In the event that rework is required on a sub-contracted operation, the following steps need to be done:

1.Go to the WO screen in Progress and locate the WO affected

2.Open the WO to view the details

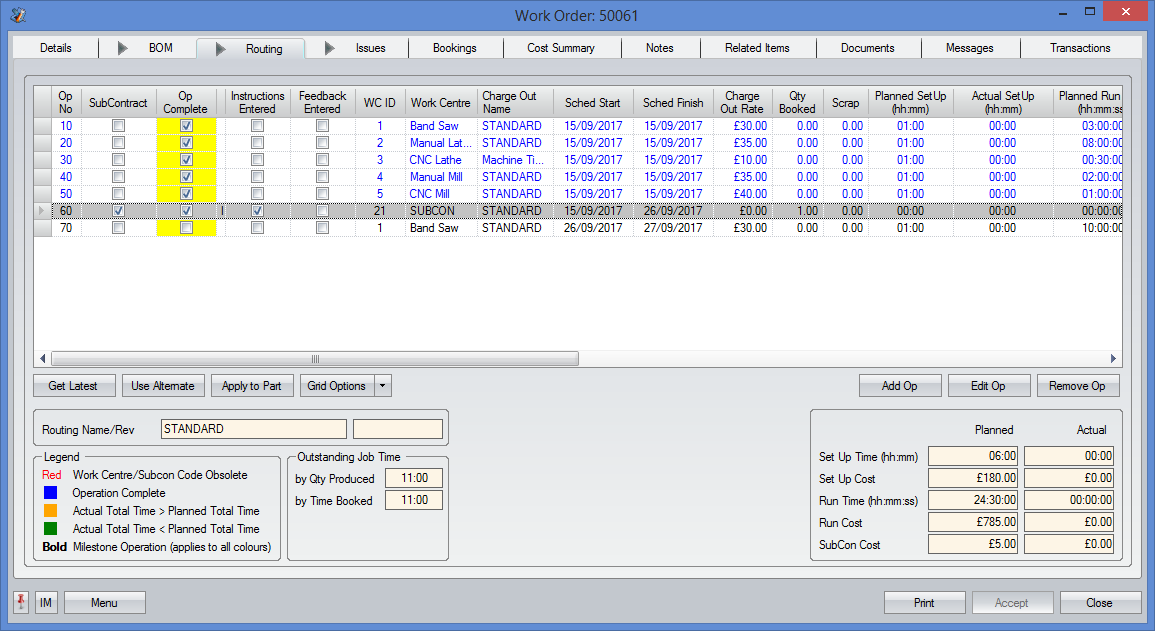

3.Identify the Subcon item/operation on the WO routing tab

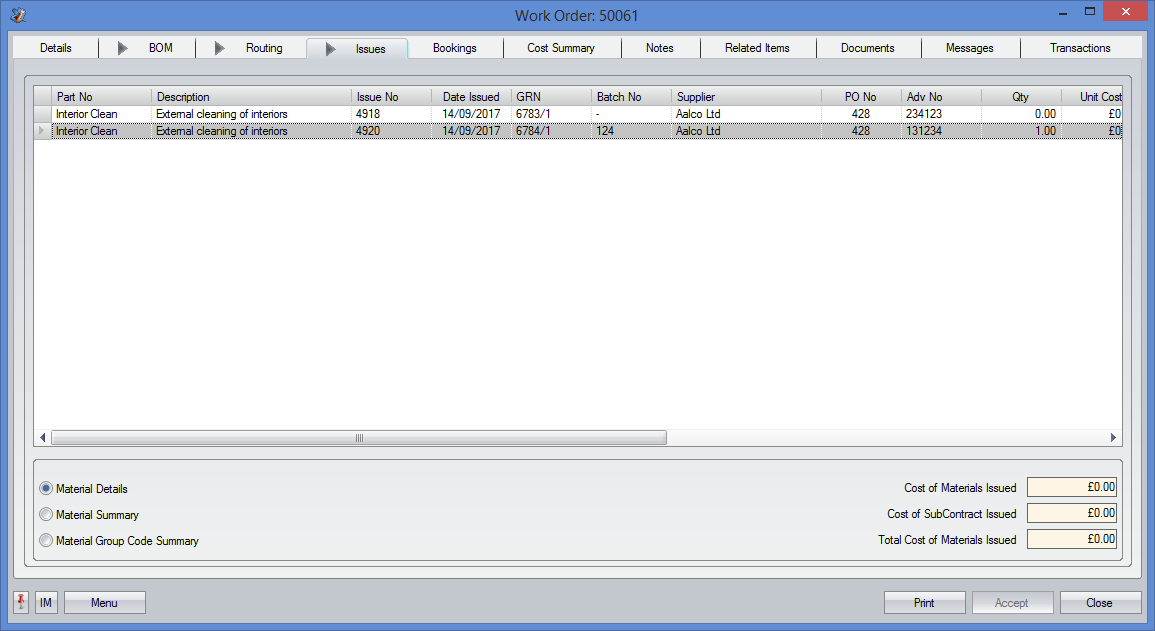

4.This can be verified against the Material Issues screen

5.Make a note of the WO number, the WO operation number and the PO number associated with the subcon item.

6.Click on the INVENTORY section

7.Click on the RECEIPTS option

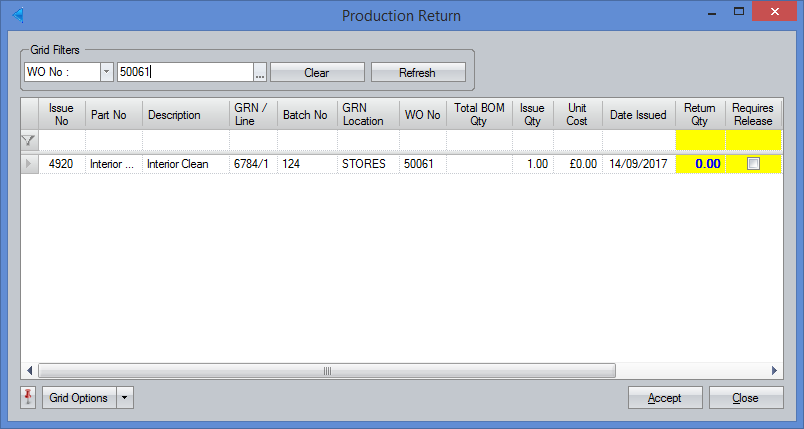

8.Select the PRODUCTION RETURNS option

9.Enter the WO number and press REFRESH option

10.When the details appear, enter the qty of the Subcon item to be returned to inventory

11.Once entered, press ACCEPT to complete transaction

12.This will now be removed from the WO and returned to inventory

13.Return to the INVENTORY section

14.Select ISSUES option

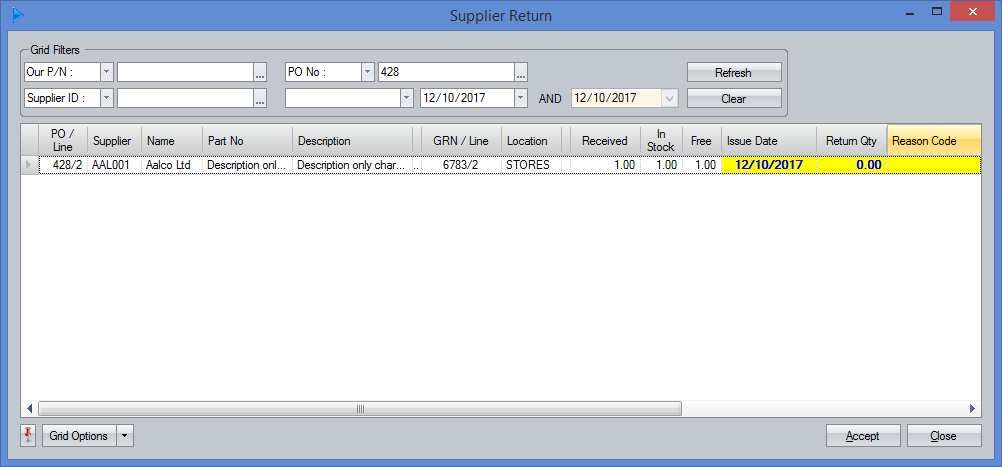

15.Select the SUPPLIER RETURNS option

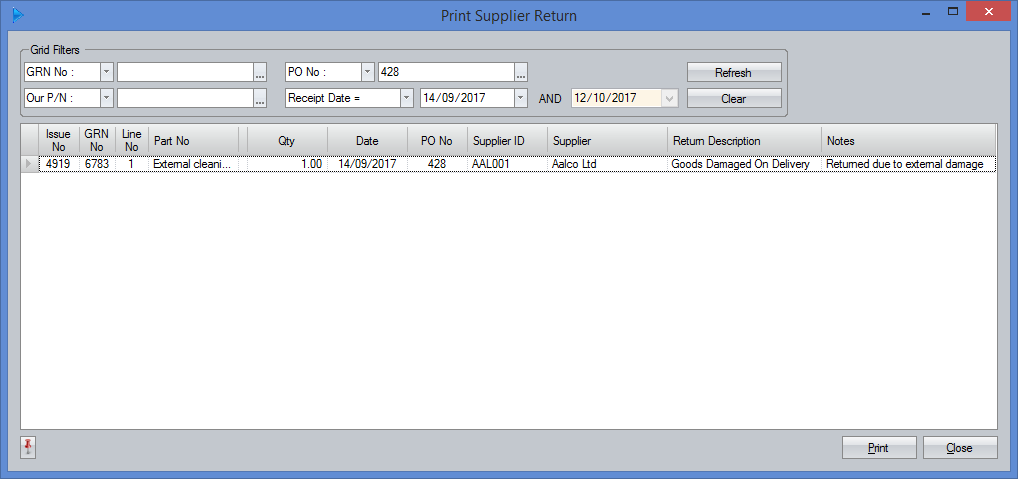

16.Enter the PO number the subcon items were originally received on and click REFRESH.

17.Enter the return quantity required and set a reason code if required.

18.Press ACCEPT when complete to complete the return

The user can also generate a Supplier Return document for returning with the goods. To generate this, follow the steps below:

1.Return to the Inventory section

2.Click on the Issues option

3.Click on the Print Supplier Return option

4.Use the grid filters to identify the supplier return to be printed

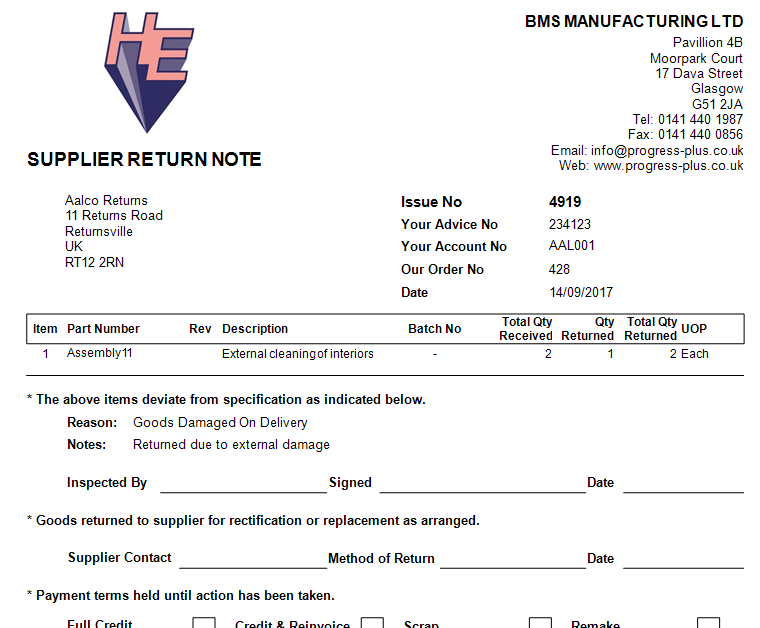

5.Highlight the selected supplier return transaction and then click the PRINT option to generate the document. An example of one is shown below.

NOTES:

•WO must be open for the steps above to be complete. If the WO has been closed/completed, re-open first before proceeding.

•The original SubConn PO will reopen when the return is complete. This will be the PO to re-receive the material when it returns again.

•If the above process is done simply due to an error with the original PO receipt, then the supplier return document does not need to be generated – this is just if the goods are being physically returned to the supplier.