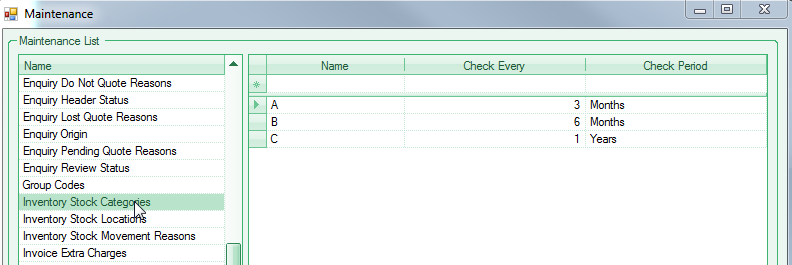

Enter the “Inventory Stock Categories” into List maintenance, defining the periods for checking these items of stock. ABC is a common way of categorising, but the names can be specific to your specific requirements.

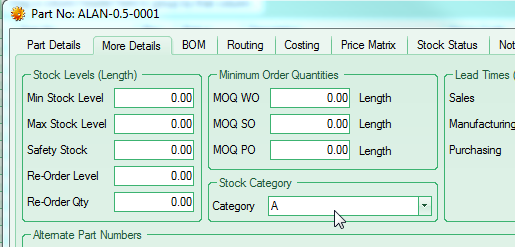

Apply the category to each part, which can be carried out through a stock export and import.

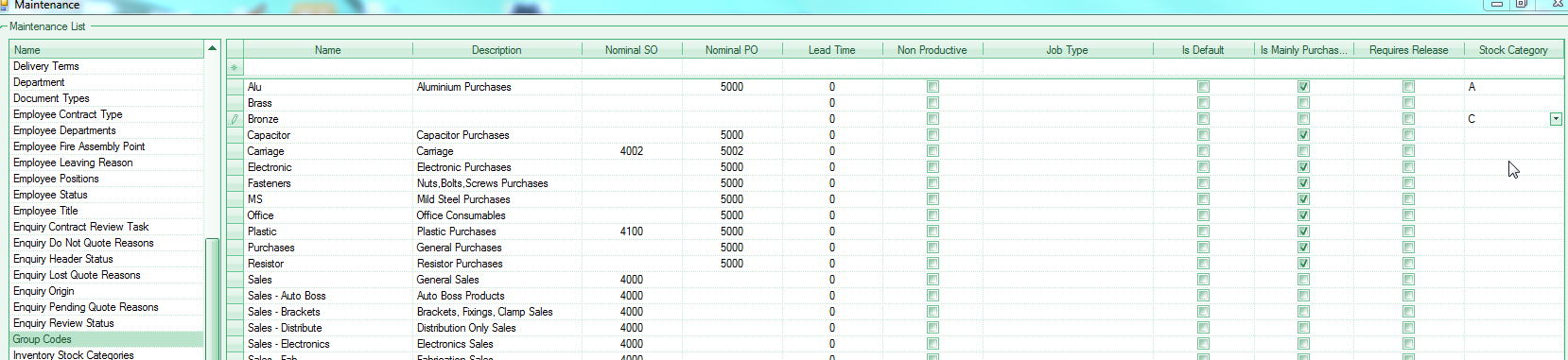

Going forward, for new parts you can apply a category to a group code and it will automatically be applied to the part when you select a group code.

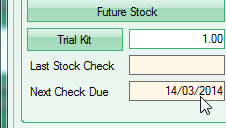

Once everything is setup, the actual control of the stock is all through exporting and importing the stock, which sets a last stock check date on a part, to then work out the “Next Check Due” date, displayed on the Stock Status screen of a part.

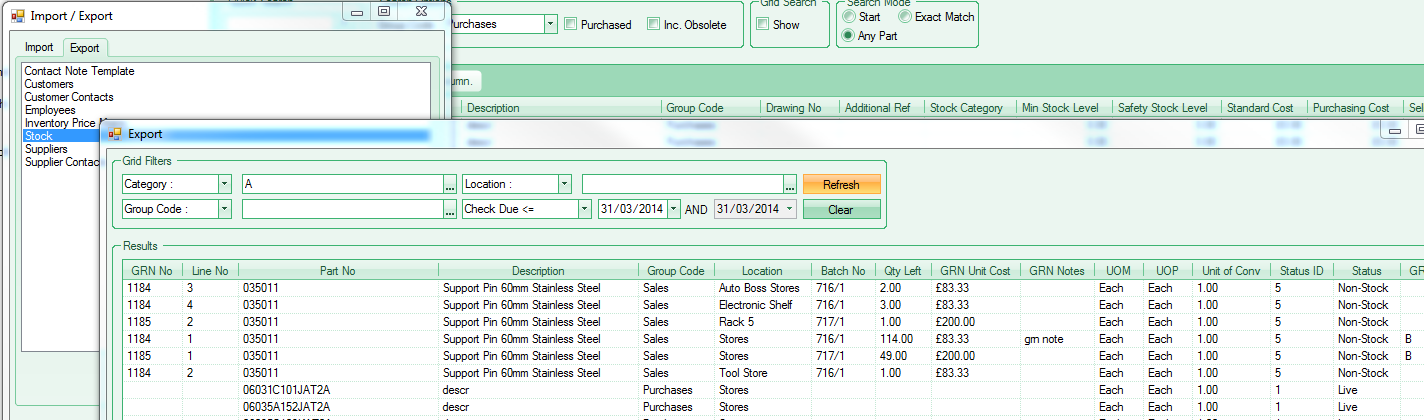

To export the parts that are due for checking go to Tools, Import/Export Data, then select Stock and filter the screen to suit. In the example below the filter is Stock Category “A” due for checking before the end of the month.

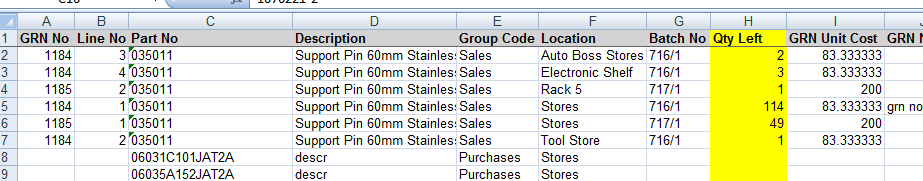

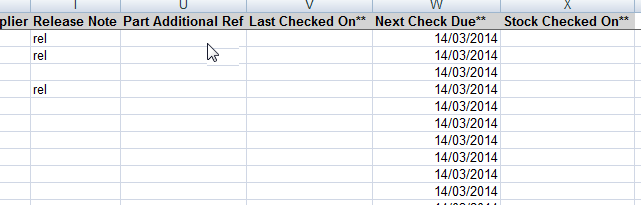

The spreadsheet contains all the information on all the parts and also shows the individual batches of each part.

To maintain the original GRN details change the “Qty Left” against the specific GRN.

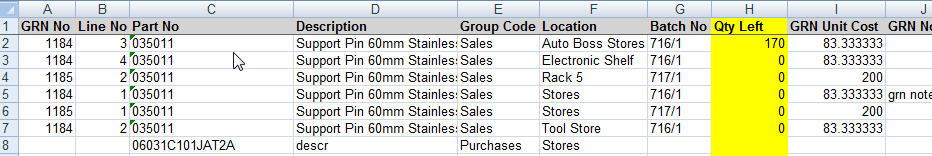

Or to consolidate different GRNs together put the total on one line and zero the others.

Keeping the parts on the spreadsheet will update their Checked date, even no changes are made, however to specify a different date, manually enter the date in the “Stock Checked On” field, and if it is left blank it will assume the actual date of the import.

To Import again, keep the format of the spreadsheet exactly the same with the same column headings and order of columns then follow the Tools, Import/Export Data then Import, Stock.

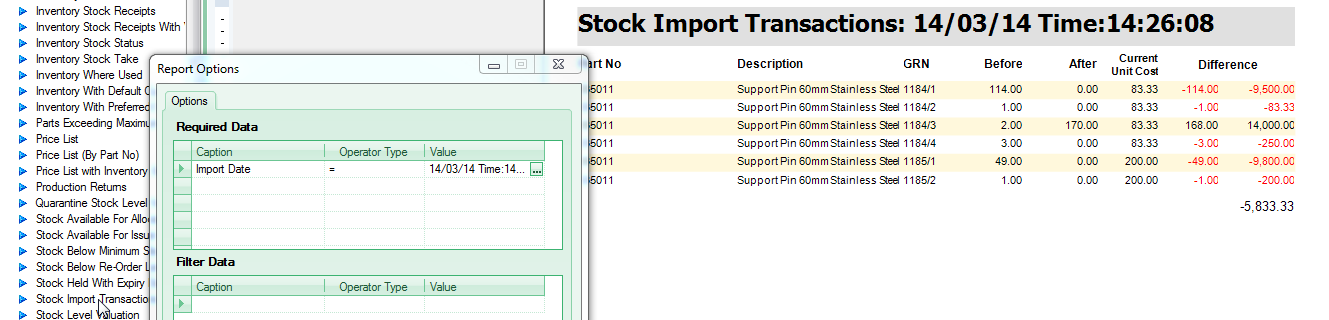

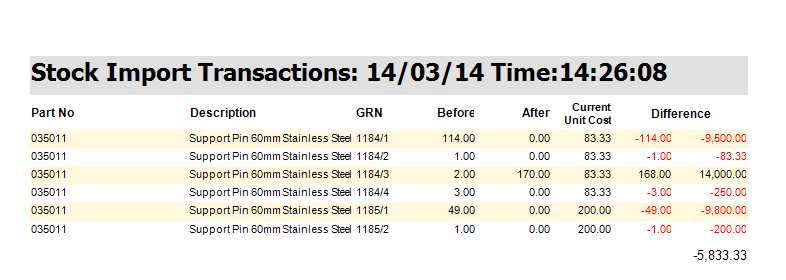

After importing the system shows a report detailing any changes:

The same report can then be run subsequently from the reports section, inventory and “Stock Import Transactions”