The SFL screen displays information for up to the next 11 weeks from the current week. Work that should have been completed prior to the current week is automatically added to the loading for the current week. Only outstanding planned hours are included in the SFL calculations e.g. if an operation was planned to take 5 hours and 3 hours time has been recorded against this operation the SFL system will assume 2 hours work is still outstanding and use the 2 hours in the loading calculations.

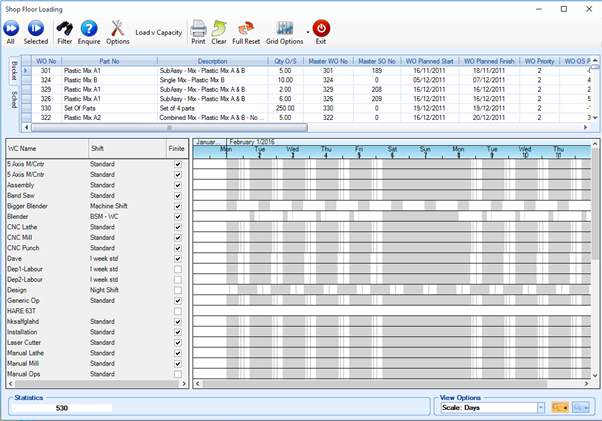

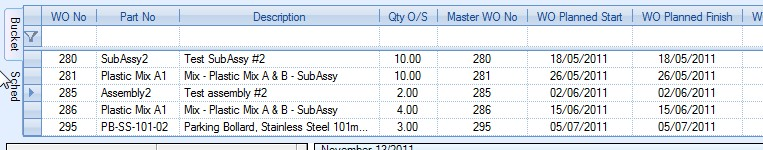

On choosing the SFL option a screen similar to the following will be displayed.

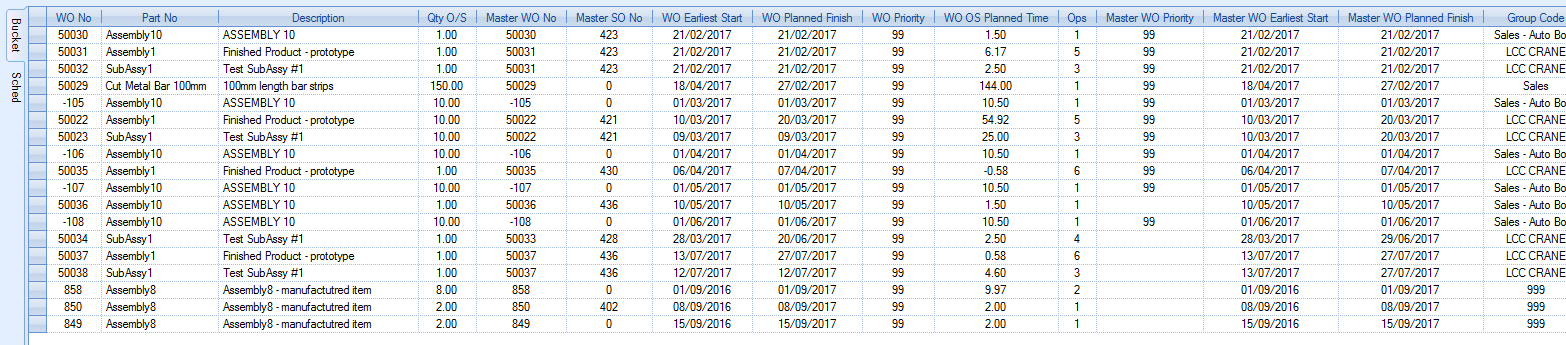

At the top of the screen is two sections; Bucket and Sched. The Bucket tab shows WOs with current outstanding planned routing times which have not yet been planned in SFL screen while the Sched tab shows any WOs that have already been planned in the SFL screen.

The bottom part of the screen lists all active work centres as well as any already planned WO operations against the work centres.

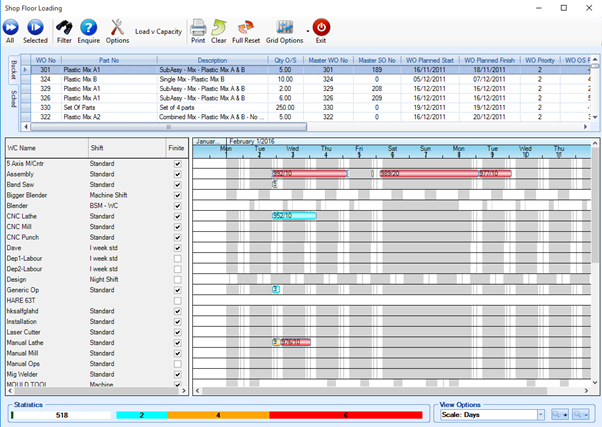

As WOs start to be scheduled on the SFL screen, the screen may look similar to the following:

When all jobs have been scheduled:

- drag the cursor over each bar to check the start and finish date/time of each op

- right click to open the WO to check the detail, or highlight the specific WO on the Gantt chart to look at all the WO ops together

- The result of the schedule is that the operation start and finish dates change on the routing section of the WO to reflect the schedule on the Gantt chart. These are the dates which dictate the order operations are shown in the Work to List, hence reflecting the most efficient order to carry out the work.

- As well as the Op dates being updated on the routing tab, the WO's SFL scheduled start/finish dates are populated in the WO detail, and are taken from the start date of the first op and the finish date if the last op. This can change each time the WO is scheduled, but the main WO start and finish date can only be changed manually.

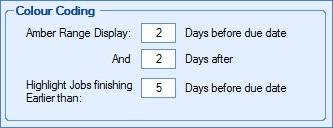

- The colour coding for this screen is as follows:

| Green | WOs due to finish on time |

| Blue | WOs finishing earlier than the number of days specified in the SFL options (using the above settings, this would be 5 days) |

| Amber | WOs finishing date falls within no of days specified in the SFL options (using the above settings, this would be 2 days before or 2 days after) |

| Red | WOs overdue |

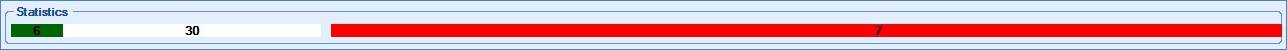

The statistics chart at the very bottom of the SFL screen uses the same colour coding, but would include the following:

| White | WOs unscheduled |

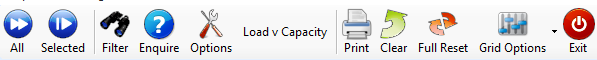

The top of the screen has several options for the user to use:

All

This will attempt to plan all WOs listed in the Bucket tab into the grid below using the sequencing set in the SFL options.

Selected

This will attempt to plan any WOs selected from the Bucket tab into the grid below using the sequencing set in the SFL options.

Filter

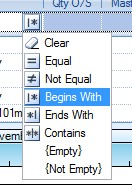

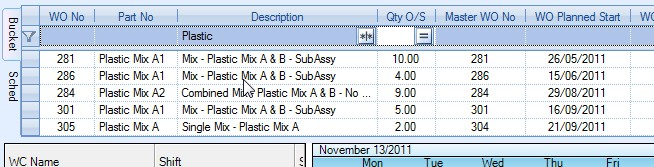

This allows the user to filter the WOs in the Bucket tab or Sched tab. A filter line will be shown as displayed below:

The user can then filter any of the fields displayed using the filter commands available as shown below

Applying the chosen filter displays only the required WO entries.

Enquire

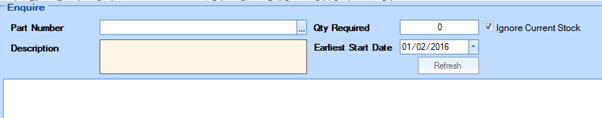

This option allows the user to see the completion date/time of a potential WO. When selected, the user will be presented with the following screen:

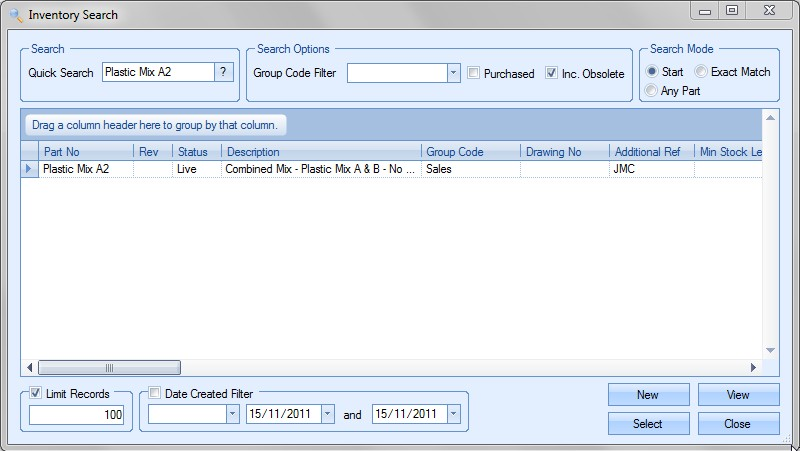

The user can select the part required using the standard inventory search screen by clicking on the little search box at the end of the part number field.

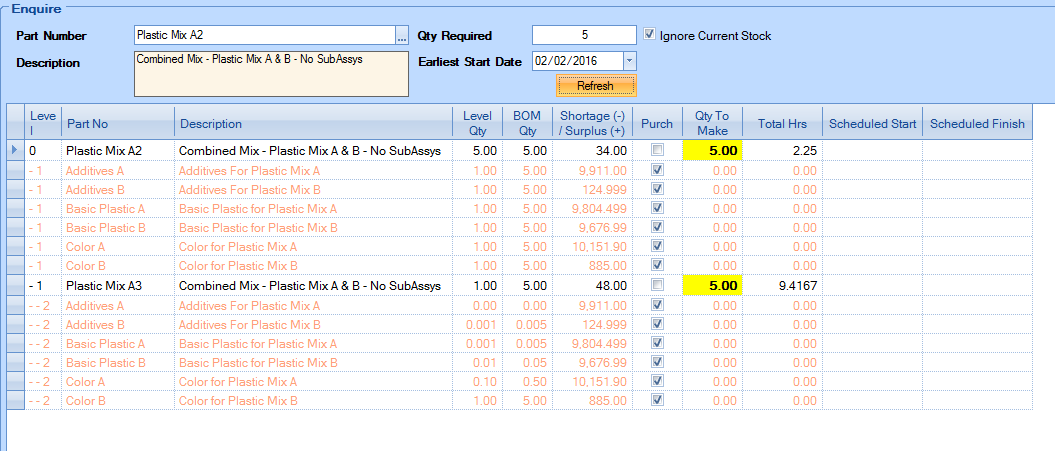

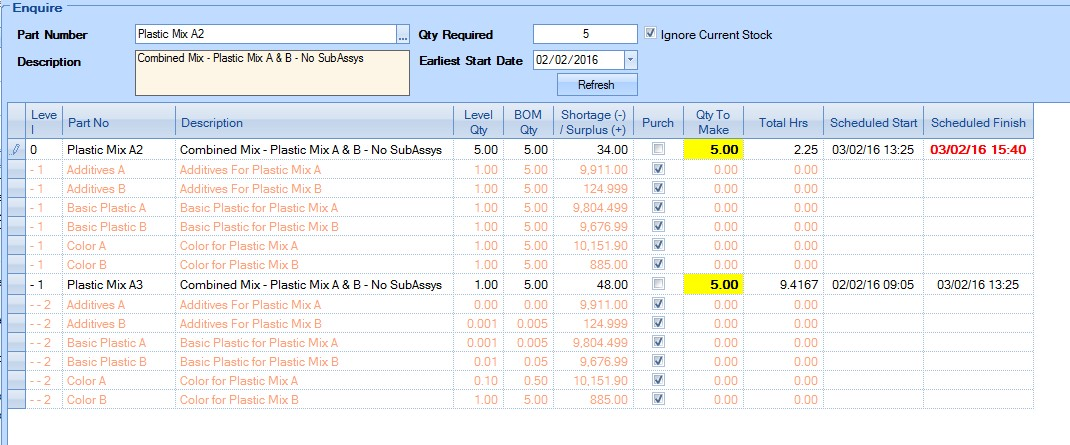

Once the part have been selected, the current BOM is displayed. This also displays the shortage or surplus for each item, whether it is purchased or not, the quantity to make and the total hours to make the selected quantity.

The user can use this screen to enquire on how a potential WO could fit into the schedule of currently planned WOs. The user can specify the quantity required for the potential WO and then use the Enquire option to see to see how soon this job could be completed.

![]()

In the scenario above, for a WO quantity of 5, the user earliest scheduled start date would be 02/02/16 at 09:05 and the earliest scheduled finish date would be 03/02/16 at 15:40.

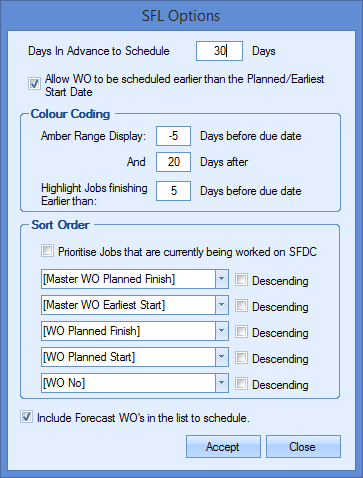

Options

This option will display the current SFL options and allow the user to amend if necessary.

The user can set the number of days ahead that they want to schedule and also whether WOs can be scheduled earlier than their planned date.

The sort order specifies the sequence by which the WOs are scheduled when loaded into the SFL plan when all WOs are loaded together. The Bucket tab also displays any unplanned WOs in the same sequence. The user can also determine whether current jobs are also given priority when scheduling. This allows existing work to be scheduled so its completed instead of being abandoned for other work which may not yet have been started.

![]()

The user also has an option to allow forecast work orders to be included in the schedule. This allows planning of potential work which may well become actual work orders in future.

![]()

This option lists the forecast work orders alongside the actual work orders raised.

Load Vs Capacity

This option will take the user to the Load Vs Capacity screen. More details on this can be found in the Load Vs Capacity section.

Clear

This option will clear all unlocked WOs from the grid and return them to the Bucket list at the top.

Full Reset

This option will clear all WOs, locked or unlocked, from the grid and return them to the Bucket list at the top.

Grid Options

The user can adjust the position of the columns and set them as the default. The columns can be dragged to a suitable position and the small arrow to the right of Grid Options selected. This allows the user to choose either “Save as Standard” or “Reset to Standard”. Saving the options will save the column positions while resetting them will put them back to the default positioning in Progress.

Exit

This will close the current SFL screen

Additional SFL Notes

One operation cannot start until the previous one is complete, hence the WO will be staggered across the Gantt chart

The available spaces are dictated by the start, finish and break times set against the shifts.

When the system has loaded the first WO it will then go to the next, and for each operation it will look for the first blank space on the work centre that is large enough to accommodate the full planned time. Unfortunately this may not be the first space available, depending on the way previous ops have been loaded and likewise the operation might fit into a space which comes before operations that were planned to be carried out before the current one, hence the final list of jobs may not look in the correct order, according to the WO dates.

If more than one machine is available on a work centre, the system will check available time across all machines, but the system cannot share work across multiple machines

SFL Related Reports

- Reports > Sales Orders > Sales Orders Outstanding Showing Scheduled Finish Dates

Report can be filtered by specific customers or other criteria and shows possible delivery dates of the current live order book.

- Reports > Works Order > Work Order Schedule Comparison Report

To assess the possible finish date of works orders compared to what was planned.