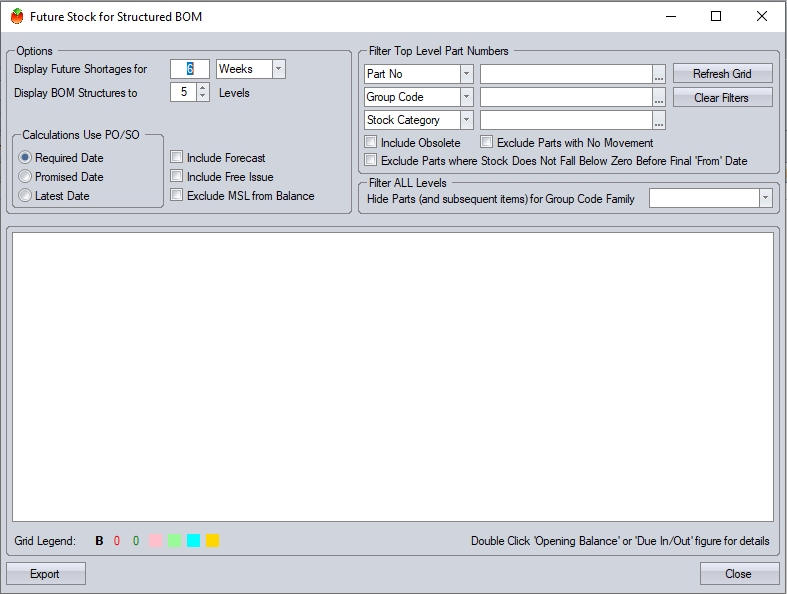

This tool allows access to future stock information based on all incoming and outgoing stock.

The Options section allows the user to set the period of time the calculations are to occur over, the date to be used for POs/SOs and the number of BOM levels that are to be displayed.

If the user selects "Months" as the time category, the system will display the monthly supply and demand for the number of months selected. The user can view a more detailed view by selecting "Days" or "Weeks", giving a daily or weekly supply and demand view. The user can also specify whether the calculations include forecast work orders, free issue material and also whether any minimum stock levels are considered.

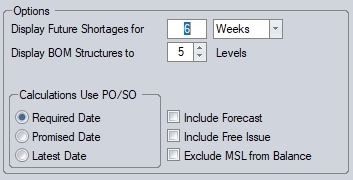

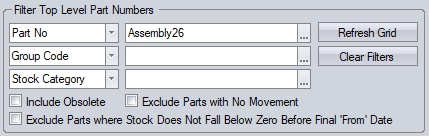

The Filter Top Level Part Number options allow filters to be applied to the top-level part results. This allows the user to filter for specific top-level parts, orders and group codes amongst other things.

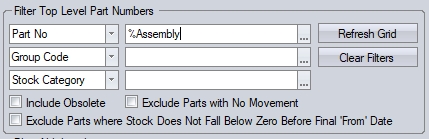

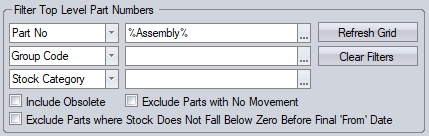

The user can use the % wildcard when filtering if a they wish to see all parts matching the filter criteria. The % wildcard can be used as follows:

(All parts that start with "Assembly")

(All parts that end with "Assembly")

(All parts that contain "Assembly")

Additional options to include obsolete parts and exclude top-level assembly parts which have no stock movement are also included for the user.

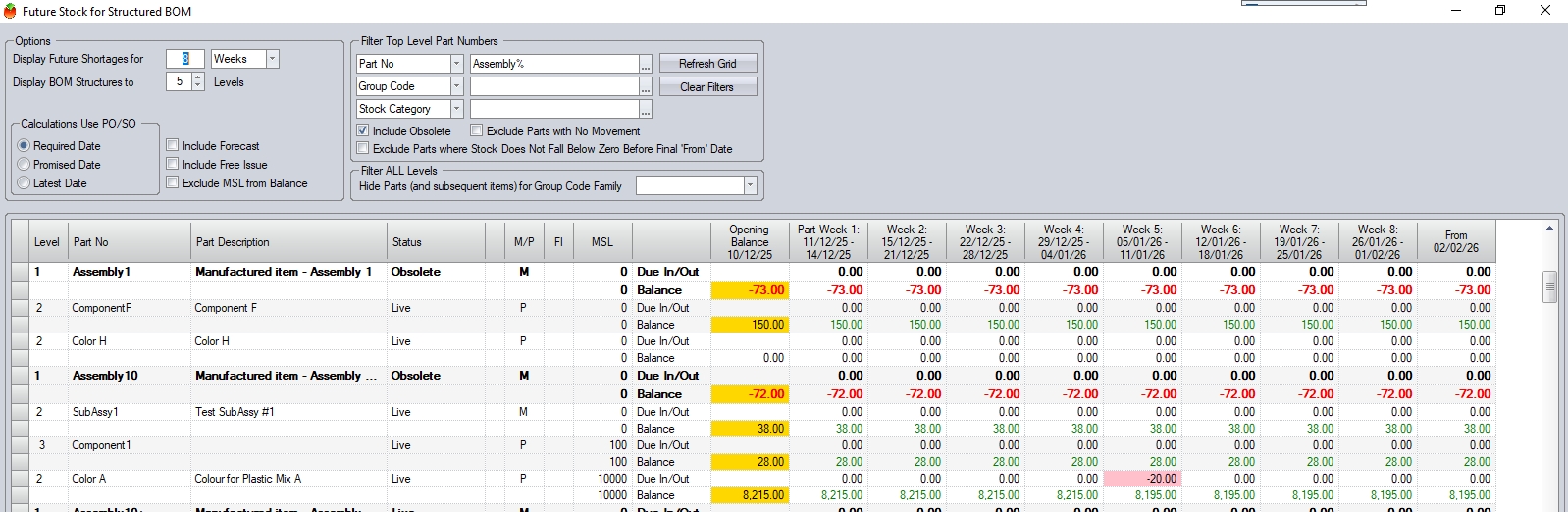

INCLUDE OBSOLETE option will simply include any obsolete top-level parts from the results.

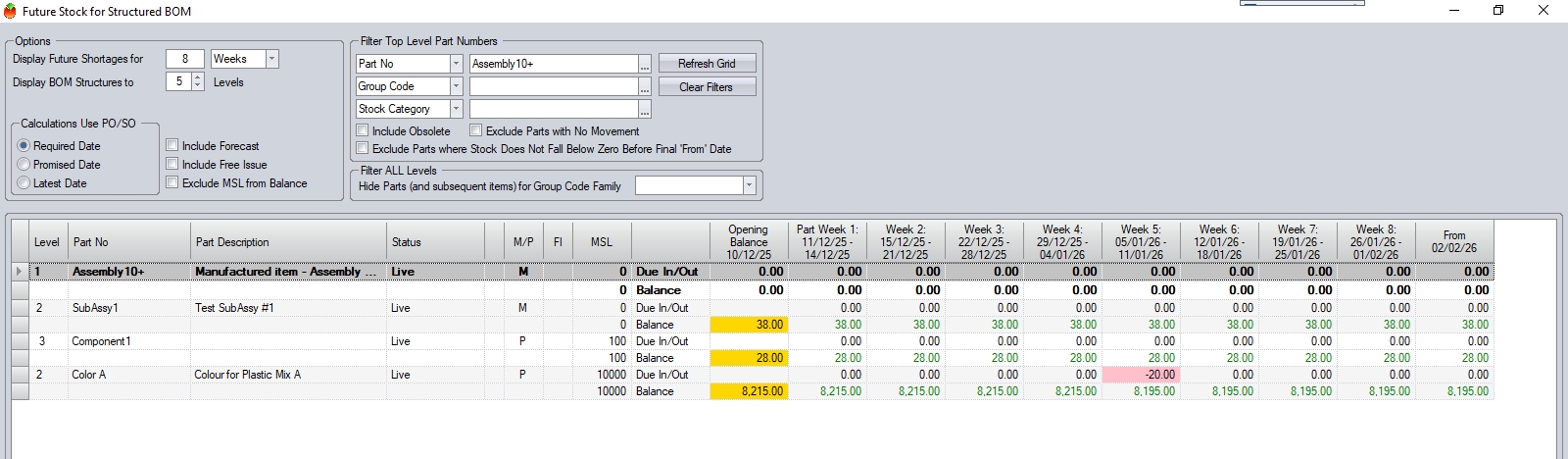

(INCLUDE OBSOLETE option unticked)

(INCLUDE OBSOLETE option ticked)

EXCLUDE PARTS WITH NO MOVEMENT option will filter out top-level parts where there is no stock activity for the period (i.e. no incoming, or outgoing stock).

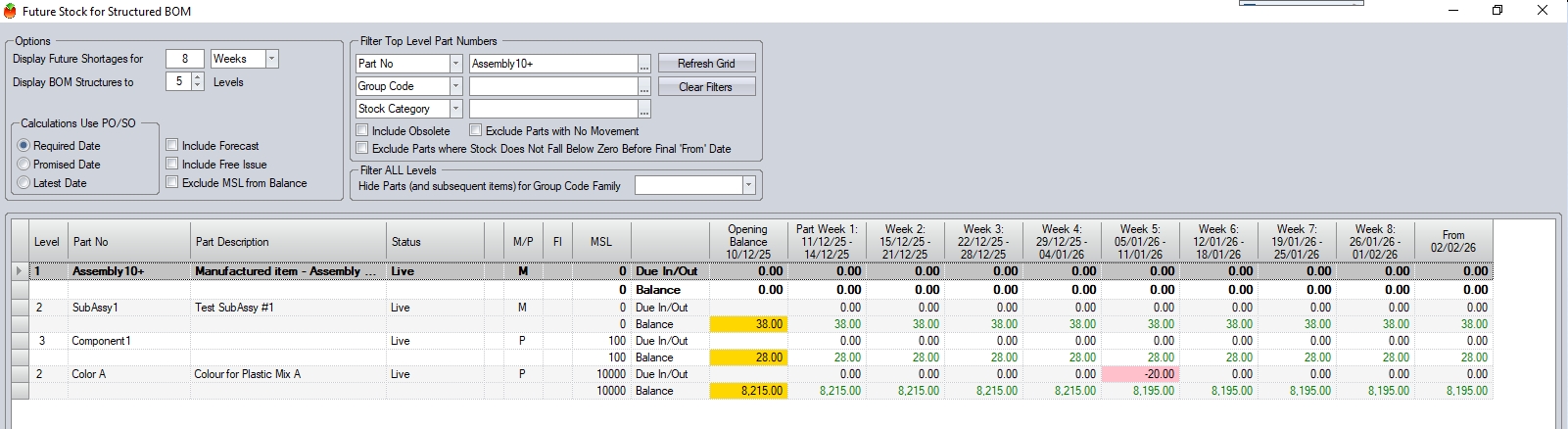

(EXCLUDE PARTS WITH NO MOVEMENT option unticked)

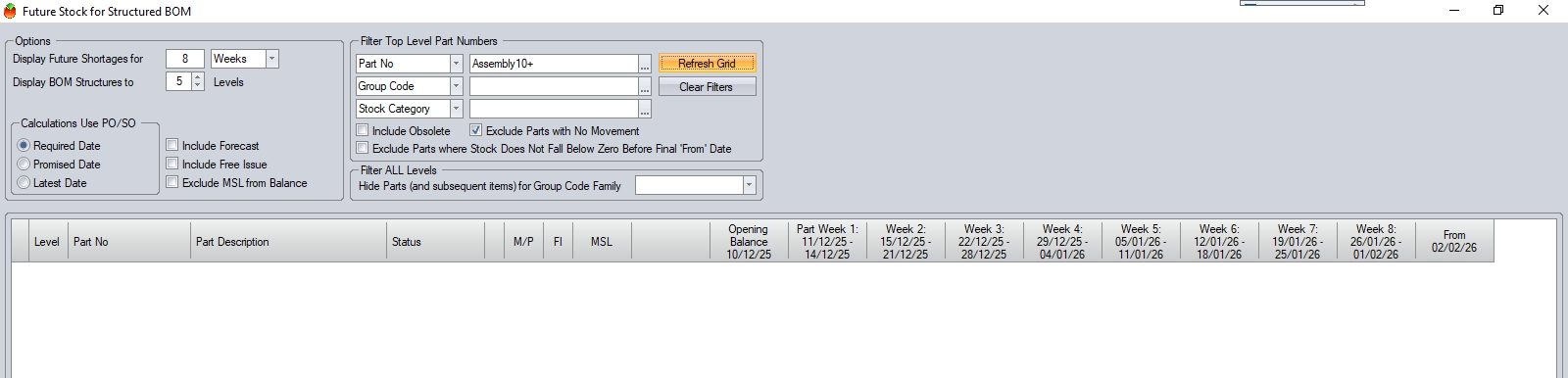

(EXCLUDE PARTS WITH NO MOVEMENT option ticked)

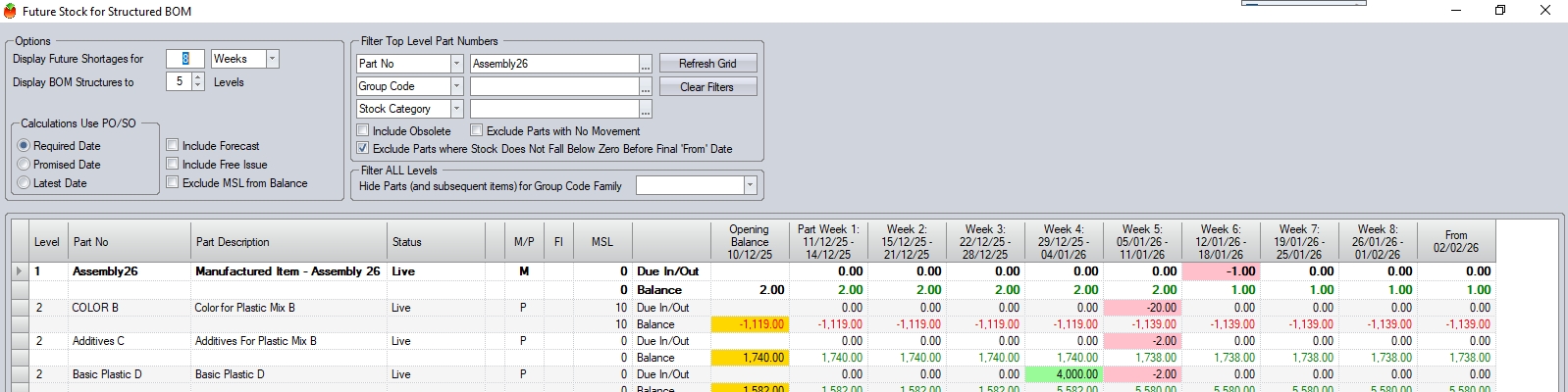

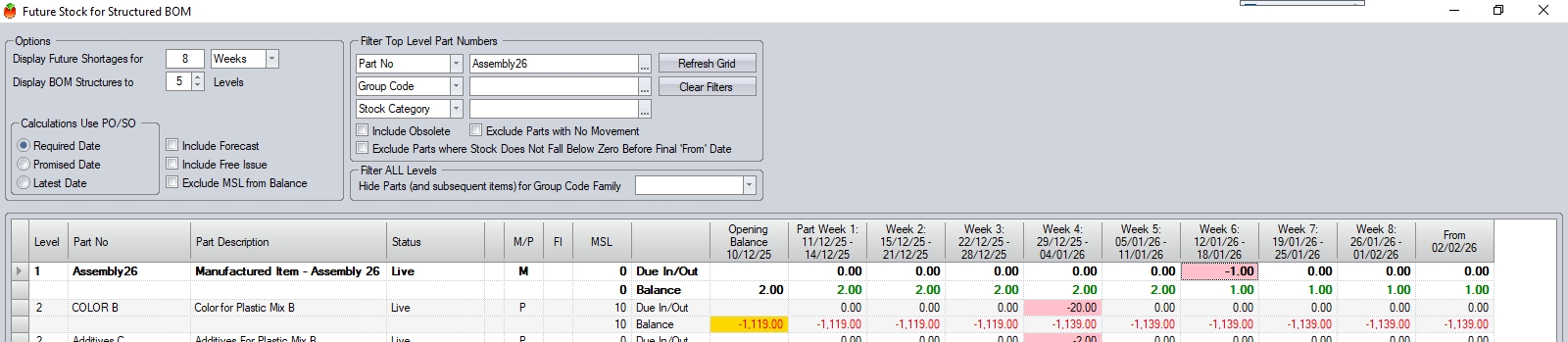

EXCLUDE PARTS WHERE STOCK DOES NOT FALL BELOW ZERO BEFORE FINAL 'FROM' DATE option will hide any top-level parts where there is no points where the stock of the part drops below zero within the specified period. This option is useful as it will show where the top-level part will drop below zero within a period of a surplus, highlighting that their incoming stock for the period will not arrive/be made before the requirement; in this scenario the NET stock movement of the top-level part would be positive overall, but the shortage will occur before the stock is replenished within the same period.

In the example below, Assembly26 will hit a shortage at the start of week commencing 12/01, however, additional supply will become available later that week on . This results in an overall surplus for the period (balance shown in green), but the part is still included in the results as the stock will drop below zero before the new stock is available.

(Supply/Demand for the period)

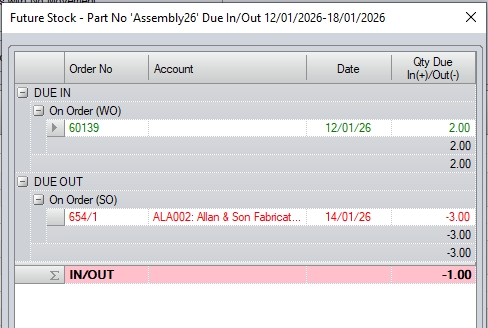

In the next example, the same part has incoming supply prior to the outgoing requirement. As a result, the top-level part's stock will not drop below zero at any point. As you can see, the grid results are the same for both scenarios. Using this option in this scenario removes the top-level assembly from the results as the part stock never drops below zero at any point.

(Supply/Demand for the period)

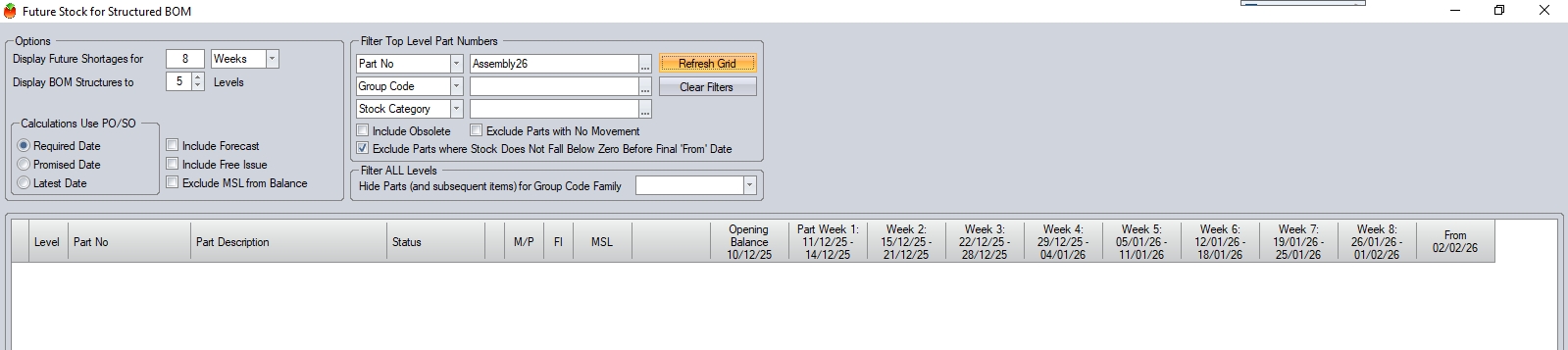

The user also has the ability to exclude parts from a specific group code family. This filter is applied at ALL levels of the BOM and will hide all lower level BOM items of manufactured parts that have the specified group code family.

![]()

To apply this filter, the user can select the group code family from the drop-down menu.

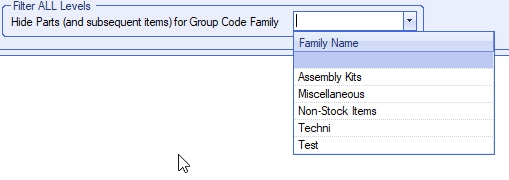

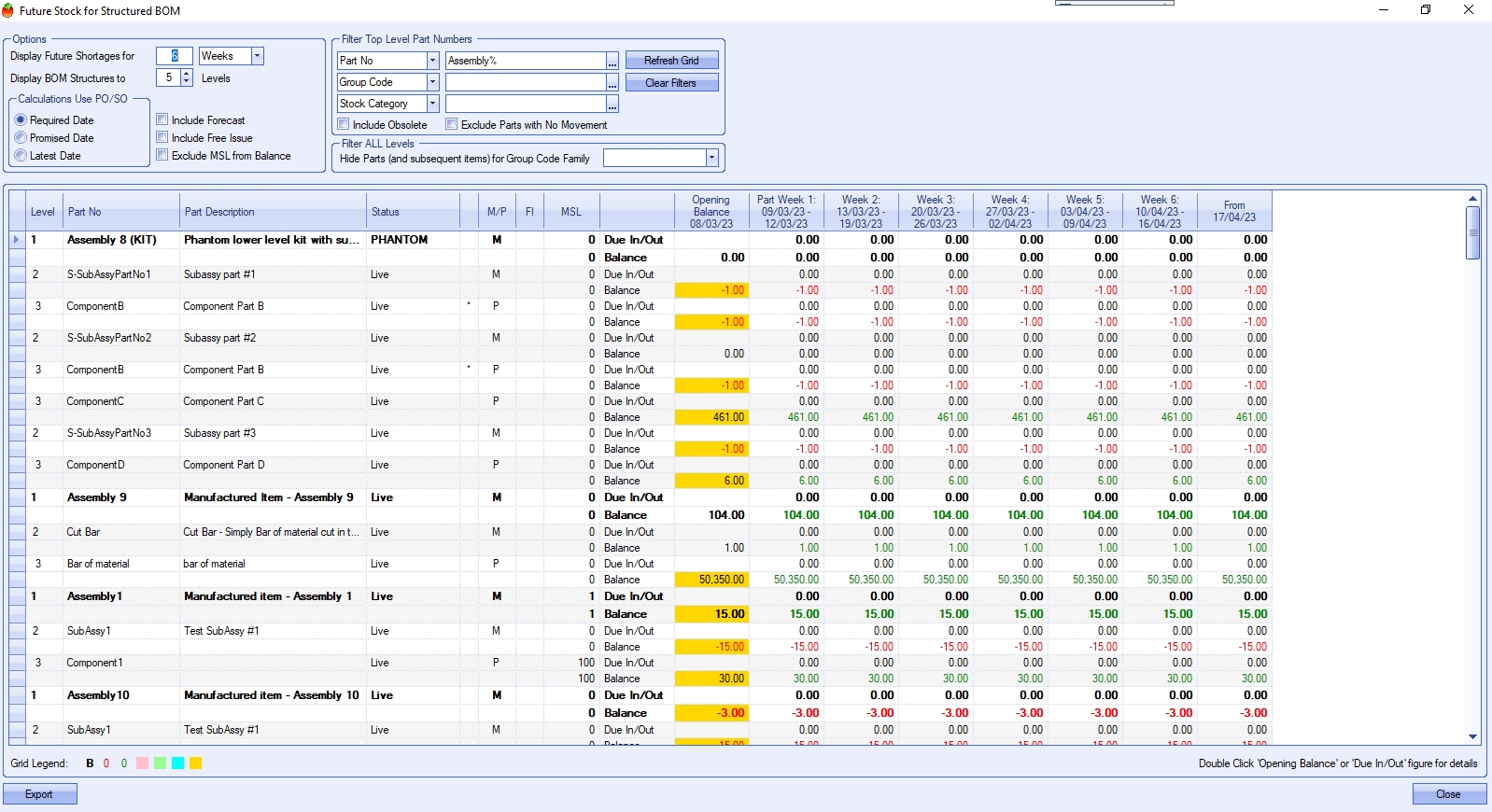

Once the required filters have been added, the user can click the REFRESH GRID option to display the results. Once refreshed, a similar screen to the following will be displayed.

Information about the individual parts such as Part No, Part Description, Status and Manufactured/Purchased are displayed. The Master Parts are highlighted in bold and the Grid Legend in the lower left corner indicates the meaning of different colours or text.

![]()

The user can hover over each legend colour to view the relevant information.

For master parts, the opening balance column displays the balance of the individual part on today’s date. This includes a total of stock that is Active (Including stock to be released), On Order (PO) and On Order (WO). Stock that is On Order (SO) and the Minimum Stock Level (if not excluded) are subtracted from this total to get the balance. Forecast WOs are also included if the Include Forecast WOs in Calculations box is ticked.

The opening balance for lower level parts displays the balance for the individual part on today’s date. This includes a total of stock that is Active (Including stock to be released), On Order (PO) and On Order (WO) (if it has lower level parts). Stock that is Required for WO, On Order (SO) and the Minimum Stock Level are subtracted (if not excluded) from this total to get the balance. Forecast WOs are also included if the “Include Forecast WOs in Calculations” box is ticked.

Quarantined stock is not included in any or the above calculations. When the stock is removed from quarantine, it will display in the opening balance.

When stock levels change, the Due In/Out row shows the change for that time period. An increase will highlight the box in green and a decrease would highlight the box in red.

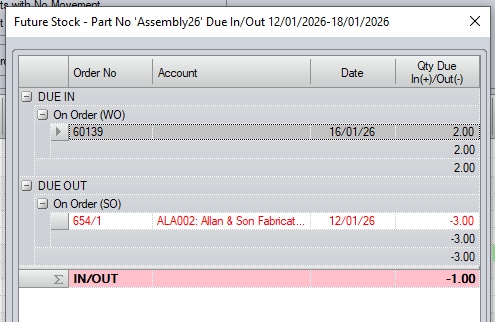

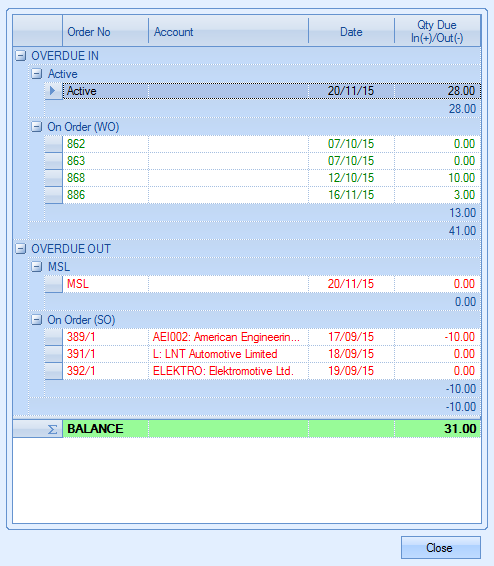

Details of the Opening Balance or Due In/Out figure can be accessed by double clicking on them. This will break down how the number has been calculated and the dates that each change will occur.

Example:

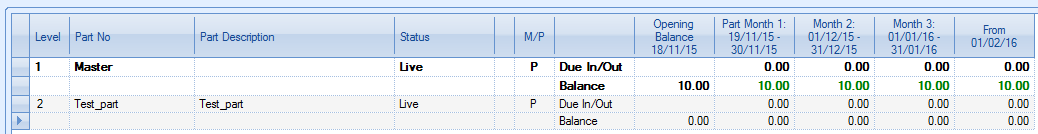

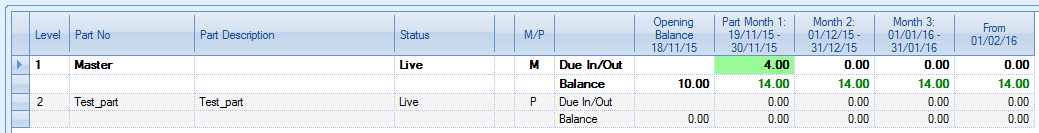

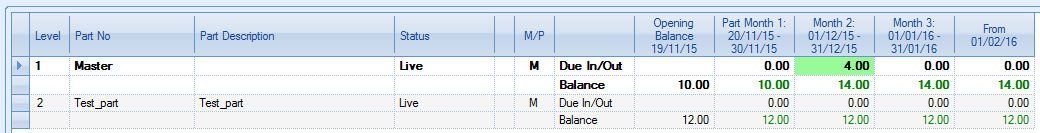

The example below shows the future stock for a part called “Master”. This has a BOM consisting of a part called “test_part” with a quantity of 2.

There are 10 masters in stock with no orders associated with it. The opening balance shows as 10 which does not change in the next 3 periods.

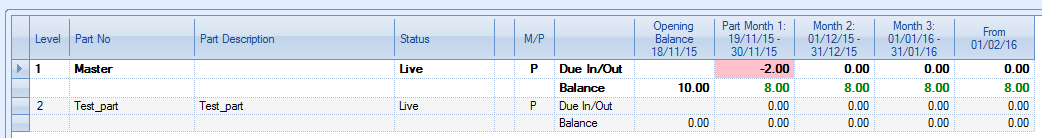

An SO is created that requires 2 Masters. The grid displays the change in stock as the part will be required for the SO, even if this is not allocated to the SO.

The balance changes according to the REQUIRED DATE within the line details.

![]()

If the REQUIRED DATE is set to today’s date, the opening balance will be changed. Adding parts on a Sales Order will not affect the lower level parts.

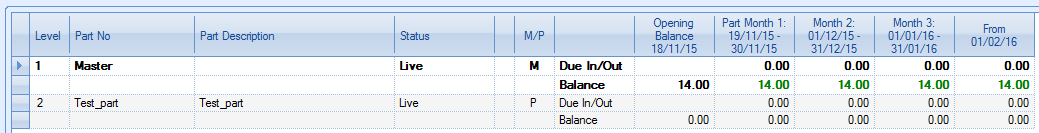

Creating a PO will add the stock according to the “Date Required” in the Line Details. With the initial balance at 10 and no other orders, the A PO is created for 4 Master parts.

If this is receipted, the Balance will be updated immediately as shown below.

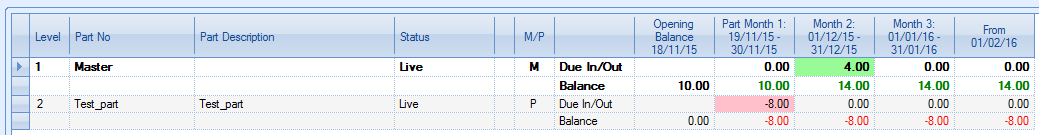

A new WO is created for 4 master parts with a Planned Start Date in the first month and a Planned Finish Date in the second month. The Due In/Out has a value of 4 in the second month as this is when it is due. The balance also increases to 14.

The lower level part shows a reduction in the stock from the Planned Start Date as this is when the parts are required (This is -8 as the BOM Qty is 2 for each Master part).

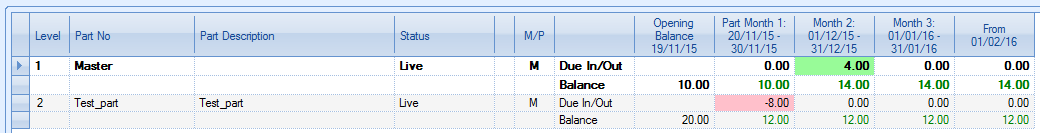

A PO is created for 20 test_parts with a required date as today.

The opening balance will change to 20 with 8 being used in the following time period. If the test_part is issued to the WO early, this will be reflected in the opening balance of the lower level part.

Exporting Results

The results displayed on screen can be exported to a spreadsheet if further analysis is required. The EXPORT option at the bottom of the screen. This will prompt the user to save the spreadsheet before generating the file.

![]()