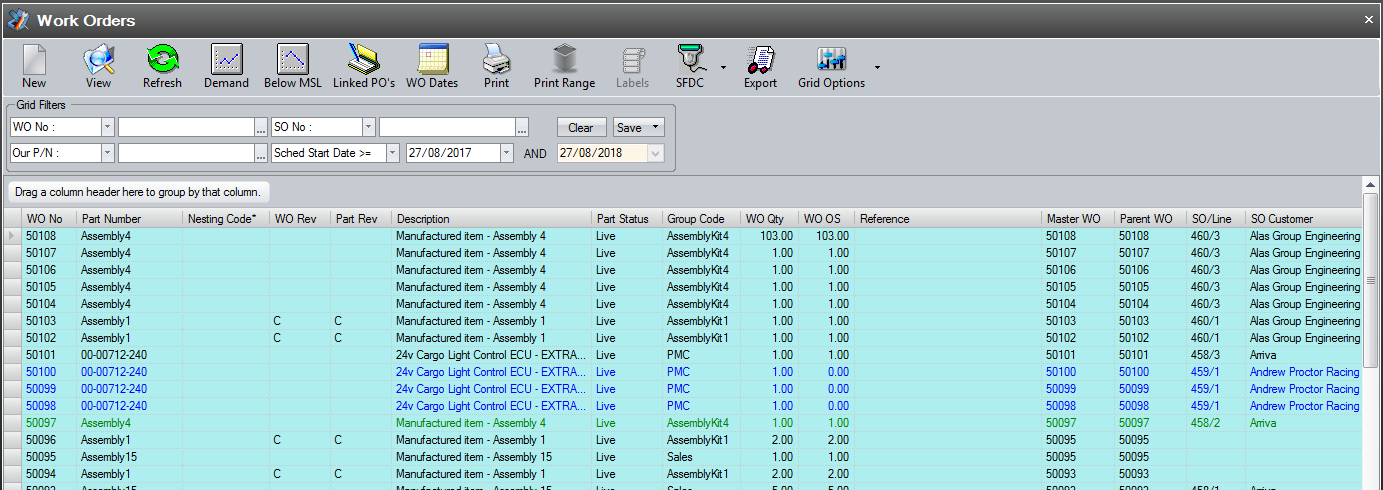

This section allows the user to create and maintain work orders in Progress.

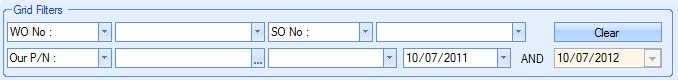

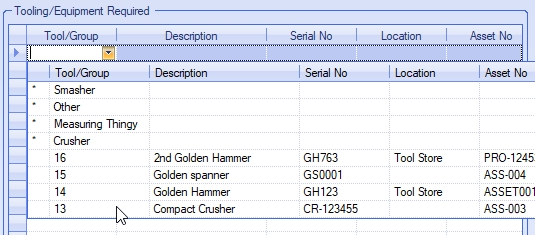

The filters at the top of the screen allow the user to search and display all work orders based on the search criteria entered.

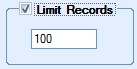

The user can apply a variety of filters to their search including a range of work order numbers and statuses as well as by customer, part number and sales order. The user can also set the maximum number of part records to be displayed on the grid using the LIMIT RECORDS option at the bottom of the screen.

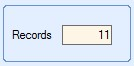

The default value of this option is set in the system options and is useful when large amounts of data are held in Progress as this limits the amount of data being displayed. The limit can be removed by the user if necessary by simply unticking the option, or they can simply increase the limit quantity to a more suitable value. The number of parts shown in the grid is also summarised at the bottom of the screen. This gives a total count of the parts shown.

Once filters and record limits have been selected, the user can view the work orders which meet the selected criteria by clicking the REFRESH option.

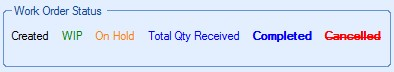

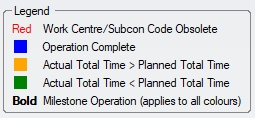

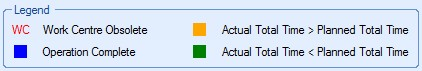

The work orders displayed in the grid are colour coded depending on their status. The legend at the bottom of the screen explains the meaning of each.

This gives the user an idea of a work order’s status at a glance.

View

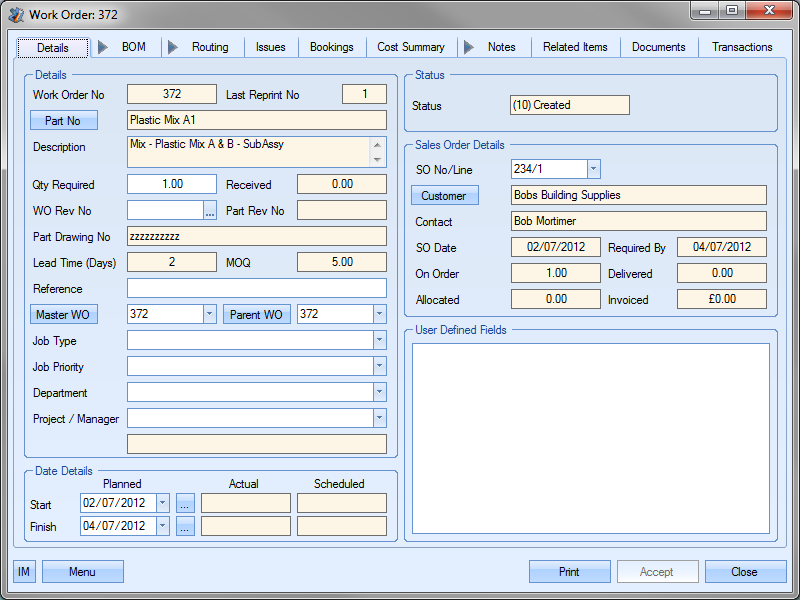

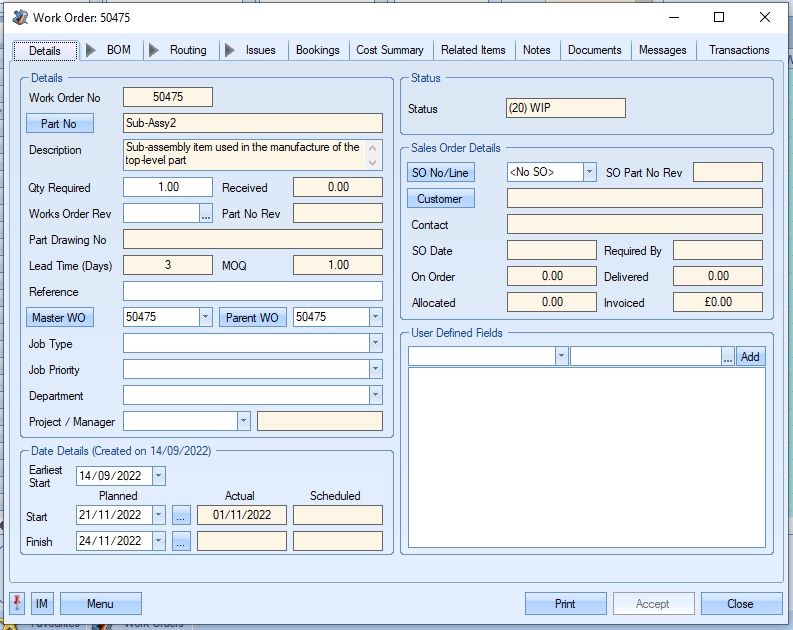

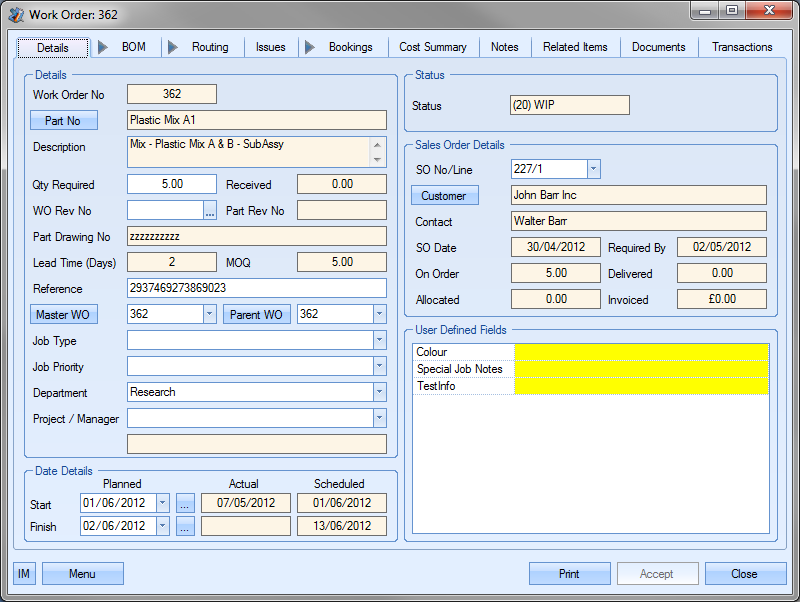

The user can view the details of any selected work order by highlighting the work order required in the grid and clicking the VIEW option. Alternatively, the user can view the details of a work order by double-clicking on the required work order directly on the grid. Either method will present the user with the following screen.

The user can now view or amend the details of the selected work order as required. Clicking the CLOSE or ACCEPT options will return the user to the Work Order screen.

WO Demand

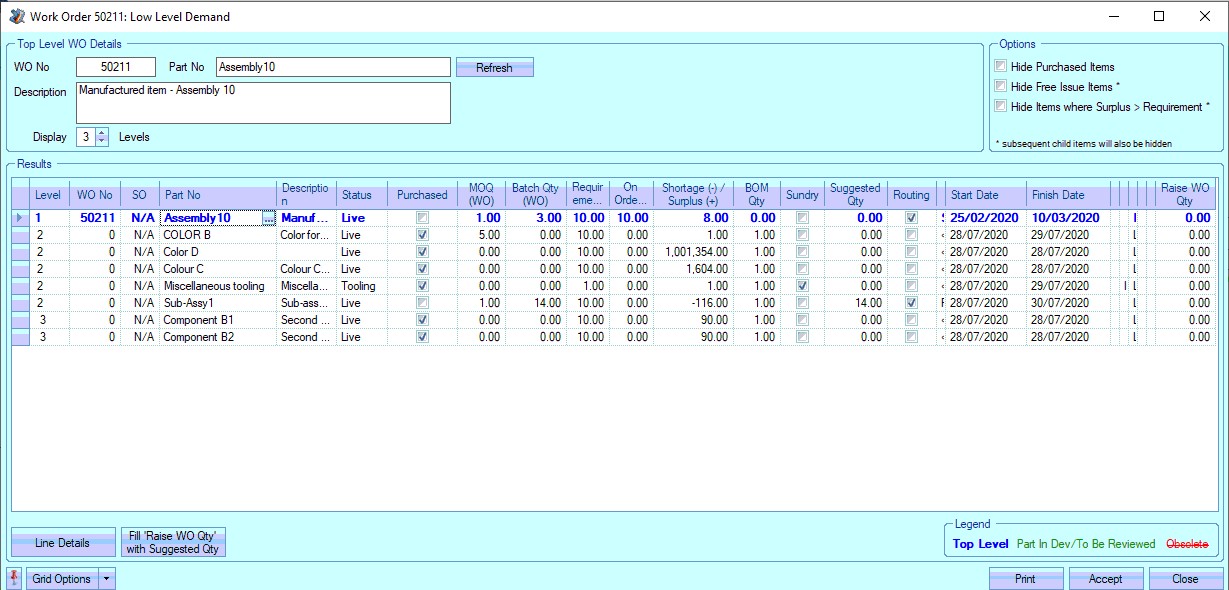

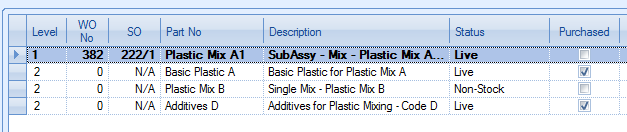

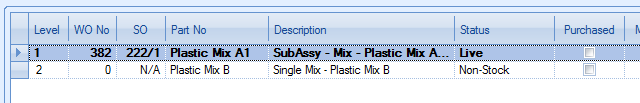

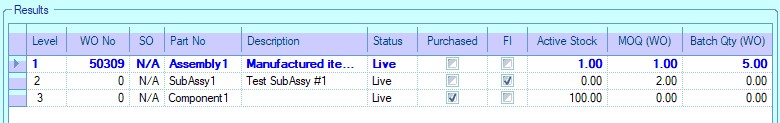

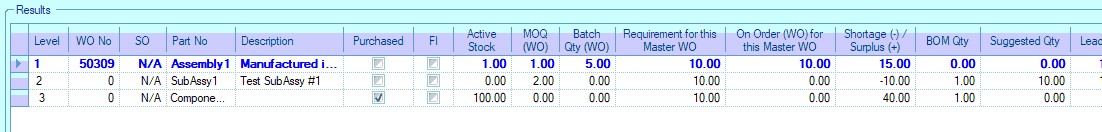

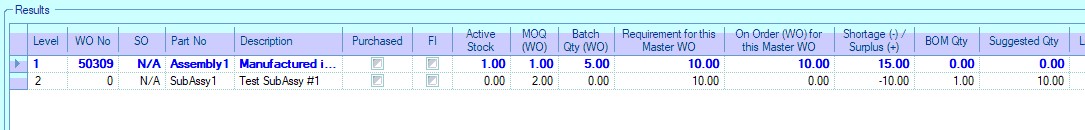

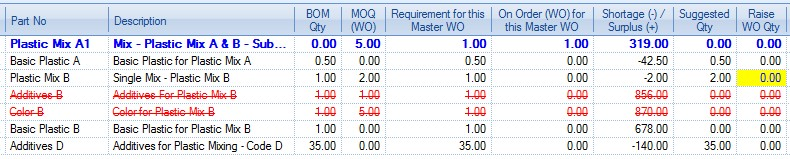

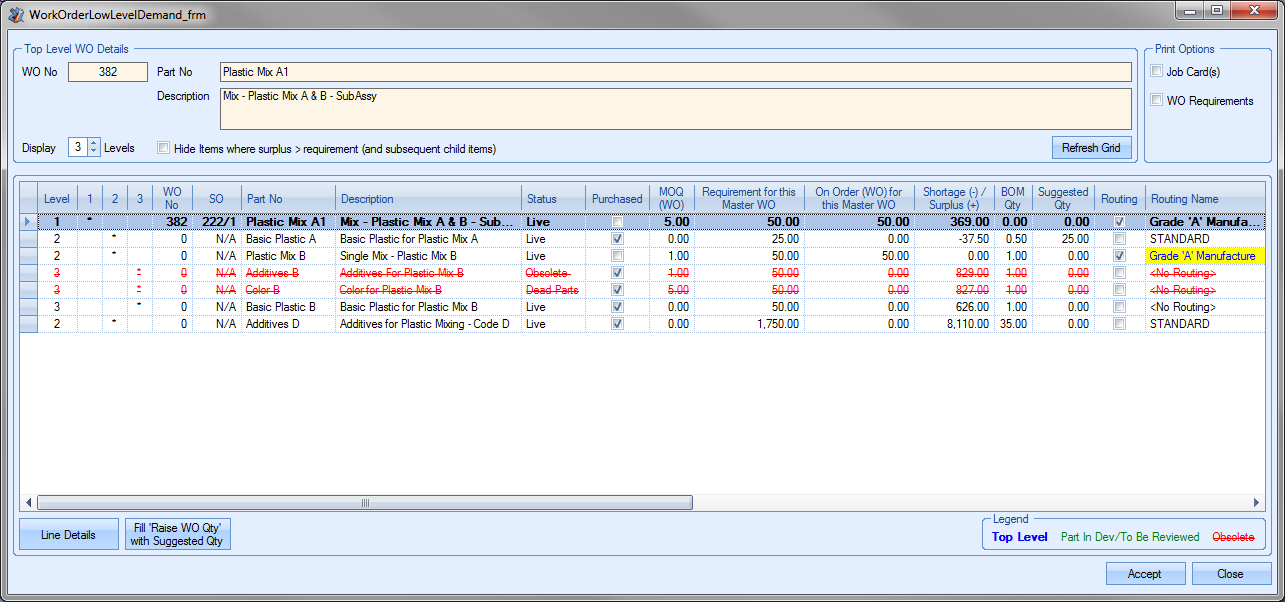

This option allows the user to view any lower level demand for a selected work order. Sub-assembly requirements are highlighted, allowing the user to create the additional work orders necessary for the selected work order. When the user clicks on the DEMAND option, the following screen is displayed.

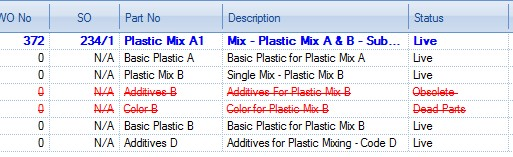

This screen presents the user with the details of the selected work order, part number and description, as well as a breakdown of the BOM for the selected work order and highlights any sub-assembly parts. The BOM levels are indented to show the multiple levels of the BOM.

The user can specify the number of levels shown using the DISPLAY X LEVELS option at the top of the screen.

![]()

Reducing the number of levels to below the number of BOM levels of the work order reduces the number of visible component parts as shown below. Any changes to the number of levels can be applied by clicking the REFRESH option.

As well as the BOM levels, the screen displays the following information.

| WO No | This is the selected WO and is the work order the requirements are being calculated for. |

| SO | This is the associated sales order for the selected work order. This only shows against the top level work order if the work order and sales order are linked. Stand alone work orders, like their component parts, are not linked to sales orders directly so show “N/A”. |

| Part No | Associated part number. For the top level work order, this is the work order part number, i.e. the part being manufactured. The top level part number and all its information are highlighted in blue. |

| Description | Inventory description recorded against aforementioned part number. |

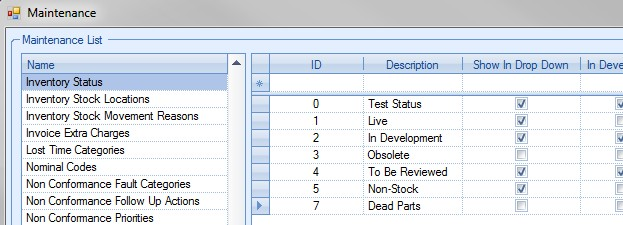

| Status | Current part number status. If any part number has an inventory status that does not have the “Show In Drop Down” option ticked in the Inventory Status screen, the part will be shown in red with a line through it. |

| Similarly, any parts with an inventory status which is marked as “In Development” are shown in the grid in green. The legend describing the colours used on the grid is shown at the bottom of the screen. |

![]()

| For more information on inventory statuses and the List Maintenance screen, please refer to the Inventory section of the manual. |

| Purchased | Tickbox to indicate whether the part number is flagged as a purchased part or manufactured part set in the parts inventory record. |

| FI | Tickbox to indicate whether the part number is flagged as aa "free issue" part number. |

| Active Stock | This shows the number of units of the part number currently in stock. |

| MOQ (WO) | Minimum work order quantity. This is the minimum quantity manufactured for work orders for the part. |

| Batch Qty (WO) | This shows the specified batch quantity set up against this part number in the inventory record. |

| Requirement For This Master WO | This is the quantity of each part required for the selected work order. This is calculated based on the work order quantity and the BOM quantity. |

| On Order (WO) For This Master WO | This is the total quantity already planned for manufacture on work orders linked to the selected work order. Any parts listed which are not manufactured parts will have a value of 0. |

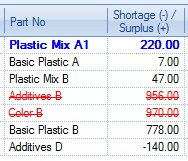

| Shortage (-) / Surplus (+) | This is the current inventory level of the part. This is based on the current stock levels, orders and requirements for the part. Shortages are shown as negative quantities while surplus stock is shown as positive quantities. These values are the same shown on the inventory part’s Stock Status screen. |

| Lead Time | This is the manufacturing lead time of the part. If the part is not a manufactured item (i.e. it has no routing) then this will be left blank. |

| BOM Qty | This is the individual component quantity on the BOM of the manufactured item. |

| Sundry | Tickbox which shows whether the component part is a sundry item or not. |

| Suggested Qty | This is the quantity Progress suggests should be ordered for the currently selected work order. For purchased parts this will be the quantity that needs to be ordered from a supplier. For manufactured parts, including sub-assembly parts, this is the suggested work order quantity. |

| Routing | Tickbox to indicate whether part number has a routing set up. Purchased parts do not have this ticked. |

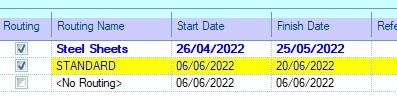

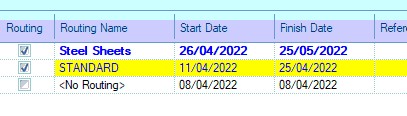

| Routing Name | This displays the name of the routing currently selected on the part. If the part number has multiple routings recorded, the user can choose an alternative routing from the highlighted drop-down list. |

| If the user chooses to create work orders for any of the highlighted sub-assembly parts, the work orders will be created using the routing selected on this screen. |

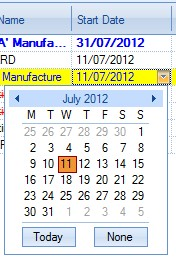

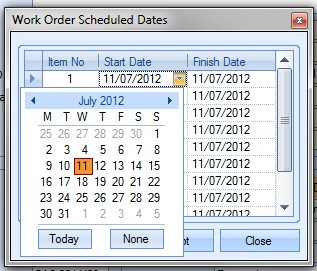

| Start Date | This is the proposed start date of any work order created for the sub-assembly part from this screen. This field defaults to the current date. The user can change the date using the drop-down calendar. |

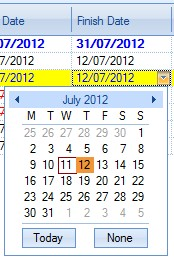

| Finish Date | This is the proposed finish date of any work order created for the sub-assembly part from this screen. This field defaults to the current date PLUS any manufacturing lead time set up against the part number. Again, the user can change this date if required using the drop-down calendar. |

| Reference | This field allows the user to record a reference for the work order being created. If the top-level work order has an existing reference, all lower level parts will share the same reference. |

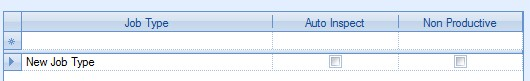

| Job Type | This field allows the user to record a job type for the work order being created. If the top-level work order has an existing job type, all lower level parts will share the same job type. If no job type is specified, the user can select a value from the drop-down list if required. |

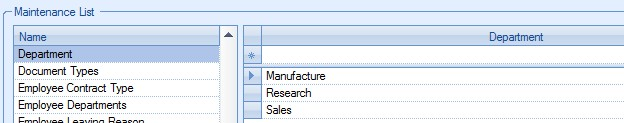

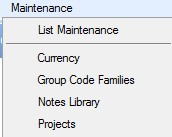

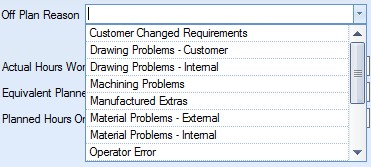

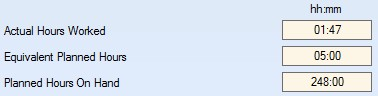

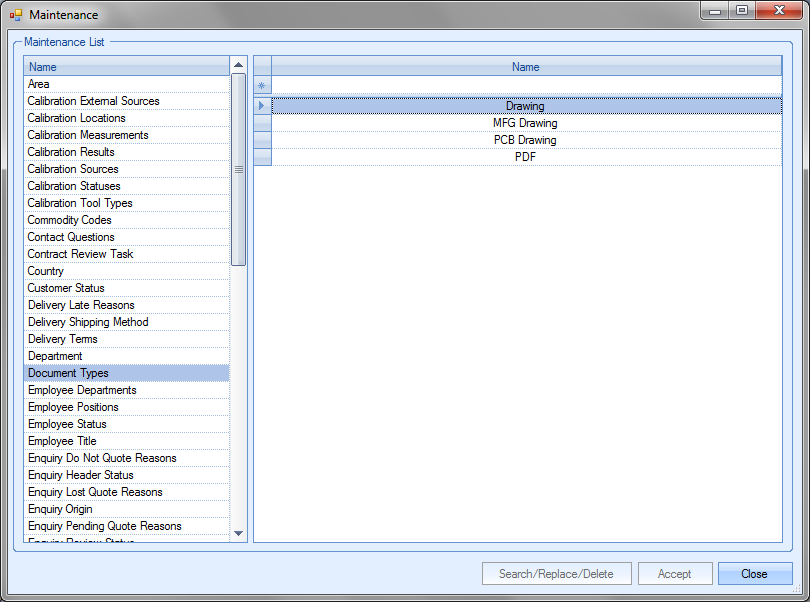

| This drop-down list can be populated from the List Maintenance section of Progress in the WO Job Type list as shown in the screen below. |

| For more information on maintaining lists and the List Maintenance section of Progress, please refer to the List Maintenance section of this manual. |

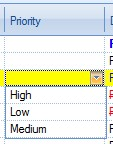

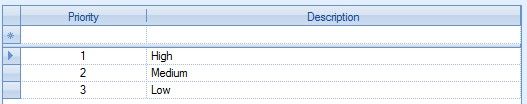

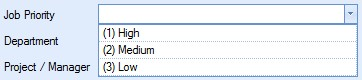

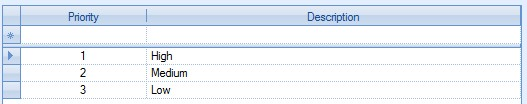

| Priority | This field allows the user to record a priority for the work order being created. If the top-level work order has an existing priority, all lower level parts will share the same priority. If no priority is specified, the user can select a value from the drop-down list if required. |

| This drop-down list can be populated from the List Maintenance section of Progress in the WO Priority list as shown in the screen below. |

| For more information on maintaining lists and the List Maintenance section of Progress, please refer to the List Maintenance section of this manual. |

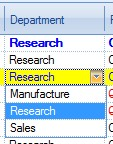

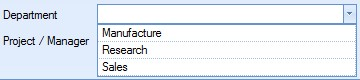

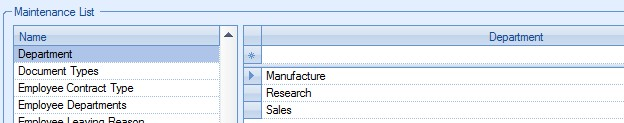

| Department | This field allows the user to record a department against the work order being created. If the top-level work order has an existing department, all lower level parts will share the same department. If no department is specified, the user can select a value from the drop-down list if required. |

| This drop-down list can be populated from the List Maintenance section of Progress in the Department list as shown in the screen below. |

| For more information on maintaining lists and the List Maintenance section of Progress, please refer to the List Maintenance section of this manual. |

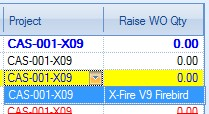

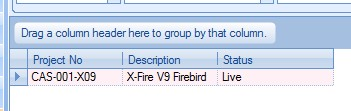

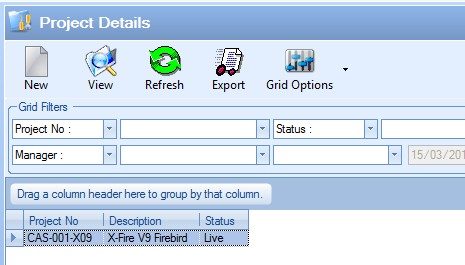

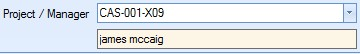

| Project | This field allows the user to record a project against the work order being created. If the top-level work order has an existing project, all lower level parts will share the same project. If no project is specified, the user can select a value from the drop-down list if required. |

| This project list can be populated from the Maintenance section of Progress in the Project section as shown in the screen below. |

| For more information on projects, please refer to the Projects section of the manual. |

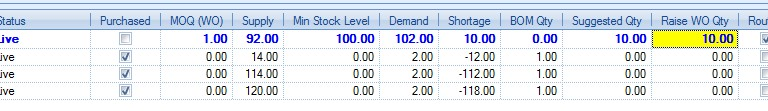

| Raise WO Qty | This field allows the user to specify the quantity for the work order to be created. |

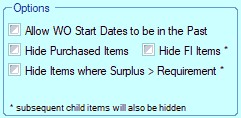

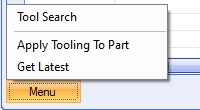

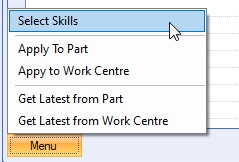

WO Demand Options

The user has a couple of options regarding the information shown. These options allow the user to remove certain parts from the demand grid to help focus on what they need to consider.

Allow WO Start Dates to be in the Past

This option allows the calculated work order dates to be prior to the current date. By default, the system would typically raise work orders with dates based on current date, however, back-dating work orders can be done using this option.

(Option unticked - system calculates WO dates based on current date)

(Option ticked - system calculates dates based on parent WO dates)

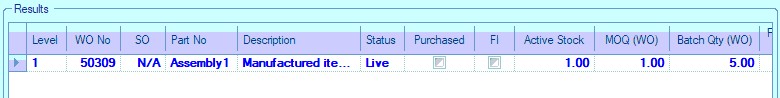

Hide Purchased Items

The user can also remove purchased parts (MP ticked) from the grid by ticking this option. Refreshing the grid removes all purchased items, leaving on manufactured parts shown.

UNTICKED (Show all parts)

TICKED (Hide all purchased parts)

Hide FI Items*

This option allows the user to hide any part that is marked as an free issue part (FI ticked). If the part marked as FI has a BOM, the lower-level parts will also be hidden.

(Option unticked - FI items shown with lower-level BOM items)

(Option ticked - FI items hidden, along with the lower-level BOM items)

Hide Items Where Surplus > Requirement

This option allows the user to hide parts where there is sufficient supply already planned. This effectively highlights parts where there is a current shortfall in supply.

(Option unticked - All parts shown regardless of surplus/shortage)

(Option ticked - Only parts with overall shortage shown)

Line Details

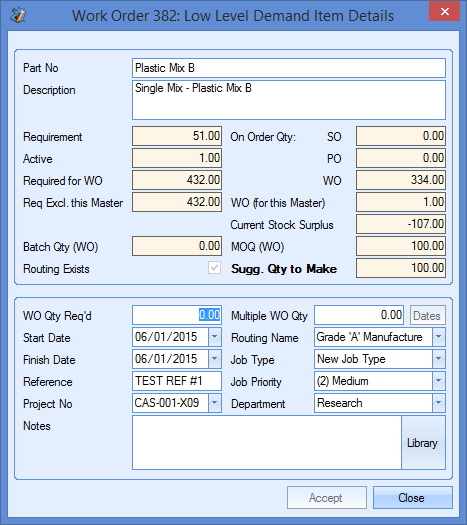

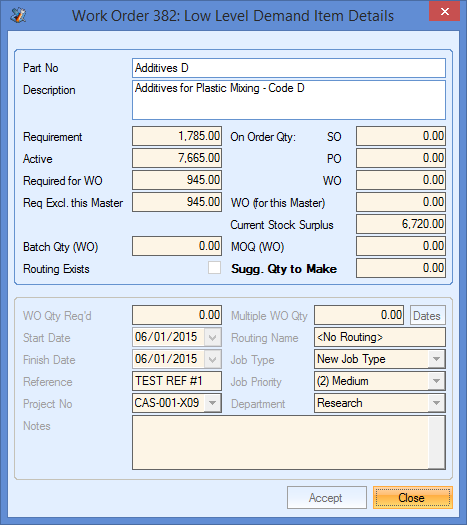

The user can further enquire into the inventory status of any component or sub-assembly by clicking on the LINE DETAILS option at the bottom of the screen. This presents the user with a more detailed view of the part in question as shown below.

When viewed for a purchased part, the screen shows a more detailed view of the stock status of the selected component, much like can be seen on the parts Stock Status screen. The bottom half of the screen is locked down as this is only for use with non-purchased parts. An example for a non-purchased part is shown below.

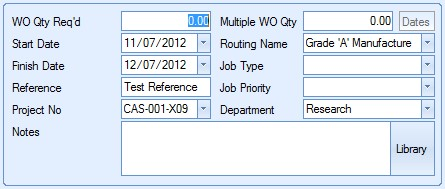

Again, a more detailed look at the stock status of the selected part can be seen at the top half of the screen. The bottom half of the screen allows the user to specify details to be used in creating a work order.

The user can specify the required work order quantity as well as a batch quantity if required. This would create multiple work orders, each for the specified batch quantity, to the total quantity required.

![]()

For single sub-assembly work orders, the user only need add the WO QTY REQ’D value.

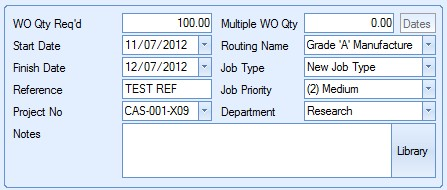

The user can then specify the rest of the details, including dates, using the fields displayed. If the user wanted to create the work order quantity of 100 units in batches of 10 units, the user could set up the details as follows.

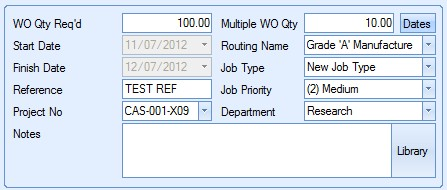

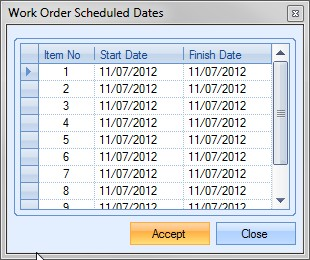

As can be seen, the option to choose START and FINISH dates are now locked. The user can now use the DATES option to specify the dates for each individual batch.

![]()

Clicking on the DATES option presents the user with the following window.

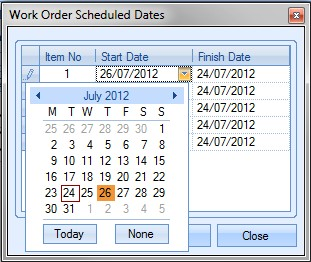

Both dates will default to the current date. The user can change the dates using the drop-down calendar for each item (work order) listed.

Once all the dates have been amended accordingly, the user can click ACCEPT to save the dates and return to the work order details screen. Once all the details have been entered, clicking ACCEPT will return the user to the initial work order Demand screen, where any details selected will now be shown.

Alternatively, the user can have Progress plus generate work ordered based on a “suggested quantity”. This quantity is calculated and shown in the main grid above.

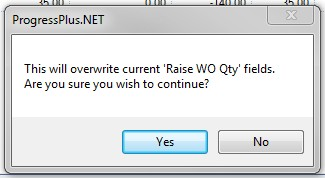

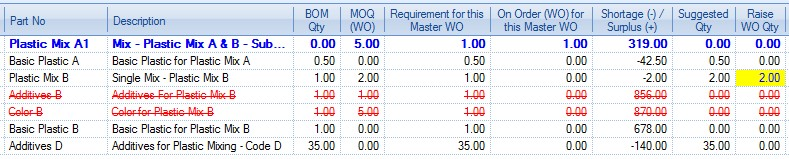

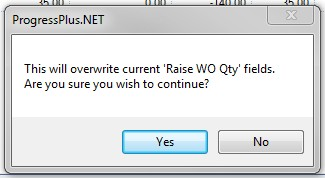

If the user wishes to proceed with the suggested quantity, the user can click the FILL ‘RAISE WO QTY WITH SUGGESTED QTY option.

![]()

This will populate the RAISE WO QTY field with the suggested quantity calculated by Progress. The user will be prompted to confirm that they wish to proceed.

Once confirmed, the screen will be updated to show the suggested quantity in the RAISE WO QTY field.

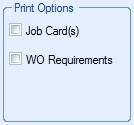

Once the user has entered the work order quantities required, they can choose whether they wish the paperwork associated with the new work orders printed upon creation. This can be specified using the printing options at the top right of the screen.

Selecting the Job Card(s) option will automatically generate and print the job card documentation for the new work orders. Selecting the WO Requirements option will generate the WO Requirements By WO report for the new work order. This will highlight any outstanding requirements for the work order as well as show a summary of the component stock status.

Once the work order quantities have been decided and the printing requirements selected, the user can generate any work orders by clicking the ACCEPT option. The system will create the specified work orders and then produce the selected paperwork. Once the user has finished generating the required work orders, they can return to the main work order screen by clicking the CLOSE option.

Below MSL

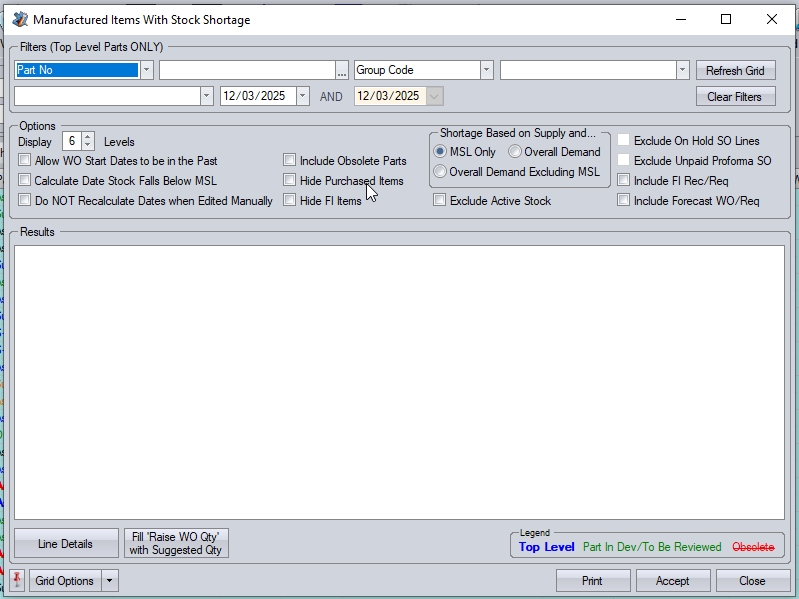

This screen allows the user to see current shortages of manufactured parts. This works in a similar way to the PO Shortage screen, but for manufactured parts as opposed to purchased parts. Clicking on this option presents the user with the following screen.

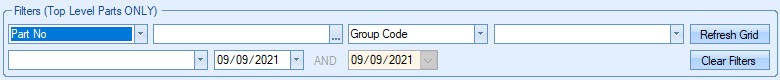

The user can filter this screen using the grid filters at the top of the screen if they know the part number or group code they wish to view.

If specific details are not known, the user can simply click the REFRESH option to view all current manufactured shortages. The user can clear any existing filters using the CLEAR FILTERS option at the top.

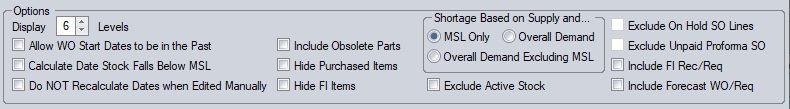

The user has some additional options which can be applied to the calculations.

Display X Levels

This allows the user to set how many BOM levels they wish to consider in the calculations.

Calculate Date Stock Falls Below MSL

This option will calculate the date the stock will fall below the part number's minimum stock level (MSL). The system will look at the dates of all incoming supply and dates of demand to determine a date when the stock level will breach the set minimum stock level. This only applied to the top-level items; does not get calculated for lower-level items.

NOTE: Applying this option may cause a refresh of the Below MSL screen to take longer due to the additional calculations being carried out.

Do NOT Recalculate Dates when Edited Manually

If the user decides to manually edit the start or finish dates of the WO they wish to create, the system will, by default, calculate the other date based on the default WO Dates settings in the Admin. For example, changing the start date would recalculate the finish date, and vice versa. Having this option ticked would NOT recalculate the dates. This would allow the user to amend either of the dates without recalculating the other.

Hide Purchased Items/Hide FI Items

These options simply remove any parts that are marked as mainly purchased or free issue. This is useful when working with large BOMs and where the user is only interested in manufactured parts that require work orders.

Shortage Based on Supply and...

This section allows the user to determine what constitutes the demand to be considered. The user has three options:

oOverall Demand - Includes all demand (On Order (SO), Req for WO, MSL and potentially forecast requirements if option ticked)

oOverall Demand Excluding MSL - All demand (see above), excluding the part's minimum stock level.

oMinimum Stock Level Only - Only considers part's minimum stock level figure for demand.

Exclude Active Stock

This option removes any current active stock from the supply calculation. The supply calculation will then be based on outstanding POs and WOs only.

Exclude On Hold SO Lines

This option removes any outstanding SO line quantities if the SO line has a status of ON HOLD. This is useful if you only want to consider confirmed sales orders. This option will only be available if the system is configured to NOT exclude these lines by default. If the system is configured to exclude these SO lines in the system options, the option will not be available on the Below MSL screen, as the SO lines will automatically be excluded from the demand calculations.

![]()

(Options unavailable due to ON HOLD SO lines automatically being excluded due to system options)

![]()

(Options available as ON HOLD SO lines not automatically excluded by system options)

Exclude Proforma Unpaid SO from Demand

This option removes any outstanding SO lines quantities if the SO is a proforma order and has not yet been paid. This is useful if you only want to consider confirmed sales orders. Like the Exclude On Hold SO Lines option above, this option will only be available if the system is configured to NOT exclude these lines by default. If the system is configured to exclude these SO lines in the system options, the option will not be available on the Below MSL screen, as the SO lines will automatically be excluded from the demand calculations.

![]()

(Options unavailable due to Unpaid Proforma SO lines automatically being excluded due to system options)

![]()

(Options available as Unpaid Proforma SO lines not automatically excluded by system options)

Include FI Receipts/Reqs

This option removes all free issue (FI) receipts and requirements from the supply and demand calculations. This is useful if the user only wants to consider requirements which are not being fulfilled by a third party.

Include Forecast WO/Req

This option allows the user to include forecast WOs in the supply and demand calculations. This option is only available if the Forecast functionality is activated.

NOTE: Any changes to the filters, options or BOM levels to be displayed require the user to click the REFRESH option to update the screen accordingly.

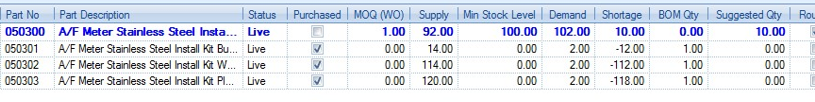

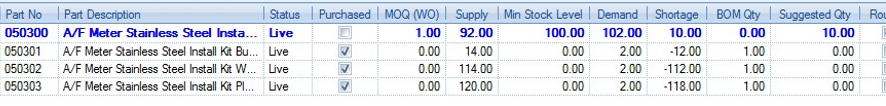

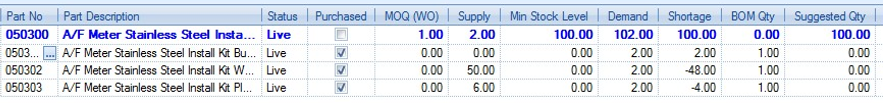

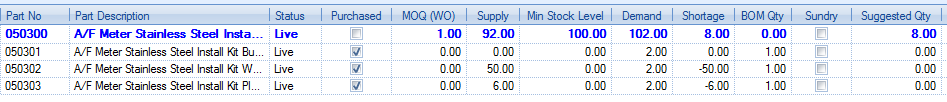

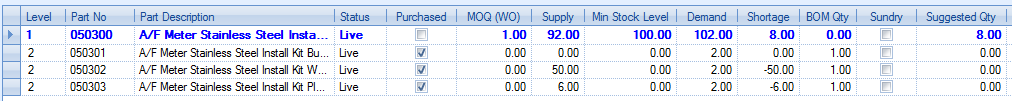

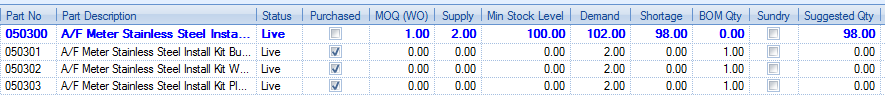

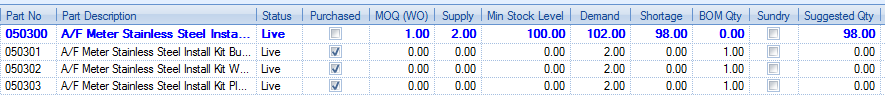

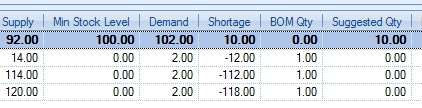

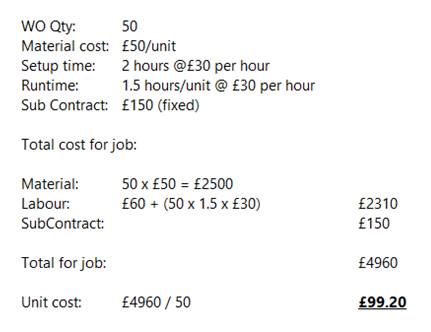

Looking at an example, the following shows how these options influence the calculations.

Supply And Overall Demand Example (Including available stock)

The MOQ (WO) value is the minimum order quantity for the part. This value is displayed for the top level part as well as any lower level manufactured parts. Purchased parts would not normally have a MOQ (WO) value recorded so typically show zero.

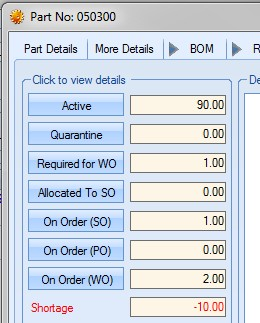

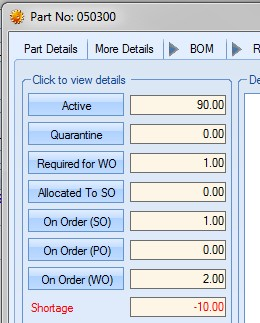

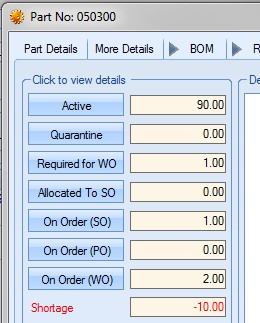

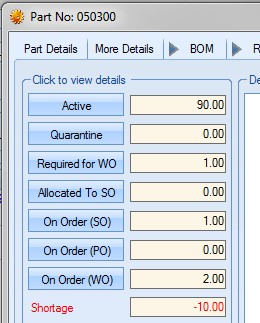

The SUPPLY figure shown for the top level item is calculated based on current available inventory (active and in quarantine) and existing work orders and purchase orders already on the system. The same calculation is used for any lower level manufactured items. The SUPPLY figure can be confirmed looking at the part’s stock status screen as shown below.

SUPPLY = ACTIVE + QUARANTINE + ON ORDER (WO) + ON ORDER (PO) = 90 + 0 + 2 + 0 = 92

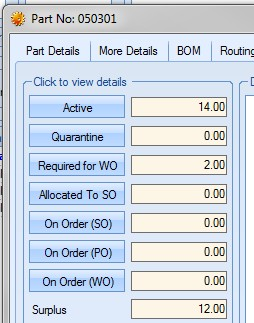

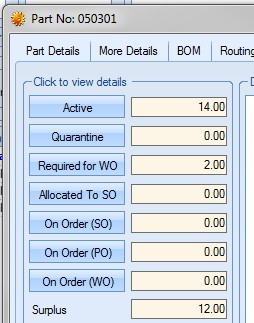

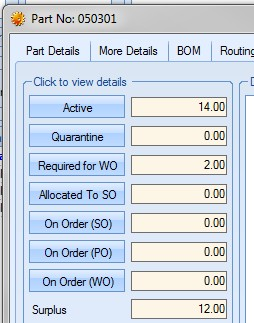

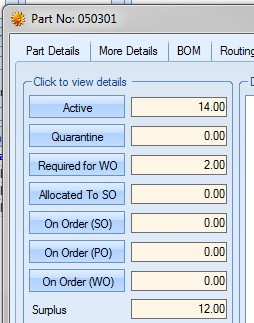

The SUPPLY figure for any PURCHASED component parts is calculated based on outstanding purchase orders and any available inventory currently in Progress. Again this can be confirmed looking at the component part’s stock status screen.

SUPPLY = ACTIVE + QUARANTINE + ON ORDER (PO) = 14 + 0 + 0 = 14

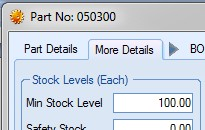

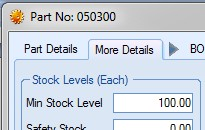

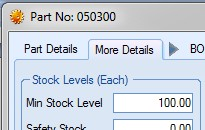

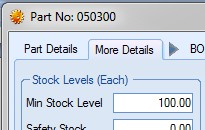

The MIN STOCK LEVEL (MSL) value is the minimum stock level recorded against the part record.

The DEMAND value is calculated based on the current requirements for the part. This is calculated based on the MSL value of the part, any requirements from existing work orders or sales orders. For the top level part in this example, the DEMAND is calculated as follows.

DEMAND = MSL + REQUIRED FOR WO + ON ORDER (SO) = 100 + 1 + 1 = 102

The same calculation is used for any lower level manufactured components and components marked as PURCHASED.

The SHORTAGE value shown is calculated as the difference between the DEMAND and the SUPPLY. This is the same calculation for all parts listed. For our top level part example, the calculation is as follows.

SHORTAGE = SUPPLY – DEMAND = 92 – 102 = 10

Shortages shown as negative numbers, like the component parts in this example, indicate that sufficient stock is available. Shortages shown as positive number are where there are shortages.

The BOM QTY value shown is the quantity required in the manufacture of the top-level part. This value is the value recorded against the top level part’s BOM and only shows for lower level items, both manufactured and purchased.

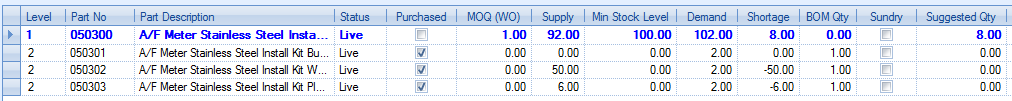

The SUGGESTED QTY shown is calculated based on the shortage value and the MOQ (WO) value. In the example shown here, the total shortage is 10. As the MOQ (WO) value is 1, the system suggests raising a work order for the total shortage quantity of 10.

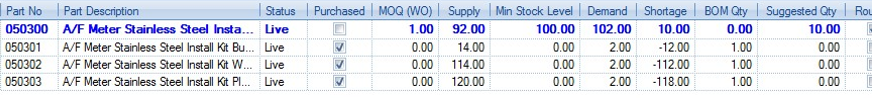

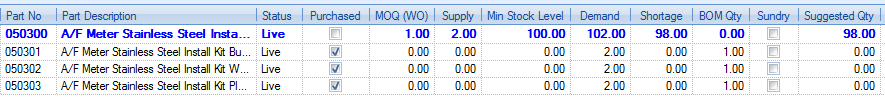

If the MOQ (WO) quantity is set to 100, then the SUGGESTED QTY is 100 as shown below.

The suggested quantity will be the total shortage quantity, unless it's less than the MOQ (WO) in which case the suggested quantity will be the MOQ (WO).

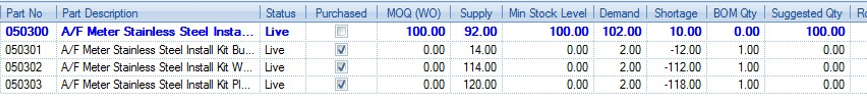

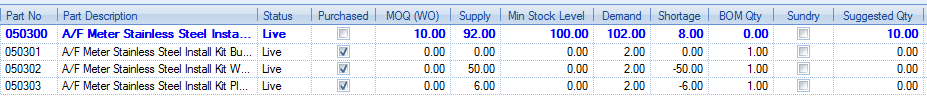

Supply And Overall Demand Example (Excluding available stock)

The SUPPLY figure shown for the top level item is calculated based only on existing work orders and purchase orders already on the system. The same calculation is used for any lower level manufactured items. The SUPPLY figure can be confirmed looking at the part’s stock status screen as shown below.

SUPPLY = ON ORDER (WO) + ON ORDER (PO) = 2 + 0 = 2

The SUPPLY figure for any PURCHASED component parts is calculated based only on outstanding purchase orders currently in Progress. Again this can be confirmed looking at the component part’s stock status screen.

SUPPLY = ON ORDER (PO) = 0

As before, the MIN STOCK LEVEL (MSL) value is the minimum stock level recorded against the part record.

The DEMAND value is still calculated based on the current requirements for the part. This is calculated based on the MSL value of the part, any requirements from existing work orders or sales orders. For the top level part in this example, the DEMAND is calculated as follows.

DEMAND = MSL + REQUIRED FOR WO + ON ORDER (SO) = 100 + 1 + 1 = 102

The same calculation is used for any lower level manufactured components and components marked as PURCHASED.

The SHORTAGE value shown is calculated as the difference between the DEMAND and the SUPPLY. This is the same calculation for all parts listed. For our top level part example, the calculation is as follows.

SHORTAGE = SUPPLY – DEMAND = 2 – 102 = -100

As before, the parts shown with positive shortages are those which have insufficient stock.

The SUGGESTED QTY shown is calculated based on the shortage value and the MOQ (WO) value. In the example shown here, the total shortage is 100. As the MOQ (WO) value is 1, the system suggests raising a work order for the total shortage quantity of 100.

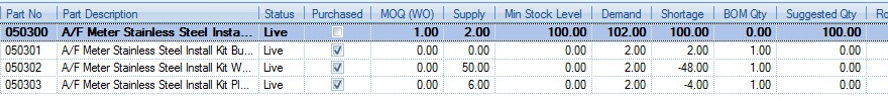

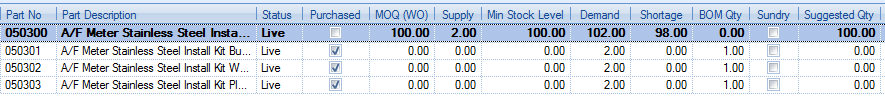

Supply And Min. Stock Level Only Example (Including available stock)

The SUPPLY figure shown for the top level item is calculated based on current available inventory (active and in quarantine) and existing work orders and purchase orders already on the system. The same calculation is used for any lower level manufactured items. The SUPPLY figure can be confirmed looking at the part’s stock status screen as shown below.

SUPPLY = ACTIVE + QUARANTINE + ON ORDER (WO) + ON ORDER (PO) = 90 + 0 + 2 + 0 = 92

The SUPPLY figure for any PURCHASED component parts is calculated based on outstanding purchase orders and any available inventory currently in Progress. Again this can be confirmed looking at the component part’s stock status screen.

SUPPLY = ACTIVE + QUARANTINE + ON ORDER (PO) = 14 + 0 + 0 = 14

As before, the MIN STOCK LEVEL (MSL) value is the minimum stock level recorded against the part record.

The DEMAND value is calculated based on the current requirements for the part. For this option, this is calculated based on the MSL value of the part. For the top level part in this example, the DEMAND is therefore calculated as follows.

DEMAND = MSL + REQUIRED FOR WO + ON ORDER (SO) = 100 + 1 + 1 = 102

The same calculation is used for any lower level manufactured components and components marked as PURCHASED.

The SHORTAGE value shown is calculated as the difference between the SUPPLY and the MSL value. This is the same calculation for all parts listed. For our top level part example, the calculation is as follows.

SHORTAGE = SUPPLY – DEMAND = 92 – 100 = -8

As before, the parts shown with positive shortages are those which have insufficient stock.

The SUGGESTED QTY shown is calculated based on the shortage value and the MOQ (WO) value. In the example shown here, the total shortage is 8. As the MOQ (WO) value is 1, the system suggests raising a work order for the total shortage quantity of 8. If the MOQ (WO) was 10, then the system would suggest raising a WO for a quantity of 10 as shown below.

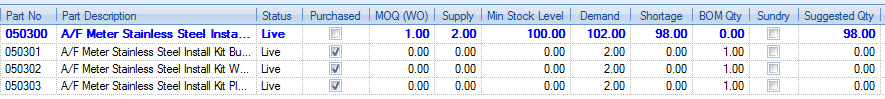

SUPPLY AND MIN. STOCK LEVEL ONLY EXAMPLE (Excluding available stock)

The SUPPLY figure shown for the top level item is calculated based on existing work orders and purchase orders already on the system. The same calculation is used for any lower level manufactured items. The SUPPLY figure can be confirmed looking at the part’s stock status screen as shown below.

SUPPLY = ON ORDER (WO) + ON ORDER (PO) = 2 + 0 = 2

The SUPPLY figure for any PURCHASED component parts is calculated based on outstanding purchase orders currently in Progress. Again this can be confirmed looking at the component part’s stock status screen.

SUPPLY = ON ORDER (PO) = 0

As before, the MIN STOCK LEVEL (MSL) value is the minimum stock level recorded against the part record.

The DEMAND value is calculated based on the current requirements for the part. For this option, this is calculated based on the MSL value of the part. For the top level part in this example, the DEMAND is therefore calculated as follows.

DEMAND = MSL + REQUIRED FOR WO + ON ORDER (SO) = 100 + 1 + 1 = 102

The same calculation is used for any lower level manufactured components and components marked as PURCHASED.

The SHORTAGE value shown is calculated as the difference between the SUPPLY and the MSL value. This is the same calculation for all parts listed. For our top level part example, the calculation is as follows.

SHORTAGE = SUPPLY – DEMAND = 2 – 100 = -98

As before, the parts shown with positive shortages are those which have insufficient stock.

The SUGGESTED QTY shown is calculated based on the shortage value and the MOQ (WO) value. In the example shown here, the total shortage is 98. As the MOQ (WO) value is 1, the system suggests raising a work order for the total shortage quantity of 98. If the MOQ (WO) was 100, then the system would suggest raising a WO for a quantity of 100 as shown below.

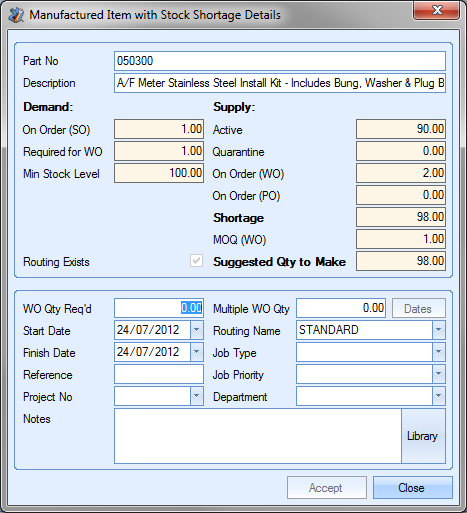

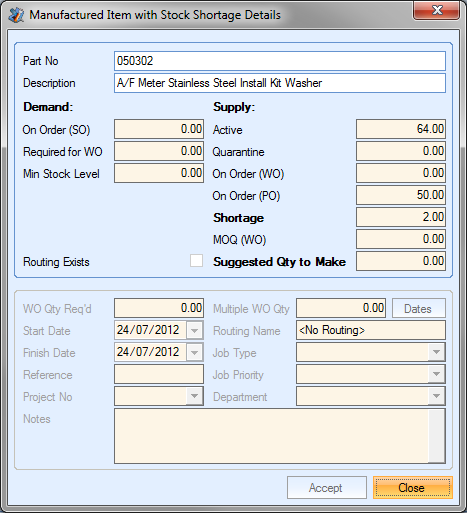

The user can further enquire into the inventory status of any component or sub-assembly by clicking on the LINE DETAILS option at the bottom of the screen. This presents the user with a more detailed view of the part in question as shown below, as well as the calculated shortage and suggested quantities.

When viewed for a purchased part, the screen shows a more detailed view of the stock status information for the selected component, much like can be seen on the parts Stock Status screen. The bottom half of the screen is locked down as this is only for use with non-purchased parts. An example for a purchased part is shown below.

For a manufactured part, a more detailed look at the stock status of the selected part can be seen at the top half of the screen. The bottom half of the screen allows the user to specify details to be used in creating the required work orders.

The user can specify the required work order quantity as well as a batch quantity if required. This would create multiple work orders, each for the specified batch quantity, to the total quantity required.

![]()

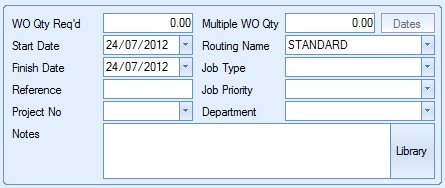

For single sub-assembly work orders, the user only need add the WO QTY REQ’D value.

![]()

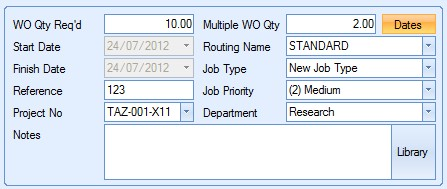

The user can then specify the rest of the details, including dates, using the fields displayed. If the user wanted to create the work order quantity of 10 units in batches of 2 units, the user could set up the details as follows.

As can be seen, the option to choose START and FINISH dates are now locked. The user can now use the DATES option to specify the dates for each individual batch.

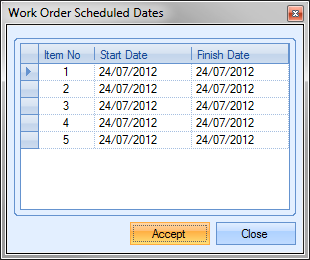

![]()

Clicking on the DATES option presents the user with the following window.

Both dates will default to the current date. The user can change the dates using the drop-down calendar for each item (work order) listed.

Once all the dates have been amended accordingly, the user can click ACCEPT to save the dates and return to the work order details screen. Once all the details have been entered, clicking ACCEPT will return the user to the Below MSL screen, where any details selected will now be shown.

Alternatively, the user can have Progress plus generate work ordered based on a “suggested quantity”. Based on the method of calculation chosen by the user initially, this quantity is calculated and shown in the main grid.

If the user wishes to proceed with the suggested quantity, the user can click the FILL ‘RAISE WO QTY WITH SUGGESTED QTY option.

![]()

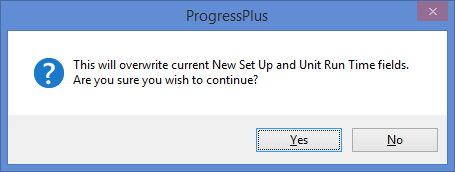

This will populate the RAISE WO QTY field with the suggested quantity calculated by Progress. The user will be prompted to confirm that they wish to proceed.

Once confirmed, the screen will be updated to show the suggested quantity in the RAISE WO QTY field.

Once the user has entered the work order quantities required, they can choose whether they wish the paperwork associated with the new work orders printed upon creation. This can be specified using the printing options at the top right of the screen.

Selecting the Job Card(s) option will automatically generate and print the job card documentation for the new work orders. Selecting the WO Requirements option will generate the WO Requirements By WO report for the new work order. This will highlight any outstanding requirements for the work order as well as show a summary of the component stock status.

Once the work order quantities have been decided and the printing requirements selected, the user can generate any work orders by clicking the ACCEPT option. The system will create the specified work orders and then produce the selected paperwork. Once the user has finished generating the required work orders, they can return to the main work order screen by clicking the CLOSE option.

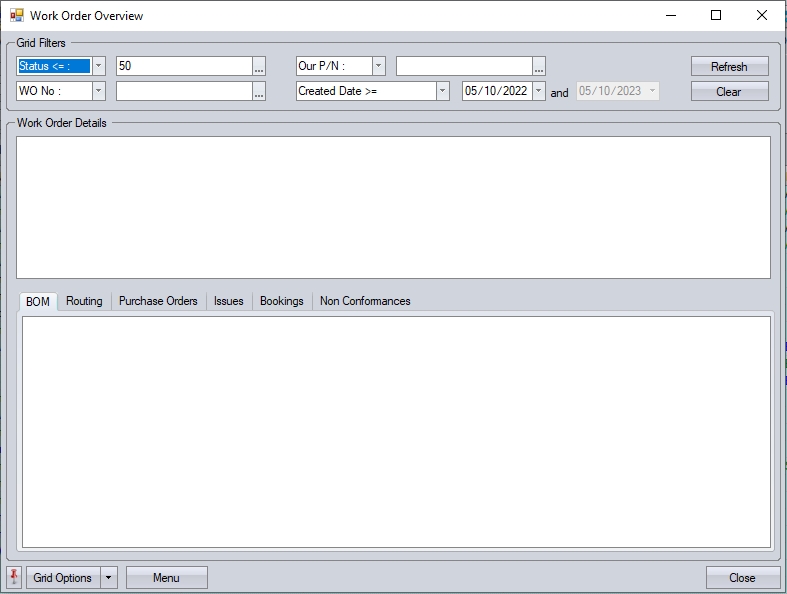

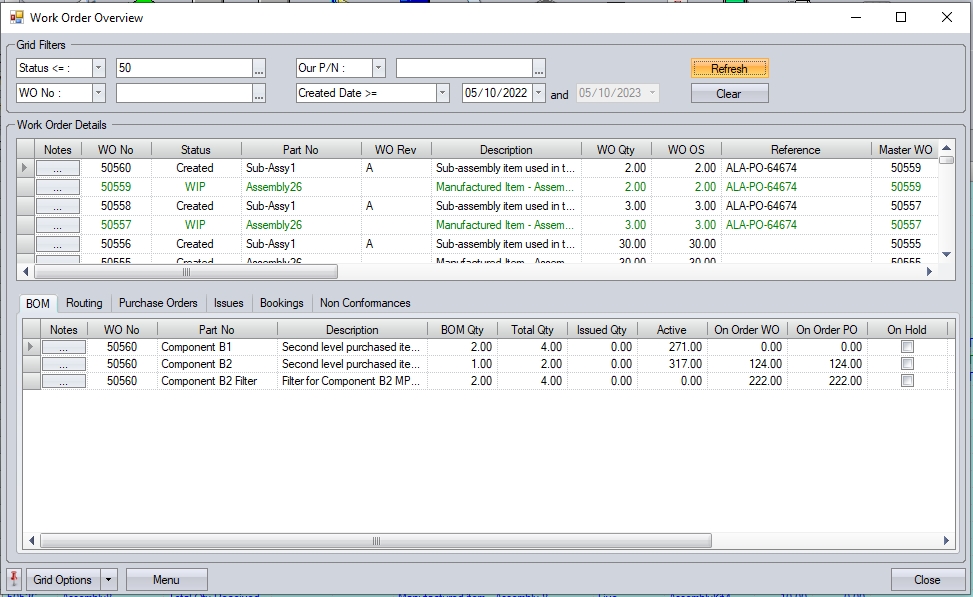

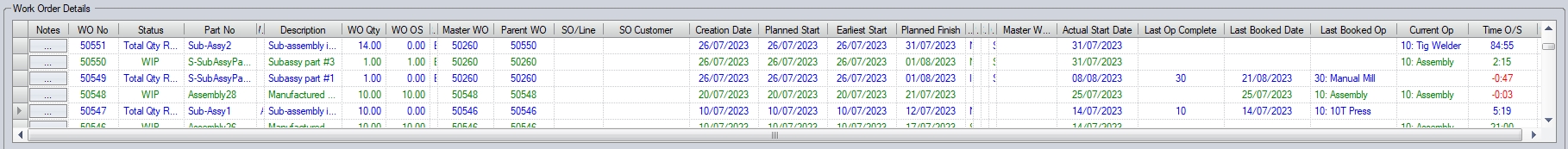

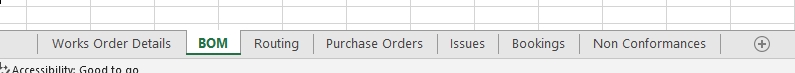

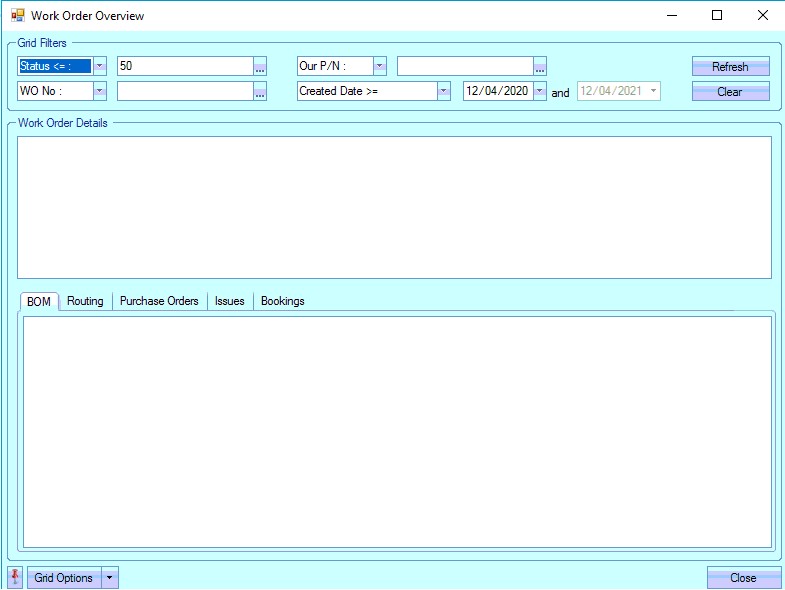

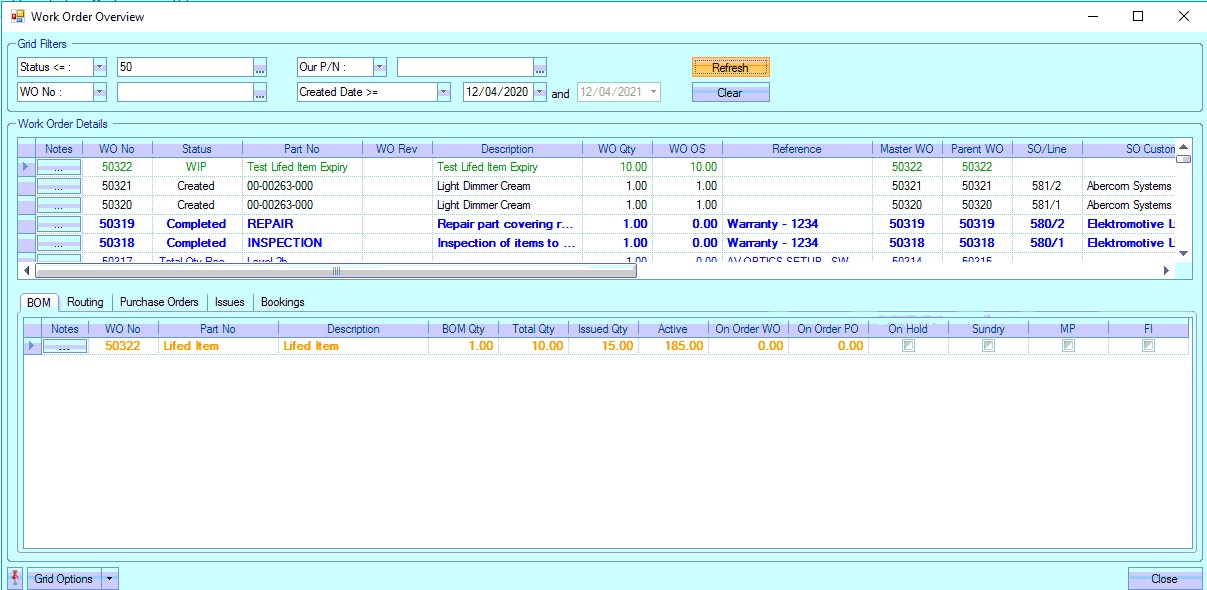

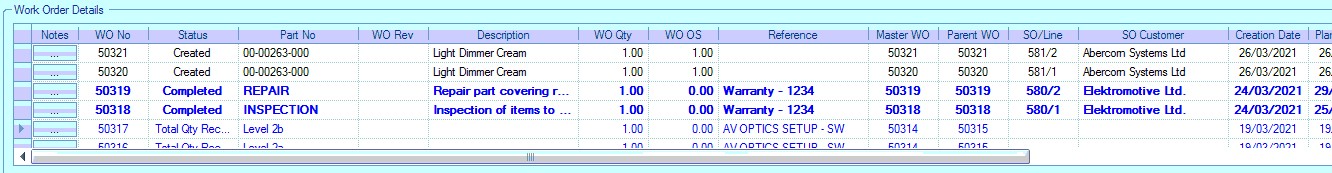

WO Overview

This option presents the user with an overview of the active work orders. The user can select a range of work orders and see all the associated information in one place, as well as allow them to add notes quickly to any associated item. Details of the WO BOM, routing, material issues, labour bookings and non-conformances are also visible when a WO is highlighted.

When the user selects this option, they will be presented with the following screen.

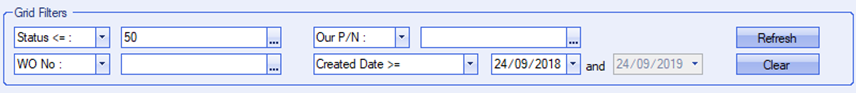

The grid filters at the top of the screen allow the user to filter for the work orders they wish to view, including by any work order user-defined fields (UDFs) set up against the work orders.. By default, the screen will display any WOs with a status less than "complete", however, the user can use the filters to search as required.

Once the relevant filters have been applied, the user can click the REFRESH option to display the work order information.

The first section of this screen shows the work order details.

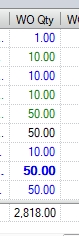

The grid also has summary totals for WO QTY and TIME O/S columns, which can be viewed at the bottom of the list.

(Summary totals for WO quantity and time outstanding)

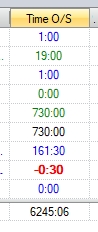

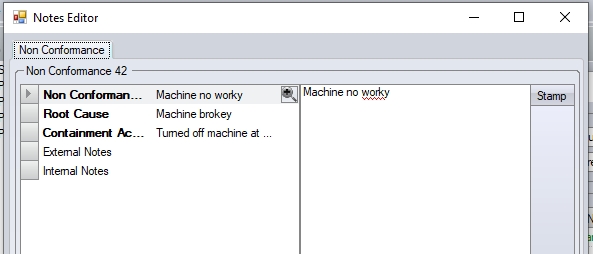

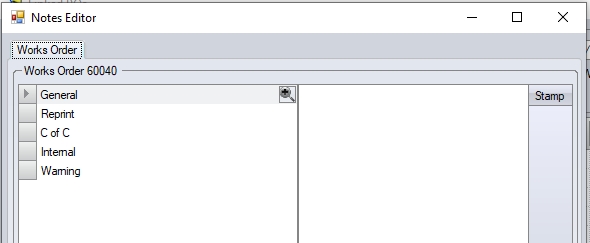

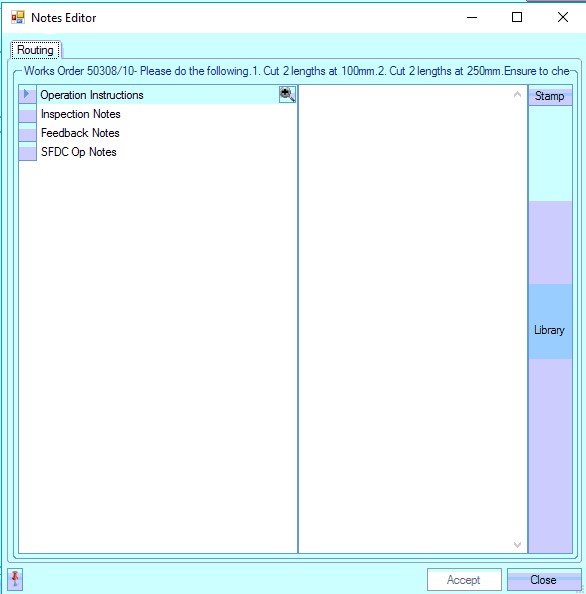

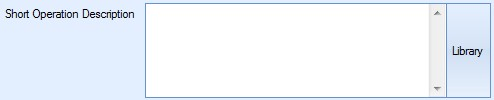

Not only does this section allow the user to see all the relevant details for each work order, but also allows them to access the WO notes sections directly using the ![]() option at the start of each line. Clicking this option presents the user with the Notes Editor window, which allows them to add comments/notes in relation to the selected work order.

option at the start of each line. Clicking this option presents the user with the Notes Editor window, which allows them to add comments/notes in relation to the selected work order.

Once any notes have been added, the user can click ACCEPT to save the details. CLOSE will return them to the main Overview screen.

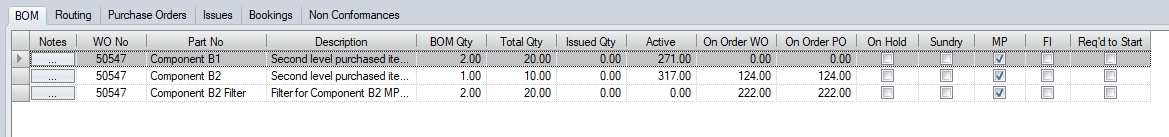

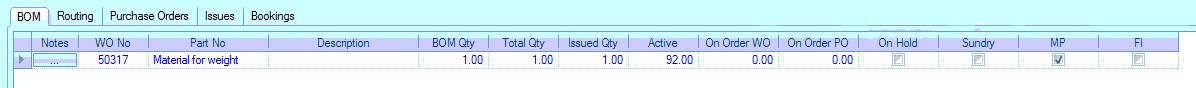

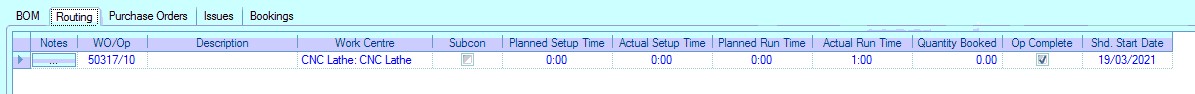

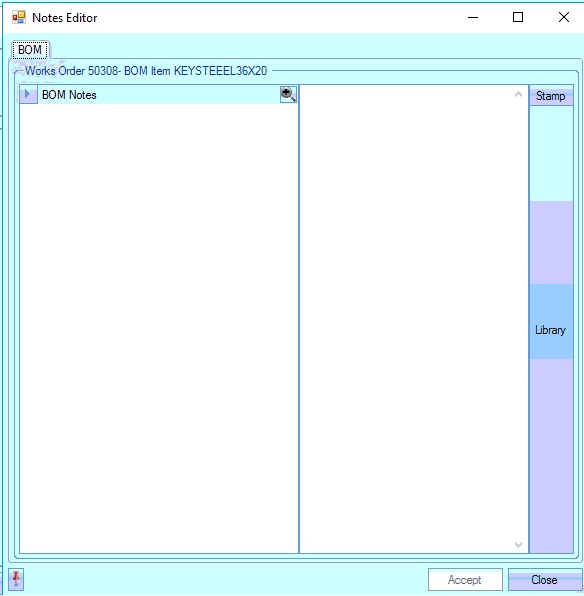

The bottom section of the Overview screen shows the associated BOM, routing, purchase orders, issues, bookings and non-conformances for the selected work order in the first section. To flip between each of these sections the user simply clicks on the relevant tab.

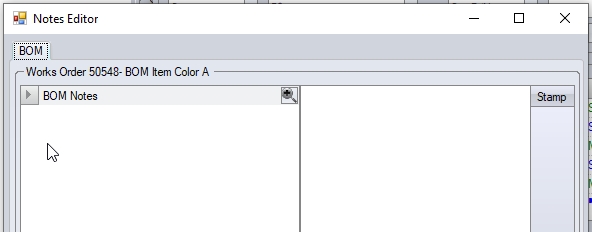

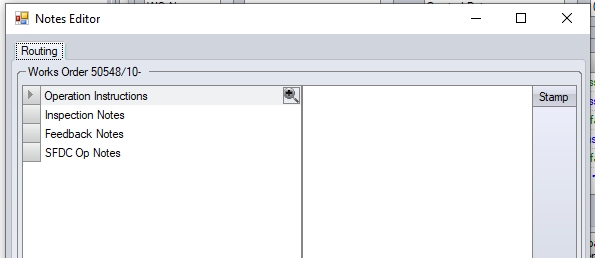

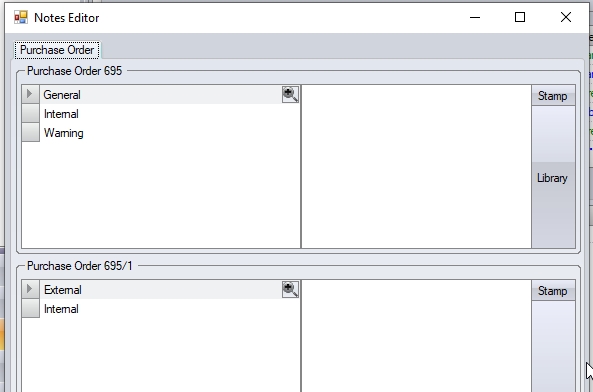

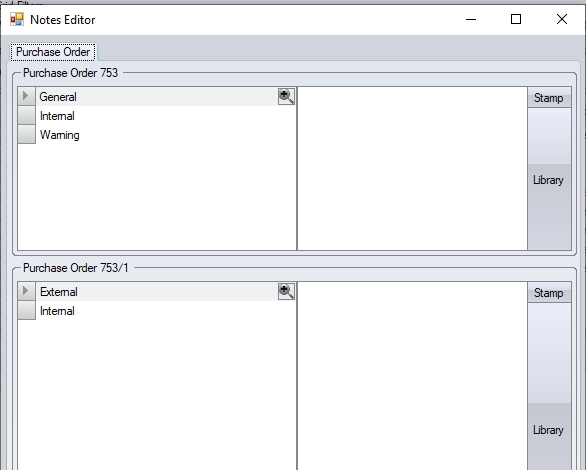

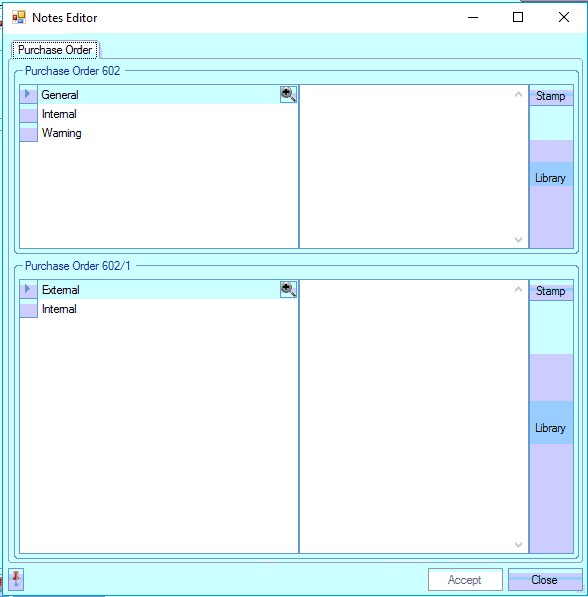

Again, like the first section, the user can click on the notes option ![]() , to access the Notes Editor window and add notes to any items as required. This will present the user with the relevant notes sections for the selected item. The examples below show some examples of the different items that can be added to via the Notes Editor.

, to access the Notes Editor window and add notes to any items as required. This will present the user with the relevant notes sections for the selected item. The examples below show some examples of the different items that can be added to via the Notes Editor.

(WO BOM Notes Editor)

(WO Routing Notes Editor)

(Purchase Order Notes Editor - header and line notes)

(Non-Conformance Notes Editor)

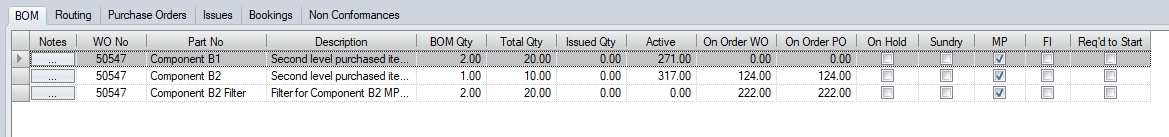

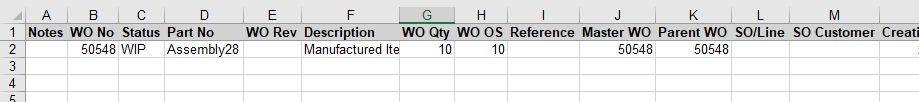

Selecting the BOM tab allows the user to see the WO's BOM. This allows the user to see what was required, issued, any PO quantities as well as the current active stock of the part. The colour coding shows the current issue status of the BOM part, as per the WO BOM screen legend.

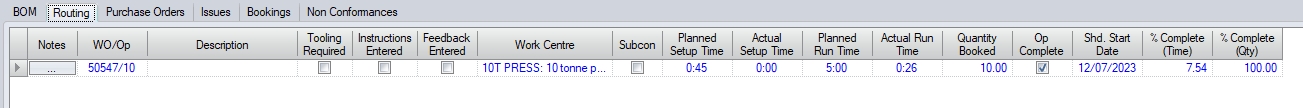

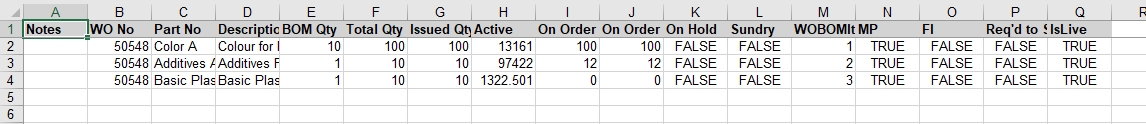

Selecting the Routing tab allows the user to see the associated routing information for the work order selected. This will include both internal and external (i.e. sub-contract) operations and their current status as per the WO routing legend.

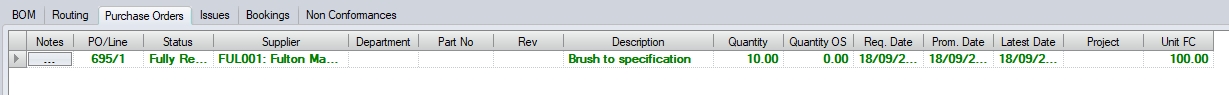

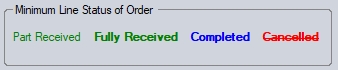

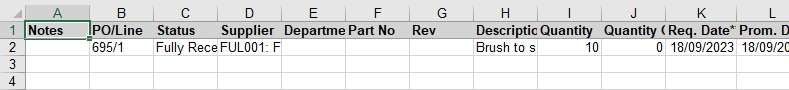

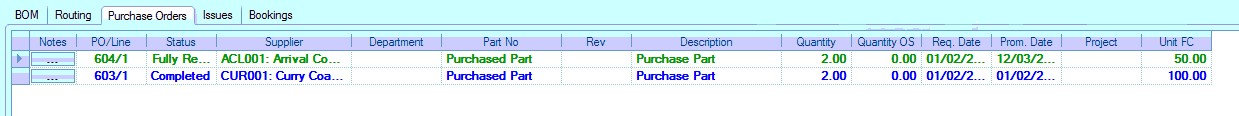

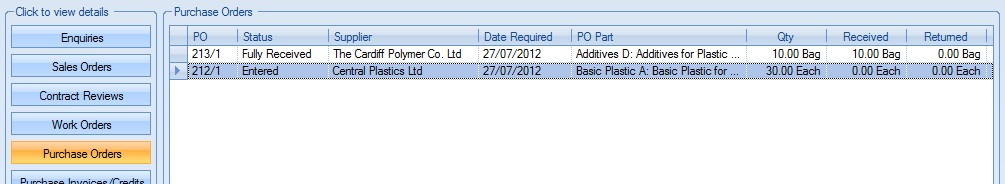

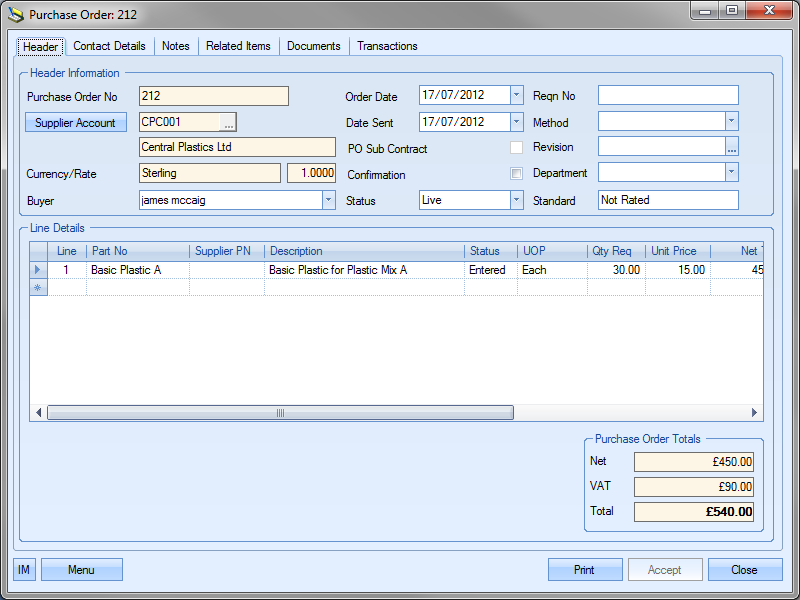

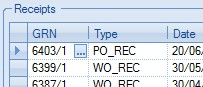

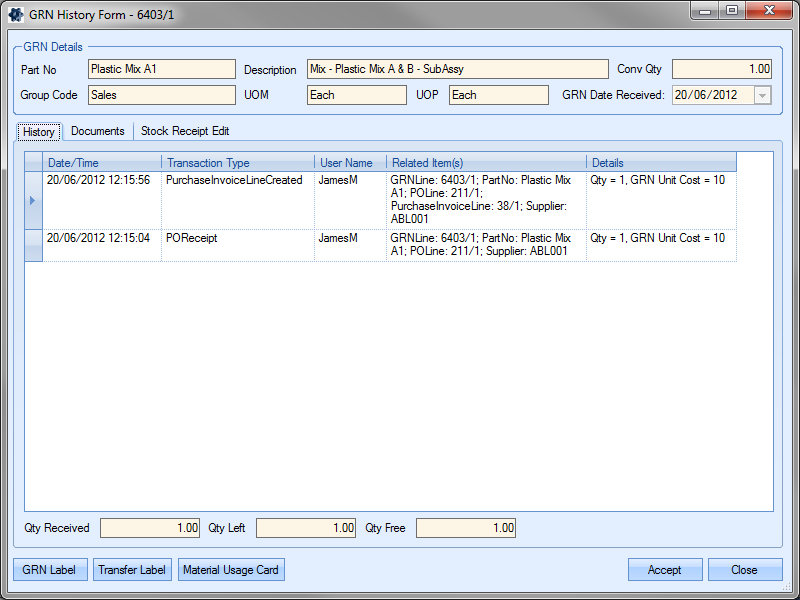

Selecting the Purchase Orders tab allows the user to see the associated purchase order information for the work order selected in the top section of the screen. This will display any details of the purchase orders that are directly linked to the work order selected in the top section of the screen. The colour coding indicates the status of the PO line as per the main PO status legend.

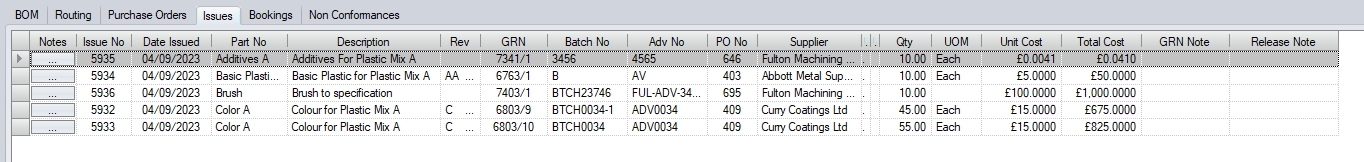

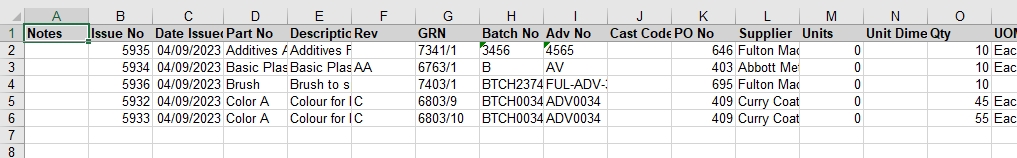

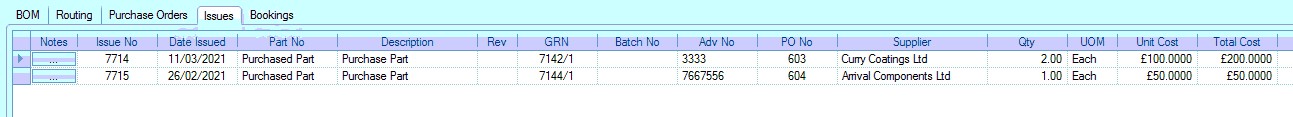

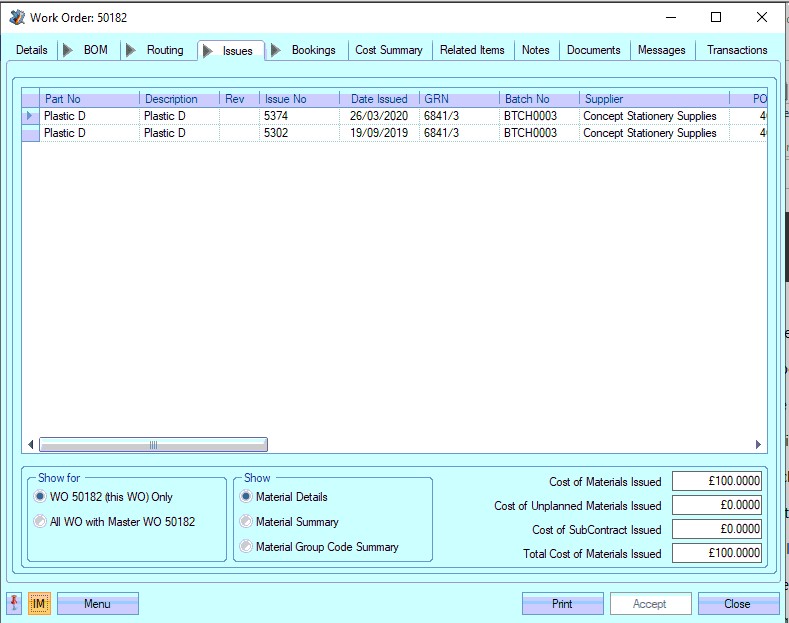

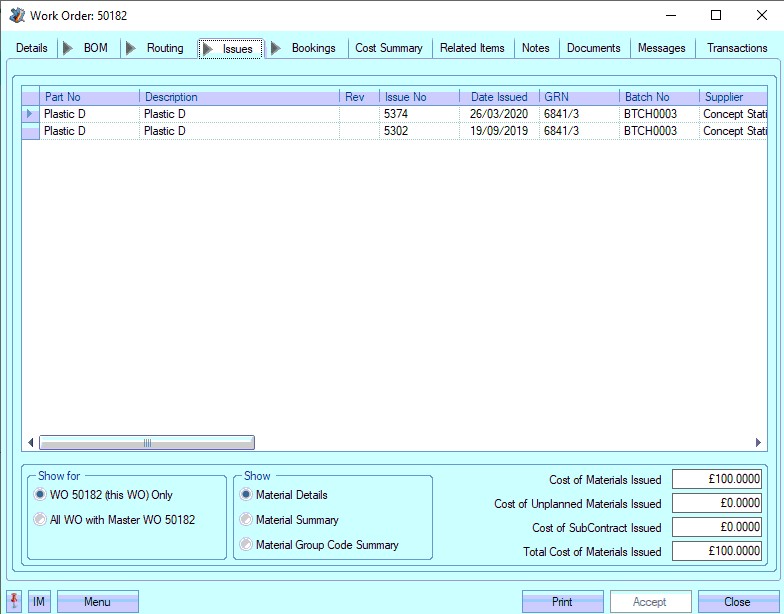

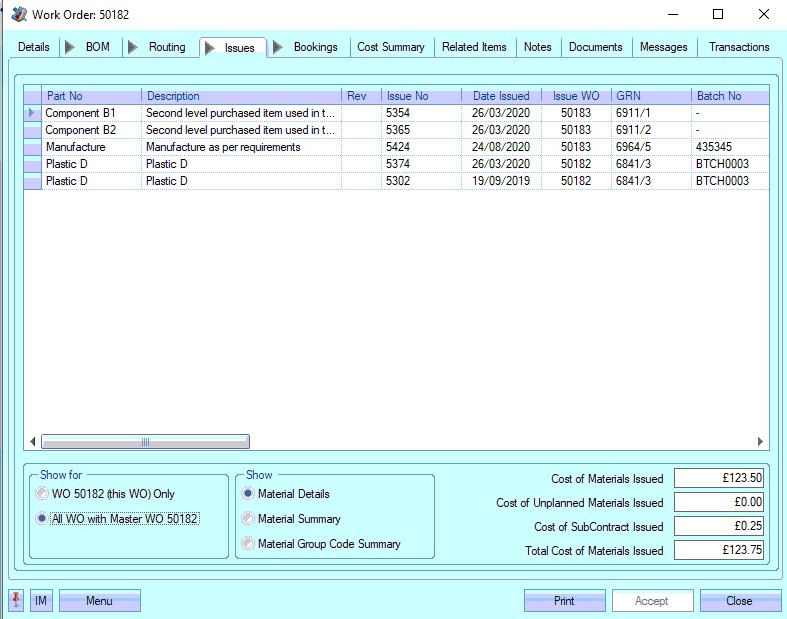

Selecting the Issues tab will display any material issues that have been made to the work order selected in the top section. This includes all batch and supplier information where applicable, as well as the issue date.

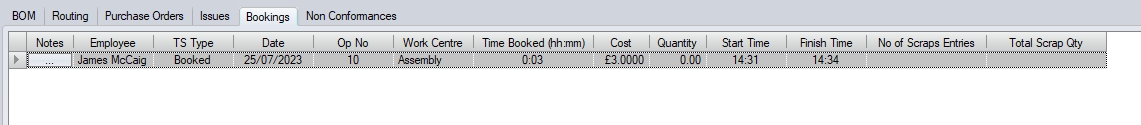

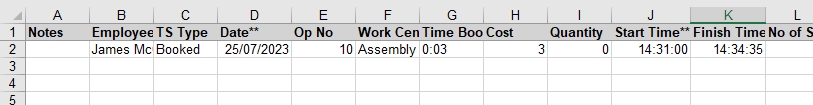

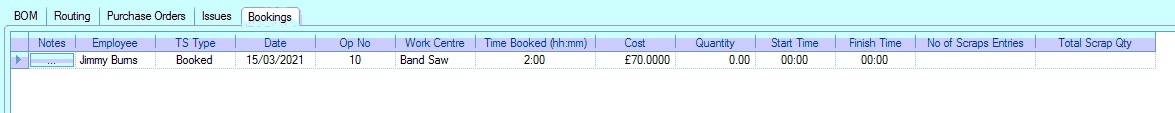

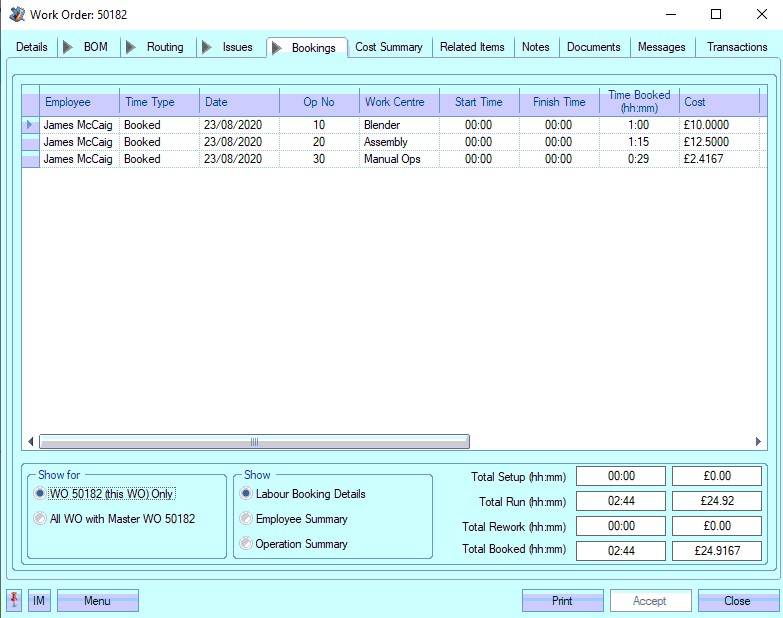

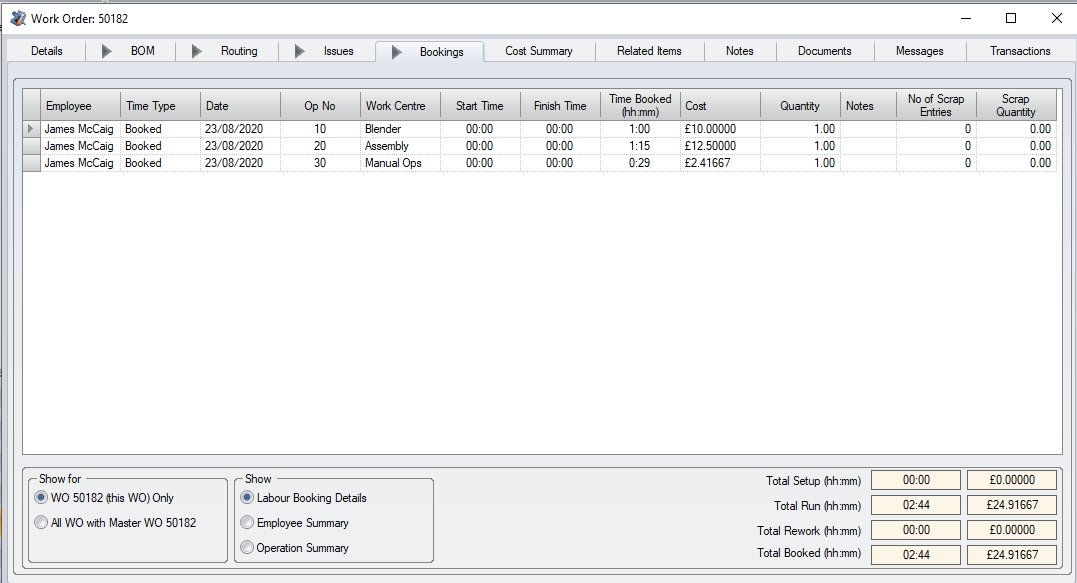

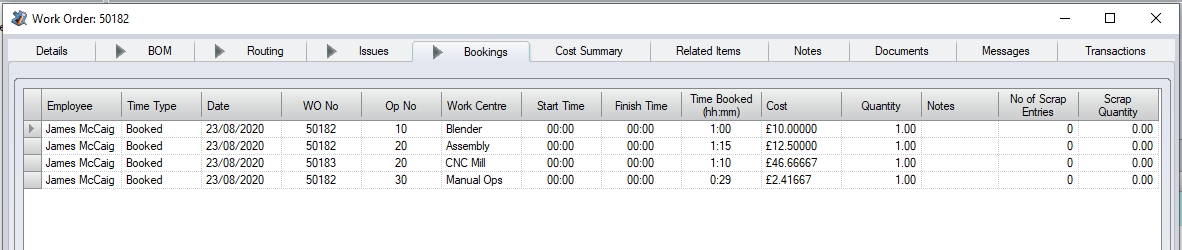

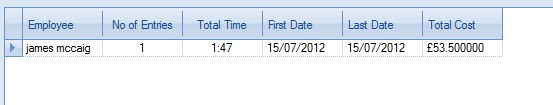

Selecting the Bookings tab will display any information for labour bookings against the work order selected in the top section of the screen.

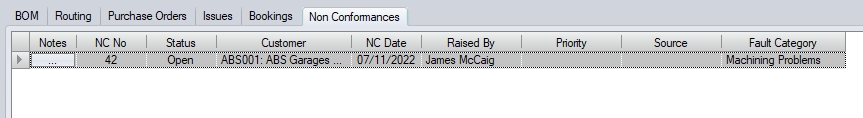

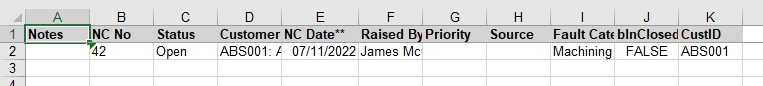

Selecting the Non-Conformances tab will display the details of any non-conformances that have been raised against the work order selected in the top section of the screen.

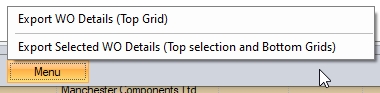

The user also has the ability to export the Overview details to Excel for further analysis if desired. The MENU option at the bottom of the screen allows the user to export the full list of WOs (i.e. all WO details from top-grid) or all the details of the selected WO (i.e. top and bottom grid of selected WO).

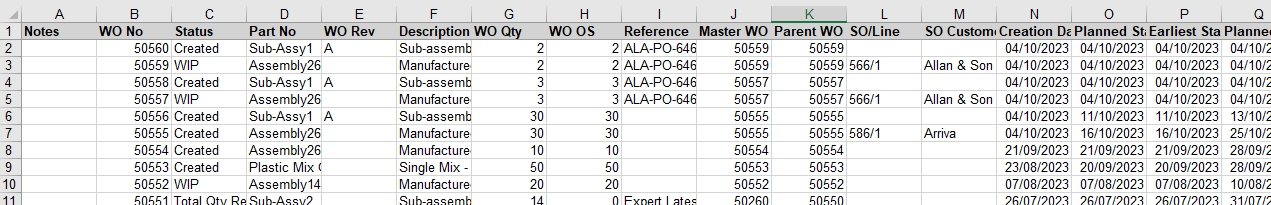

Both of these options will create a spreadsheet with the relevant details, based on the option selected. Selecting the first option will create a spreadsheet with the details of all WOs listed in the top-grid.

(Export of WO details - top grid)

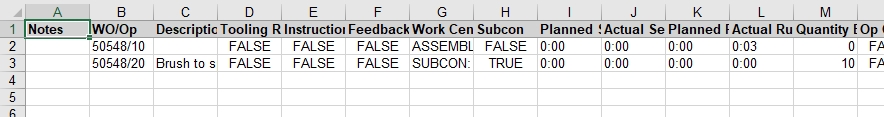

Selecting the second option will create a spreadsheet of the selected WO's details, with additional tabs for the different items shown in the bottom-grid.

(Tabs showing different associated details of the selected WO)

(WO details)

(WO BOM details)

(WO routing details)

(WO PO details)

(WO issue details)

(WO bookings details)

(WO non-conformance details)

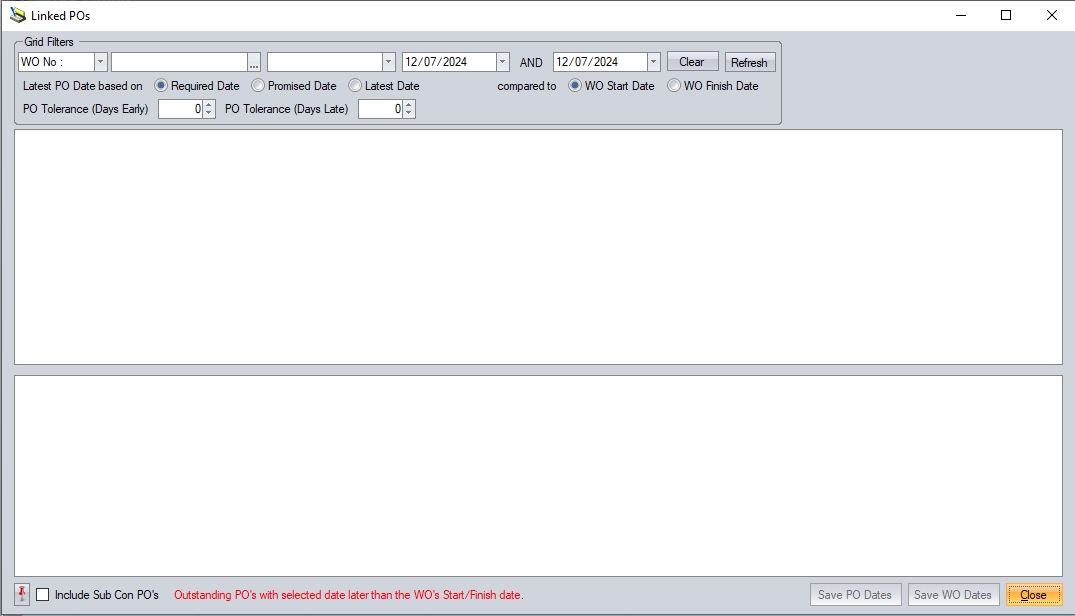

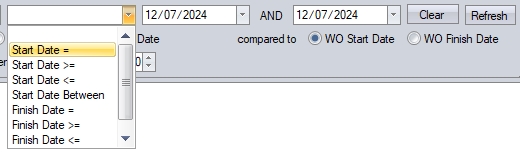

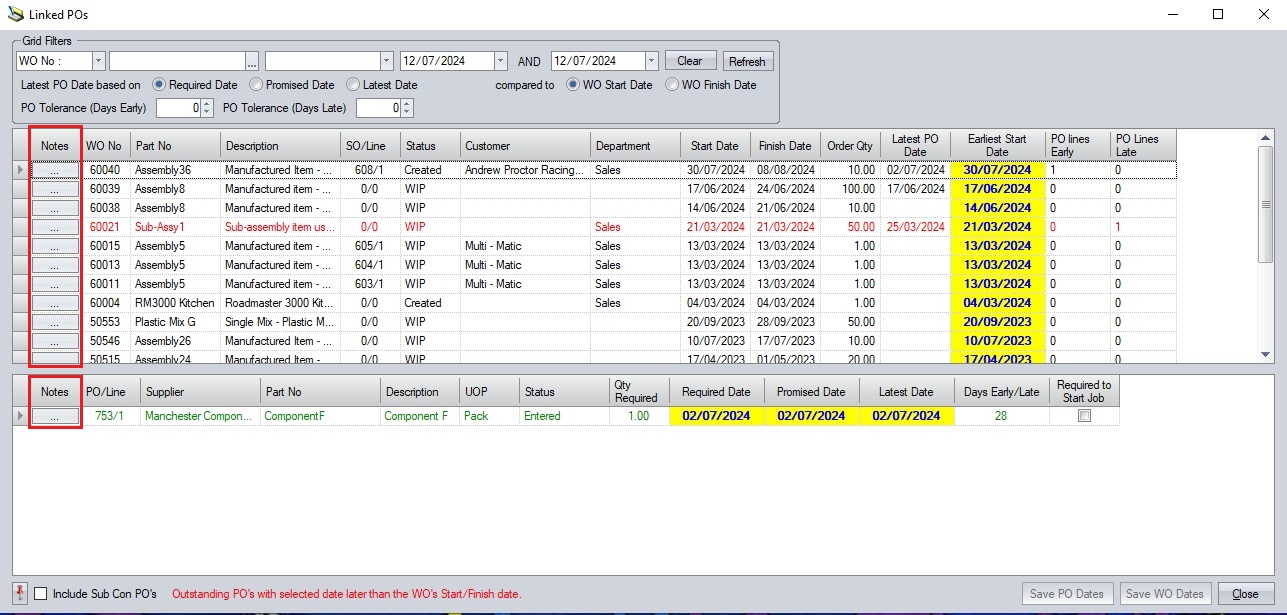

Linked POs

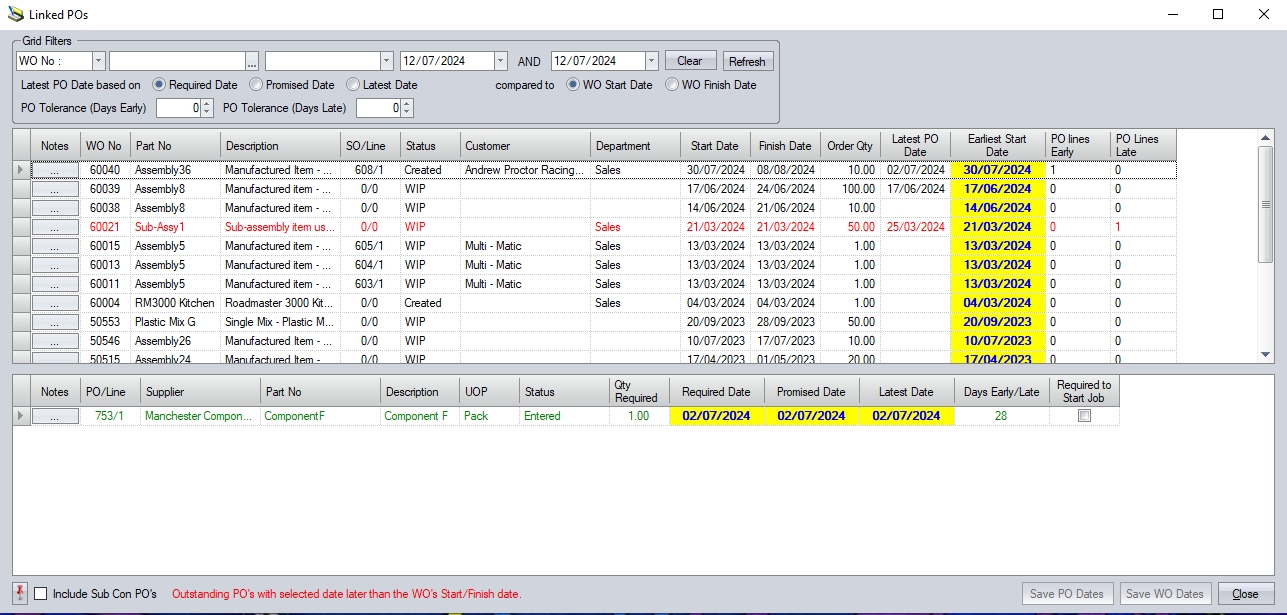

This option allows you to see the various dates associated with open WOs not yet fully received, and update the EARLIEST START DATE of the WO based on the dates on any linked POs.

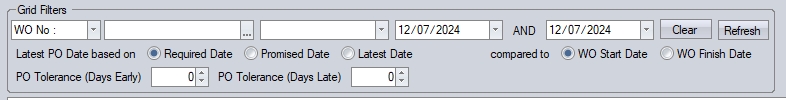

The user can use the filter options at the top of the screen to identify the work orders they are after. Here, the user can also set tolerances in relation to the number of days early and/or late, as well as select the PO and WO dates to be used for comparison. The user can also filter by WO start or finish date.

Once any filters have been applied, or if the user simply wants to see all work orders, they can click REFRESH to populate the screen.

The top-half of the screen lists all WOs which are not yet fully received and shows the latest PO date associated with the selected WO. The user can include subcon POs in the list of POs shown by ticking the relevant option.

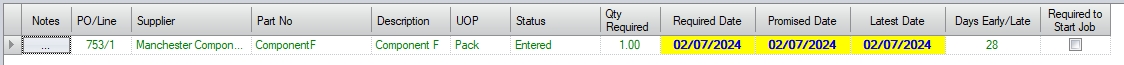

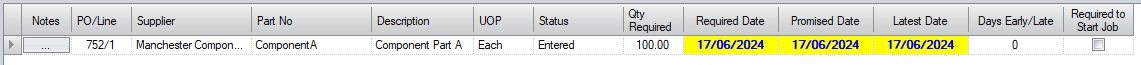

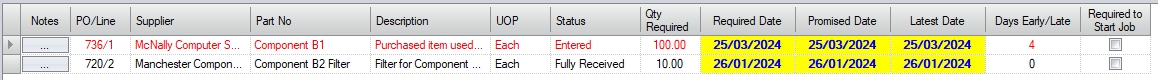

![]()

The screen also highlights a summary total for POs arriving late and early, with the associated POs being colour coded in the bottom grid to also highlight their status, along with whether the item is required to start the WO based on the WO BOM settings for the parts.

(POs arriving early are shown in green)

(POs arriving on time are shown in black)

(POs arriving late are shown in red)

The screen also provides direct access to notes fields associated with the WOs and POs as highlighted below.

Clicking on these options will present the user with the associated notes fields for review/completion.

(WO notes option)

(PO notes option)

When the user refreshes the details on the screen, the system suggests the Earliest Start Date for the WO based on the dates. Clicking ACCEPT will update the WOs with the suggested Earliest Start Date. The Earliest Start Date is then used by the Shop Floor Loading (SFL) section of Progress to ensure the WOs are scheduled accordingly. Changes to the PO dates can also be made on this screen with the user updating the PO using the SAVE PO DATES option.

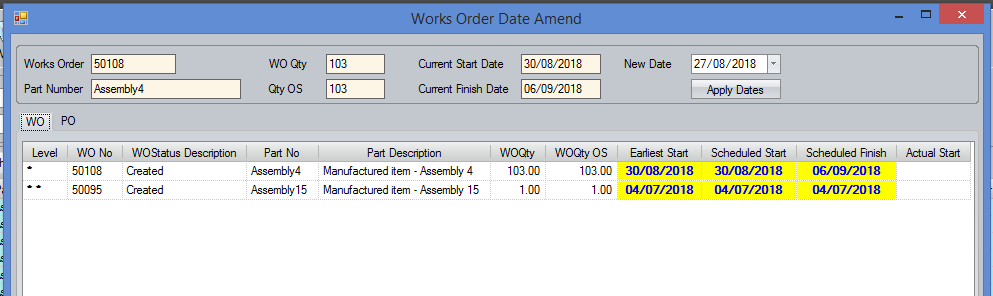

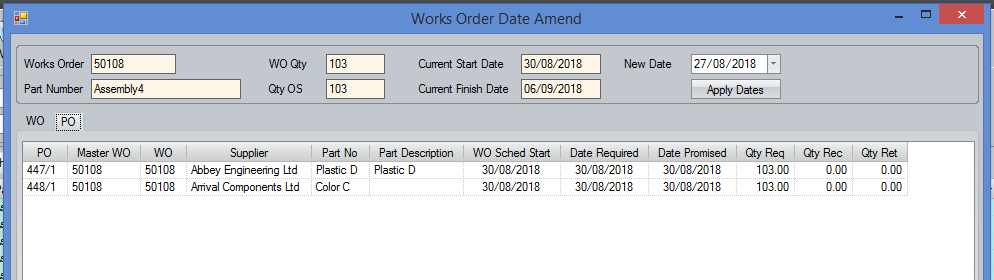

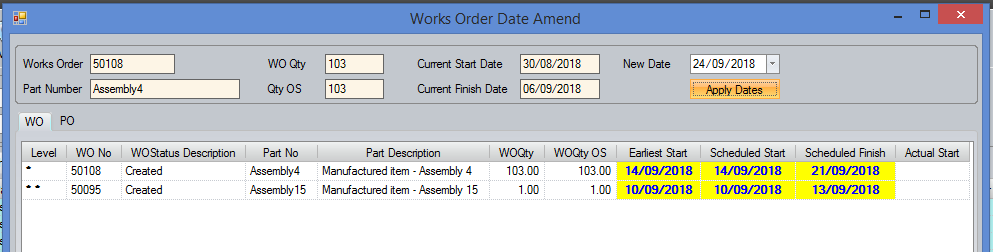

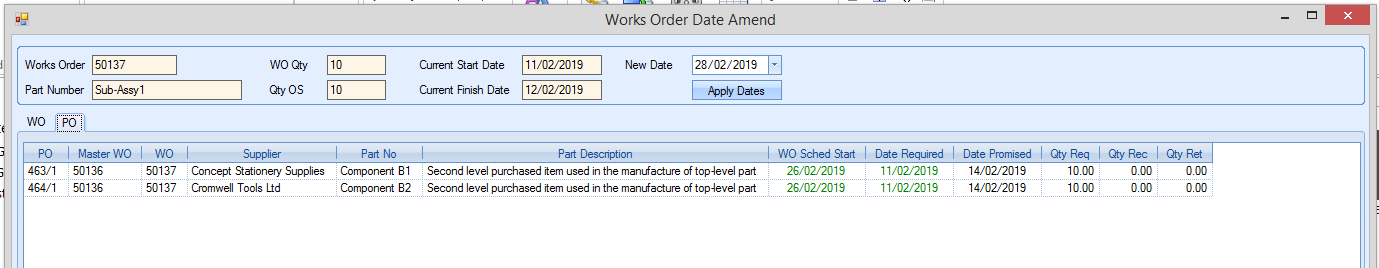

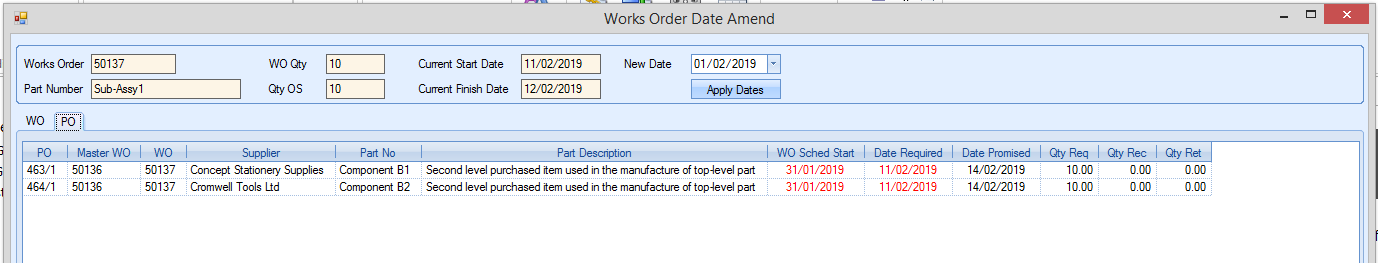

This option allows the user to view and amend the dates of a WO, updating the selected WO dates as well as the dates of any associated work orders (sub-assys) and purchase orders relating to the purchase of material for the job. To use this option, the user simply highlights the work order in question and clicks on the WO DATES option. This will open a screen similar to that shown below, showing a list of all the work orders associated with the selected work order and also a list of associated purchase orders (under the PO tab).

The screen shows the current work order dates at the top and provides a field to allow the user to select the new date required. Clicking the APPLY DATES option will update the work order(s) listed below.

The PO tab will be updated to highlight any existing purchase orders which may now be affected by the date change by highlighting their dates in red to draw the users attention to the purchase orders which will be due to arrive AFTER the associated WO has started. If the associated purchase order dates need to be amended, the user can drill into them using the ![]() option against the PO number to allow any changes to be applied.

option against the PO number to allow any changes to be applied.

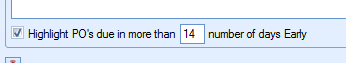

Any existing PO which is now due early as a result of the date changes to the WO will be highlighted in green, based on the specified number of days in the option at the foot of the window.

If the existing POs are going to arrive late compared to the start of the WO, then the PO dates will be highlighted in red.

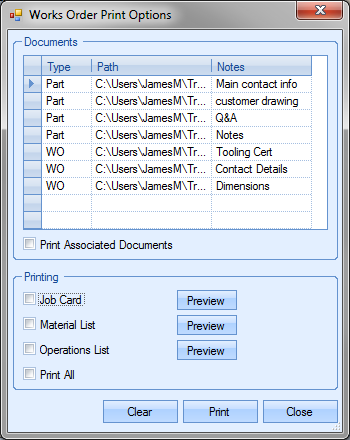

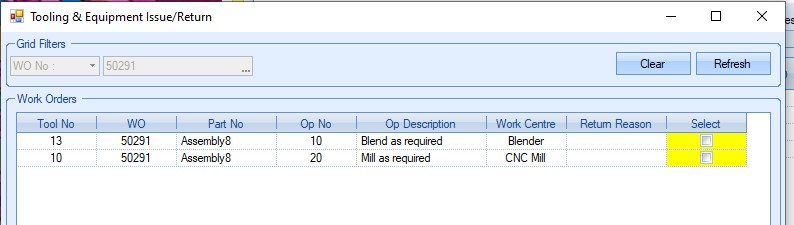

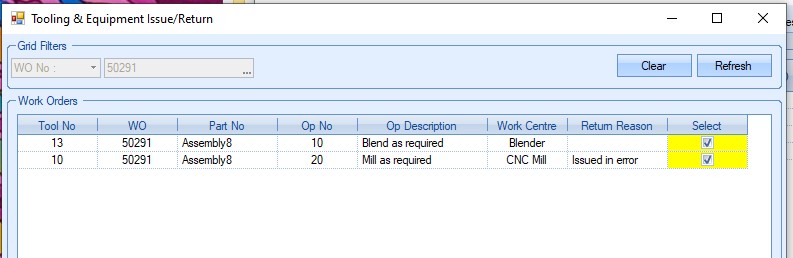

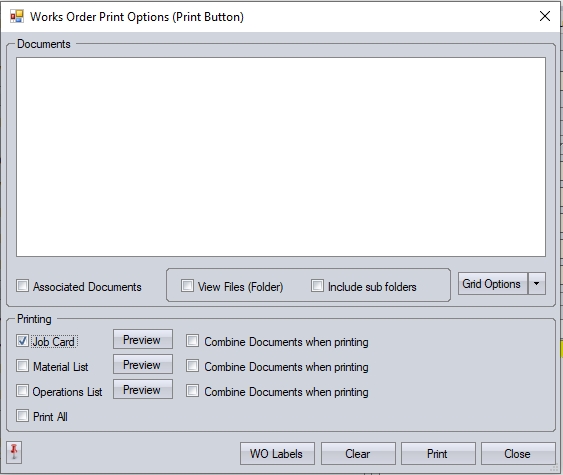

This option allows the user to print work order documentation directly from the main WO grid. The user can select the required work order and click the PRINT option. This presents the same print window as used within the individual work order screen.

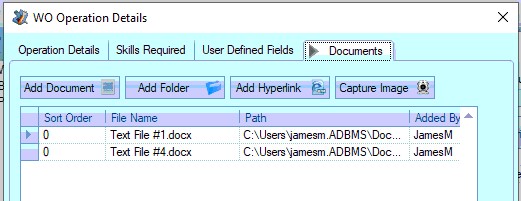

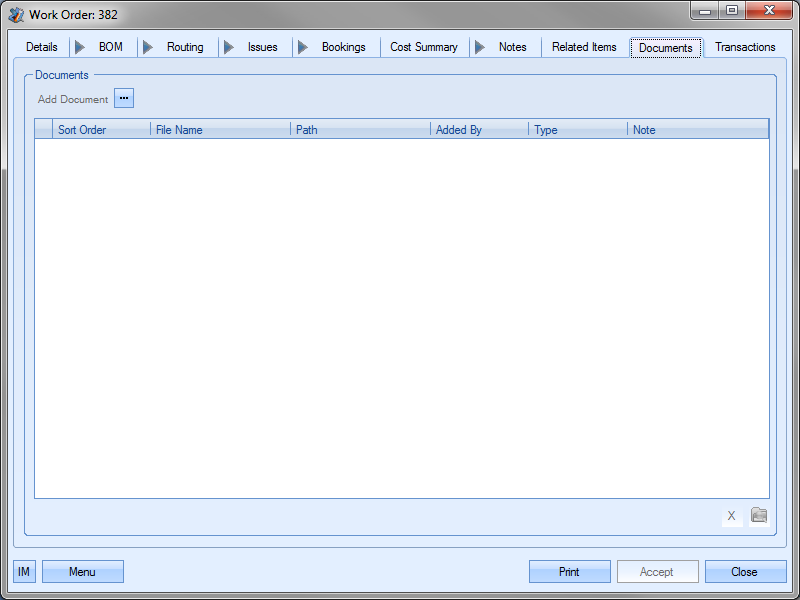

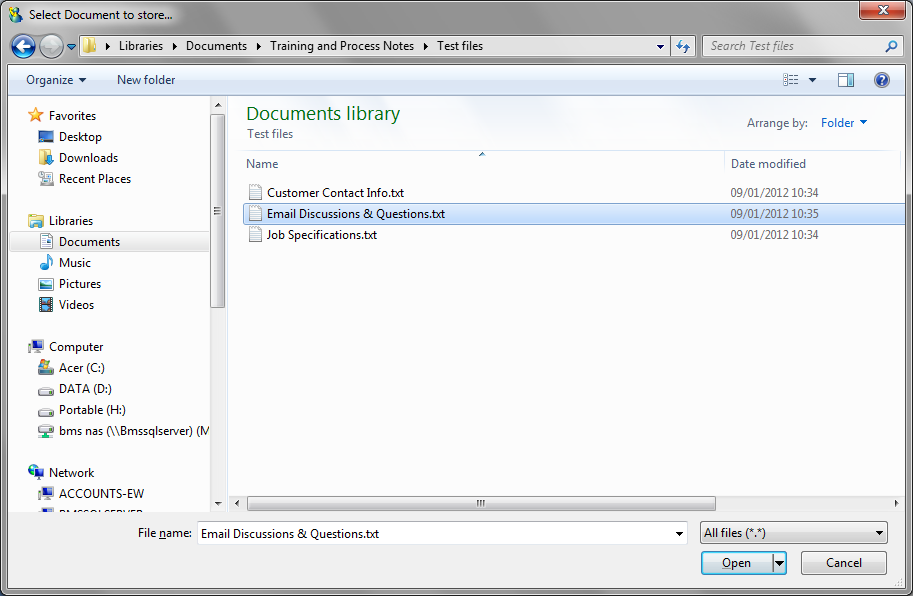

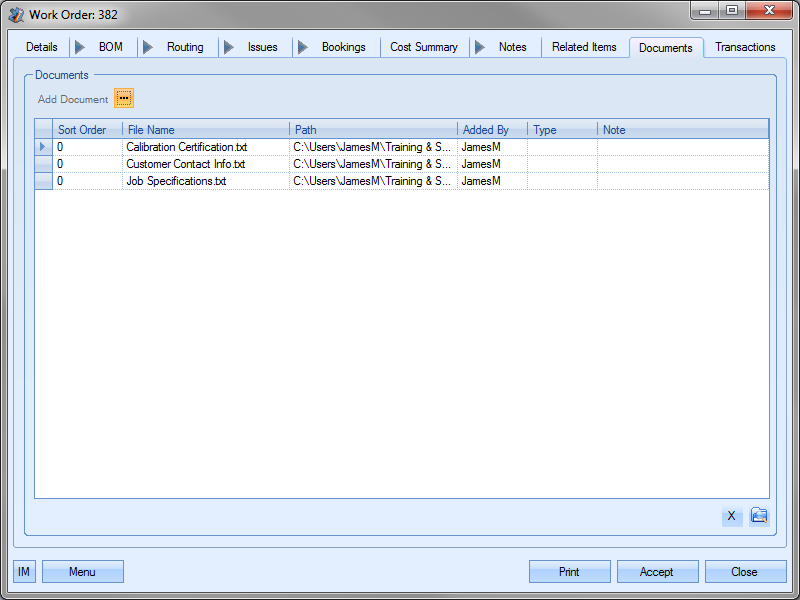

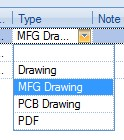

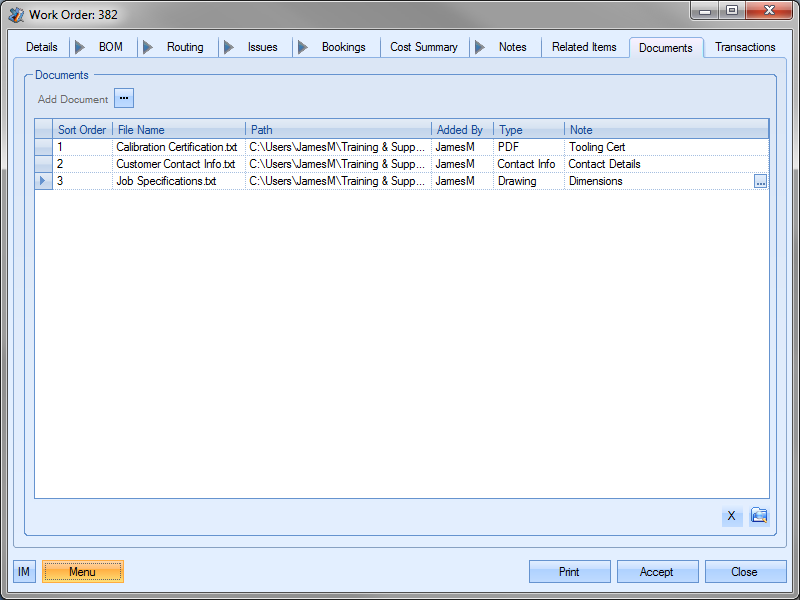

The user has the option of printing any of the work order’s associated documents from this screen along with the required work order documents. The grid at the top of the screen shows all the associated documents, their relationship with the work order and the file path. The option under the grid allows the user to choose whether these documents are printed.

![]()

If the user ticks this option and clicks the PRINT option at the bottom of the print options screen, each of the associated documents will be printed.

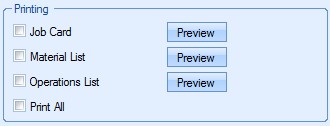

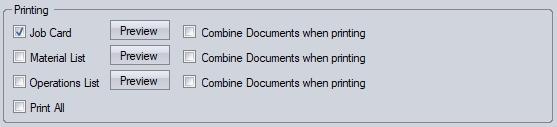

If the user only wants to print the work order documents, they can select the required document(s) from the options at the bottom of this screen.

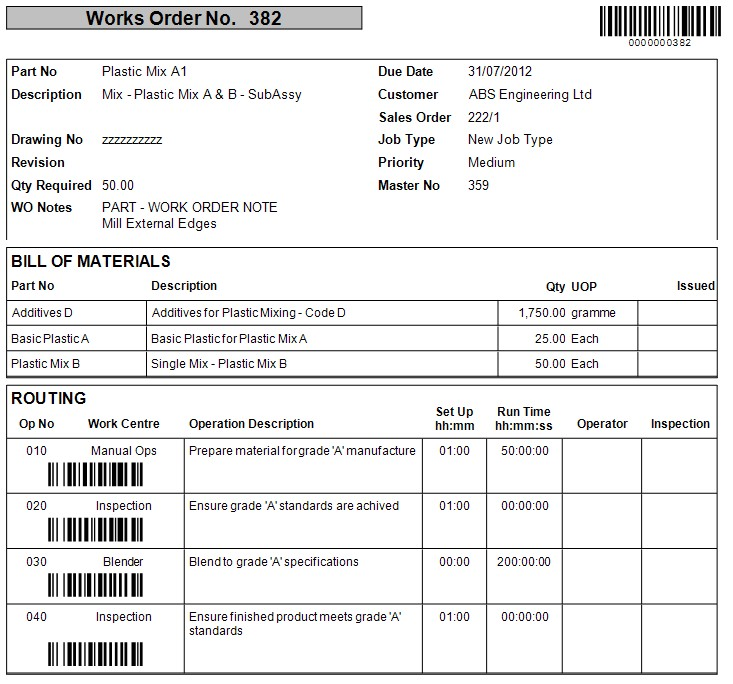

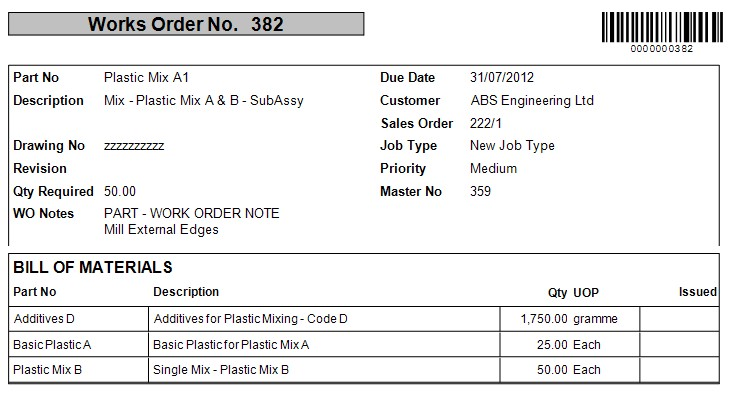

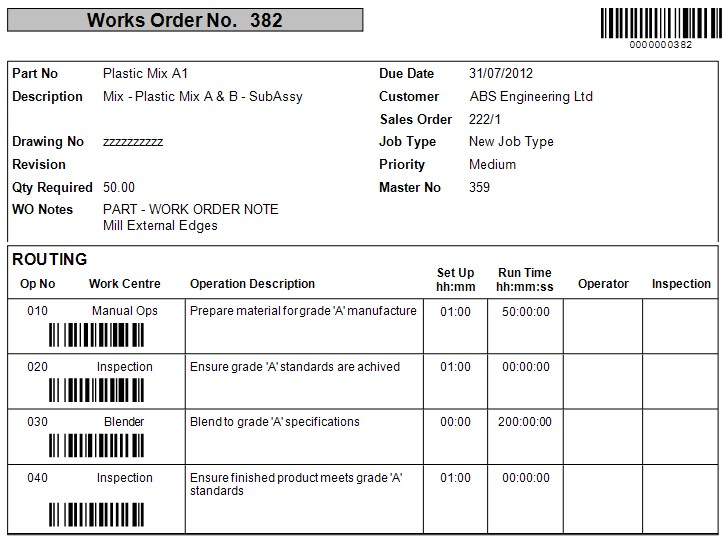

The Job Card is the most comprehensive work order document as this typically contains the work order, sales order, material and operation details for the current work order. The Material List document typically focuses on the material requirements for the job, while the Operations List focuses on the routing operations to be carried out for the work order.

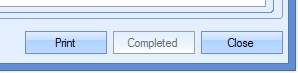

The user can tick the box next to the documents they wish to print, be it one or all three. The PREVIEW options to the right of each work order document allows the user to view the document on screen as opposed to printing a hard copy. Ticking the PRINT ALL option automatically ticks all of the document options, including the associated documents. This is just a quick way to select all documents. Once the user has selected the required documents, they can click the PRINT option to print hard copies. The CLEAR option will remove all selections already made and allow the user to reselect as required. The user can return to the main work order screen at any time by clicking the CLOSE option.

Print Range

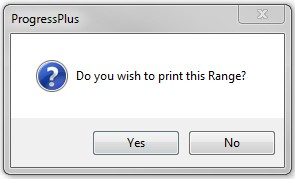

This option allows the user to print the work order documentation for a range of work orders. The user can specify the work orders required using the grid filters on the main work order screen, for example, by date or master work order number. Once the user has the required work orders showing on the screen, they can click the PRINT RANGE option to generate the documents.

Firstly, the user is prompted to confirm that they wish to print the documents for the selected range.

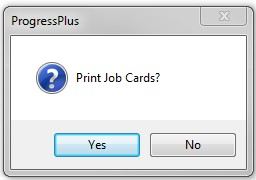

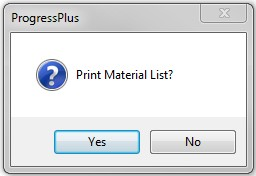

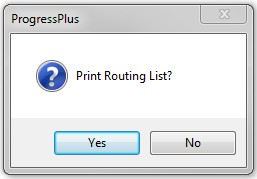

If the user clicks NO, the user is returned to the main work order screen with no documents printed. If the user clicks the YES option, the user is then prompted to confirm which documents they wish to print. The prompts are as follows.

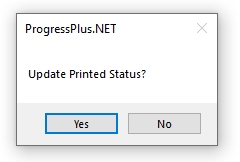

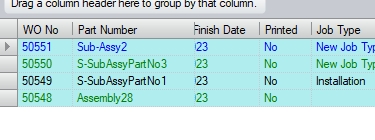

Once the user has responded to each of the prompts, Progress sends the requested documentation directly to the printer. If the system is configured to prompt user before updating printed status, the user will be asked to confirm.

Selecting YES will update the PRINTED status of all the work orders in the range selected to 'Yes'. Selecting NO will leave the work orders PRINTED status as 'No'.

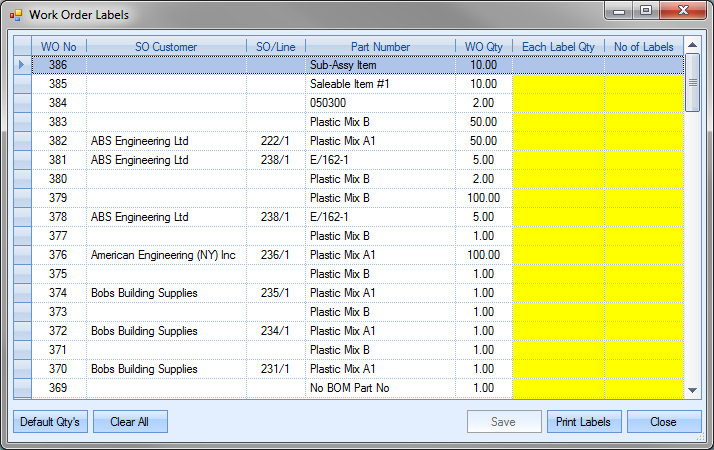

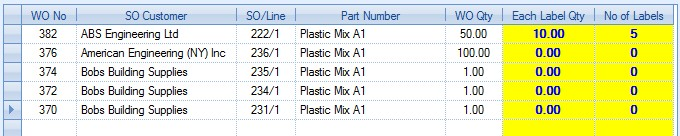

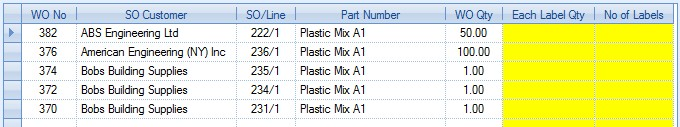

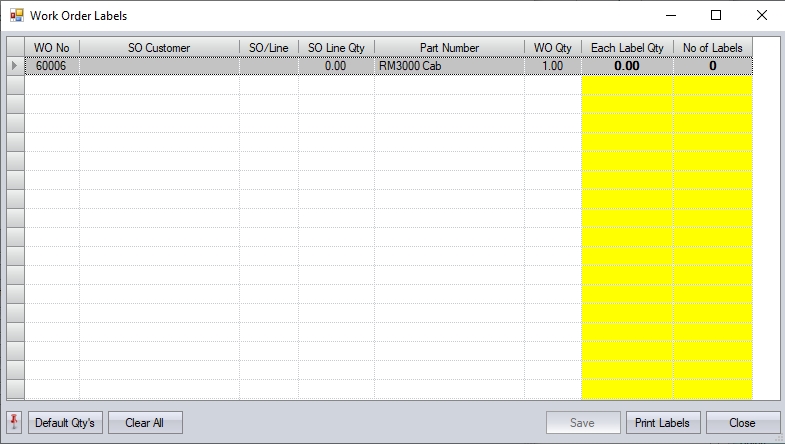

This option allows the user to generate work order labels for the work orders currently displayed on the main work order grid. Clicking this option presents the user with the following screen.

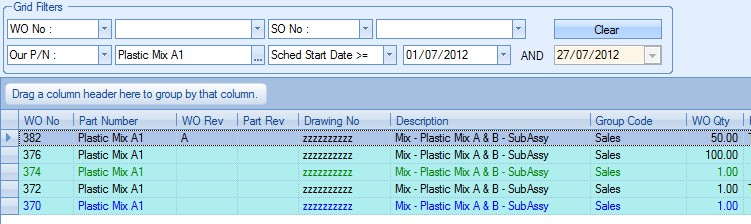

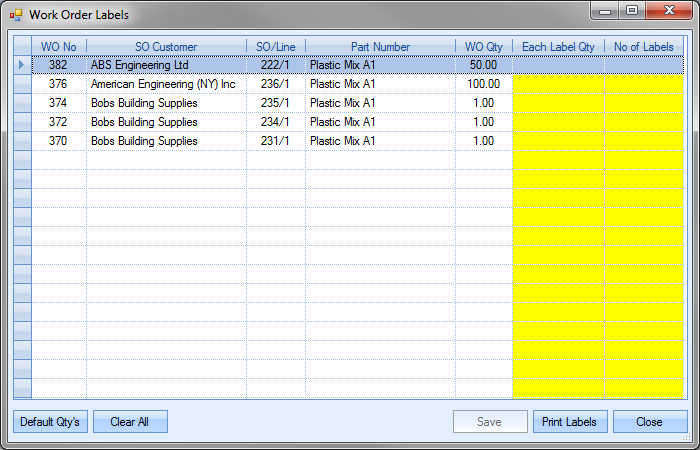

The user is presented with a list of work orders based on the orders listed on the main work order screen. If the user has filtered the main work order screen to view specific orders, clicking the LABELS option will present the same list in the labels screen as is shown below.

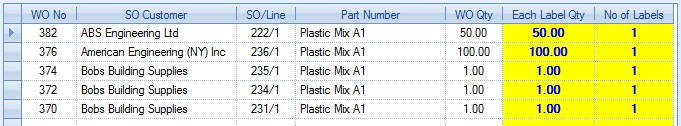

The label screen displays some basic information regarding each work order and allows the user to specify the quantity to be printed on each label as well as the number of labels to be printed. These fields are highlighted in yellow. The user can manually enter these values as required of they can user the DEFAULT QTYS option. Clicking this option will default the label quantity to the work order quantity and the number of labels to 1.

If the user wishes to produce more labels, they can amend the details as required. For example, if they are receiving the 50 units from the first work order shown above in boxes of 10 units, they may wish to print 5 labels of 10 units. To do this, the user simply has to change the details as follows.

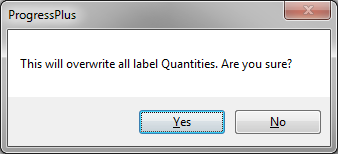

Once the user has entered the required label quantities, they can print the labels by clicking the PRINT LABELS option. This will automatically print the labels off on the specified printer. If the user wishes to remove the specified quantities, they can either manually replace with zero, or can click the CLEAR ALL option to remove all label quantities displayed on the screen. The user will be prompted to confirm this

Clicking YES will return the label screen to its initial state without quantities.

If the user has specified label quantities for a range of work orders in preparation for printing the labels, they can save the entered quantities by clicking on the SAVE option. This will record the details entered allowing the user to return to the label screen at a later date without having to re-enter all the label quantities again.

Once the user has printed the required labels or has saved the label quantity details as required, they can return to the main work order screen by clicking on the CLOSE option.

Overview

This option present the user with an overview of the selected work orders. The user can select a range of work orders and see all the associated information in one place as well as allow them to add notes quickly to the WOs and/or POs and also see the details of associated WO's BOM, routing, associated purchase orders and any issues or booking that have been made to the works orders.

When the user clicks this option, they will be presented with the following screen.

The grid filters at the top of the screen allow the user to filter for the works orders they wish to view.

Once the relevant filters have been applied, the user can click the REFRESH option to display the works order information.

The upper section of this screen shows the works order details.

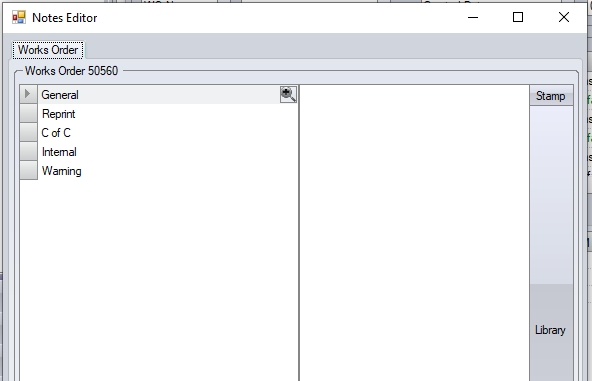

This allows the user to see all the relevant details for each works order but also allows them to access the NOTES section using the ![]() option at the start of each line. Clicking this option presents the user with the Notes Editor window, which allows them to add comments/notes in relation to the selected works order.

option at the start of each line. Clicking this option presents the user with the Notes Editor window, which allows them to add comments/notes in relation to the selected works order.

The bottom section of the Overview window allows the user to see the BOM, routing, associated purchase orders and any bookings and issues that are linked to the selected works order. for the selected work order in the middle section. Clicking on the relevant tab will display the associated info. Examples of these are shown below.

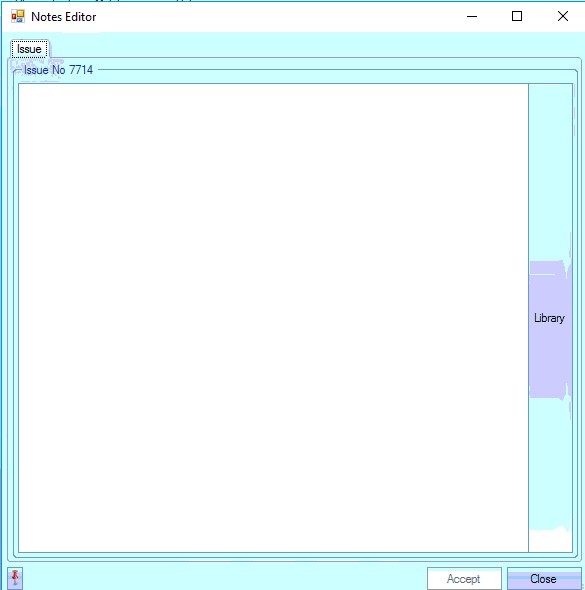

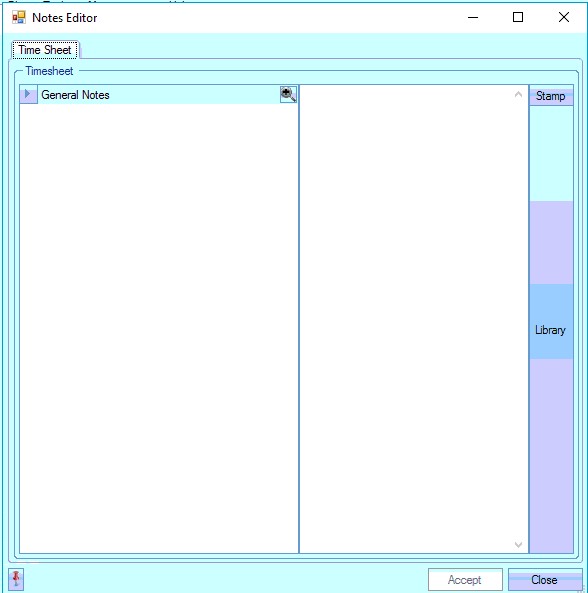

Again, like the previous sections, the user can click on the Notes option, ![]() , to access the Notes Editor window to add notes to the any of the items listed as required. The screen below shows some examples of the notes sections available.

, to access the Notes Editor window to add notes to the any of the items listed as required. The screen below shows some examples of the notes sections available.

(BOM item notes)

(Routing Operation notes)

(PO and PO Line notes)

(Issue note)

(Booking/Timesheet note)

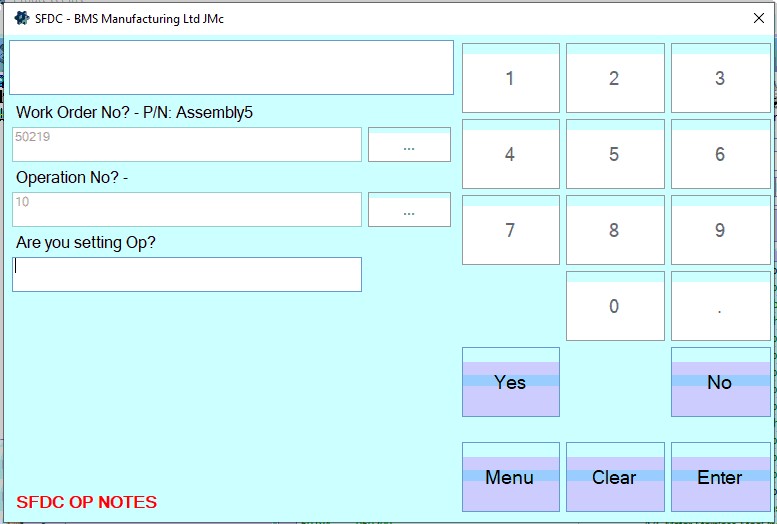

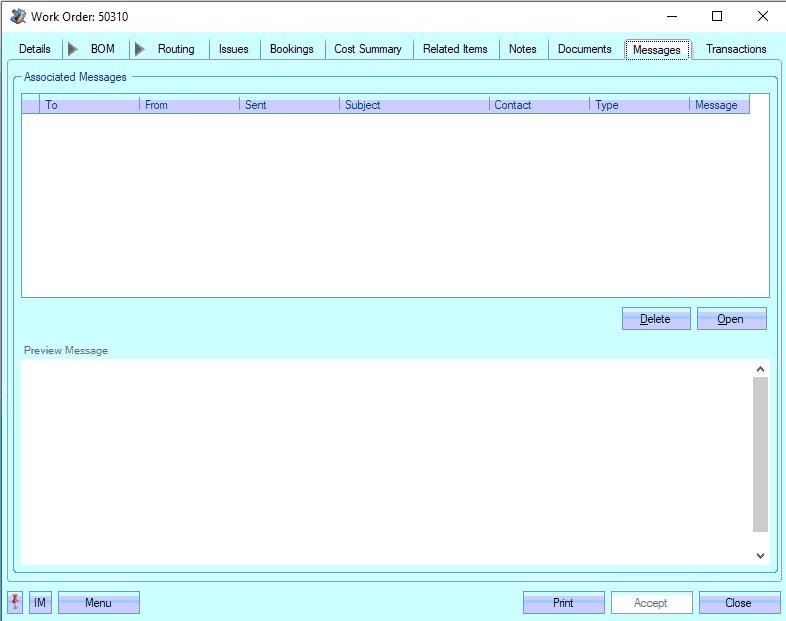

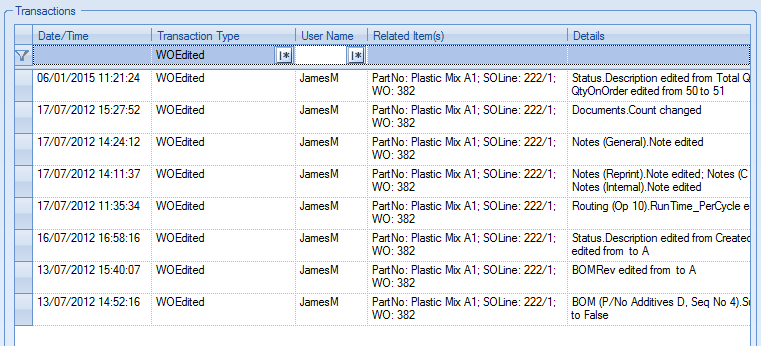

SFDC (Shop Floor Data Capture)

This option allows the user to start up the SFDC modules. There are Labour ("SFDC") and Material ("SFDC Material) modules which are additional modules for the system, and can be purchased for Progress. When the user clicks on the SFDC icon they will be presented with the following options.

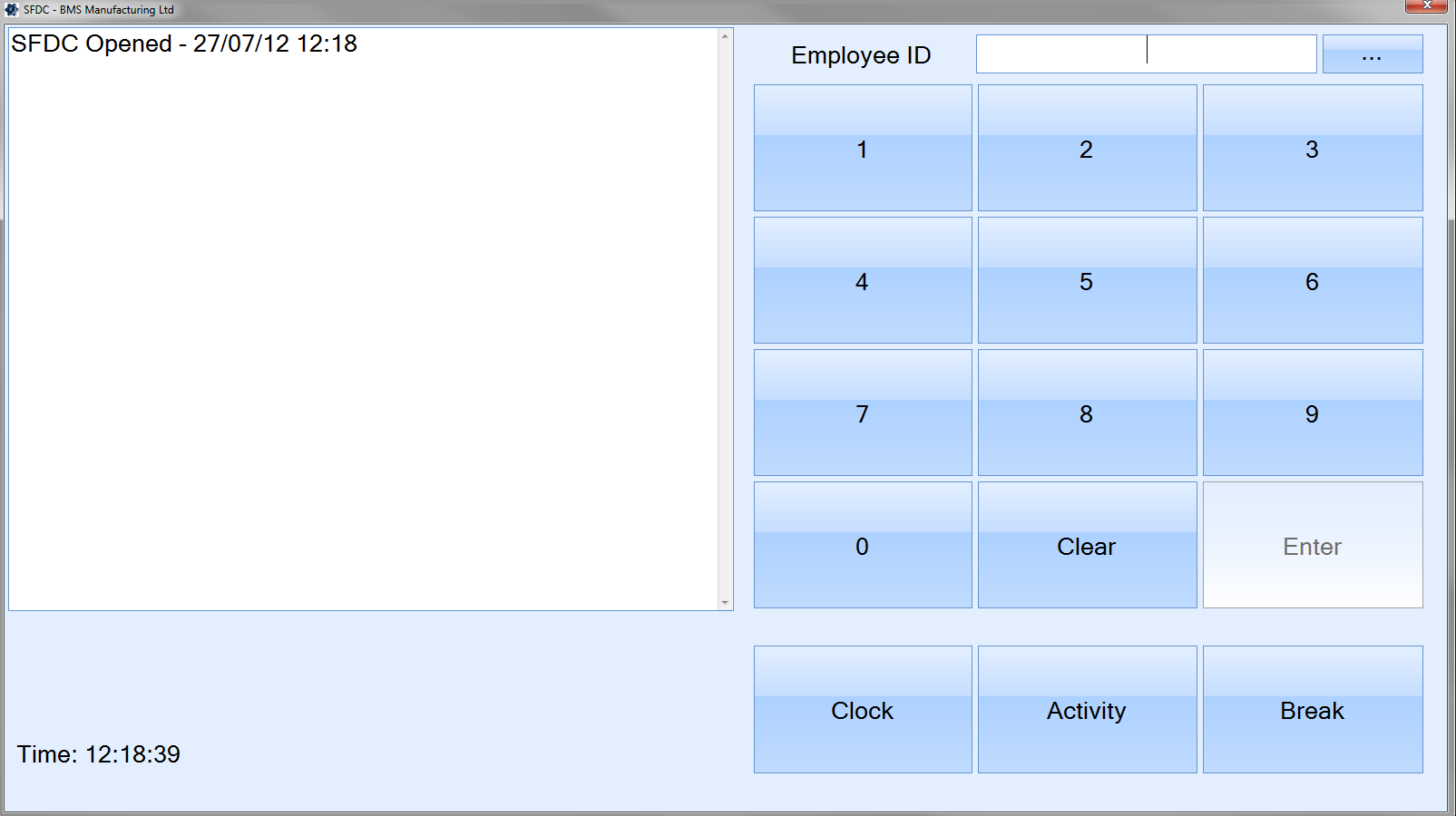

The Labour ("SFDC") module allows employees to record labour times against work order operations, as well as record time and attendance information if the module is used in conjunction with the additional Time & Attendance module of Progress.

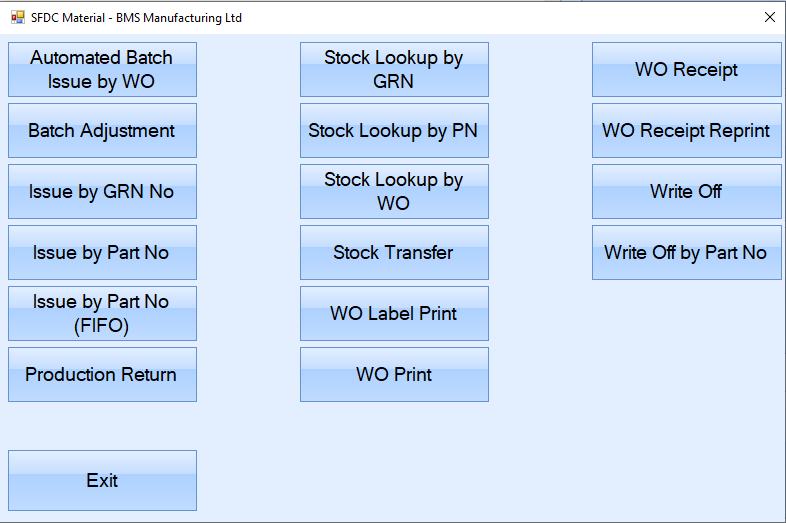

The SFDC Material module will allow the user to do a variety of things such as batch adjustments, issuing to work orders, production returns, stock look ups, work order receipts and some other options. The user will be presented with the following screen.

For more information on the user of the SFDC modules, please refer to the SFDC section of the manual.

In addition to allowing the user to directly access the SFDC module, the user also has an option to view the SFDC STATUS screen. This is available from the drop-down list attached to the SFDC option. More information on this can be found in the next section.

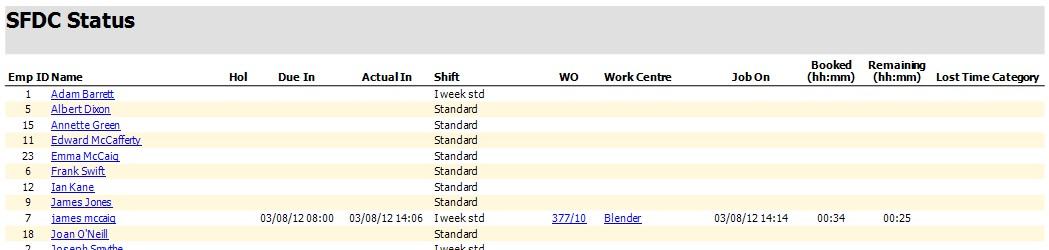

SFDC Status

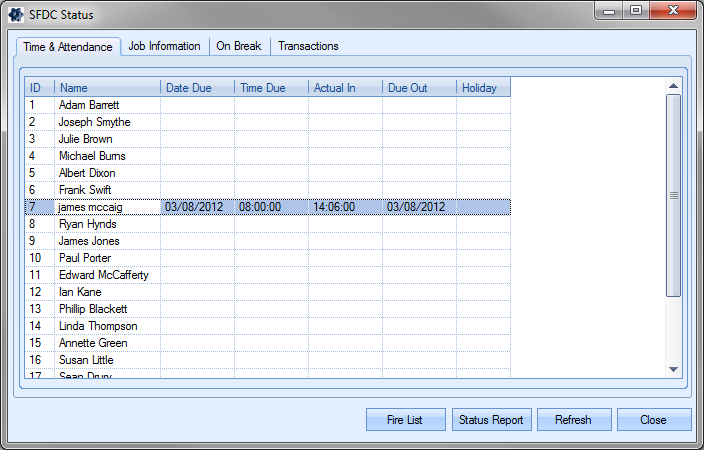

Clicking on the SFDC STATUS option presents the user with the following screen.

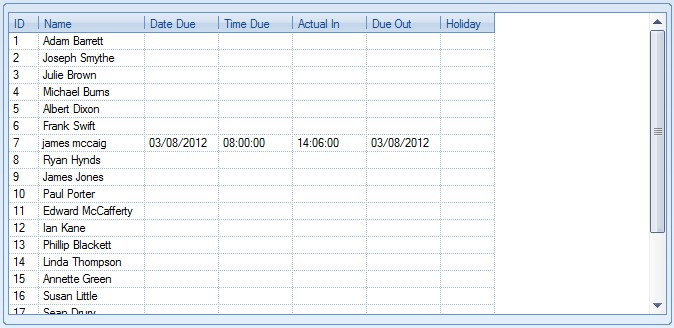

The SFDC Status screen shows a variety of information in relation to employees, their clocking information, job information, break information and the individual transactions recorded on the system and allows the user to see whats going on real-time.

This section shows the clocking times for each employee. The shift times for the current date and the actual clocking in times are both shown. This gives the user the ability to quickly see who’s clocked into the system and the time they clocked in at.

The user can refresh the screen to display the latest information using the REFRESH option at the bottom of the screen. The CLOSE option will close the SFDC Status screen and return the user to the main work order screen.

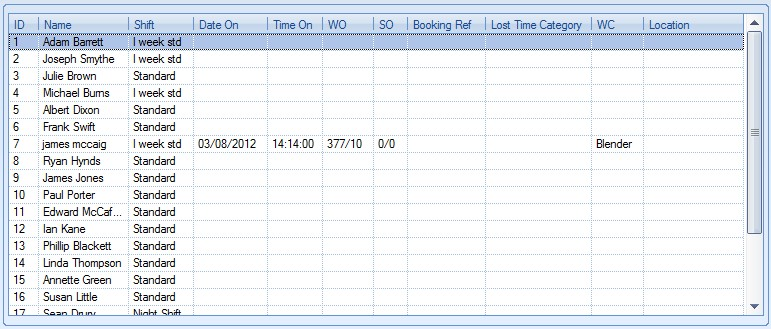

This section shows the current jobs being worked on by the employees.

This screen provides the details of when the employee started the job as well as some other associated job information. The user can refresh the screen to display the latest information using the REFRESH option at the bottom of the screen. The CLOSE option will close the SFDC Status screen and return the user to the main work order screen.

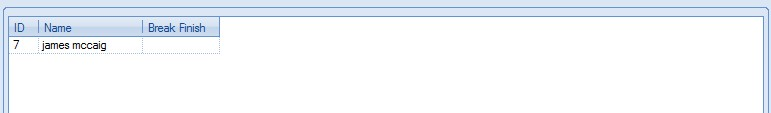

This screen shows all employees who are currently on a break as well as when their break is due to finish.

If the employee has went onto a break manually, no Break Finish time will be present. If the employee has went onto a break automatically due to a predefined break set up against their shift, the time they are due off break is shown.

The user can refresh the screen to display the latest information using the REFRESH option at the bottom of the screen. The CLOSE option will close the SFDC Status screen and return the user to the main work order screen.

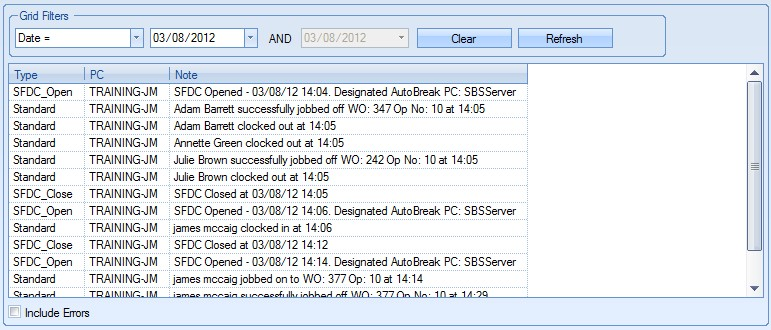

This screen shows all the SFDC transactions made by all employees as well as system messages relating to SFDC.

The user can use the grid filters at the top of the screen to filter the transactions by date and also has an option to select whether error transactions are visible. This option is useful for determining if there are any issues with SFDC, auto-breaks or why employees are not clocked in to the system as expected. The number of day’s history held by the SFDC module is specified in the SFDC system options.

![]()

For more information on the SFDC system options, please refer to the System Administrator Functions section of the manual.

The user can refresh the screen to display the latest information using the REFRESH option at the bottom of the screen. The CLOSE option will close the SFDC Status screen and return the user to the main work order screen.

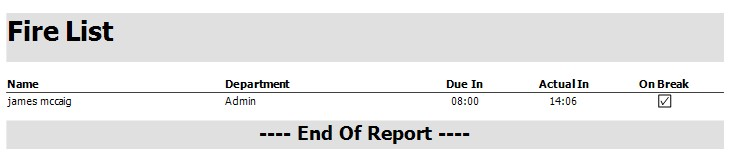

Fire List

The user has an option on this screen to generate a Fire List report. This report provides a complete list of all employees currently clocked into the system. In the event of an emergency, the user can generate a full list of employees expected to be present in the building and ensure everyone can be accounted for.

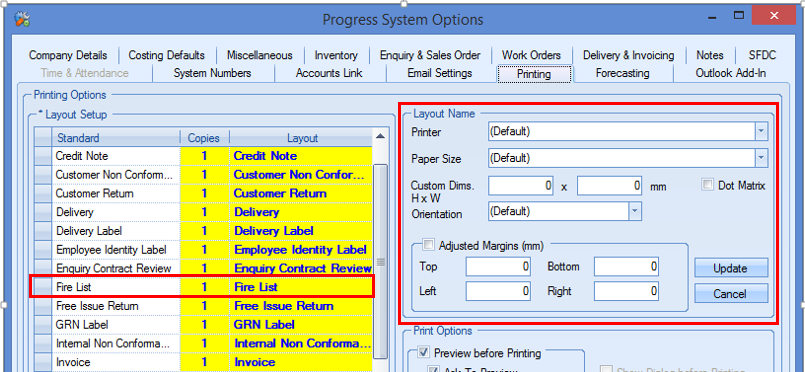

The fire list document can also be set up to be sent to a specific printer just like any of the other layouts in Progress. This can be set up in the Admin settings under the printing options.

Status Report

The user has an option on this screen to generate a SFDC Status report. This report provides a complete list of all employees currently clocked into the system, the jobs they are working on and the times spend on the jobs so far. This report summarises the information shown on the SFDC Status screens.

Export

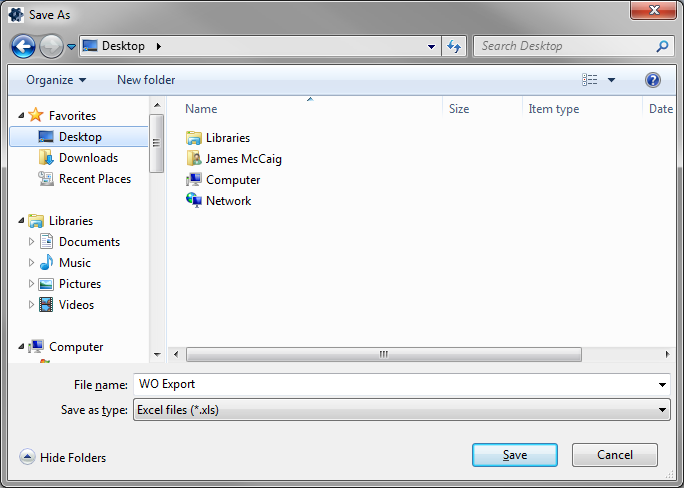

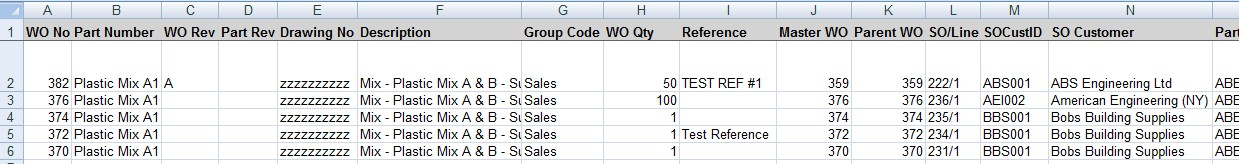

The Export option allows the user to export the current list of work orders to an Excel spreadsheet for further analysis. This option can be used in conjunction with the filters available at the top of the screen or can be used with the full list of work orders if required. Clicking the Export option will prompt the user to create an Excel file.

The user can specify the name required and where the exported file is saved. Clicking SAVE will generate the file. Once saved, the spreadsheet will be automatically opened for the user to view, an example of which is shown below.

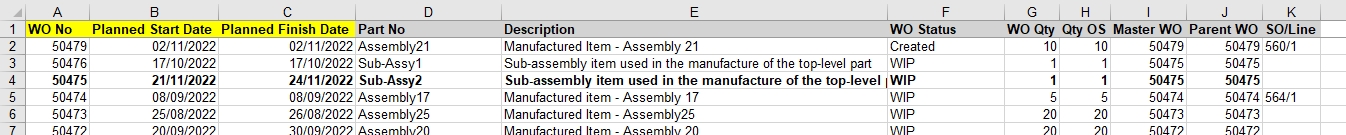

Export - WO Planned Dates

This option allows the user to export out the planned work order dates from the system. These can be amended in the spreadsheet and re-imported to update the work orders and their operations accordingly.

NOTE: This option is only available if the system option has been enabled. The system option can be found in the Work Orders section of the system options (Admin > Options > Work Orders).

![]()

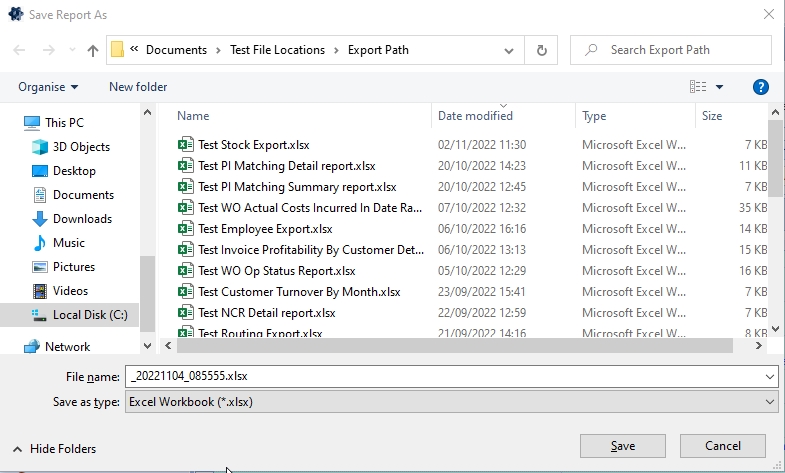

As per the standard export process, this option will create a spreadsheet of information based on the work orders list on the main screen. The user can apply any filters they wish to identify the work orders they need to export. Once the work orders have been selected, clicking the Planned Dates export option will prompt the user to save a spreadsheet with the details.

Once saved, the spreadsheet should appear (example below).

NOTE: The highlighted columns are the main pieces of information on this spreadsheet. Part No, Description, Status, etc. are all included just for reference and cannot be amended and re-imported to update the system.

Once the user has amended the Planned Start Date and/or Planned Finish Date of any work orders in the spreadsheet, they can import the new details to Progress to update the planned work order dates and the associated operation dates. The highlighted work order below has had its dates amended

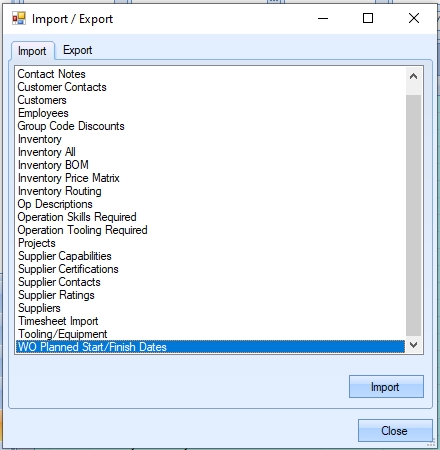

The option to import the new details can be found in the Tools menu (Tools > Import/Export Data > Import).

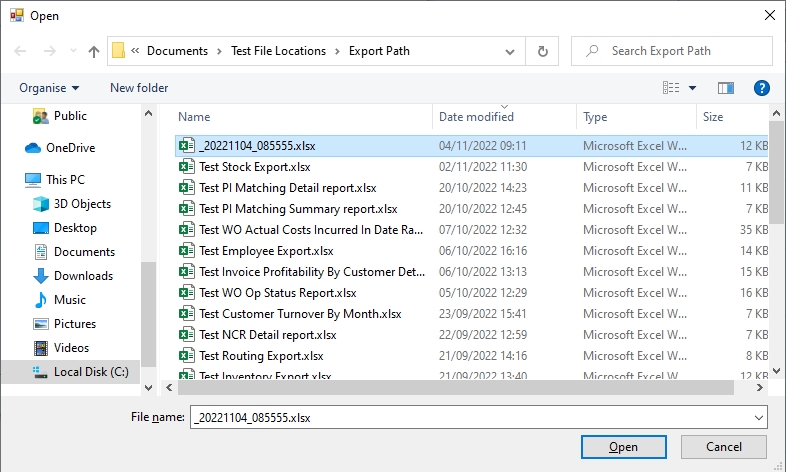

Clicking the IMPORT option when selected will prompt the user for the import file.

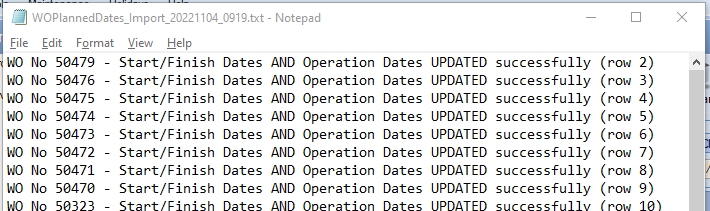

The user can select the file and click OPEN to start the import. Upon completion of the import, the system will present the user with a report on the import's success.

If the work order planned dates and the associated operation dates are successfully updated, the report will show this as:

WO No xxxx – Start/Finished Dates AND Operation Dates UPDATED successfully (row xxx)

If the work order status is COMPLETED or CANCELLED, neither the work order nor the operation dates will be updated. This will be shown on the report as:

WO No xxxx – Status is Completed/Cancelled – NO CHANGES MADE (row xxx)

If the work order is currently loaded into the shop floor loading schedule, only the work order planned dates will be update. Operation dates will not be updated. This will be shown on the report as:

WO No xxxx – Start/Finish Dates UPDATED, but WO is Scheduled, so operation dates NOT updated (row xxx)

Once the import is done, the updated work orders and operations should reflect the new dates. Looking at the example from above, you can see the new planned dates and operation dates.

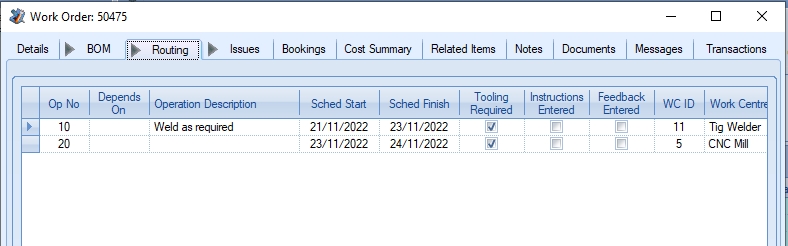

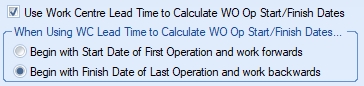

The work order's operation dates will be updated based on the system configuration. These options can be found in the Inventory system options.

This will work in two ways:

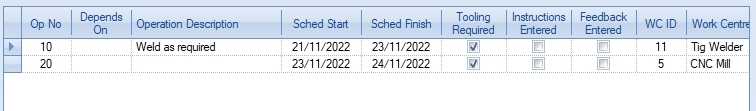

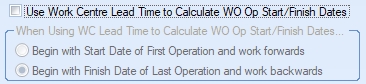

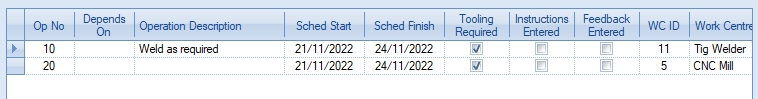

•If the system is configured to use the individual work centre lead times (i.e. option ticked), the system will calculate the operation dates based on either the planned start date of the work order, working forwards, or based on the planned finish date of the work order and work backwards (based on the method selected in the system options above).

(Using work centre lead times)

•If the system is not configured to use the individual work centre lead times (i.e. option unticked), the system sets the operation dates to match the work order dates

(Not using work centre lead times)

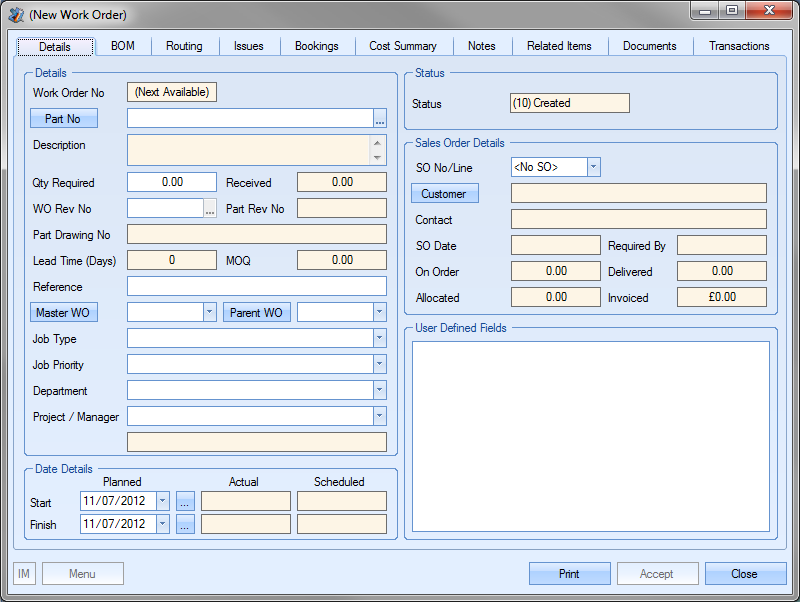

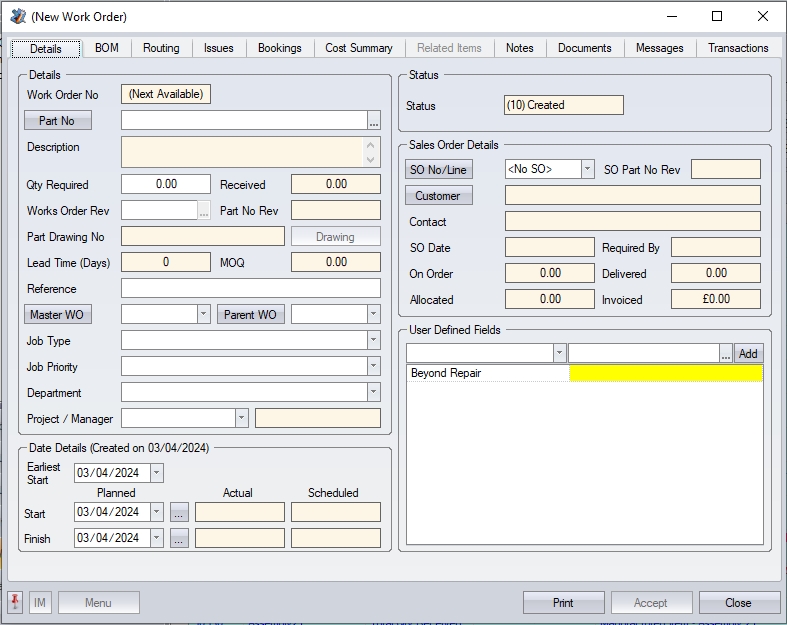

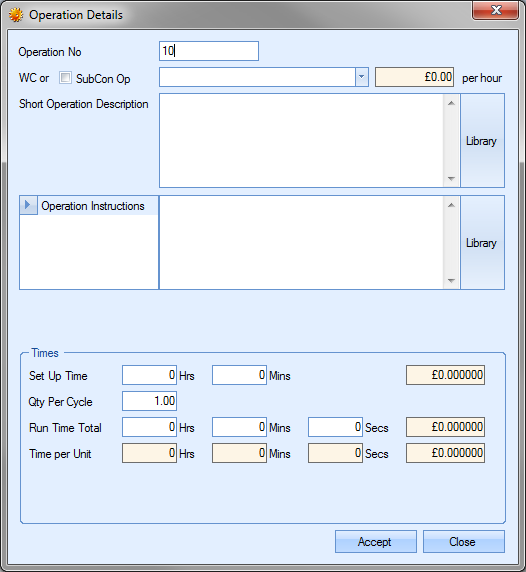

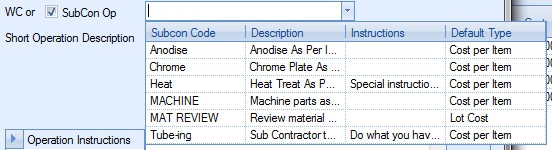

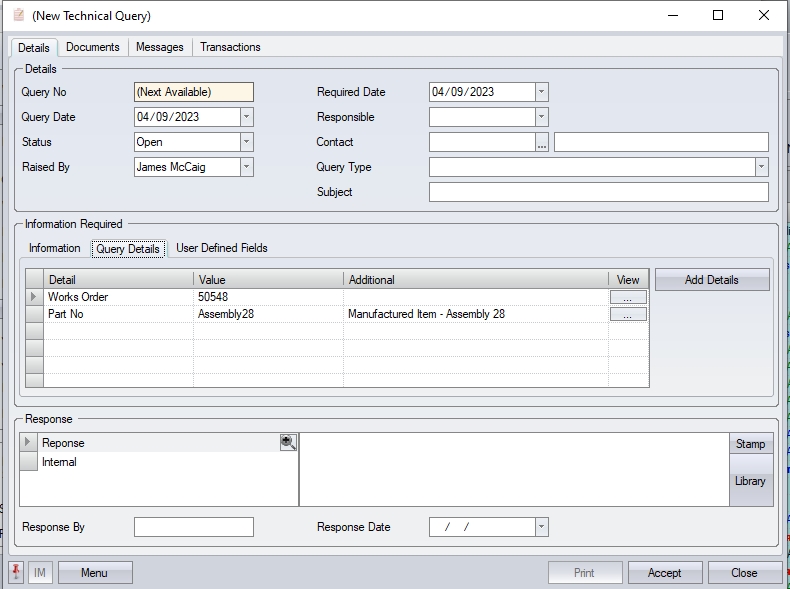

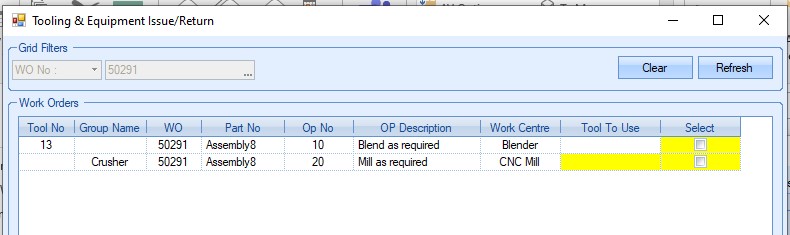

This option allows the user to manually create work orders. Clicking this option presents the user with the following screen.

The user can create a work order by completing the information required on these screens. The following sections detail the different subsections of the work order screen.

WO Details

This is the main section of the work order screen and is the default view for the work order when opened. Fields that can be edited by the user are shown as white. All non-white fields are calculated or automatically populated by the system.

The system generates a work order number upon creation of the works order and allocates the next number in the work order number sequence. The fields shown are as follows:

| Part No | This is the part number being manufactured by the work order. This can be the top-level part or can be a sub-assembly linked to another work order. For works orders linked to a sales order, this will be the sales order line item that the work order is linked to. The user can also access the inventory record of the selected part number by clicking on the PART NO option to the left of this field. |

| Description | This is the description recorded against the aforementioned inventory part number. |

| Qty Required | This is the planned work order quantity, i.e. the quantity to be manufactured. This will default to the minimum order quantity of the selected part if one has been entered. |

| Received | This is the quantity of completed items received into stock so far. |

| WO Rev No. | This field allows the user to specify a revision for the work order. Once the work order has been created, the user can add details against the revision or change the revision by clicking on the |

| Part Rev No. | This field shows the revision of the part at the point the work order was created. This is recorded against the work order when the work order is recorded and remains with the work order even if revision changes are made against the part itself. |

| Part Drawing No. | This is the drawing number recorded against the part. This is recorded against the work order when the work order is recorded and remains with the work order even if revision changes are made against the part itself. The user can open the drawing from the WO itself by clicking on the DRAWING option to the right of the drawing field. This option will only be available if the part itself has a drawing path specified, otherwise the option will be unavailable. |

![]()

| Lead Time (Days) | This is the selected part’s manufacturing lead as recorded in the parts inventory record. |

| MOQ | This is the selected part’s minimum work order quantity. |

| Reference | This field allows the user to record a reference against the WO if required. If the work order is created from a sales order line, this field will default to the customer order number entered against the sales order. |

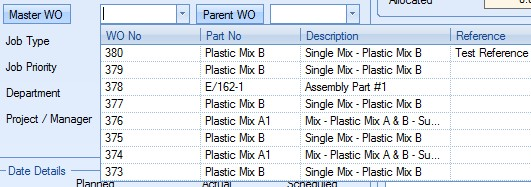

| Master WO | This is the master work order number that the work order is associated with. In the manufacture of an item containing a multi level BOM, this will be the work order number of the top level part. If the work order created is not linked to a master work orders then this field will reference the current work order number. The user can link the current work order to an existing work order by selecting from the drop down list. |

| If a master work order has been specified, the user can view the master work order directly from this screen by clicking on the MASTER WO option to the left of this field. |

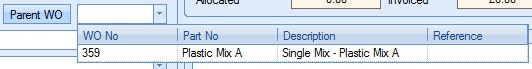

| Parent WO | This is the parent work order number that the work order is associated with. In the manufacture of an item containing a multi level BOM, this will be the work order number of the part immediately above in the BOM. If the work order created is not linked to a parent work order then this field will reference the current work order number. The user can link the current work order to an existing work order by selecting from the drop down list. |

| This list will only show active work orders where the current part is on the BOM. |

| If a parent work order has been specified, the user can view the master work order directly from this screen by clicking on the PARENT WO option to the left of this field. |

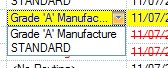

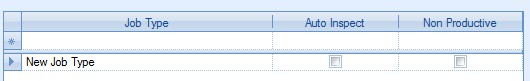

| Job Type | This field allows the user to specify a job type for the work order. The user can select a value from the drop-down list. |

![]()

| This drop-down list can be populated from the List Maintenance section of Progress in the WO Job Type list as shown in the screen below. |

For more information on maintaining lists and the List Maintenance section of Progress, please refer to the List Maintenance section of this manual.

| Job Priority | This field allows the user to specify a job priority for the work order. The user can select a value from the drop-down list. |

| This drop-down list can be populated from the List Maintenance section of Progress in the WO Priority list as shown in the screen below. |

For more information on maintaining lists and the List Maintenance section of Progress, please refer to the List Maintenance section of this manual.

| Department | This field allows the user to specify a department associated with the work order. The user can select a value from the drop-down list. |

| This drop-down list can be populated from the List Maintenance section of Progress in the Department list as shown in the screen below. |

For more information on maintaining lists and the List Maintenance section of Progress, please refer to the List Maintenance section of this manual.

| Project / Manager | This field allows the user to specify a project associated with the work order. The user can select a value from the drop-down list. |

![]()

| This project list is populated based on the live projects currently recorded in Progress. The listed projects can be maintained via the Projects section, which can be accessed from the Maintenance menu. |

| Once the user selects a project from the drop-down list, the associated project manager is displayed below the project field. |

For more information on projects, please refer to the Maintenance > Projects section of the manual.

| Earliest Start | This field is the earliest date that the WO can be started. By default this will be the same as the Start Date (Planned) however this can be amended manually and via the LINKED POs option on the main WO screen. Typically this is updated to reflect any delays in material which result in the WO not being able to start on the planned start date, which the LINKED POs option will do based on the dates of any linked POs. |

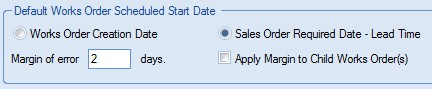

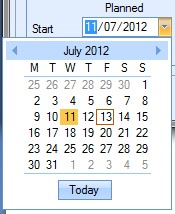

| Start Date (Planned) | This field is the date that the user wishes the work to begin on this job. When raising a works order to satisfy a sales order demand this field is the Works Order Start Date and will be set based on how the following system options have been configured. |

| The user may change this date by clicking on the drop-down calendar that is at the end of this field. |

| The user also has the option of calculating the planned start date based on a planned finish date that may have been set. To do this, the user can click on the |

| For more information on the work order start date options, please refer to the work order options in the System Options section of the manual. |

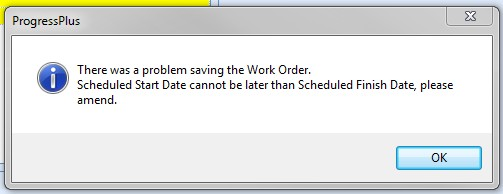

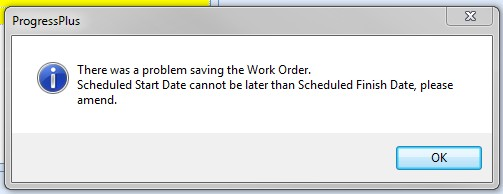

| If the user attempts to set a start date after the finish date, the user will be prompted to correct the dates. |

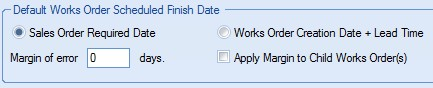

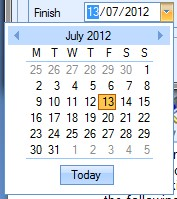

| Finish Date (Planned) | This field is the date that the user plans to finish working on this order. When raising a works order to satisfy a sales order demand this field is the Works Order Finish Date and will be set based on how the following system options have been configured. |

| The user may change this date by clicking on the lookup box that is at the end of this field. |

| The user also has the option of calculating the planned finish date based on a planned start date that may have been set. To do this, the user can click on the |

| For more information on the work order finish date options, please refer to the work order options in the System Options section of the manual. |

| If the user attempts to set a finish date prior to the start date, the user will be prompted to correct the dates. |

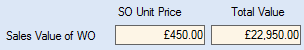

| Start Date (Actual) | This calculated field shows the date when the work order was actually started. This date is the date when either labour was first booked against the work order or the date that material was first issued to the job. |

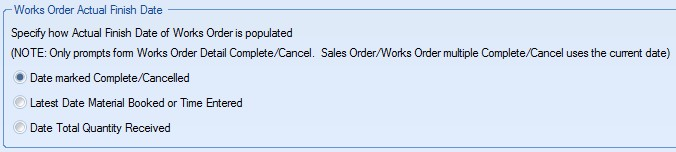

| Finish Date (Actual) | This calculated field shows the date when the work order was recorded as finished. This date is calculated based on how the system options for work order finished date have been set. |

| For more information on the actual work order actual finish date options, please refer to the System Options section of the manual. |

| Start Date (Scheduled) | This field shows the current scheduled start date of the work order as scheduled in the Shop Floor Loading section of Progress. For more information on scheduling work orders within the Shop Floor Loading section of Progress, please refer to the Shop Floor Loading section of the manual. |

| Finish Date (Scheduled) | This field shows the current scheduled finish date of the work order as scheduled in the Shop Floor Loading section of Progress. For more information on scheduling work orders within the Shop Floor Loading section of Progress, please refer to the Shop Floor Loading section of the manual. |

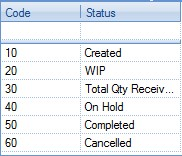

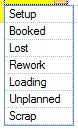

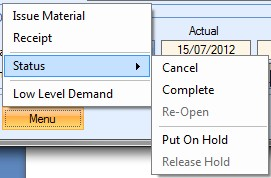

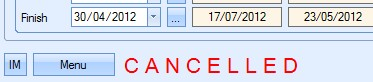

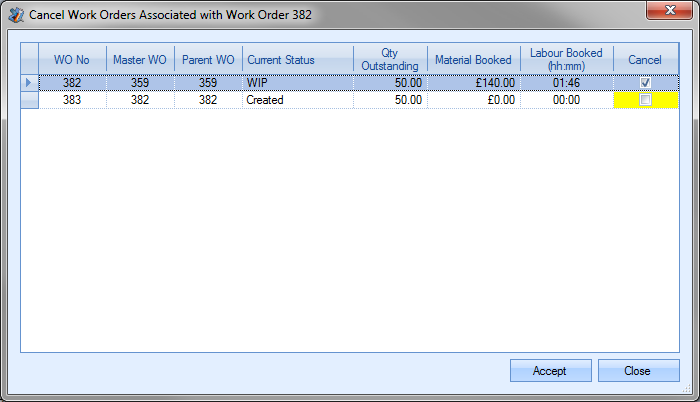

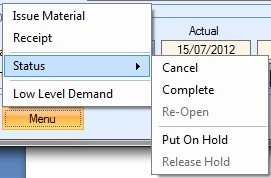

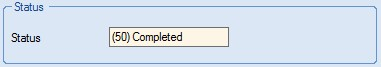

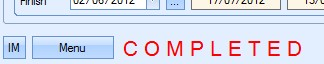

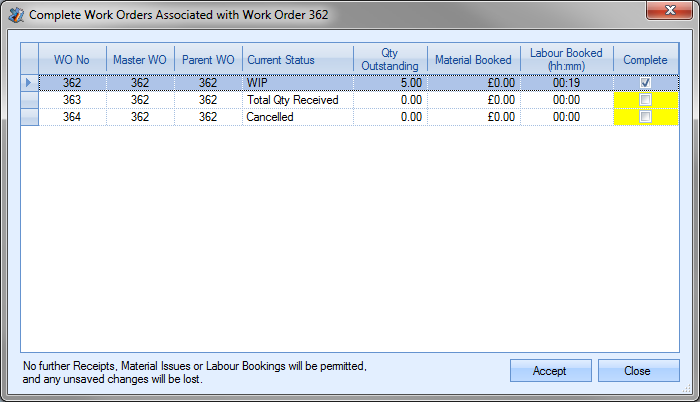

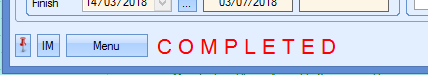

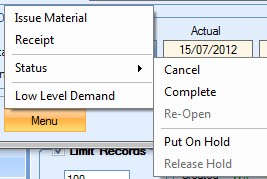

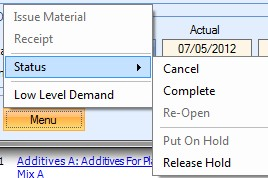

| Status | This field shows the current work order status. This field defaults to CREATED status when a new work order is created. As the work order progresses, the status is updated accordingly. The work order statuses used in Progress are as follows. |

| Created - Initial status of any new work order. Work order will remain at this status until the work order is started, placed on hold or cancelled. |

| WIP - Work In Progress (WIP). This status indicates that the work order has been started. This status is triggered when either labour is booked against the work order or material is issued to the work order. |

| Total Qty Rec - This status indicates that the full work order quantity has been booked into stock. |

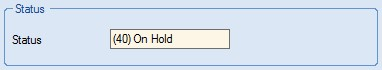

| On Hold - This status is the result of someone manually placing the work order on hold. If the work order is placed on hold, no transactions can be made against the work order. |

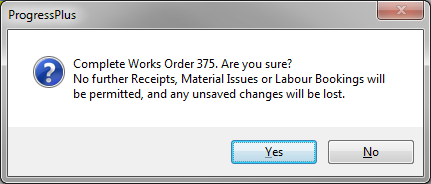

| Completed - This status is the result of someone manually marking the work order as complete. This status would be used when all labour and material issues have been made against the work order. Once the work order is set to this status, no further transactions can be made against the work order. |

| Cancelled - This status is the result of the work order being cancelled. This can be done manually by the user or as the result of an associated sales order line being cancelled (user is prompted to decide when sales order line is cancelled). Once the work order is set to this status, no further transactions can be made against the work order. |

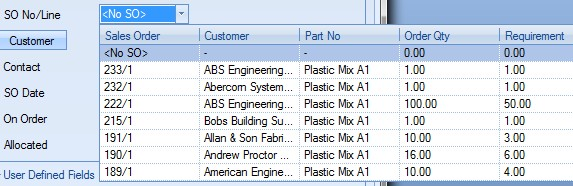

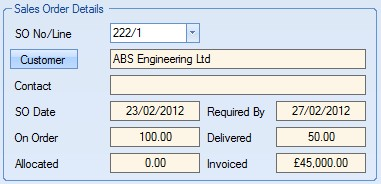

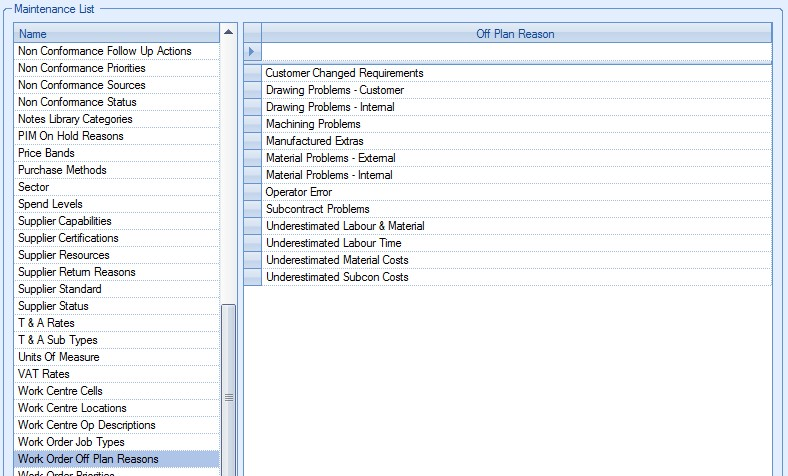

| SO No/Line | This is the associated sales order and sales order line number that this work order is linked to. This information can be set manually by the user using the drop down list. |

| If the work order is created from a sales order line requirement, this information will be automatically populated by Progress when the work order is created. If the work order is being created to create stock, then no sales order information will be populated. Once the user selects a sales order from the list, the following fields are populated based on the sales order information |

| Customer | This field is populated based on the sales order/sales order line selected in the drop-down list above. This is the customer from the selected sales order. |

| Contact | This field is populated based on the sales order/sales order line selected in the drop-down list above. This is the contact name from the selected sales order. |

| SO Date | This field is populated based on the sales order/sales order line selected in the drop-down list above. This is the date the selected sales order was created. |

| Required Date | This field is populated based on the sales order/sales order line selected in the drop-down list above. This is the customer required date recorded against the sales order line. |

| On Order | This field is populated based on the sales order/sales order line selected in the drop-down list above. This is the quantity ordered by the customer and the quantity on the sales order line. |

| Delivered | This field is populated based on the sales order/sales order line selected in the drop-down list above. This is the quantity already delivered to the customer against this sales order line. |

| Allocated | This field is populated based on the sales order/sales order line selected in the drop-down list above. This is the quantity currently allocated to the selected sales order line, ready for delivery. |

| Invoiced | This field is populated based on the sales order/sales order line selected in the drop-down list above. This is the total value already invoiced against the selected sales order line. |

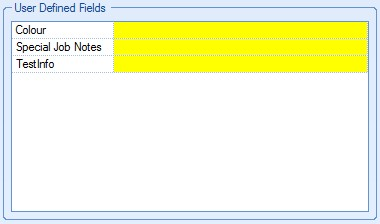

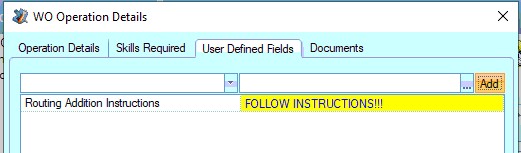

| If user defined fields have been created in Progress for use on against work orders, these will be displayed in the section below as shown. |

| The user can populate these fields as required. |

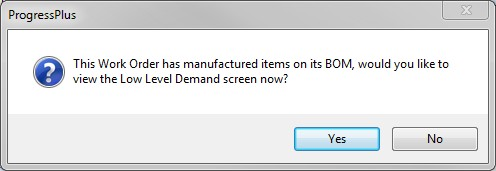

| Once all the details have been entered for the work order, the user can save the work order by clicking the ACCEPT option. This will allocate a work order number to the order and save the order in the system. If the work order part number has a sub-assembly part on its BOM, the system will prompt the user to review lower level requirements the new work order has to decide on whether associated work orders need to be created for the lower level requirements. |

| If the user clicks YES, they will be taken to the work order demand screen to review the requirements. If the user clicks NO, the user will remain on the work order screen. The user can click CLOSE to return to the main work order screen. For more information on the work order demand screen, please refer to the WO Demand section of this manual. |

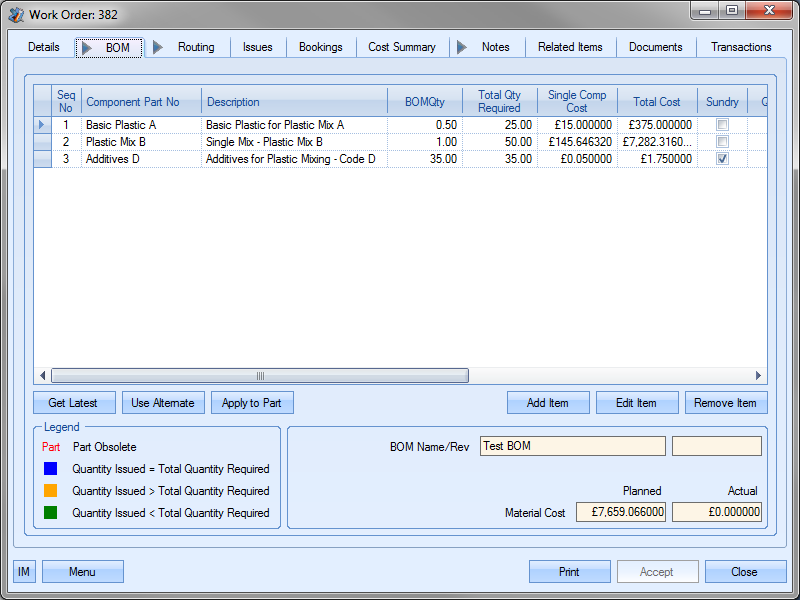

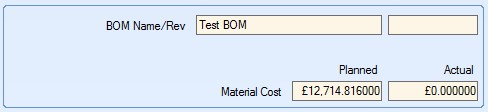

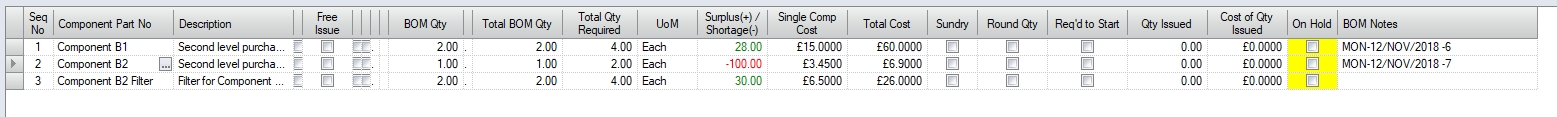

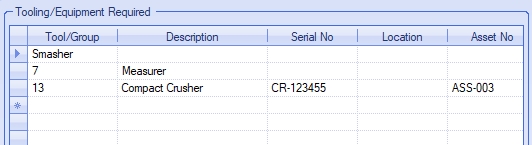

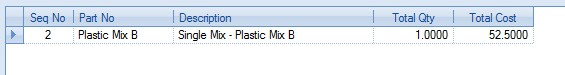

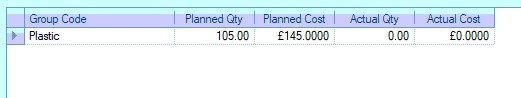

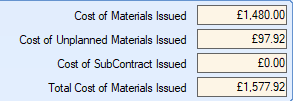

WO BOM

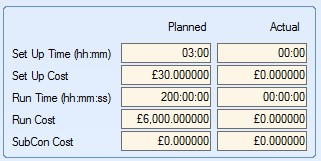

This section of the work order shows the BOM set up against the work order. This will default to the current BOM selected against the master part number. The name and revision of the BOM is shown at the bottom of the screen, along with the planned and actual material costs. The planned material cost is the total of all the total costs of each component part listed in the BOM. The actual cost shown is the total cost of material issued to the work order based on the individual GRN costs associated with the batches issued to the work order.

The top half of the screen displays a list of all the component parts required for this work order.

The information shown is as follows. Most of this information will default based on the master part's default BOM, although the user can amend these on the individual work order to allow for exceptions.

| Seq No | BOM sequence number. This is the sequence number specified against the component part on the manufactured parts BOM. |

| Component Part No | Part number of component part. |

| Description | Inventory part description as recorded against part number. |

| Free Issue | Indicates that the component part is a free issue part for this work order. This is typically used when the customer is providing material for the job. |

| BOM Qty | Quantity of component part required to make one unit of the manufactured part as recorded on the manufactured part’s BOM. |

| Total Qty Required | Total quantity of component part required to manufacture the work order quantity. This is calculated based on the BOM quantity of the component multiplied by the work order quantity. |

| UOM | Component unit of measure |

Surplus(+)/Shortage(-) Current snapshot of component part's stock status. Colour coding indicates whether there is a current surplus (green) or shortage (red) of the part.

| Single Comp Cost | This is the costs associated with a single unit of the component part. For purchased parts, this is the costs of a single unit of measure (UoM). For manufactured parts this is the cost of manufacturing one unit. |

| Total Cost | Total cost of each component part required based on the Single Comp Cost and the total quantity of each component required and is calculated based on the Total Qty Required multiplied by the Single Comp Cost. Also used to calculate the Planned Material Cost at the bottom of the screen. |

| Sundry | Flag indicating whether the component is a sundry item (fixed cost regardless of work order quantity). |

| Round Qty | Flag that indicates whether the cost of the component part is rounded to the nearest UOP value. |

| Required To Start | Flag indicating that the component part must be issued to the job before work can commence. |

| Qty Issued | Quantity of component part that has been issued to the work order. |

| Cost of Qty Issued | Value of component part issued to the work order. |

| On Hold | This flag indicates whether the component part has been placed on hold in the current work order. This can only be set against purchased parts. Placing a purchased part on hold with this flag removes the requirement for this part on this work order. Any overall requirements for this component part will not include any requirements for this work order. |

| BOM Notes | Notes recorded against component parts on manufactured part’s BOM. This pulls through from work order part’s BOM. |

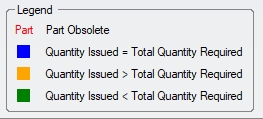

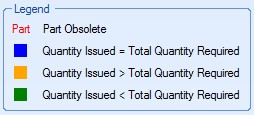

| The BOM component grid uses a colour coding to indicate the status in relation to material issues. The colour coding used is shown in the legend displayed at the bottom of the screen. Initially items are shown in black as no material has been issued. |

BOM Maintenance

The user has a few options available here in relation to the work order BOM. These options are as follows.

Get Latest

![]()

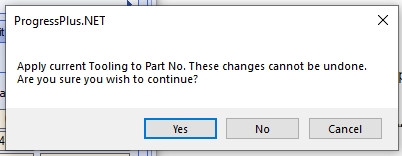

This option updates the work order BOM with the latest BOM from the work order part. The existing work order BOM will be overwritten with the current BOM against the part.

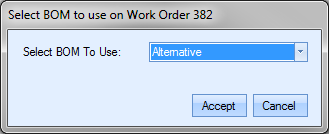

Use Alternate

![]()

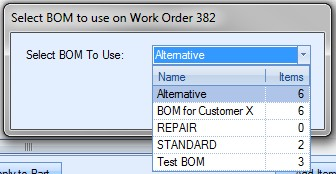

This option allows the user to select an alternative BOM from those set up against the work order part. When the user selects this option, they are prompted to select an alternative BOM to use.

The user can then select an alternative BOM from the drop down list.

Once the alternative BOM has been selected, the user can update the work order BOM to the selected alternative by clicking the ACCEPT option. The work order BOM will be updated accordingly.

Apply To Part

![]()

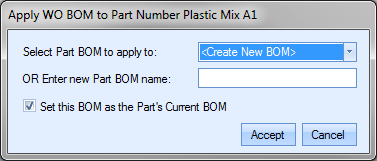

This option allows the user to update the work order part’s inventory record with the WO BOM. When this option is clicked, the user is prompted to choose between creating a new BOM against the part or to update an existing BOM. They can also specify whether the new or updated BOM is used as the default BOM.

Once the user has selected the BOM to update or entered the new BOM name, the user can click ACCEPT to save the BOM as required.

In addition to the above options, the user has options to amend the details of the work order BOM items themselves. These options only allow changes to the current BOM items and do not impact any BOM details recorded against the part itself. The options available are as follows.

Add Item

![]()

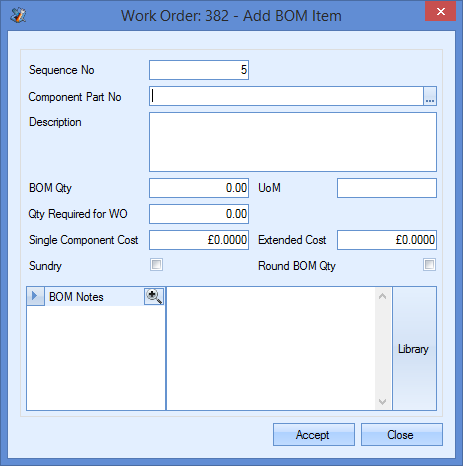

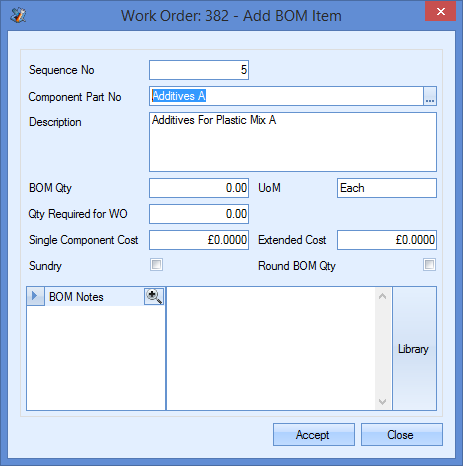

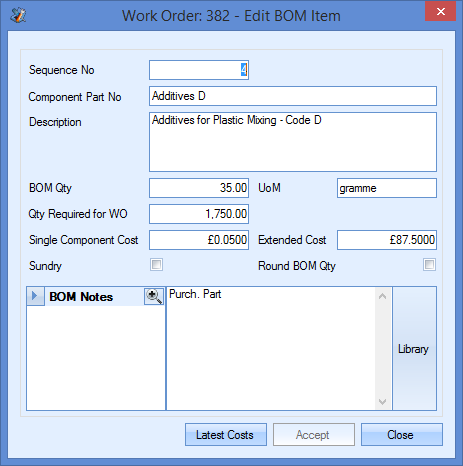

This option allows the user to add parts to the work order BOM. This option can be used if there are custom or additional components that need to be used on the job. Clicking this option presents the user with the following screen.

The user can complete this screen to add the required part number to the existing BOM. The information required is as follows.

| Sequence No | BOM sequence number. This is a numerical sequence number. This defaults to the next number in the BOM sequence. |

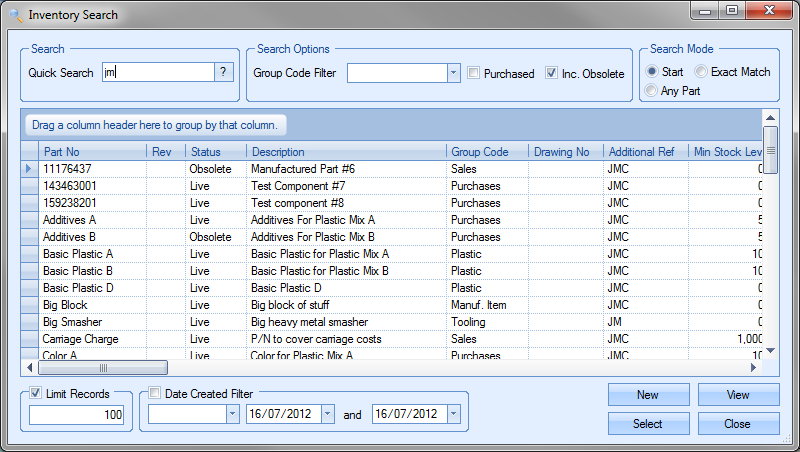

| Component Part No | Part number to be added to the BOM. The user can select the part number required from the inventory parts list by clicking on the |

The user can create a new part number if required by selecting the NEW option. If the part already exists, the user can search and select the part required by clicking the SELECT option. This will return the part to the Add BOM Item screen.

| Description | Defaults to the inventory description once user has selected the part number required. |

| BOM Qty | The quantity required for making one unit of the manufactured item. |

| UoM | Unit of measure of the selected part. Defaults to the unit of measure set against the selected part in the inventory record. |

| Qty Required For WO | Calculated field which defaults to the total quantity required based on the work order quantity and the BOM quantity specified. |