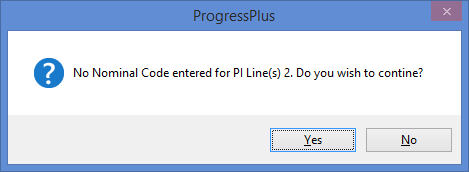

Check PO Line Has Nominal Code

This option will highlight any purchase order lines where no nominal code has been specified. The system will present the following message to the user.

This is just a warning and will allow the user to proceed with the creation of the PO.

Remove PO Material Requirements When SO Put On Hold

This option will remove any material requirements related to SOs which have been placed on hold from the PO Shortage calculations.

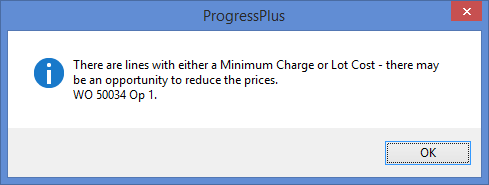

Show Job Lot/Min Charge Message On Subcon Shortages Form

This option highlights any attempts to raise a subcontract PO where the is an a job lot or minimum charge for the work to be done. The user will be presented with the following message to highlight this.

Use Purchase Requisition Approval

Similar to the option above, this allows you to set up approval levels for purchase requisitions. Again, these settings allows you to set different levels of authorisation against users for approving and processing purchase requisitions in Progress. Switching this on allows you to amend the user access rights in the same way as the PO approval process works.

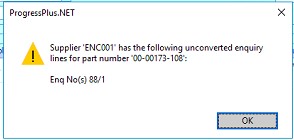

Warn If Unconverted PE Line Exists For Supplier/Part No at PO Entry

This option highlights to the user if there are any open purchase enquiries for the supplier/part combination when they are raising a purchase order. This allows the user to decide whether the existing purchase enquiry is in relation to the order being placed so they can either convert the purchase enquiry to get the PO they are after or close out the purchase enquiry if its no longer required.

This is simply a message to inform the user and will allow them to proceed with the purchase order when they click OK.

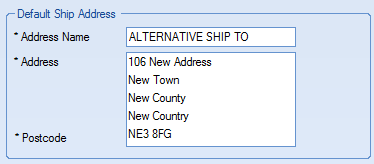

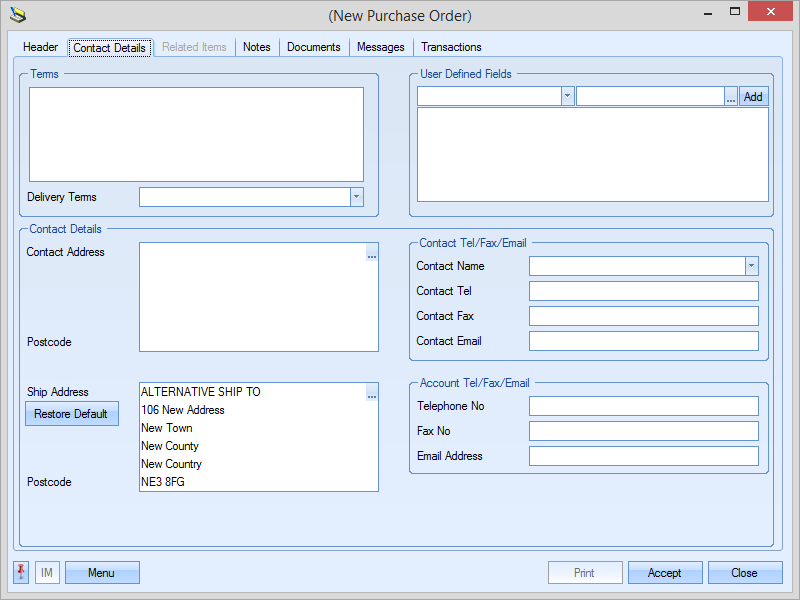

Defaults Ship Address

This option allows the user to specify a different SHIP TO address for when new POs are created, If this is populated, this address will be used as the SHIP TO address on new POs. If left blank, the SHIP TO address will default to the company address set in the Company Details tab of the Admin options.

PO Shortage Defaults

The following options are associated with the PO Shortage screen and allow the user to configure the defaults for the various calculations it does. These can still be amended on the PO Shortage screen if required too.

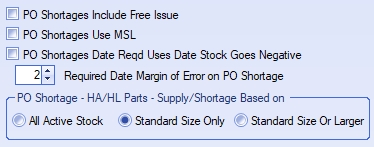

PO Shortages Include Free Issue

This option allows the PO Shortages screen to be configured to include free issue material by default. Ticking this option will tick the INCLUDE FREE ISSUE option on the PO Shortages screen by default.

PO Shortages Use MSL / PO Shortages Date Reqd Uses Date Stock Goes Negative

These options allow the user to configure the PO Shortage screen so the system highlights when the overall stock drops below the part's minimum stock level (MSL) or when it falls below zero. Its not possible to have both options ticked; system can only work one way or the other. If neither option is ticked, the system will calculate the date based on the part's stock reaching zero.

Required Date Margin Of Error On PO Shortage

This option allows the user to set up a "buffer" number of days when placing POs.

![]()

By default, Progress will calculate the PO Required Date to be the earliest required date for general purchases (i.e. for no specific job), the start date of the specific WO or the required date of the specific sales order. This option allows the user to build in extra days so the goods arrive prior to the calculated date by the specified number of days, effectively allowing the user to specify the number of days goods are to be received prior to the actual date they are needed.

Example:

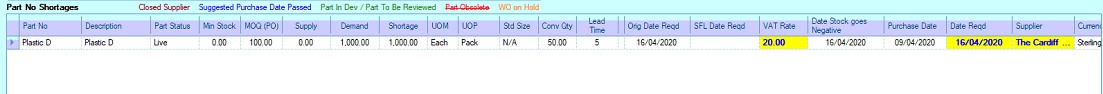

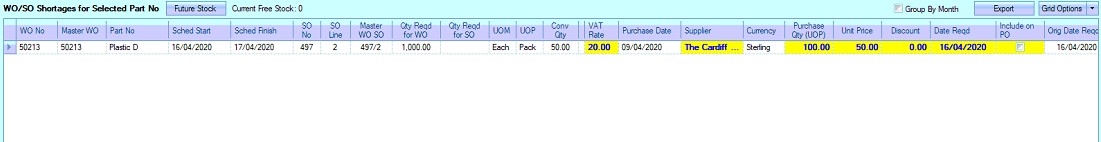

The purchase requirement below shows a part with a planned WO start date of 16/04/2020. Based on a PO date buffer of zero days, the general PO purchase (i.e using the top-half of the PO Shortage screen) calculates the PO line required date as the 16/04/2020 (i.e. when the job is due to start) as this is the earliest requirement. Where there are more than one WOs and/or SOs, this would be based on the earliest requirement.

Using the bottom half of the screen, looking at specific requirements, the system would calculate each required date based on the associated WO start date or the required date of the associated SO line.

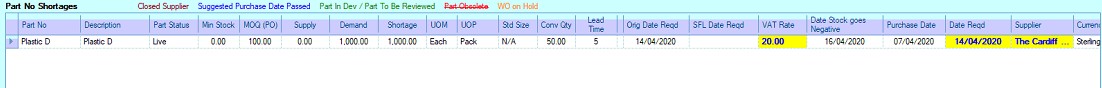

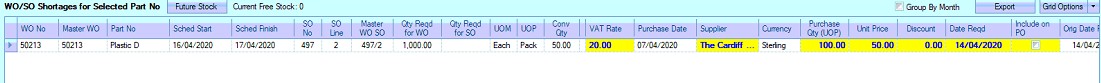

With a PO date buffer applied, now set to 2 days in this example, the system includes this is the calculated required date. Ignoring non-working days, this pushes the calculated date back to the 14/04/2020. This calculation applies to both parts of the PO Shortage screen as per the previous above and is shown below.

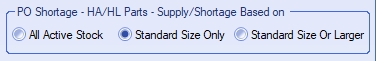

PO Shortage - HA/HL Parts - Supply/Shortage Based On

This option allows the user to specify what stock is included in the SUPPLY figure/SHORTAGE calculation for HAS AREA/HAS LENGTH parts.

The user has three options available when considering HA/HL parts:

All Active Stock The SUPPLY calculation for the part includes all stock, including GRNs that are for fractions of a standard length or area of the part.

| Standard Sizes Only | The SUPPLY calculation for the part only considers GRNs that are the part's exact standard size. Any stock smaller (or larger) than the part's standard size will not be included in the SUPPLY figure of the part. This is based on the standard size of the part set in the master part record. |

Standard Size Or Larger The SUPPLY calculation for the part only considers GRNs that are the part's standard size or greater. Any stock smaller than the part's standard size will not be included in the SUPPLY figure of the part. Again, this is based on the standard size of the part set in the master part record.

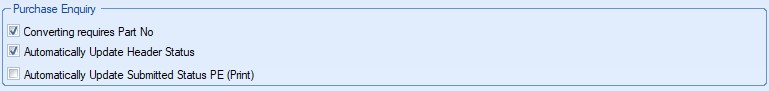

Purchase Enquiry Options

These options relate to purchase enquiries in Progress Plus.

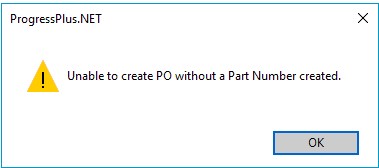

Converting Requires Part No

Enabling this option forces the user to select an existing part number prior to converting the purchase enquiry to a purchase order. This stops ability to enter just a description and to convert this to a text-only PO line.

If the user attempts to convert a description-only purchase enquiry to a PO, they will be presented with the following message, and they will have to select an existing part number on the purchase enquiry line before they are able to convert.

Automatically Update Header Status

This option will automatically update any purchase enquiry header status based on the lowest line status on the purchase enquiry. This removes the need for a user to manually update the overall enquiry status.

Automatically Update Submitted Status PE (Print)

This option automatically marks the purchase enquiry as "Submitted" when the purchase enquiry is printed. Leaving this unticked requires the user to mark the purchase enquiry as "submitted" manually.

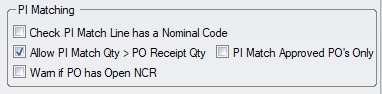

Purchase Invoicing Options

These options relate to the purchase invoice matching (PI Matching) process in Progress Plus.

Check PI Match Line Has Nominal Code

This option will highlight any PI matches which have no nominal specified. The system will present the following message to highlight the missing info.

This is just a warning and will allow the user to proceed with the PI match.

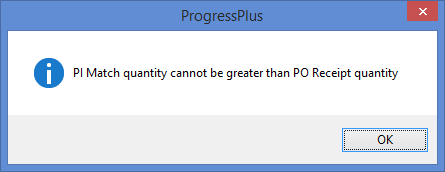

Allow PI Match Qty > PO Receipt Qty

This option allows the user to PI match a quantity which is greater than the PO receipt quantity. With this switched on, the user will be able to raise a PI match for a greater quantity. With this option switched off, the system will stop the creation of the PI match and display the following message to the user.

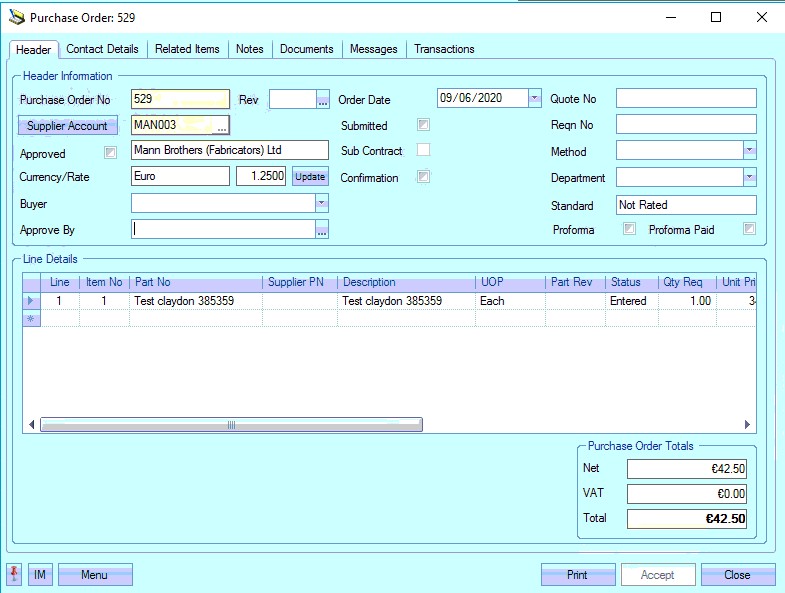

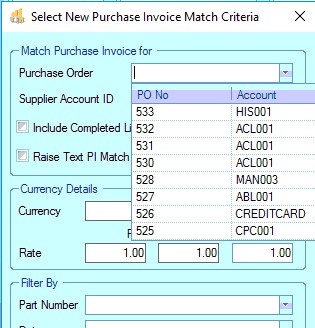

PI Match Approved POs Only

This option stops the purchase invoicing of any purchase order that is not yet been approved. This is done by hiding the unapproved PO from the list of POs available for matching on the example shown below.

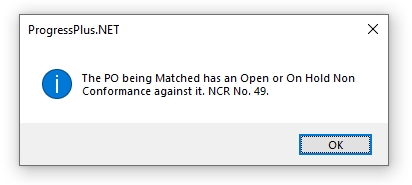

Warn If PO Has Open NCR

This option will display a warning message to the user if the selected purchase order line for PI matching has an open NCR against it. The warning is displayed if the user includes the PO line in their PI Match.

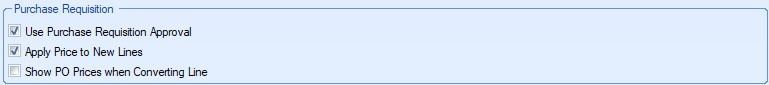

Purchase Requisition Options

These options relate to purchase requisitions in Progress Plus.

Use Purchase Requisition Approval

This option enables the approval process for any Purchase Requisitions created. This means they need to be approved by someone with suitable permissions. For more on this, please refer to the Administrator Functions > Access section of this manual on granting users approval rights.

Apply Prices to New Lines

This option defaults the UNIT PRICE field on the purchase requisition based on supplier price matrices and purchasing cost. The system will check for existing pricing and set it accordingly. If left unticked, then the UNIT PRICE on the purchase requisition will default to zero.

Show PO Prices when Converting Line

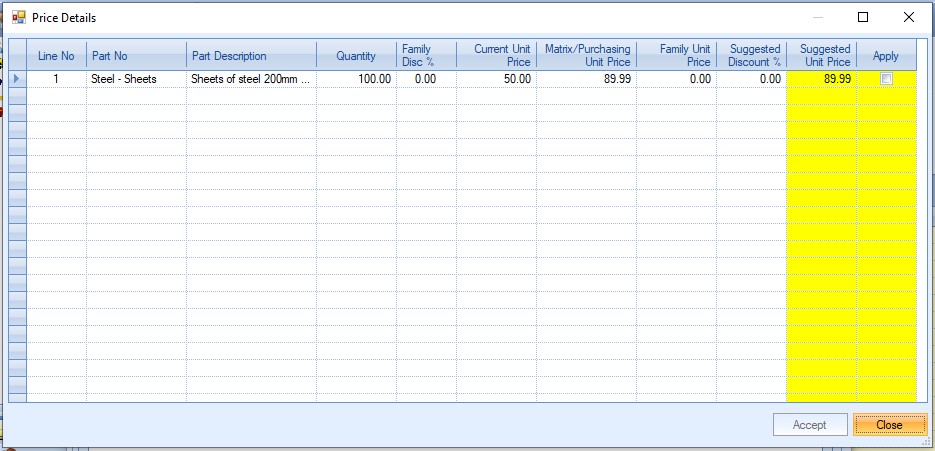

This option will present the user with any existing prices in the system when the requisition is being converted to a PO. The screen displayed is shown below. From here the user can ensure the new PO line is created with the correct price.

This screen highlights the details of the line(s) being converted, along with the current unit price on the purchase requisition. The user is also shown any existing supplier-specific pricing as well as a suggested price, which is what the system thinks the price should be based on existing information for the part number and supplier.

The user can amend the Suggested Price to any value they wish, before ticking the APPLY option and clicking ACCEPT to convert the details into the new or existing PO.

This option can be used in conjunction with the Apply Prices to New Lines option so the system sets the UNIT PRICE automatically on the purchase requisition line based on existing pricing. The screen above can still be displayed for confirmation purposes if required.