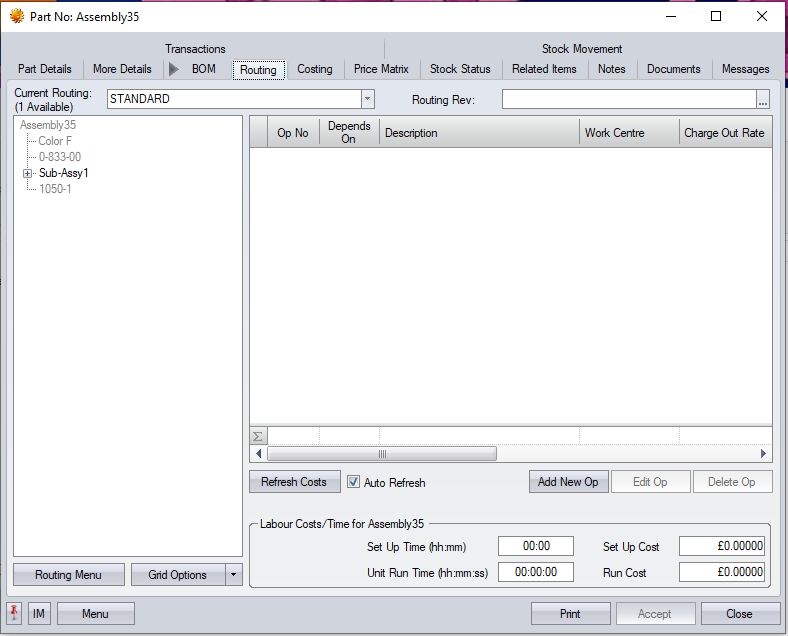

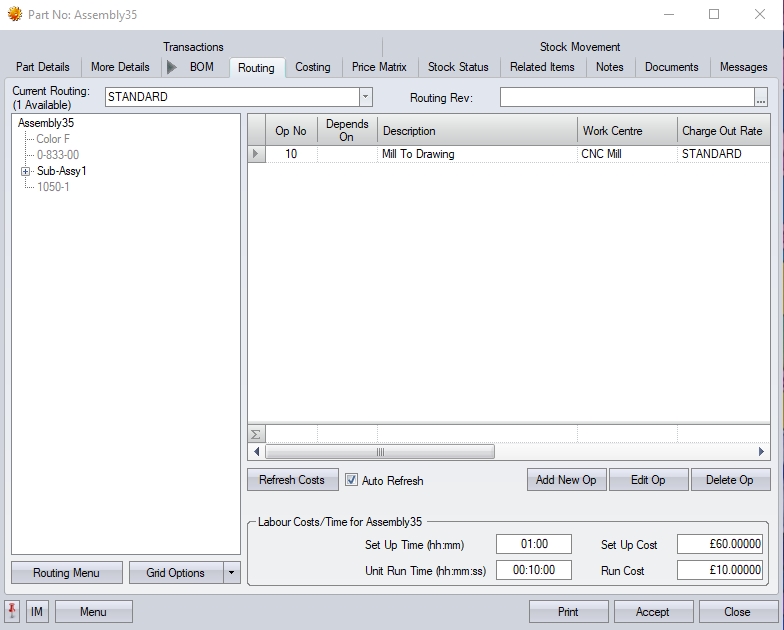

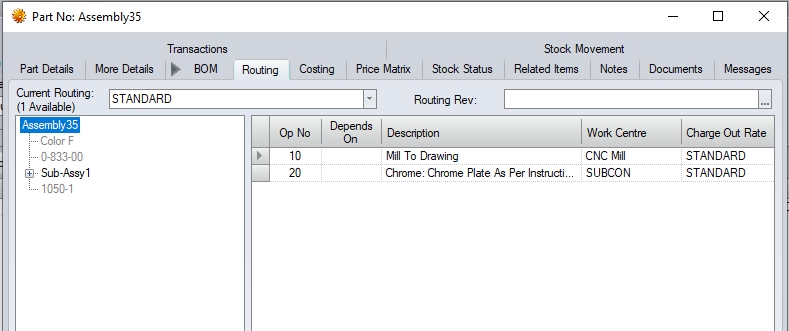

The routing screen is where the user can specify the processes and work centres that the job will pass through during production, both internal and external (i.e. subcontract operations). Clicking the Routing tab will display a screen similar to the following.

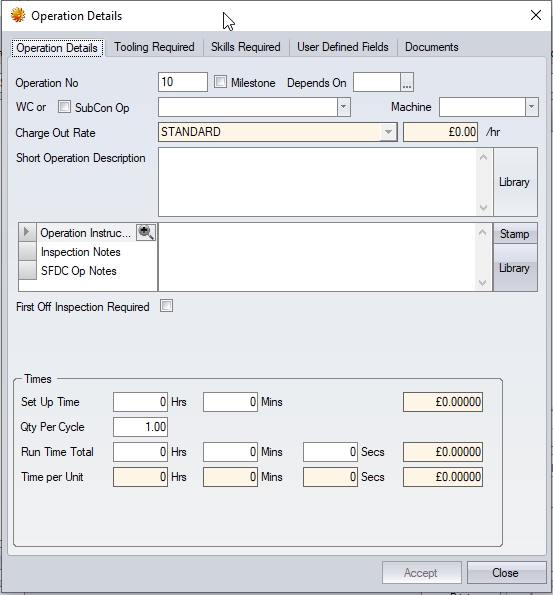

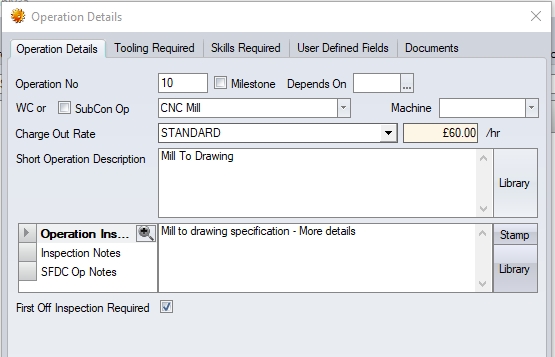

To enter a new operation, internal or external, the user must click the ADD NEW OP button. A screen similar to the following will be displayed.

Adding a Standard (Internal) Operation

Internal operations are those carried out on site. To set this up, the following information is required.

| Operation No. | This counter defaults to increments of 10 but can be overwritten by the user if required |

| WC or SubCon Op | For internal operations, the SUBCON OP option should be unticked. |

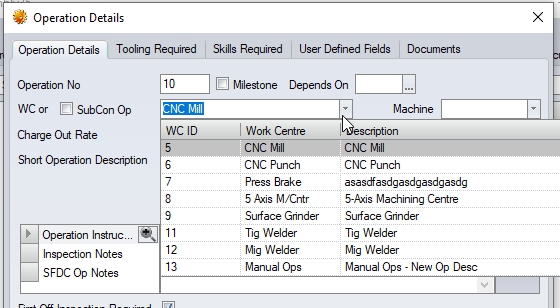

| The user can select the required internal work centre via the drop-down list. The work centre must exist prior to the routing operation being added and can be entered via the Maintenance – Work Centres section. |

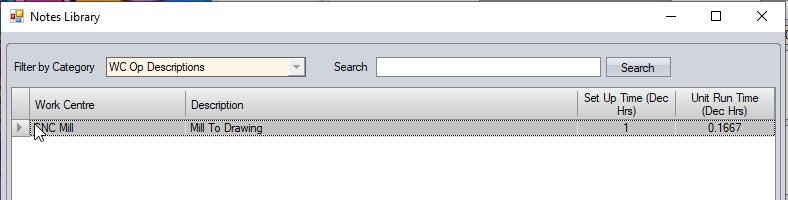

| Short Operation Description | The user can enter a new operation description into this field or click on the LIBRARY option to choose from a list of previously entered operation descriptions relating to the selected work centre. The required operation can be chosen by clicking on the line and pressing the SELECT button. |

(selecting an existing operation description via the Notes Library)

| Operation Instructions | If required the user can enter more detailed information regarding this operation. These extra notes can print off onto job cards if desired. Previously entered notes can be chosen from the Library or new ones typed in and saved. |

| First Off Inspection Required | This option allows the user to specify whether the operation requires a first off inspection as part of its process. If required, this option should be ticked. |

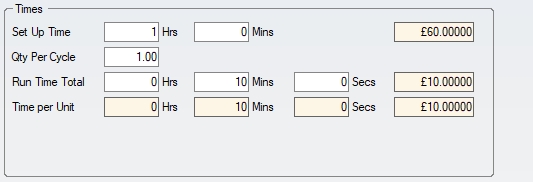

| Times | Details of any time required to set up and operate the work centre for this operation can be entered here. The system will also display a cost for these based on the work centre charge rate selected in the operation. |

| The SET UP TIME field allows the user to enter a setup time for the operation in hours and minutes. |

| The RUN TIME for the operation can be entered in hours, minutes and seconds. This is the time per part and not for the entire job. |

Once all the details have been entered, clicking the ACCEPT button will save the details of the operation being entered. The user will then be returned to the maion Routing screen with the added operations listed.

If further internal processes are required for the part, then the user can repeat the steps above to add further operations to the part's routings.

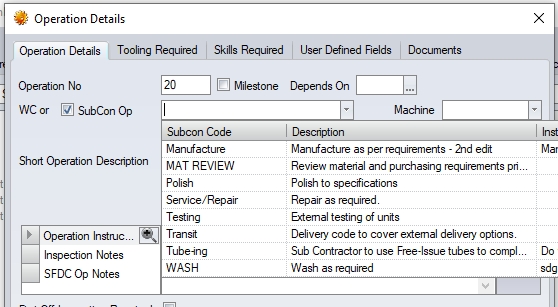

Adding a Subcontract (External) Operation

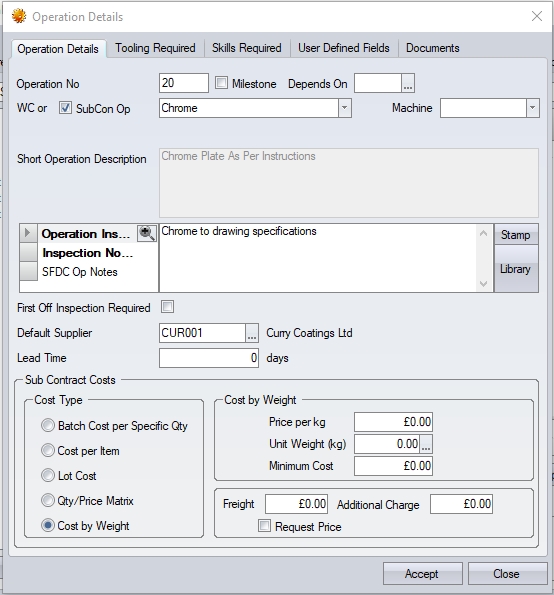

Subcontract operations are processes that are done, externally, by a supplier. To set up a subcontract operation, the following information is required.

| Operation No. | This counter defaults to increments of 10 but can be overwritten by the user if required |

| WC or SubCon Op | For external operations, the SUBCON OP option should be ticked. |

| The user can select the required subcontract code via the drop-down list. The subcontract code must exist prior to the routing operation being added and can be entered via the Maintenance > Sub-Contract Codes section. |

| Once selected, the screen will populate with the details of the subcontract operation, including any default suppliers and pricing methods that may be specified against the subcontract code. The SHORT OPERATION DESCRIPTION is not editable and will display the subcontract codes description. |

Op Instructions/Inspection Notes These will default to any notes that have been set against the master subcontract code, however the user can amend these as required.

First Off Inspection Required This option allows the user to specify whether the operation requires a first off inspection as part of its process. If required, this option should be ticked.

| Default Supplier/Lead Time | These allows the user to specify the supplier to be used, and the associated lead time for the supplier to carry out the process. These will default based on the master subcontract record, but can be amended as required. |

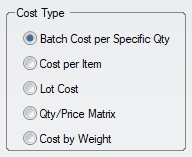

| Sub Contract Costs | This section allows the user to specify how the subcontract operation is cost. Again, this will default based on the master subcontract code but can be amended as required. There are a number of costing methods available for the user to select from: |

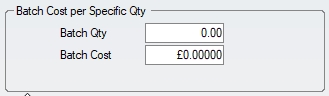

Batch Cost per Specific Qty - This option allows the user to specify a batch quantity and batch price.

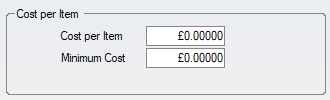

Cost Per Item - This option allows the user to enter a cost per unit, as well as any minimum costs specified by the supplier.

Lot Cost - This option allows the user to specify a fixed cost for the job, regardless of the number of units being done.

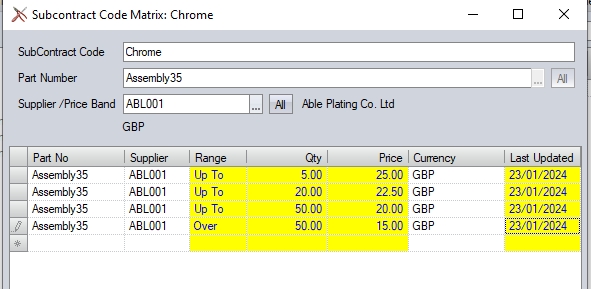

Qty/Price Matrix - This option allows the user to set up supplier specific pricing, based on price breaks/quantities.

(Example supplier price matrix for subcontract op)

| Cost By Weight - This option allows the user to specify the cost based on the units weight, as well as any minimum costs specified by the supplier. |

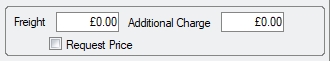

Freight/Additional Charge - This section allows the user to specify any freight or additional charges associated with the subcontract operation.

Once all the details have been entered, clicking the ACCEPT button will save the details of the subcontract operation. The user will then be returned to the main Routing screen with the added operation listed.

If further subcontract processes are required for the part, then the user can repeat the steps above to add further operations to the part's routings.