Creating New GRNs For Single Stock Total Qty

This process reduces the stock levels to zero and then creates new GRNs through a new stock import.

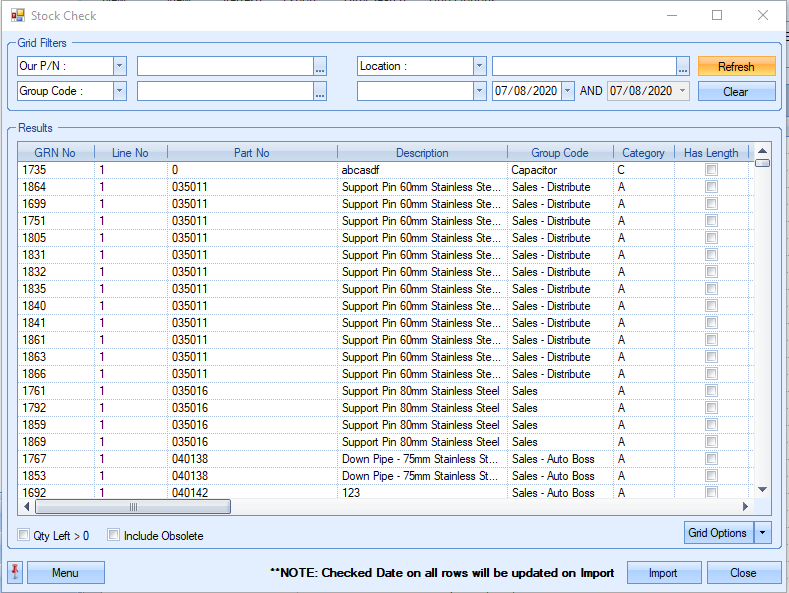

Go to Inventory > Stock Check.

This screen can be filtered to show specific items or refreshed to show all inventory.

Once the user has identified the parts that they are interested in, they can export the stock details using the MENU > EXPORT GRID option. When prompted, save the spreadsheet with a name such as “Stock Export 7th August 20".

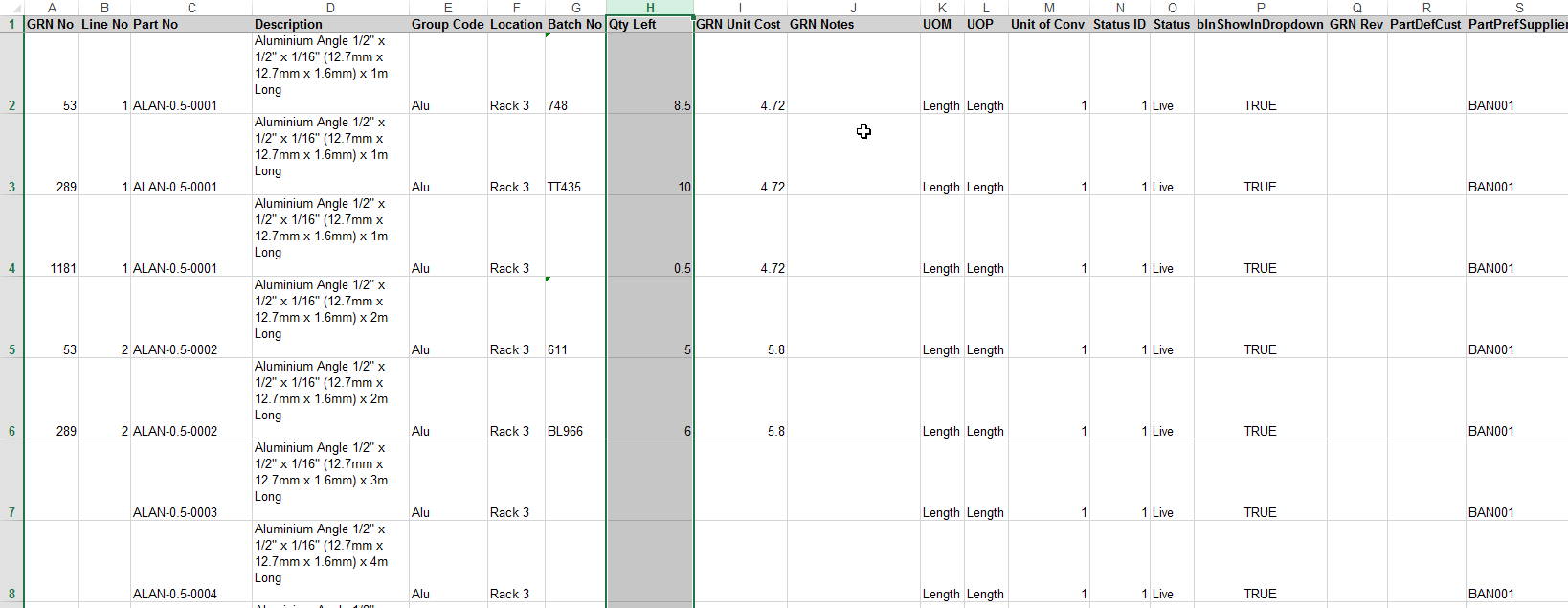

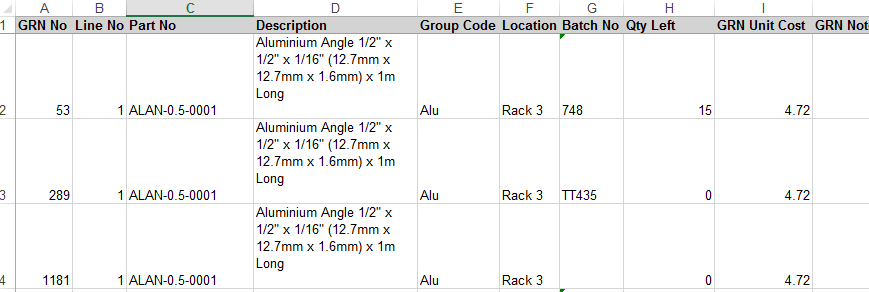

The spreadsheet created contains all batches of all items, hence the same part number may be repeated if you have different batches. Each batch can have a different cost, batch numbers, GRN Notes or Release Notes, plus, will refer back to its source, such as a PO or WO.

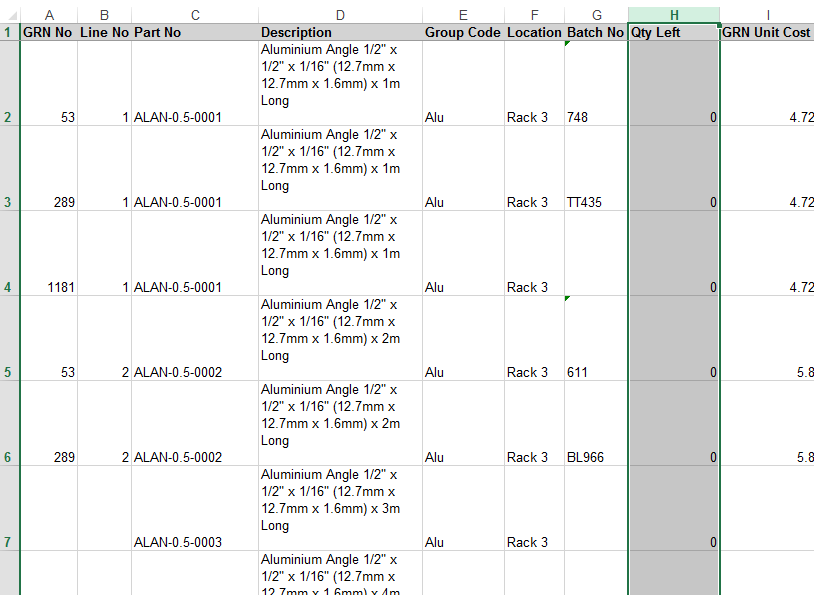

If only one entry per part number is required, the user can zero the quantities of all existing GRNs, import the spreadsheet to zero existing stock and then export again to give a list of all part numbers, with a QTY LEFT of zero. To do this, the user must first set the QTY LEFT column to zero for each GRN listed in the spreadsheet. The spreadsheet can then be saved as a new spreadsheet e.g. “Stock Import 7th August 20 Zeroed”.

NOTE: As this import process uses a fixed-format spreadsheet, the user must ensure the columns and headings are exactly the same as the exported spreadsheet.

To import the zero quantities, the user can click on the MENU > POPULATE GRID FROM .XLS/.XLSX option, before selecting the spreadsheet with the zero quantities. Once the screen is populated, the user can click IMPORT to update all existing GRNs to zero quantities.

Once done, the Stock Take screen will provide a clear list of all the stock items. The user can now export this stock list to a spreadsheet which will provide a single entry for each selected part number and with no GRN numbers listed.

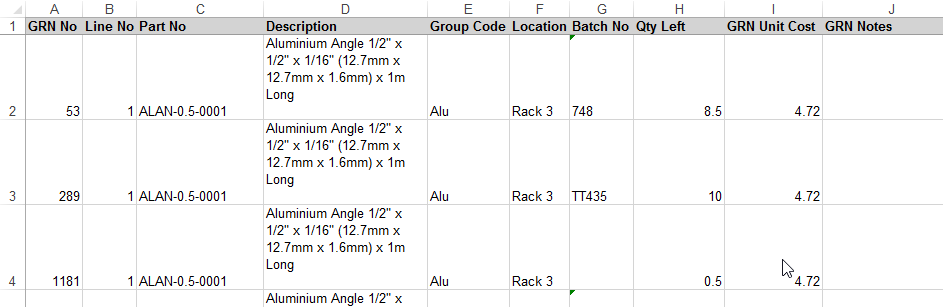

The user can then update the QTY LEFT column against each part numbers indicating the total stock quantity they currently and any batch number, location and GRN Unit Cost information they want to record too. Once done, the user should save the spreadsheet as this will be the data they reimport.

NOTE: If no costs are entered the GRN will be zero value.

The updated spreadsheet can now be imported the same way as before, MENU > POPULATE GRID FROM .XLS/.XLSX, ensuring they select the updated stock spreadsheet. Once the screen is updated to show the contents of the spreadsheet the user can update the system using the IMPORT option. The system will then assign new sequential GRN numbers and suffix /1, /2 etc for each line import.

NOTE: Do not repeatedly import this spreadsheet as it will duplicate the stock levels for each part.

Consolidation Of Stock To An Existing GRN

To save losing the existing GRN cost information, another option is to consolidate batches into one of the existing GRNs. This replaces the need to zero, import then export again.

In the example below, Part “ALAN-0.5-0001” has 3 separate batches of 8.5, 10 and 0.5, totalling 19.

If the stock is counted and there are only 15 left, to maintain batches correctly, the specific batch which has been reduced would have to be identified, but if batch control is not an issue, it can be consolidated as per the example below (i.e. 15, 0 and 0)

Importing this spreadsheet using the steps specified above will save a single total stock quantity against one GRN and the others will be zeroed, but the GRN cost still assumes the £4.72 from the original batch.