This section of the inventory screen allows the user to allocate or release inventory from sales orders.

This option allows the user to manually create inventory allocations against sales order lines with outstanding requirements. Unlike the Sales Order Line Requirements screen that is displayed when sales orders are created, this screen allows the user to select specific batches to allocate as opposed to the FIFO (First In First Out) approach used by the Sales Order Line Requirements screen. Clicking on the Create SO Allocation option presents the user with the following screen.

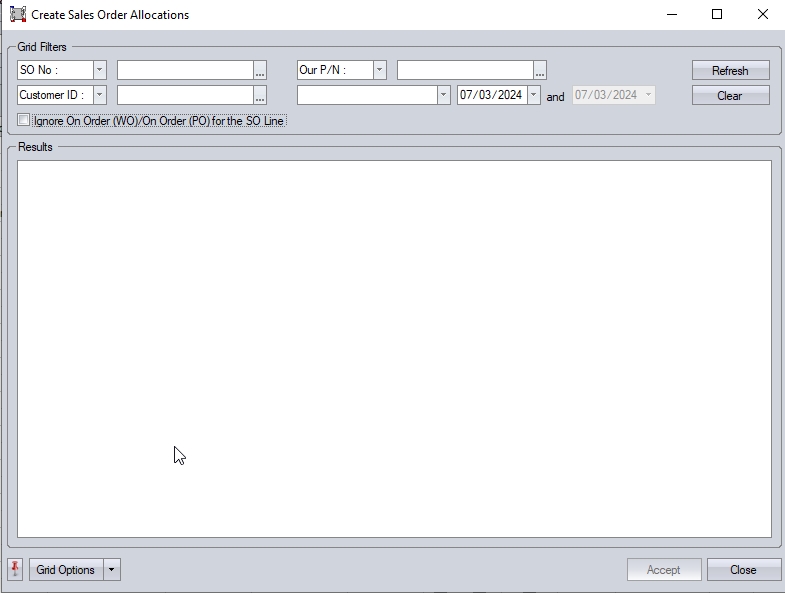

The user can search for specific orders using the grid filters at the top of the screen. Once the filters have been set the user can click the REFRESH option to update the screen. All sales orders that meet any specified criteria will then be displayed.

(Example - SO filter applied)

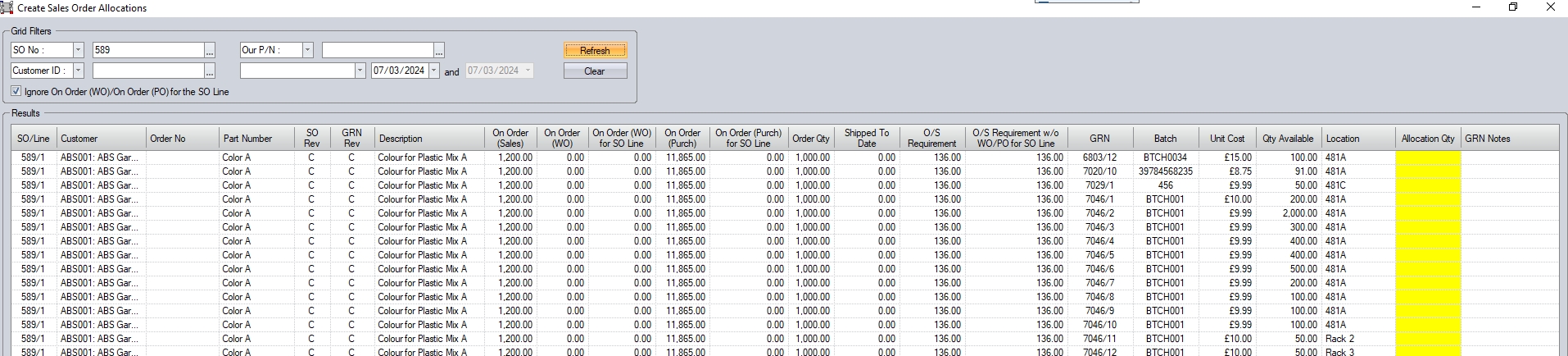

All the sales order details are shown for the user to see, including the required and promised dates and also including the outstanding quantity on the sales order line. The system then lists the inventory currently available in Progress, along with its current inventory location. For sales order line items that have multiple batches available in stock, the sales order lines details will be duplicated as shown in the example screen shot above. The column highlighted in yellow, is for the user to specify the quantity to be allocated from that batch.

The above example shows a quantity of 100 from GRN 6803/1 being allocated to sales order 589/1. This batch alone does not have enough to fulfill the SO line requirement, so an additional allocation is being made against GRN 7020/1 to fulfill the entire 136 required.

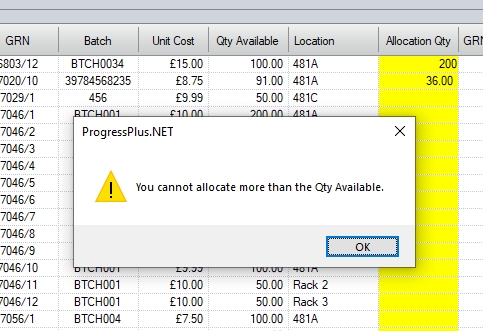

Once the allocation has been specified, the user can click the ACCEPT option to confirm and allocate the quantity to the sales order. If the sales order has been set up to allow partial deliveries, the allocated quantity will now be available for delivery. If the user attempts to allocate more than the batch quantity, the system will highlight this to the user.

(Warning when allocating more than available batch qty)

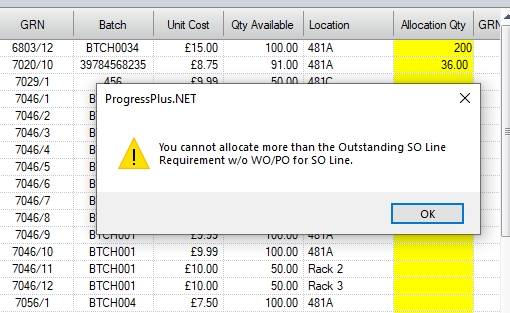

Similarly, if the user attempts to allocate more than the outstanding quantity on the SO line, the user will also be informed.

(Warning when allocating more than the outstanding SO line requirement)

NOTE: By default, allocations can only be made to an SO line if there is an existing outstanding requirement not already fulfilled by a linked WO, PO or existing allocated stock, however, it is possible to allocate stock even if there is a linked WO or PO if the user has the permissions to do so. This is set in the user's access rights in the Admin section and allows the user to allocate stock to the SO line as long as there is an outstanding quantity to be shipped.. More on this can be found in the Administrator Functions > Access section of the section of this manual.

If the user has the ability to do this, an additional option is displayed in the grid filter section at the top of the screen.

![]()

Ticking this option will allow the user to allocate existing stock to sales order lines, regardless of whether the sales order line has an associated WO(s) and or PO(s) to fulfill the sales order line requirement. The user can then proceed to allocate any existing stock to sales orders as per the allocation process above.

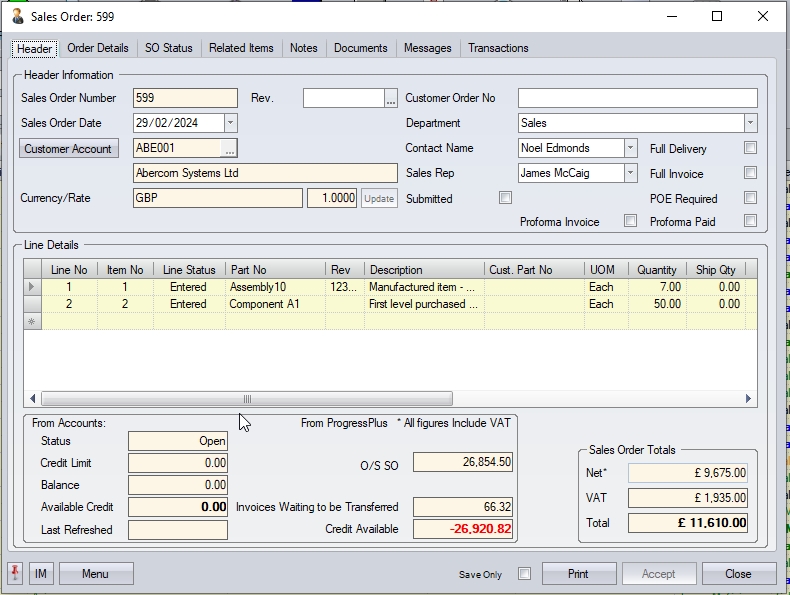

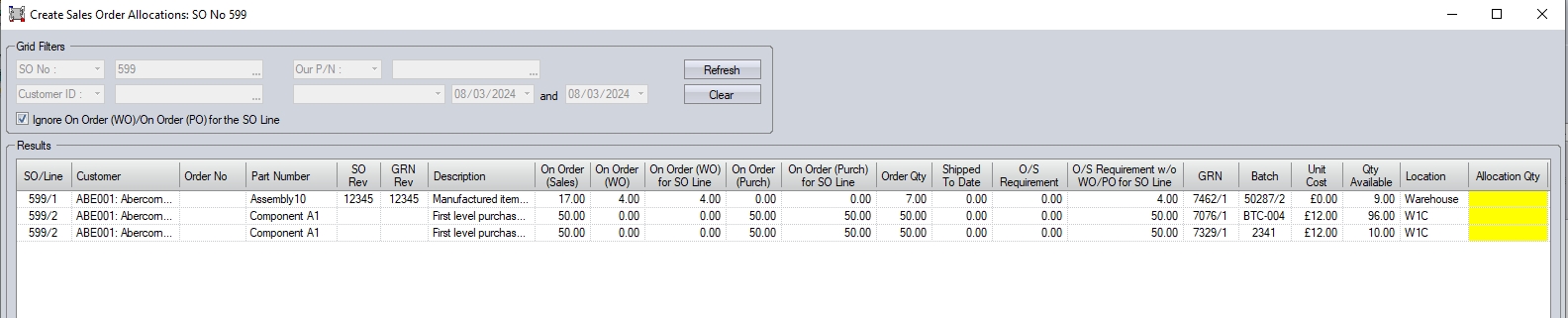

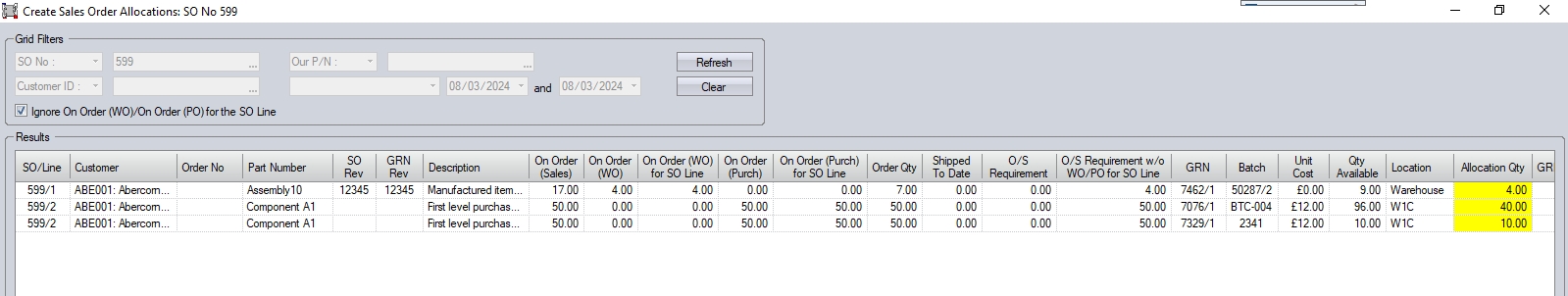

Example:

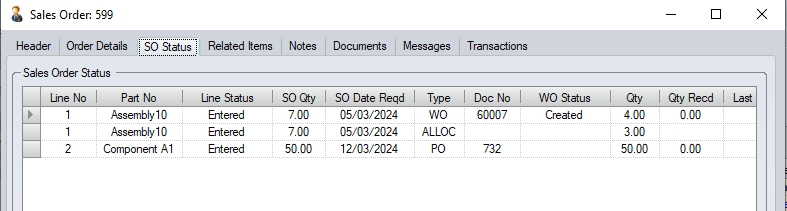

Sales Order 599 has an manufactured part (Assembly10), and a purchased part (Component A) on it.

Line 1 of the sales order has a stock allocation of 3, and a WO for the remaining 4 units required. Line 2 has a PO raised for the full 50 units. Currently, the sales order has no outstanding requirements as both lines have their requirement covered (i.e. Line 1: WO+Stock = 7, Line 2: PO = 50).

Based on this, the Create SO Allocations screen shows nothing, as there is no outstanding requirements.

Ticking the option to ignore the linked WO and PO and refreshing the screen, presents the user with both SO lines to allocate stock against.

In this example, Line 1 already had a stock allocation, so the outstanding requirement is now 4 (since we are ignoring the WO), so the user can allocate a further 4 units from stock to the SO line. Since Line 2 was fully covered by the PO raised, the user is able to allocate the full 50 units from the available batches in stock.

Once the user clicks ACCEPT, the allocations will be made to the SO line. If there was still an outstanding requirement on the SO line(s) (i.e. there was insufficient stock to cover the full outstanding requirement, the receipt of the linked WO and PO would fulfill the remaining requirements when they are receipted into stock. If there are no further requirements on the SO (i.e. sufficient stock has been allocated), receipt of the linked WO and PO will simply place those units into stock.

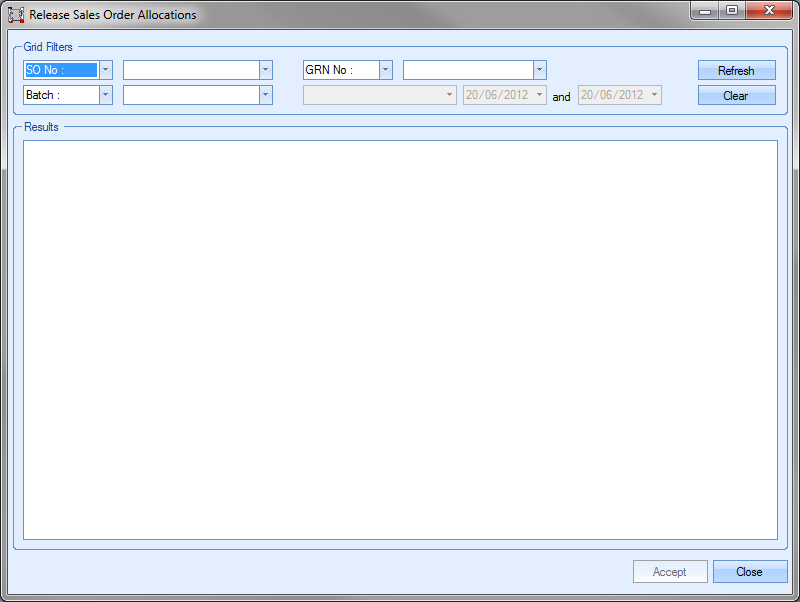

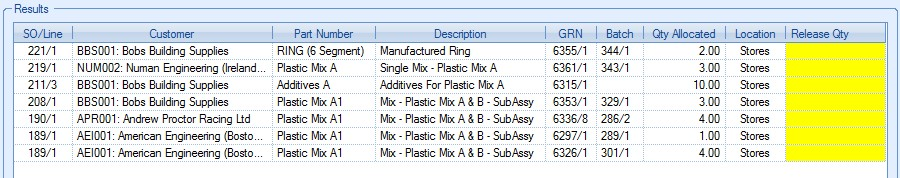

This option allows the user to remove inventory allocations against sales order. This option may be used if the wrong batch has been allocated to the sales order or if the inventory needs to be used for another sales order. Clicking on the Release SO Allocation option presents the user with the following screen.

The user can search for specific sales orders using the grid filters at the top of the screen. Once the filters have been set the user can click the REFRESH option to update the screen. All sales orders that meet any specified criteria will then be displayed.

The information displayed shows the sales order information along with the GRN, batch number and quantity currently allocated. To remove the allocation, the user simply has to enter the quantity to be released into the highlighted yellow box at the right hand side. Once the user has entered the quantity to be released, clicking the ACCEPT option proceeds to remove the allocated inventory from the sales order line. The released inventory will subsequently appear as active stock in the part’s Stock Status figures.