Manufacture lead time is the number of days from receipt of materials to completion of goods, considering the time it would take an average batch size to go through all the processes on the shop floor, including subcon lead times and waiting time.

Sales lead time is the time from order receipt to despatch, including admin time, material lead time and manufacture.

Purchase lead time is used when an item is purchased or needs to be purchased and is the time from placing the PO to receiving the goods. It is used to indicate when goods should be purchased on the PO shortage screen and applying a default required date when raising a PO

===========================================

If a part is manufactured you are only concerned with the manufacture lead time and likewise for a purchase part it is the purchase lead time which is applicable. The sales lead time comes into play when a part is entered onto a sales order and the system automatically takes the date plus the lead time to give the required date of the line.

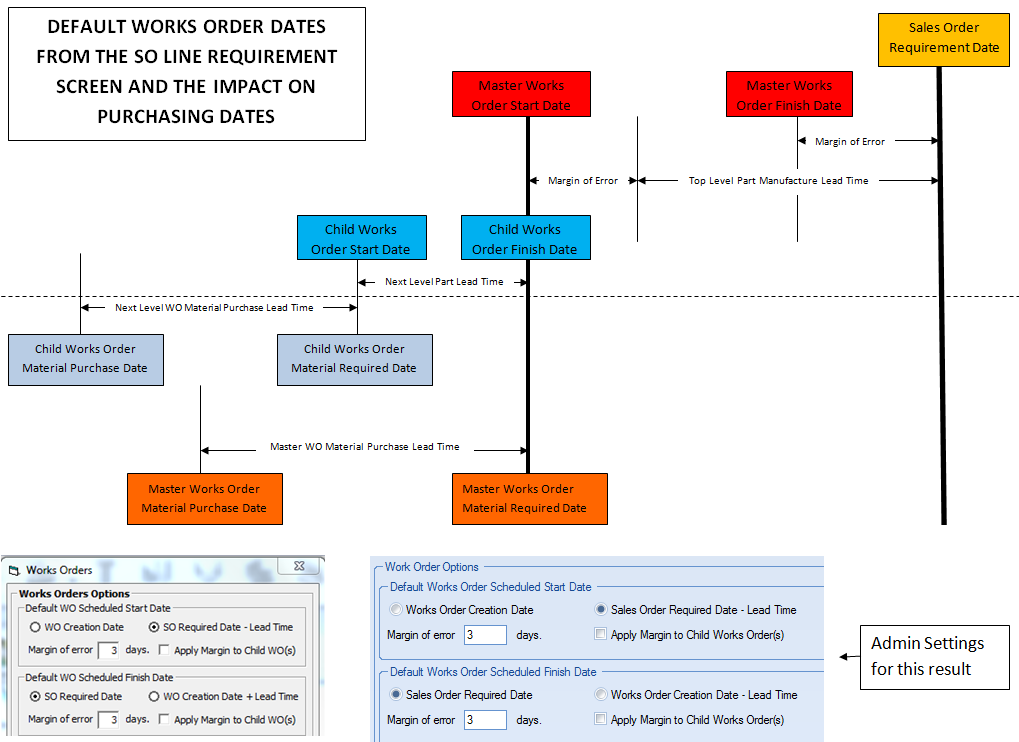

The associated diagram on page 2 explains how the settings in admin and the manufacturing lead times work together to give you accurate start and finish times that allow you to prioritise your work and know when lower level WOs and materials are required.

If the Sales Order Required date changes and Works Orders have already been raised, go to the Sales Order browse, highlight the order you want, and then click on SO Dates at the top of the page which allows you to update the SO required date and apply the change to related WOs, applying the rules from admin.