This section allows the user to create and maintain booking references in Progress. Booking references allow user to create a single common reference across multiple work orders which can be used for booking time across multiple work orders.

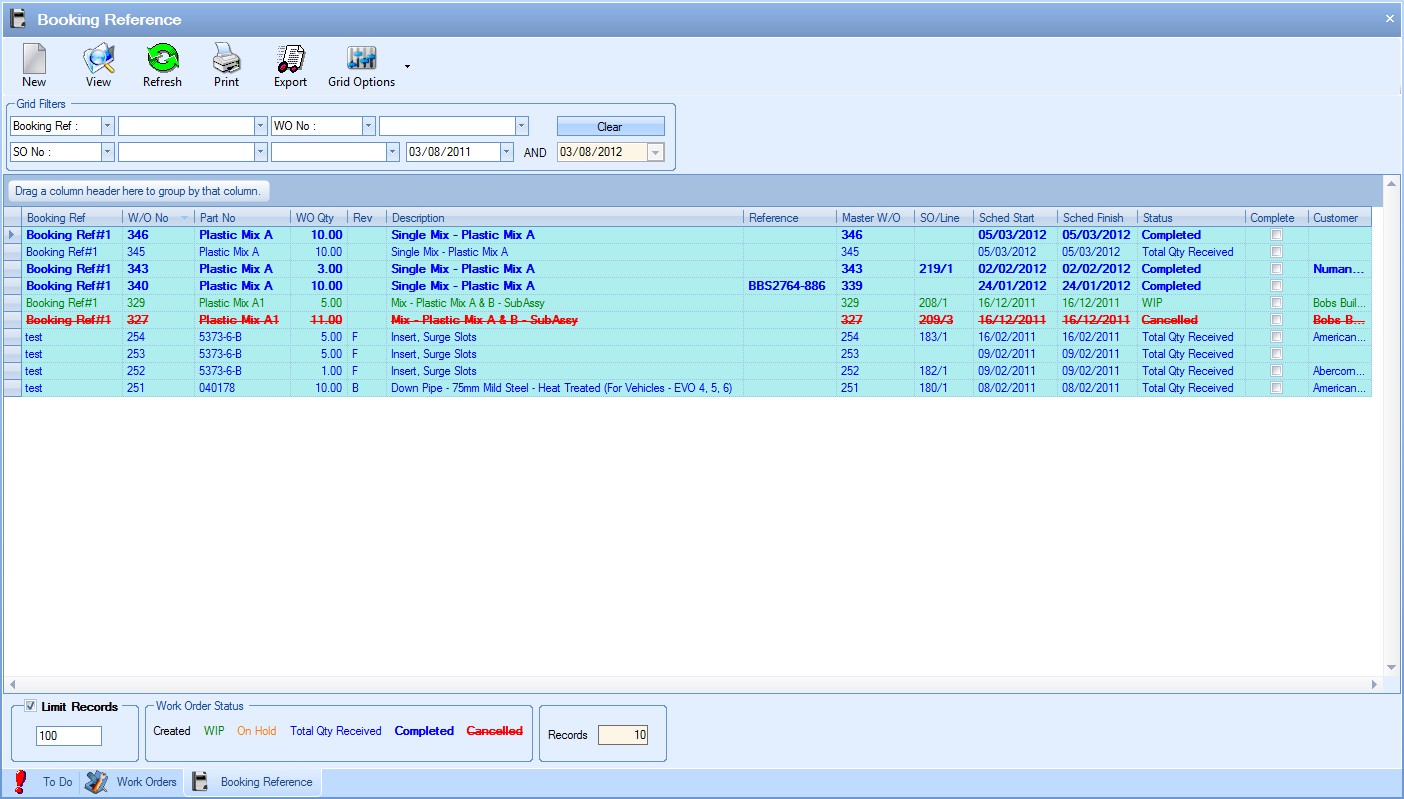

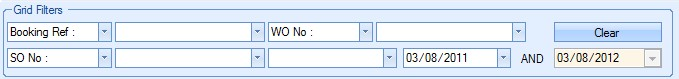

The filters at the top of the screen allow the user to search and display booking references based on the search criteria entered.

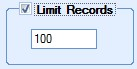

The user can apply a variety of filters to their search including a range of work order numbers and statuses as well as by customer, part number and sales order. The user can also set the maximum number of records to be displayed on the grid using the LIMIT RECORDS option at the bottom of the screen.

The default value of this option is set in the system options and is useful when large amounts of data are held in Progress as this limits the amount of data being displayed. The limit can be removed by the user if necessary by simply unticking the option, or they can simply increase the limit quantity to a more suitable value. The number of parts shown in the grid is also summarised at the bottom of the screen. This gives a total count of the parts shown.

Once filters and record limits have been selected, the user can view the booking references which meet the selected criteria by clicking the REFRESH option![]() .

.

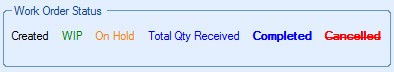

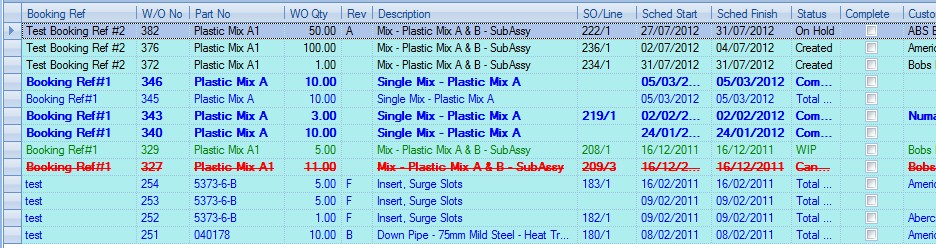

The work orders displayed in the grid are colour coded depending on their status. The legend at the bottom of the screen explains the meaning of each.

This gives the user an idea of a work order’s status at a glance.

![]()

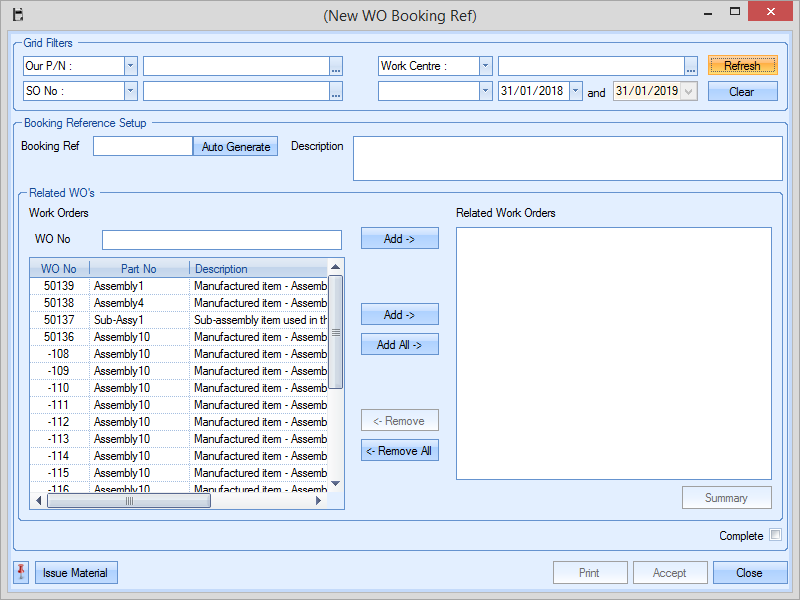

This option allows the user to create booking references. Booking references allow the user to group work orders together under a single label. This allows employees to “job on” to a single booking reference and record time against all the work orders within that booking reference where the selected work centre is common on a pro rata basis. Clicking this option presents the user with the following screen.

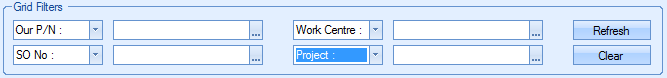

The grid filters at the top of the screen allow the user to filter the WO list by a variety of options.

This screen allows the user to give a name, a description and link the required work orders to the booking reference.

| Booking Ref | This is the label given to the booking reference as it will be referenced within Progress. The AUTO GENERATE option will append a unique number to a new booking ref name. If no name is specified, then the booking ref ID will be the next 4 digit number (i.e "0001", "0002", etc.). |

| Description | This is the description of the booking reference and is provided by the user. |

| Complete | This option allows the user to mark the booking reference as complete. A booking reference marked as complete would not be available for recording time via timesheets or the SFDC module. |

![]()

The lists below allow the user to select the work orders to be included in the booking reference being created. The list on the left is a list of all work orders that are available for the user to select from. The list on the right is the list of selected work orders currently included in the booking reference. The ADD and REMOVE options allow the user to select work orders in both lists and transfer to the other list accordingly. The screen below shows an example of selected work orders. The user can also manually enter the work order they are after and add it to the booking reference, assuming its a valid work order number.

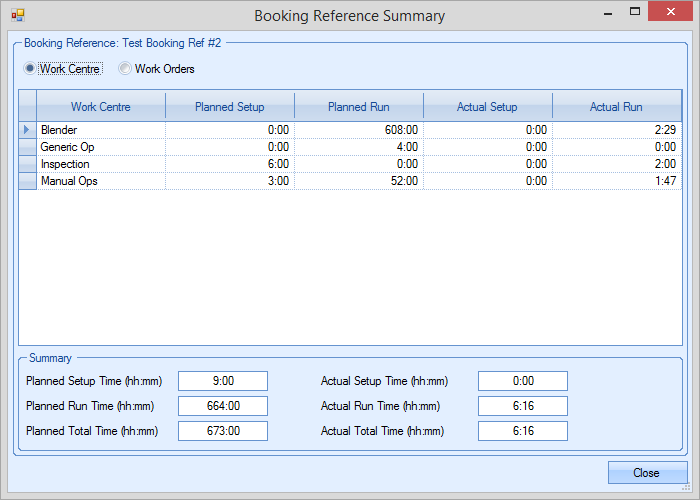

The user can view a summary of the booking reference using the SUMMARY option. From this window, the user can view planned time information from both a WO and work centre perspective as well as seeing summary totals for the entire booking reference too.

Once the user has chosen the work orders required, they can save the booking reference by clicking on the ACCEPT option. The user can return to the main booking reference screen by clicking the CLOSE option. The main booking reference screen will update to show the new booking reference.

This booking reference is now available for recording time against the work orders via the Labour section of Progress or via the SFDC module.

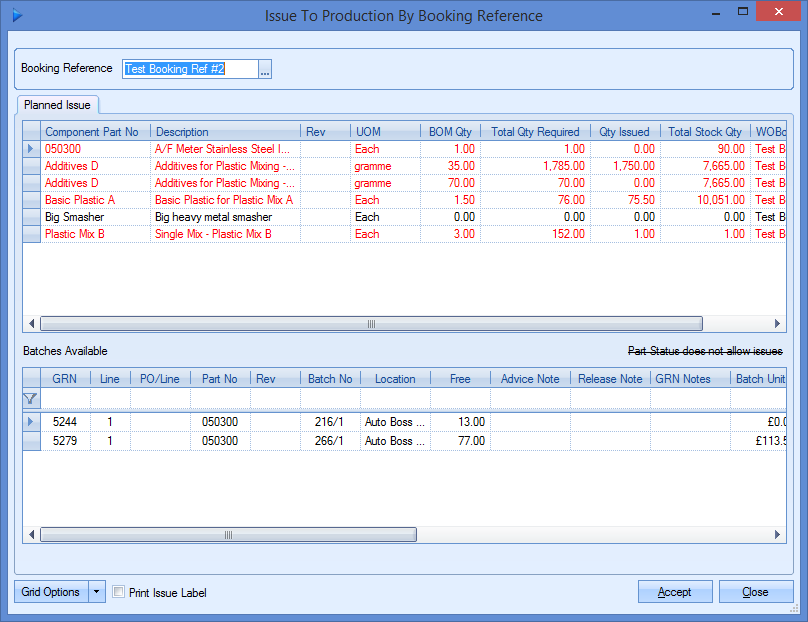

As well as creating the booking reference, the user also has an option to issue the material to the WOs associated with the booking reference.

![]()

Clicking this option opens up the Issue To Production By Booking Reference screen.

From here the user can issue material to all the WOs associated with the booking reference. This is the same screen as accessed via the INVENTORY > ISSUES section of Progress.

View

The user can view the details of any selected booking reference by highlighting the booking reference required in the grid and clicking the VIEW option. Alternatively, the user can view the details of a booking reference by double-clicking on the required booking reference directly on the grid. Either method will present the user with the following screen.

The user can now view or amend the details of the selected booking reference as required. Clicking the ACCEPT option will save any changes made by the user while the CLOSE option returns the user to the main booking reference screen.

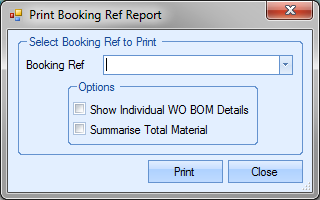

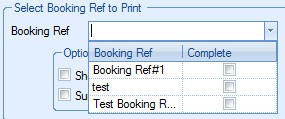

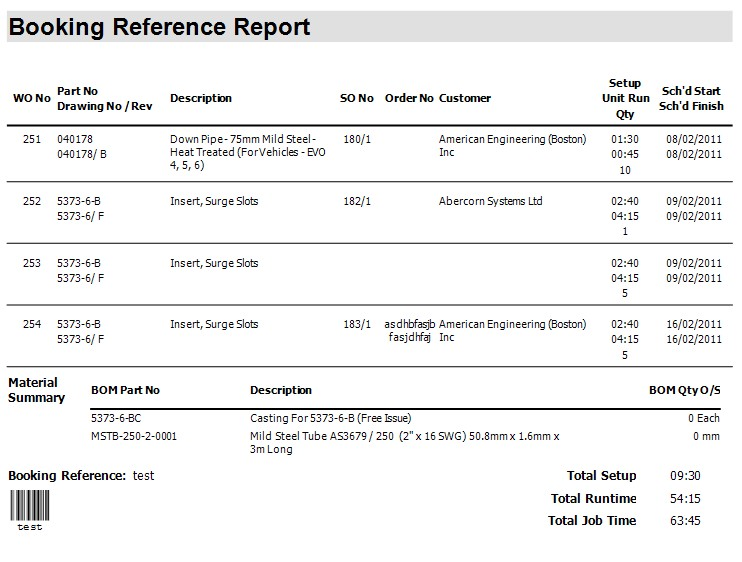

This option allows the user to print the booking reference report. Clicking this option presents the user with the following prompt window.

The user can select the required booking reference from the drop-down list.

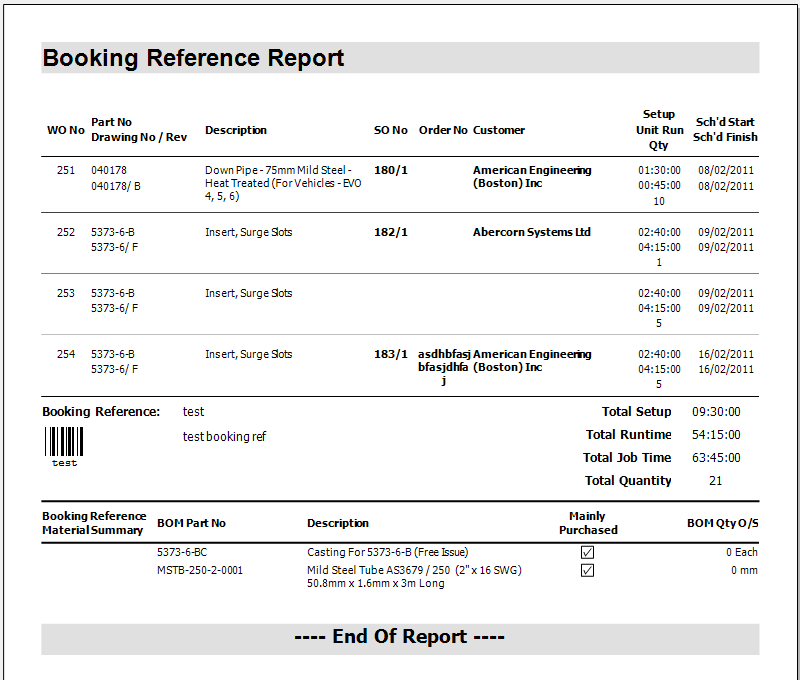

Once the user has selected the required booking reference, clicking the PRINT option presents the user with the standard booking reference report.

The report shows each work order within the booking reference, part number information, sales order information if applicable and summarised routing times along with the current scheduled start and finish dates of the work order. The report also provides summarised totals for set up and run times for all work orders included in the booking reference at the end of the report.

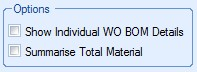

The user also has some additional options to choose from regarding the content of the booking reference report.

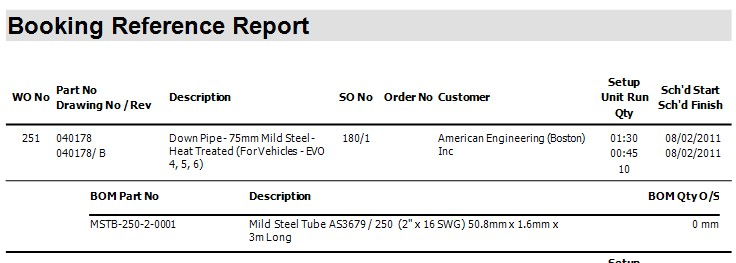

Show Individual WO BOM Details

This option includes a listing of the BOM components associated with the specified work order along with the outstanding quantity for each component. An example is shown below.

Summarise Total Material

This option provides a summary of the total quantity of each component part required for the work orders included in the selected booking reference at the end of the report. An example is shown below.

These report options are NOT mutually exclusive and can be both used together to include outstanding material requirements for both individual work orders and overall totals for the booking reference.

Export

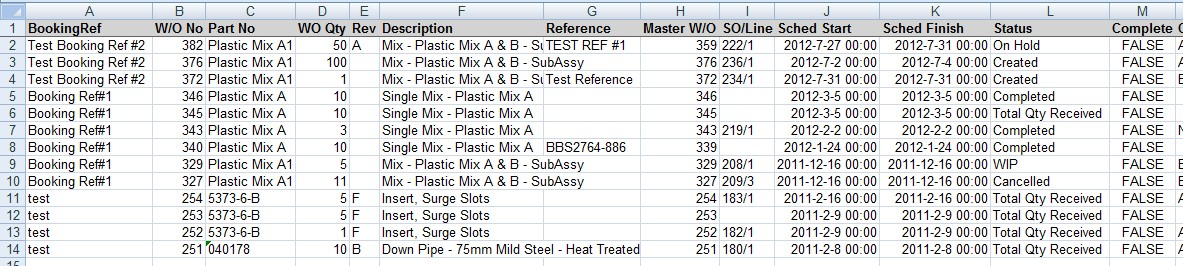

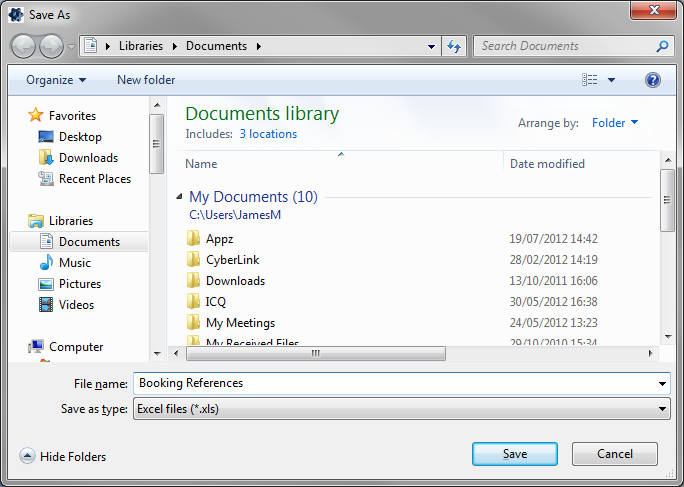

The EXPORT option allows the user to export the current list of booking references to an Excel spreadsheet for further analysis. This option can be used in conjunction with the filters available at the top of the screen or can be used with the full list of booking references if required. Clicking the EXPORT option will prompt the user to create an Excel file.

The user can specify the name required and where the exported file is saved. Clicking SAVE will generate the file. Once saved, the spreadsheet will be automatically opened for the user to view, an example of which is shown below.